The production method of high-purity 2,6-naphthalene dicarboxylic acid

A technology of naphthalene dicarboxylic acid and production method, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of a large number of solid absorbents and solvents, insufficient optimization of operating conditions, deterioration of color quality, etc., and achieves reduction of solvent circulation. The effect of reducing the energy consumption of the system and increasing the average particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

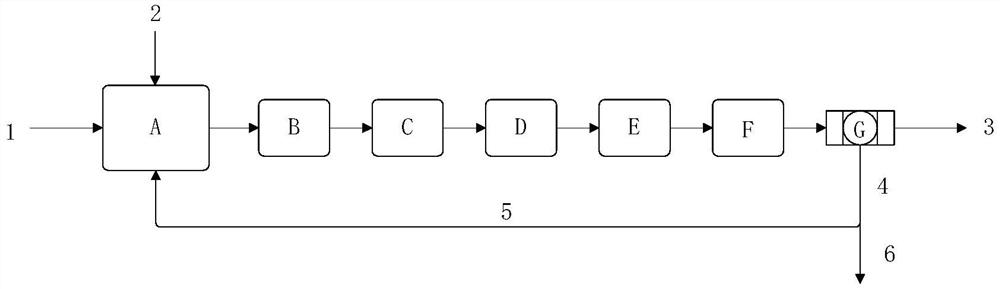

[0029] The purity of the crude 2,6-NDCA is 90%, the concentration of the slurry produced by the crude 2,6-NDCA in the mixing step is 8%, the temperature in the dissolution tank A is maintained at 330°C and 13MPa, and the dissolved slurry is sequentially Through the crystallization unit, each crystallization process lasts 60 minutes, using 4 crystallization units in series to carry out the process, in the case of four crystallization units in series, their temperature and pressure are respectively set as follows: set their temperature and the pressure were set as: 285°C and 9MPa in the first crystallization unit B, 265°C and 6.5MPa in the second crystallization unit C, 245°C and 5MPa in the third crystallization unit D, 200°C and 200°C in the fourth crystallization unit E 3.5MPa. After crystallization, the product 3 and mother liquor 4 are obtained through the solid-liquid separation unit. The ratio of the mother liquor 6 discharged from the system to the mother liquor 5 returne...

Embodiment 2

[0034] The purity of the crude 2,6-NDCA is 90%, the concentration of the slurry produced by the crude 2,6-NDCA in the mixing step is 10%, the temperature in the dissolution tank A is maintained at 340°C and 15MPa, and the dissolved slurry is sequentially Through the crystallization unit, each crystallization process lasts 60 minutes, using 3 crystallization units in series to carry out the process, and in the case of 3 crystallization units in series, their temperature and pressure are respectively set as follows: set their temperature The pressure and temperature are respectively set as: 300°C and 10MPa in the first crystallization unit B, 270°C and 7MPa in the second crystallization unit C, 230°C and 3MPa in the third crystallization unit D, and the product is obtained through the solid-liquid separation unit G after crystallization And the mother liquor, the mother liquor is partially discharged from the system 6, and part of it is returned to the dissolution tank 5. The rat...

Embodiment 3

[0038] The purity of 2,6-NDCA is 98.5%, the concentration of the slurry produced by the crude 2,6-NDCA in the mixing step is 12%, the temperature in the dissolution tank A is maintained at 350°C and 17MPa, and the dissolved slurry passes sequentially Crystallization unit, each crystallization process lasts 60 minutes, use 5 crystallization units in series to carry out described process, under the situation of 5 crystallization units in series, their temperature and pressure are respectively set as: their temperature and The pressure is set as: 270°C-285°C and 6.5-9MPa in the first crystallization unit, 250°C-265°C and 4.5-6.5MPa in the second crystallization unit, 235°C-250°C and 3.5-6.5MPa in the third crystallization unit 4.5MPa, 220°C-235°C and 2.5-3.5MPa in the fourth crystallization unit and 200°C-220°C and 2-2.5MPa in the fifth crystallization unit, after crystallization, the product and mother liquor are obtained through the solid-liquid separation unit, the mother liquo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com