Crystallization method with a fine crystal elimination

A crystallization and fine-crystal technology, applied in solution crystallization, crystallization purification/separation, organic chemistry, etc., can solve the problems of small crystal size and frequent crystallizer cleaning, and achieve the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

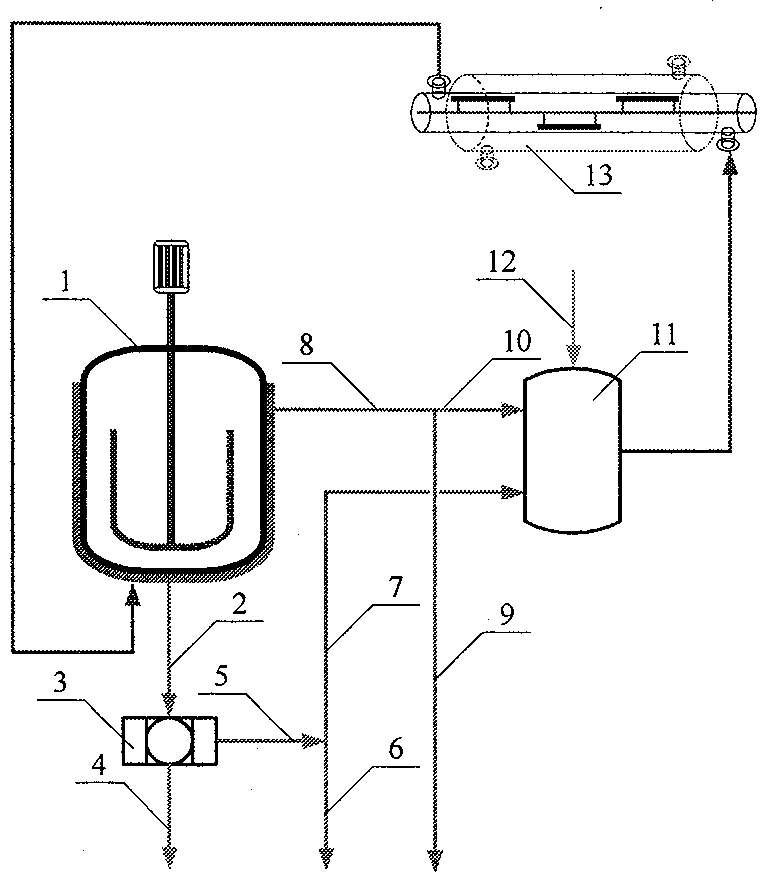

[0028]The crystallization method of band fine grain elimination described in the present invention produces p-xylene

[0029] like figure 2 Said, the mixed xylene raw material 12 contains 90% p-xylene, and the flow rate is 14864kg / h. The mixed xylenes are crystallized in tank crystallizer 1, and the crystallization temperature is -14.5°C. Crystal clear mother liquor 8 flows out from the crystallizer top in the kettle type crystallizer 1, and crystal clear mother liquor 8 is divided into two shares, and the crystal clear mother liquor 9 that the first share accounts for 50% by weight is discharged, and the crystal clear mother liquor that the second share accounts for 50% by weight 10 into the middle groove 11. The magma 2 in the kettle crystallizer 1 flows out from the bottom of the crystallizer, and is separated by a solid-liquid separator 3 to obtain p-xylene crystals 4 and crystallization and filtration mother liquor 5 . The p-xylene crystal 4 is discharged as a product...

