Crystallization method with overflow of clear mother liquor

A technology of crystallization and overflow, applied in the direction of solution crystallization, etc., can solve the problems of small crystal particle size, frequent crystallizer cleaning, etc., and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

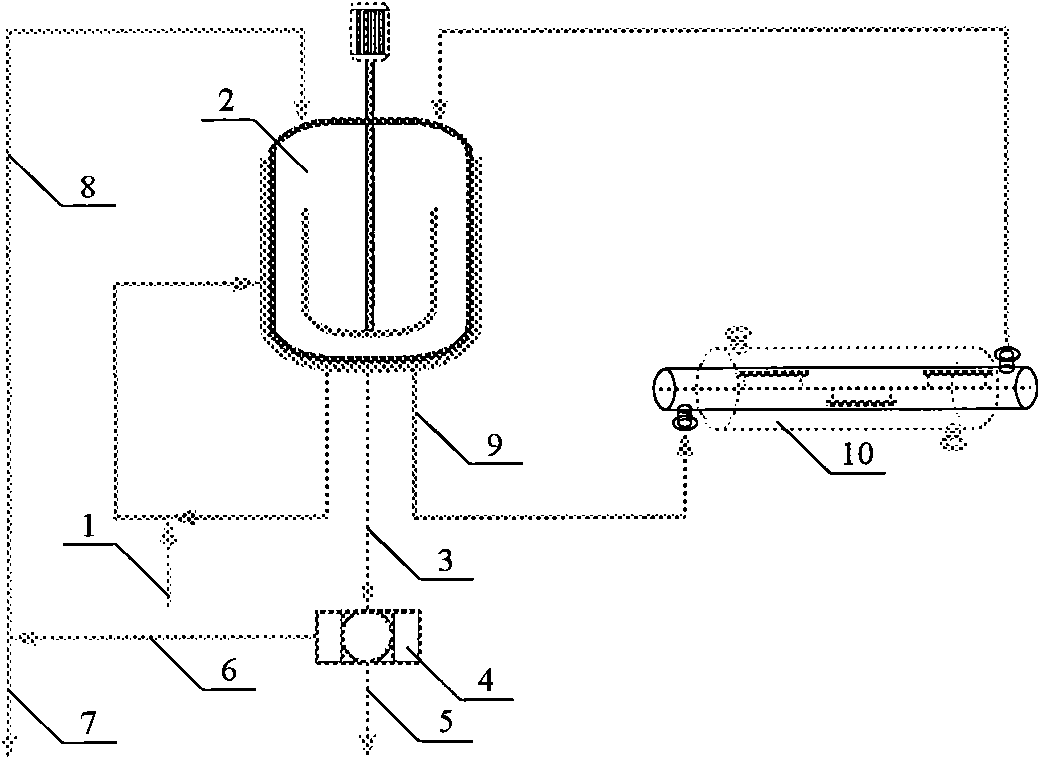

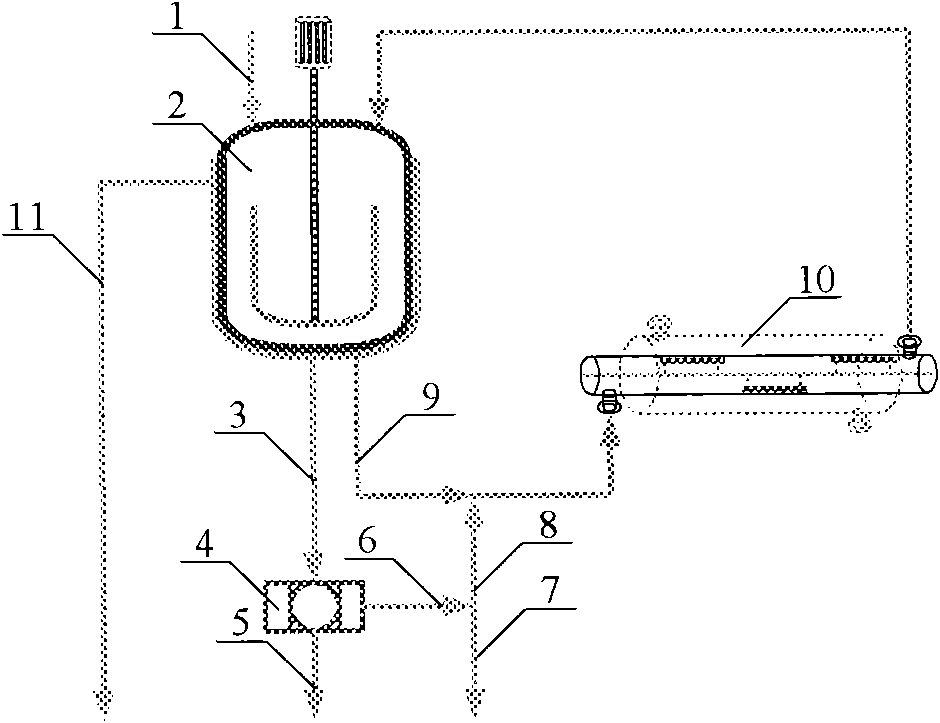

[0026] The crystallization method of belt clear mother liquor overflow of the present invention produces p-xylene

