Method for separating ethylene glycol mixture series

A separation method and mixture technology, applied in the preparation of organic compounds, ether separation/purification, chemical instruments and methods, etc., can solve problems such as high energy consumption, low separation purity, and complicated separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

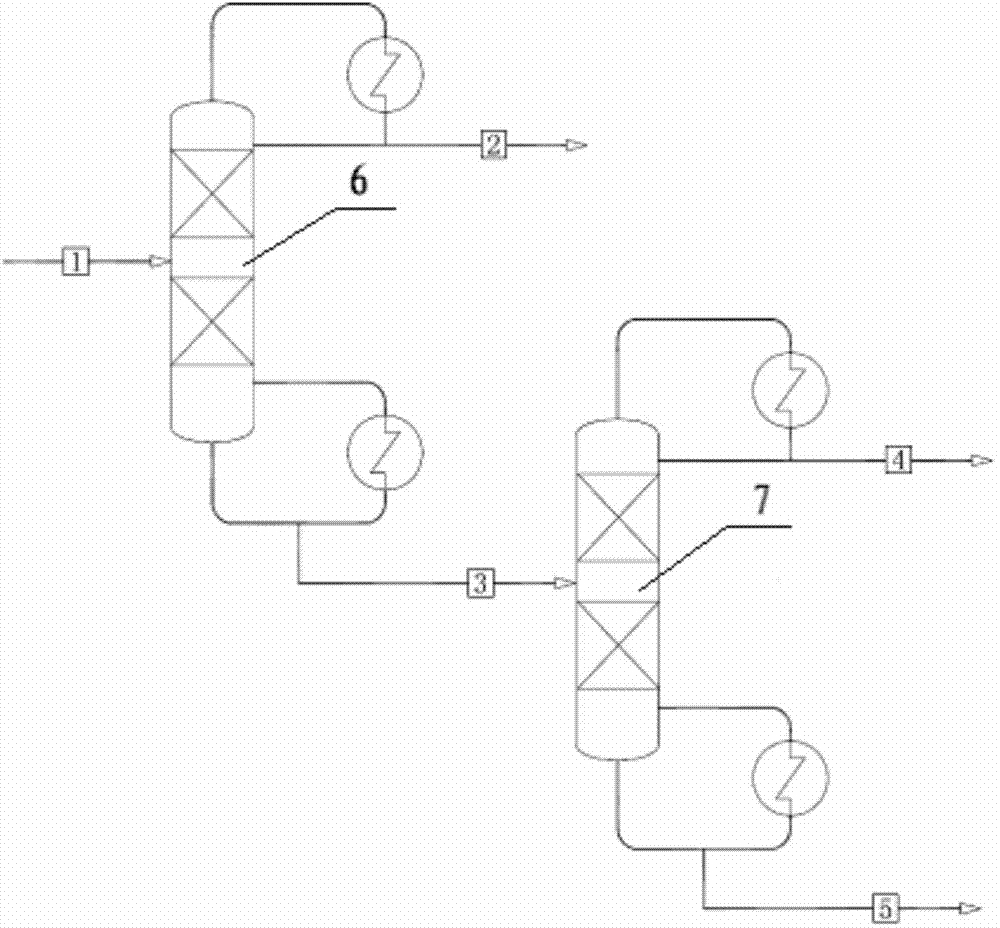

Method used

Image

Examples

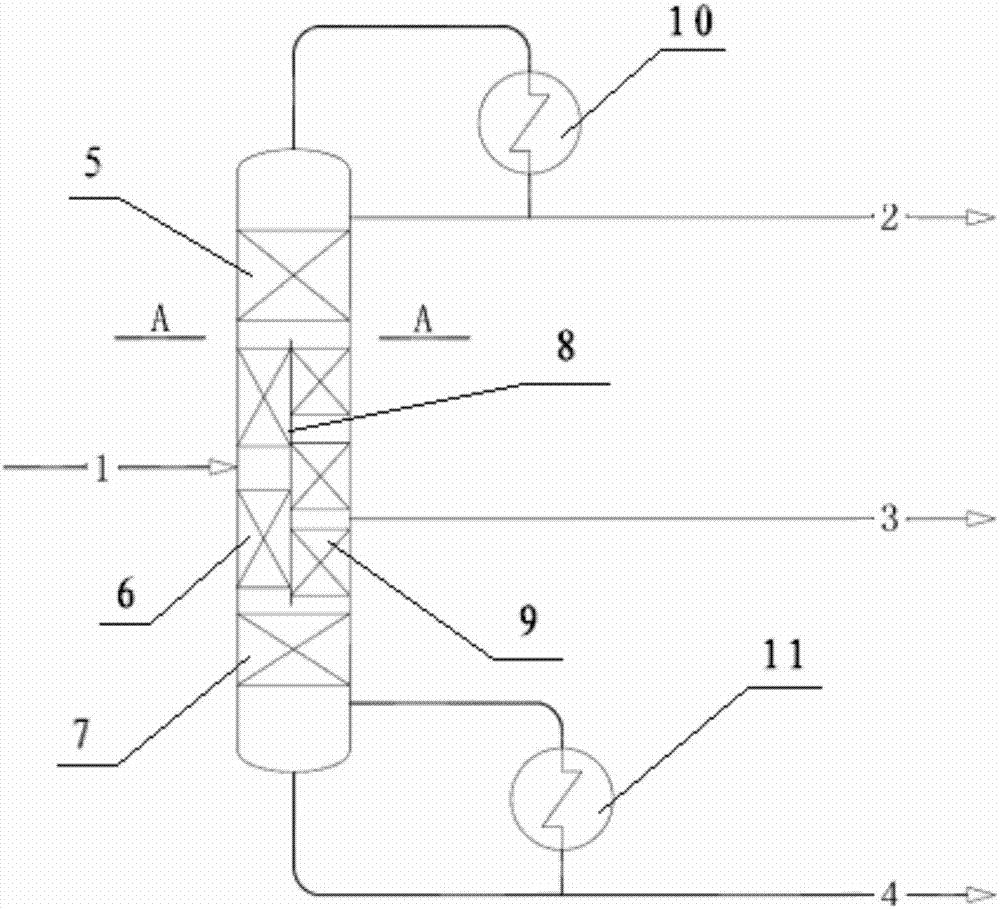

Embodiment 1

[0039] use figure 2 The flow shown is based on the 500,000 tons / year ethylene glycol plant, and the materials whose weight percentage composition is shown in Table 1 are separated. The dividing wall rectification column (packed column) used has 51 theoretical plates, and a partition is set in the dividing wall section. There are 13 theoretical plates on both sides of the dividing wall section, and the dividing plates are installed along the center line of the tower. There are 18 theoretical plates in the section, the operating pressure is 1 kPa absolute pressure at the top of the tower, and the reflux ratio is 0.55 by weight; the feed is fed to the 24th tray, and the extraction position of the side line DEG is the 26th block from the top of the tower. theory board.

[0040] For comparison, the operating conditions and separation results are listed in Table 17.

[0041] The detailed component separation effect of the corresponding dividing wall rectification column is as follo...

Embodiment 1)

[0046] Device No

Embodiment 2

[0048] According to the conditions described in Example 1, the total number of theoretical plates of the dividing wall rectification column, the number of theoretical plates on both sides of the dividing plate, the feed position, the side draw position and the reflux ratio were changed.

[0049] The dividing wall type rectifying column (packed column) that adopts has 55 theoretical plates, each has 15 theoretical plates on both sides of the partition of the dividing wall, and the stripping section has 21 theoretical plates, and the reflux ratio is 0.65 by weight; The 24th tray is fed, and the extraction position of the side line DEG is the 27th theoretical tray from the top of the tower.

[0050] For comparison, the operating conditions and separation results are listed in Table 17.

[0051] The detailed component separation effect of the corresponding dividing wall rectification column is as follows:

[0052] Table 7: Detailed table of separation results of dividing wall rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com