Production equipment for PET (poly(ethylene terephthalate)) chip

A production equipment and slicing technology, applied in the field of PET slice production equipment, can solve the problems of too many transition materials, long transition transition time, affecting production costs, etc., and achieve the effects of less transition materials, short transition time, and lower production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

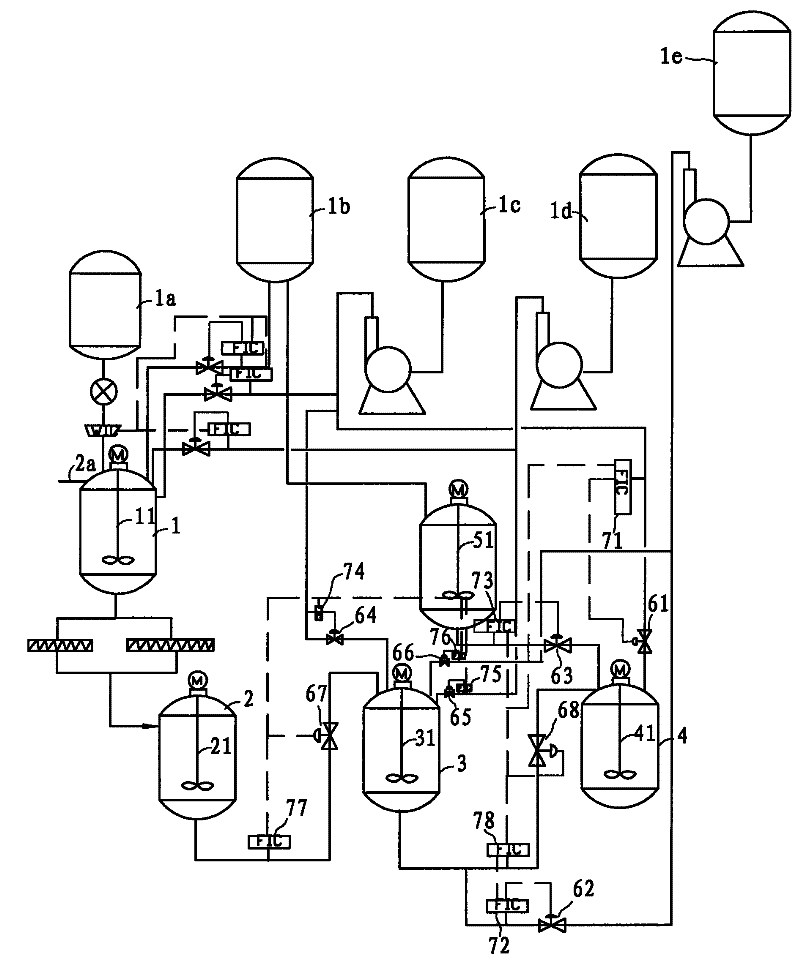

[0026] Such as figure 1 As shown, the PET chip production equipment includes a slurry tank 1, a first esterification reactor 2, a second esterification reactor 3, a mixing tank 5, a pre-condensation reactor 4 and a final polycondensation reactor (not shown on the way),

[0027] The slurry tank 1 has a PTA inlet, a MEG inlet, an IPA inlet, a toner inlet, an endothermic agent inlet and a first agitator 11, the PTA inlet is connected to the PTA feeding tank 1a through a pipeline, and the MEG is added The inlet is connected to the MEG feeding pipe 2a, the IPA inlet is connected to the pipeline of the IPA feeding tank 1b, the toner inlet is connected to the toner feeding tank 1c, and the endothermic agent inlet is connected to the pipeline of the endothermic agent feeding tank 1d.

[0028] The first esterification reactor 2 has a second agitator 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com