Embodiment 2

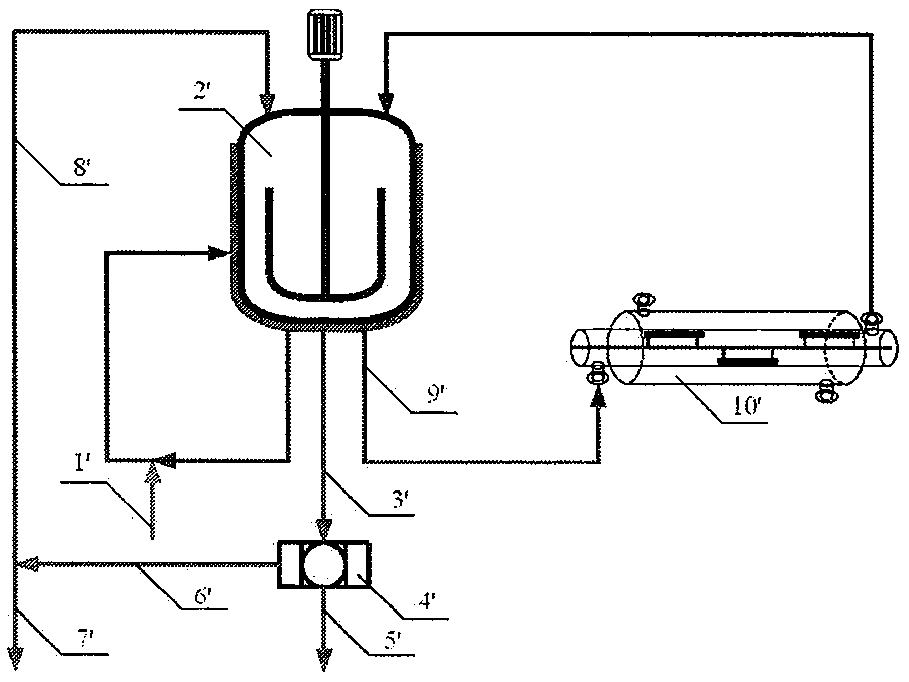

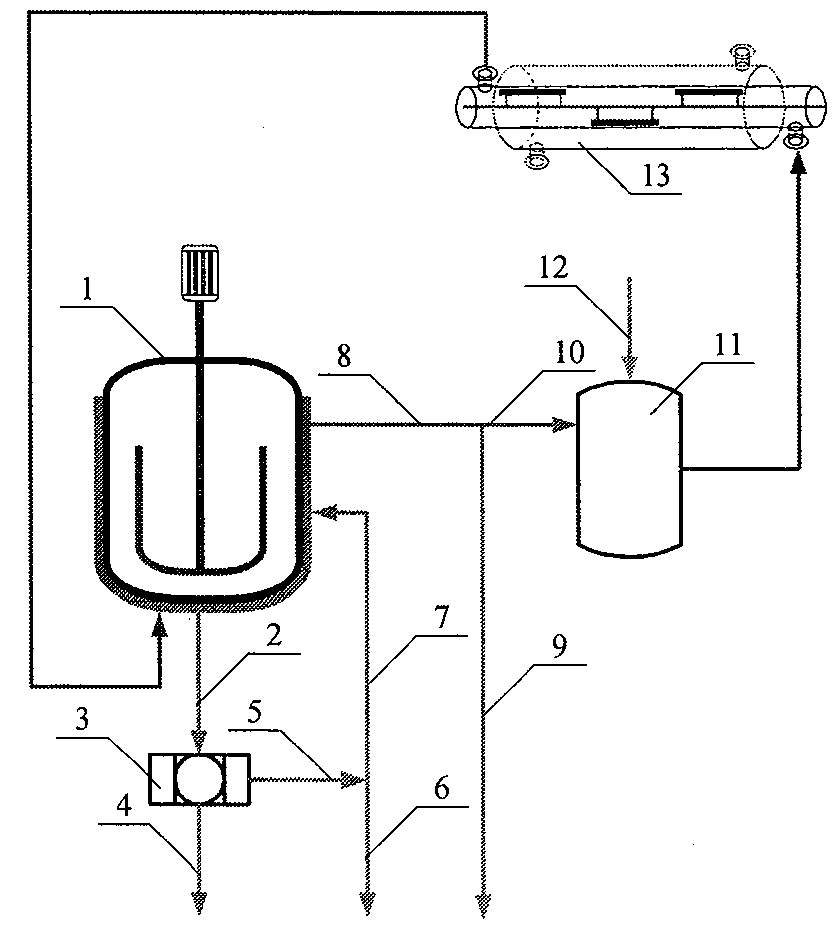

[0031] The crystallization method of band fine grain elimination described in the present invention produces p-xylene

[0032] use as image 3 In the crystallization method with fine crystal elimination, the second crystallization and filtration mother liquor 7 accounting for 91% by weight is returned to the kettle crystallizer 1, and the operating temperature of the sleeve crystallizer 13 is -4.2°C, and the rest of the operations are The conditions are the same as in Example 1, and the results are listed in Table 1.

Embodiment 3

[0034] The crystallization method of band fine grain elimination described in the present invention produces p-xylene

[0035] use as figure 2 The described crystallization method with fine crystal elimination, wherein, the crystal clear mother liquor 8 is divided into two shares, the first crystal clear mother liquor 9 accounting for 33% by weight is discharged, and the second crystal clear mother liquor 10 accounting for 67% by weight enters the middle In the tank 11; the crystallization and filtration mother liquor 5 is divided into two shares, the crystallization and filtration mother liquor 6 accounting for 14% by weight of the first share is discharged, and the crystallization and filtration mother liquor 7 of the second share of 86% by weight enters the middle tank 11; the casing type crystallizer The operating temperature of 13 is-1.4 ℃; The weight ratio of crystallization clear mother liquor 8 and crystallization filtration mother liquor 6 is 0.68: 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com