Method for resourceful treatment of blast furnace gas mud by using slag braising process

A technology of blast furnace gas mud and resource utilization, which is applied in the field of resource utilization of blast furnace gas, can solve the problems of increasing equipment, low market price, and difficulty in large-scale operation and use, and achieves the effect of reducing costs and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

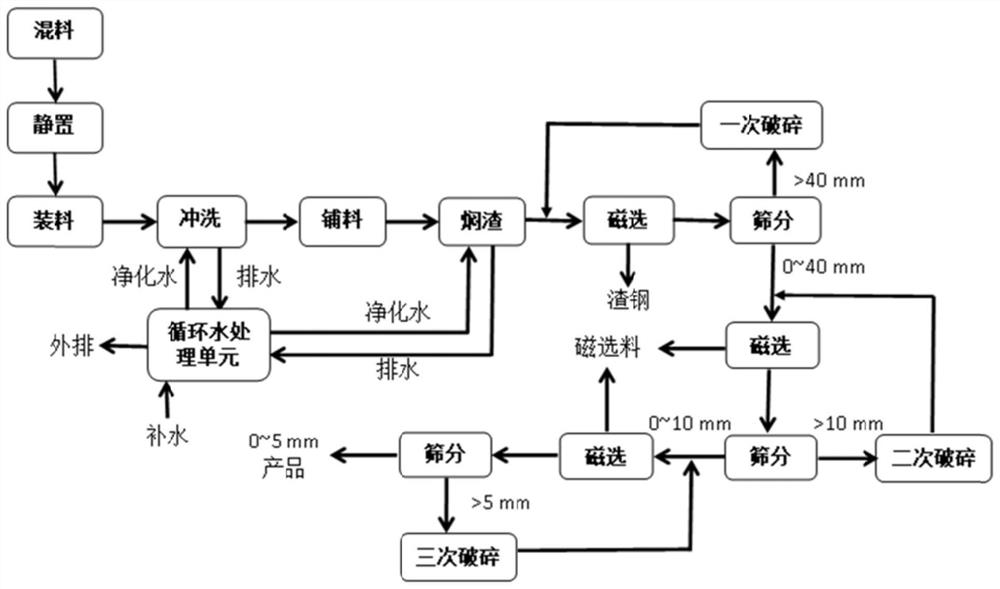

[0038]Seefigure 1 , A method for treating blast furnace gas mud by utilizing the slag slag process, which is characterized in that it comprises the steps:

[0039](1) Hardening treatment of blast furnace gas mud:

[0040]Mix 10t of blast furnace gas mud with a water content of about 36% and 2t of steel slag silt uniformly to obtain the first mixture. After standing for 3 days, the steel slag silt and blast furnace gas sludge undergo hydration and gelation reactions to make the first mixture condense. Piece;

[0041]Among them, the chemical components and weight percentages included in the dry blast furnace gas mud are: 25.0%≤TFe≤40.0%, CaO≤10.0%, MgO≤5.0%, SiO2≤15.0%, Al2O3≤10.0%, K2O≤5.0%, Na2O≤5.0%, 10%≤C≤30%; Cl≤3.0%, Zn≤3.5%, the balance is combined with Fe element O and other unavoidable impurities.

[0042]Among them, steel slag powder sand is 0~5mm natural grade steel slag particles produced during the secondary processing of steel slag. The chemical composition and weight percentage inc...

Embodiment 2~4

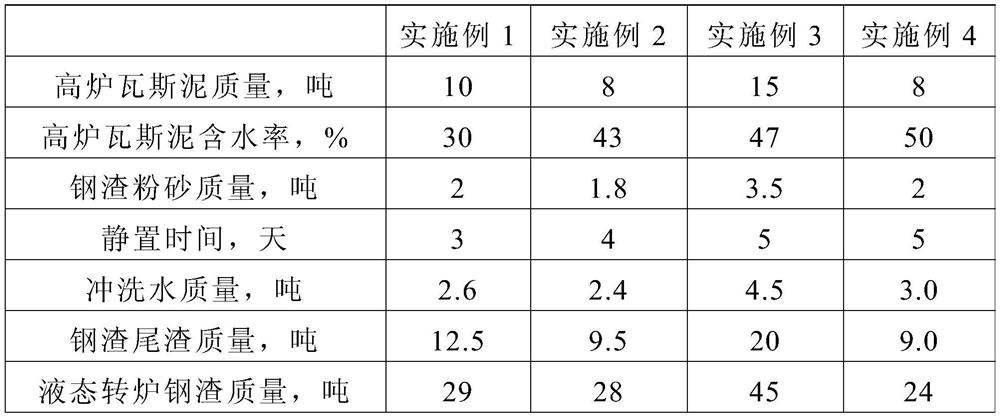

[0056]The steps of Examples 2 to 4 are the same as that of Example 1, with only the adjustment of parameters, as shown in Table 1, Table 2 and Table 3.

[0057]Table 1 Process parameters

[0058]

[0059]

[0060]Table 2 Chemical composition and weight percentage of blast furnace gas mud

[0061] Example 1 Example 2 Example 3 Example 4 TFe(%) 25403530 CaO(%) 1063.55.5 MgO(%) 52.54.53.2 SiO 2 (%)

1210.5157.8 Al 2 O 3 (%)

86.22.110 K 2 O(%)

4.53.253.6 Na 2 O(%)

4.23.63.65.0 C(%)12102030 Cl(%)2.51.23.01.7 Zn(%) 3.51.52.01.2

[0062]Table 3 Chemical composition and weight percentage of steel slag silt and steel slag tailings

[0063] Example 1 Example 2 Example 3 Example 4 TFe 5151310 CaO 55404551 MgO 5121511 SiO 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com