Process for recovering heavy oil utilizing one or more membranes

A technology for recovering oil and oil wells, applied in the direction of membrane, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high maintenance cost, expensive operation, and a large amount of chemical waste sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

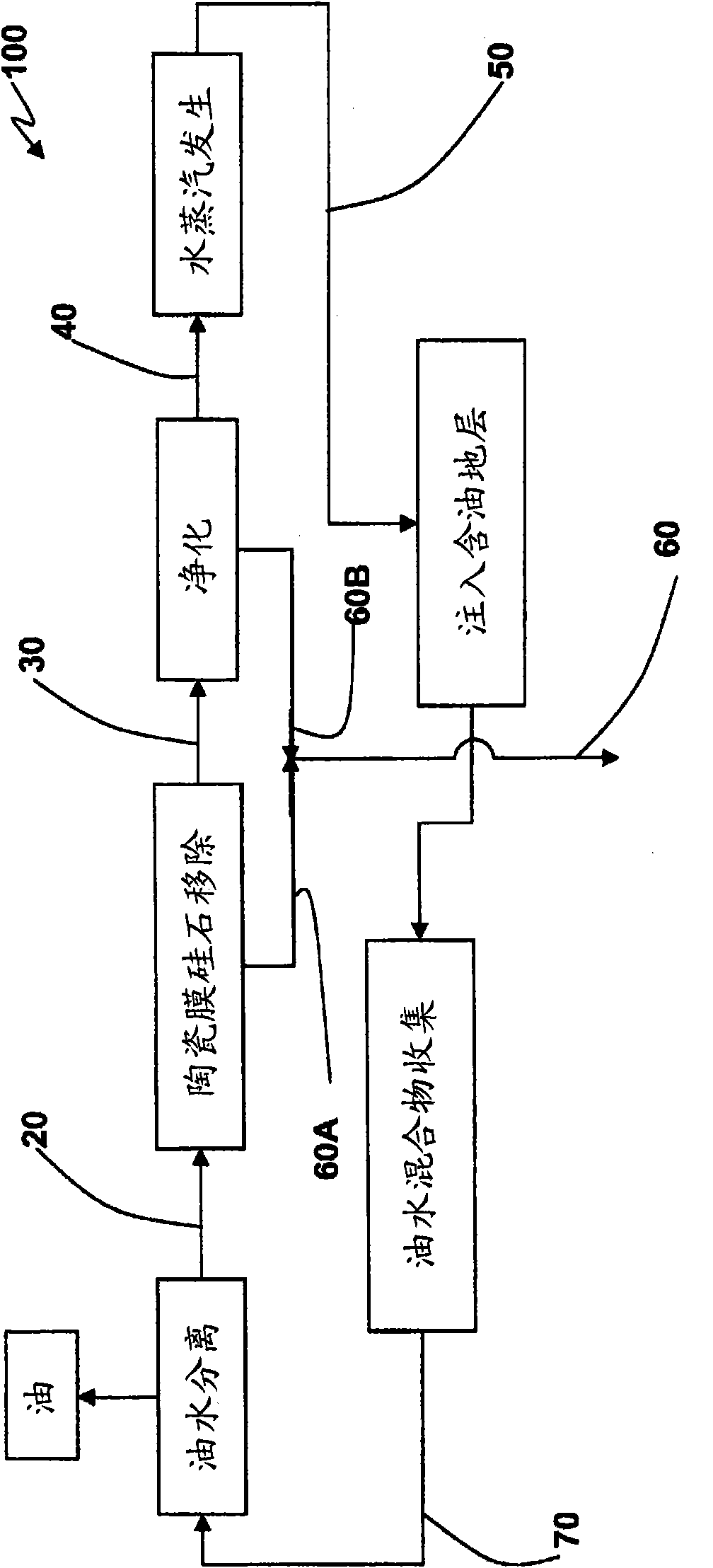

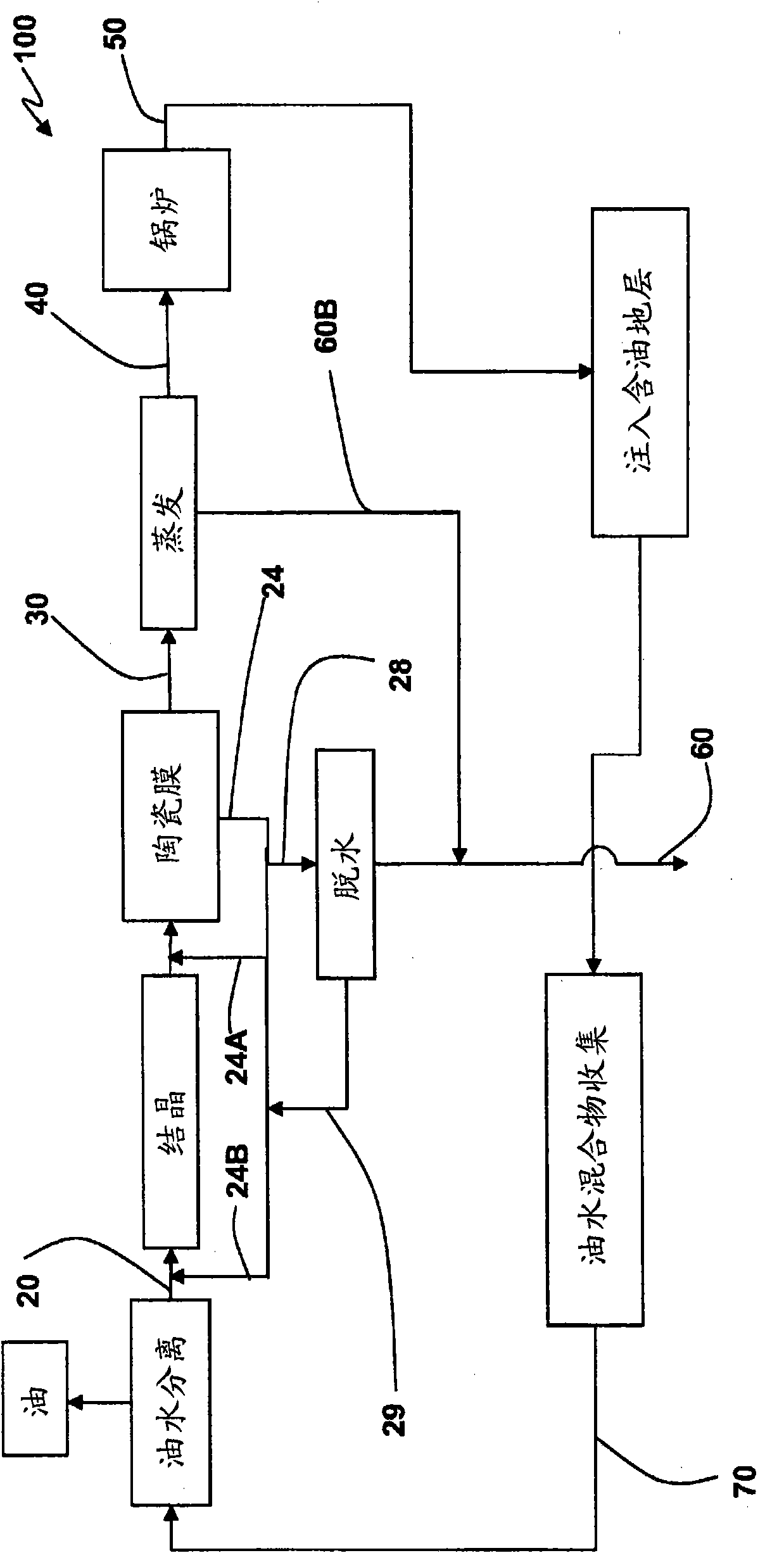

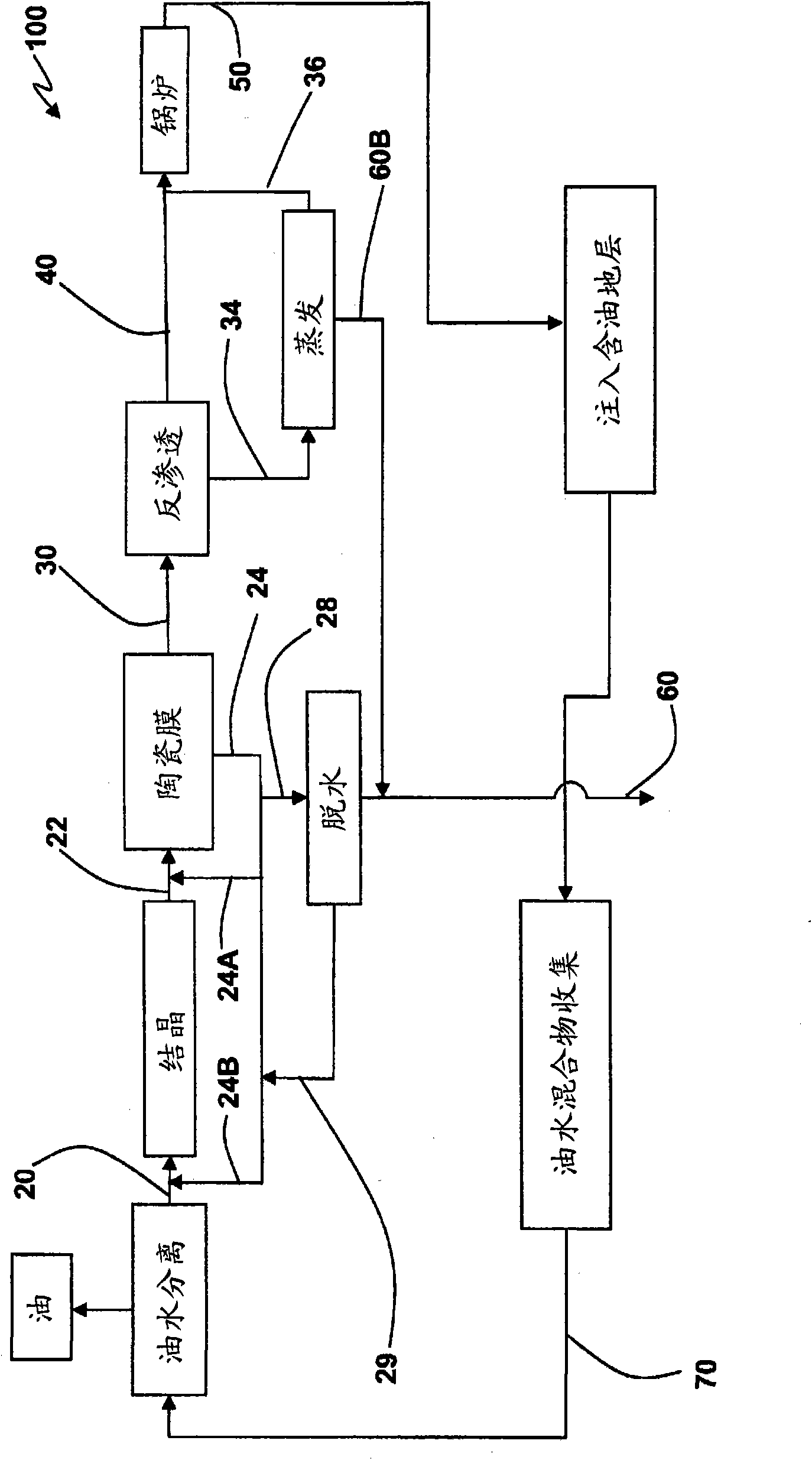

[0030] The present invention requires a process for cleaning produced water for use in steam generation in heavy oil recovery. Heavy oil recovery is generally accomplished by injecting water vapor into heavy oil-bearing subterranean formations. The water vapor heats the oil, which condenses. The resulting oil-water mixture is pumped to the surface, where the oil separates from the mixture, leaving what is known as produced water. The produced water is reused to generate water vapor that is fed back into the oil-bearing formation.

[0031] Produced water includes dissolved organic ions, dissolved organic acids and other dissolved organic compounds, suspended inorganic and organic solids, and dissolved gases. Typically, the total suspended solids in the produced water is less than about 1000 ppm. In addition to suspended solids, produced water from heavy oil recovery processes includes varying fractions of organic and inorganic solids. Dissolved and suspended solids in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com