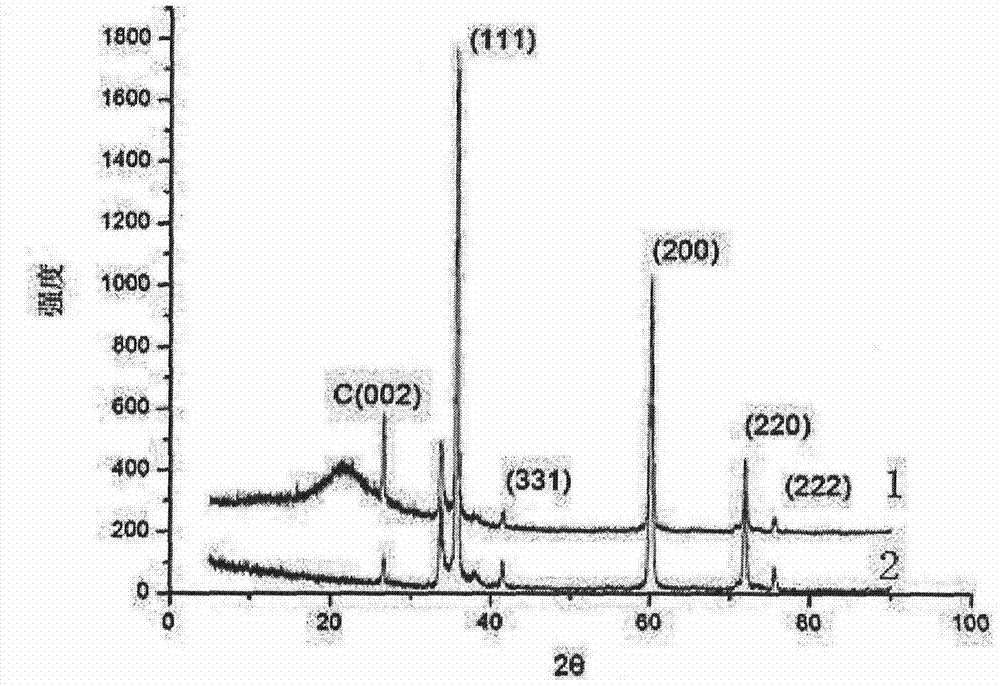

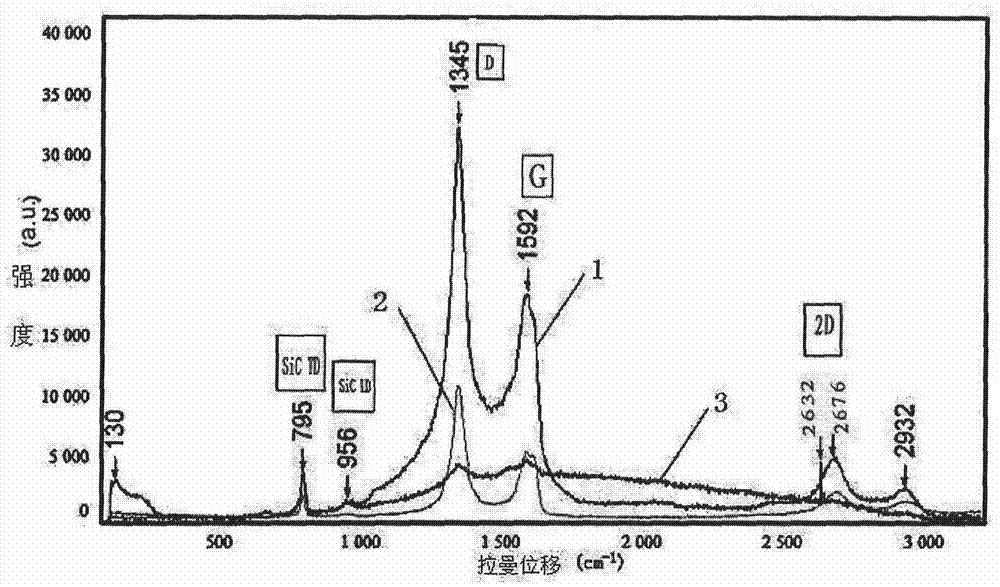

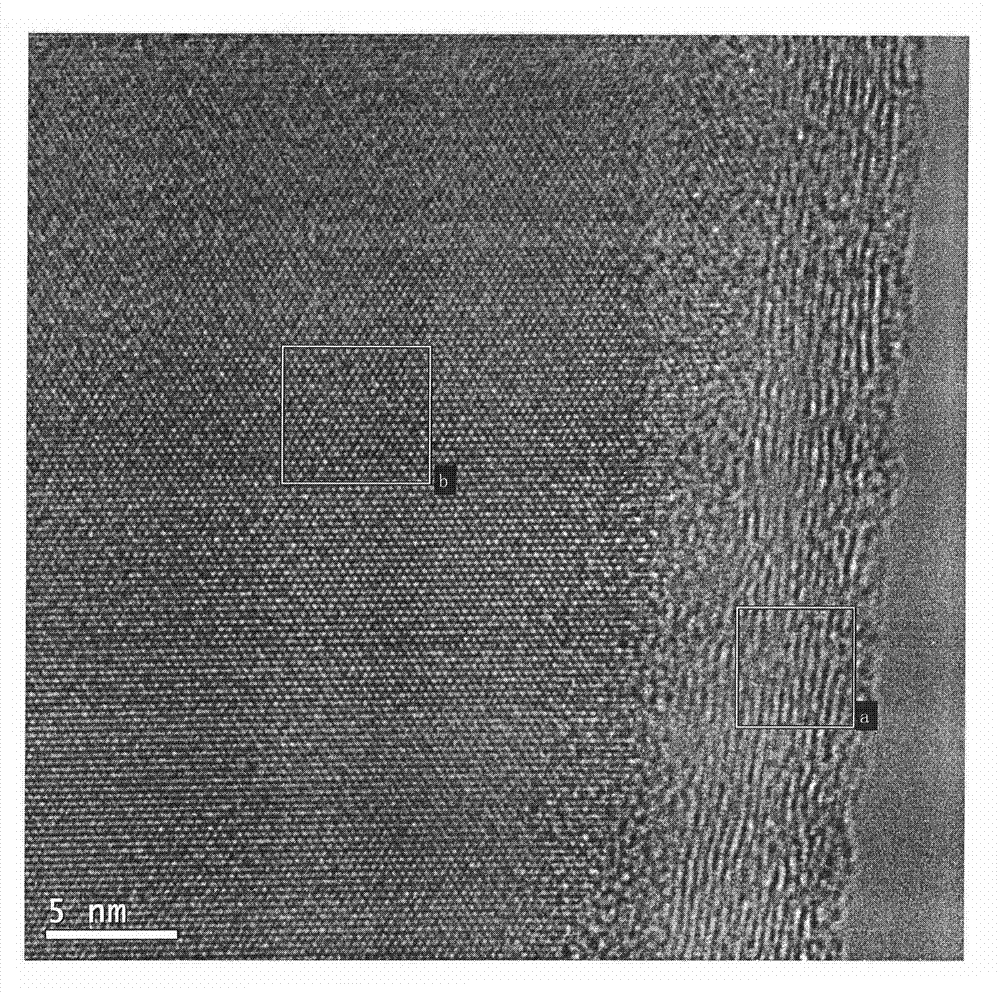

Preparation method of SiC/graphene core-shell structured nano material

A technology of core-shell structure and nanomaterials, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as high content of impurity elements and harsh reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Specific embodiment one: the preparation method of the SiC / graphene core-shell structure nano-material in this embodiment is implemented according to the following steps:

[0032] 1. Put the SiC nanowires in a heating furnace and heat them to 400-650°C for carbon removal treatment, and then soak the heated SiC nanowires in HF solution for 20-26 hours to obtain pretreated SiC nanowires;

[0033] 2. Use deionized water to repeatedly rinse the pretreated SiC nanowires, filter and put them in a drying oven to dry, and then obtain the required SiC nanowires;

[0034] 3. Weigh a certain amount of Ag powder;

[0035] Four, punch holes on the graphite paper to obtain the graphite paper after punching holes, lay Ag powder, graphite paper after punching holes, SiC nanowires and graphite paper on the bottom of the graphite crucible successively, cover the crucible lid, and then graphite The crucible is placed in an atmosphere pressure sintering furnace, and kept at a temperature ...

specific Embodiment approach 2

[0037] Embodiment 2: This embodiment differs from Embodiment 1 in that the SiC nanowires in step 1 are replaced with other SiC materials (such as powder, fiber, etc.). Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0038] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the concentration of the HF solution in step 1 is 5 vol% to 10 vol%. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2. The function of soaking in the HF solution in this embodiment is to remove the oxidized SiO on the surface of the nanowires. 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com