[0027] Such as figure 2Said, mixed xylene raw material 1 contains 90% p-xylene, and the flow rate is 14864kg / h. The mixed xylene raw material 1 directly enters the kettle crystallizer 2 for crystallization, and the crystallization temperature is -14.5°C. The crystal clear mother liquor 11 in the kettle crystallizer 2 is discharged from the upper part of the crystallizer. The magma in the tank crystallizer 2 is divided into two parts: magma 3 and magma 9 to flow out. Crystal slurry 3 is separated by centrifugal filter 4 to obtain p-xylene crystals 5 and mother liquor 6 for crystallization and filtration. The p-xylene crystals 5 are discharged as products after being washed by the pure p-xylene melt. The crystallization filtration mother liquor 6 is divided into two shares, and the crystallization filtration mother liquor 7 accounting for 11% by weight of the ...

Embodiment 2

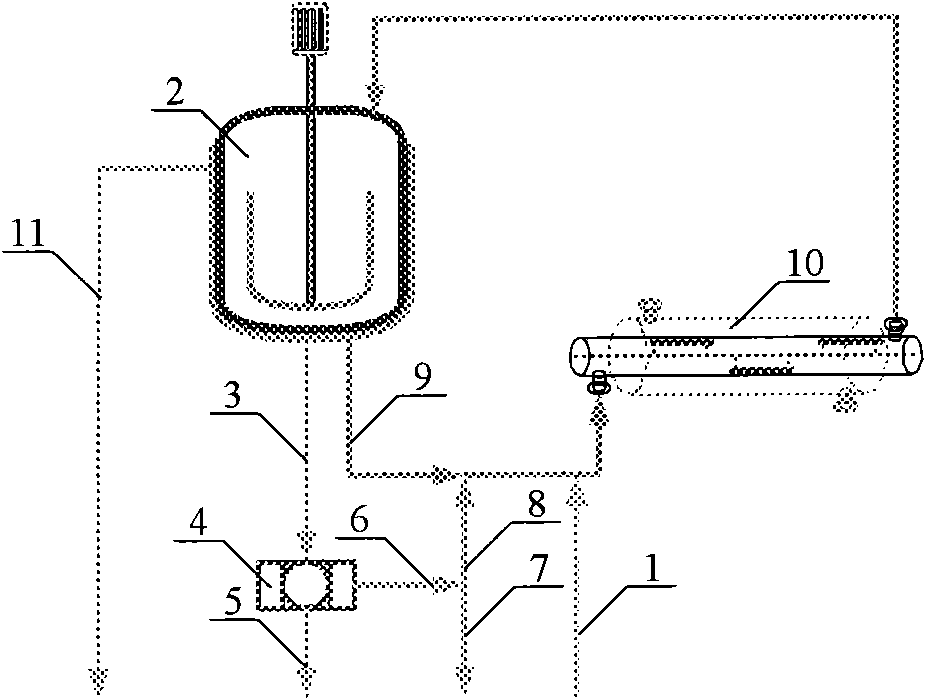

[0029] The crystallization method of belt clear mother liquor overflow of the present invention produces p-xylene

[0030] use as image 3 The crystallization method with the overflow of the clear mother liquor, wherein the mixed xylene raw material 1 is mixed with the second stream of crystallization and filtration mother liquor 8 and a part of the magma 9 in the tank crystallizer and then enters the casing type crystallizer 10, and crystallizes Clear mother liquor 11 is 0.5: 1 with the weight ratio of crystallization and filtration mother liquor 7, and solid-liquid separator 4 is a crystal washing tower, and p-xylene crystal 5 is discharged as product after being washed with pure toluene, and all the other operating conditions are identical with embodiment 1, The results are listed in Table 1.

[0031] Table 1

[0032]

Embodiment 3

[0037] The crystallization method of belt clear mother liquor overflow of the present invention produces p-xylene

[0038] use as figure 2 The crystallization method with overflow of clear mother liquor, wherein the sleeve-type crystallizer 10 is composed of a tubular heat exchanger with a scraper, the operating temperature is -17.5°C, and the remaining operating conditions are the same as in Example 1, and The results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com