Positive photosensitive resist release agent compositions

A photoresist and stripper technology, applied in the processing of photosensitive materials, etc., can solve the problems of unsatisfactory stripping performance, large resist damage, harsh etching conditions, etc., to achieve excellent solubility and stripping, low temperature Excellent peeling performance and favorable working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-18 and comparative example 1-10

[0065] According to the ratio described in Table 1 below, the organic amines, organic solvents and polar solvents were formulated to prepare the stripping solution. According to the content of the polar solvent, each release agent was evaluated in terms of peelability, corrosion and evaporation loss, and the evaluation results are shown in Table 2 below.

[0066] [Table 1]

[0067] Composition of stripping agent (wt%)

[0068] Example 7

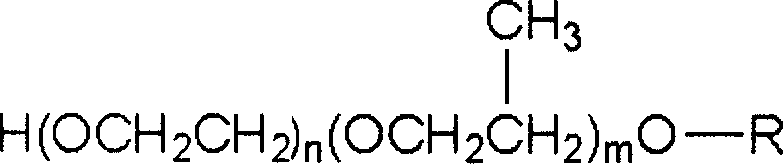

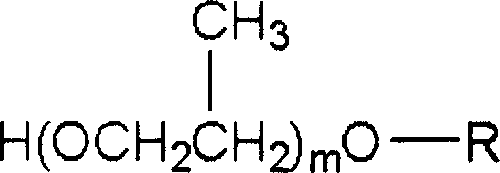

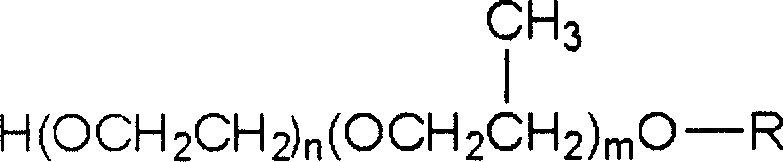

[0069] In Table 1, A: organic amine, B: diethylene glycol monoalkyl ether, C: aprotic polar solvent, D: nonionic surfactant, wherein, examples 1-5 are polyoxypropylene glycol ethers , Examples 6-10 are polyoxypropylene ethyl ethers, examples 11-14 are polyoxyethylene polypropylene glycol ethers, and examples 15-18 are polyoxyethylene polypropylene glycol ethers.

[0070] MEA: Monoethanolamine (Monoethanolamine);

[0071] DEA: diethanolamine (diethanolamine);

[0072] TEA: Triethanolamine (Triethanolamine);

[0073]BD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com