Wire harness structure design of "2 arrival and departure tracks and 1 locomotive running track between 2 arrival and departure tracks" in heavy haul railway marshalling yard

A technology for structural design and heavy-duty trains, applied to railway car body components, roads, stations, etc., can solve problems such as long train operation time, affecting transportation efficiency, and slow vehicle turnover, so as to enrich traffic flow organization, speed up vehicle turnover, The effect of improving transportation capacity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

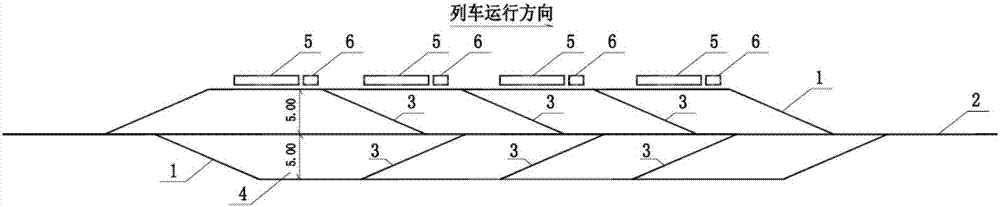

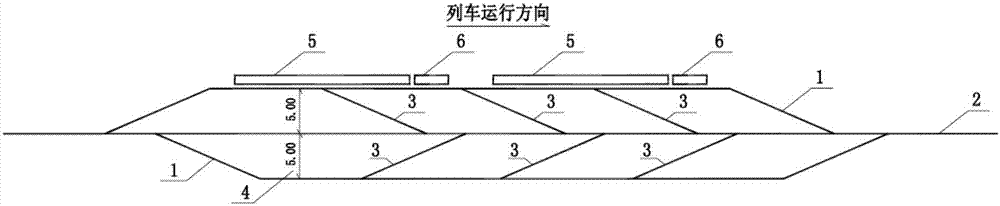

[0051] Example 1: Harness structure design of "2 wire clips and 1 machine travel" in the heavy-duty railway yard

[0052] like figure 1 and figure 2 As shown, the heavy-duty railway technical operation station yard of the present invention has a simple structure of "2 lines clamping 1 machine walking" wiring harness layout, including arrival and departure lines, locomotive running lines and 3 sets of waist forks. figure 1 is the operation situation of four 5000t unit trains, figure 2 It is the operation situation of two 10000t unit trains. After the first 5,000t or 10,000t heavy train is connected to the front of the departure line, the locomotive is off-hook and enters the standby line via the locomotive running line to wait for shift or enter the section for preparation, and the train performs train inspection technical operations; subsequent 3 5000t trains or 1 train The 10000t trains are respectively connected to the departure line at intervals of 11 minutes for the s...

Embodiment 2

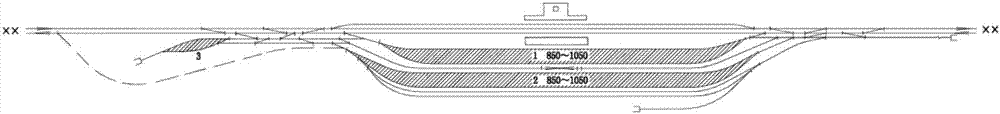

[0053] Example 2: Determination of the number of wiring harnesses

[0054] refer to Figure 5 , the line speed and the number of departure lines can be determined according to the following formula according to the locomotive coupling mode of the heavy-haul train in Table 1 and the operation process and operation time of the heavy-haul train in Table 2.

[0055] M=(N 1 *210+N 2 *144) / [(1440-T 窗 )*(1-r 空 )]

[0056] M—the number of hair lines;

[0057] N 1 - Number of 5000t trains;

[0058] N 2 - Number of 10000t trains;

[0059] T 窗 —Skylight time, comprehensive maintenance skylight time should not be less than 90 minutes for a single line, not less than 120 minutes for a double line, and not less than 180 minutes when large-scale road maintenance machinery is used for maintenance.

[0060] r 空 — Empty cost coefficient, take 0.15-0.2.

[0061] According to the current operation experience of heavy-haul railways such as Daqin Line and Shuohuang Line, each combinati...

Embodiment 3

[0062] Example 3: setting of waist fork

[0063] like figure 1 , figure 2 , 5000t trains are combined into 20000t trains to set up three waist forks between the arrival and departure lines, and the effective length of the arrival and departure lines from the throat area to the waist forks and between the waist forks should meet the needs of the receiving and dispatching unit trains. As for the number of waist forks between the arrival and departure lines of a 10000t train combined into a 20000t train, it should be determined in conjunction with the traction coupling mode of the 10000t train. When the locomotives of the 10,000t train are all in front of the train, the 20,000t train assembly is decomposed into the middle of the hairline harness, and one waist fork is installed; when the locomotive is connected in the middle of the 10,000t train, the 20,000t train assembly is decomposed into the middle of the hairline harness, and three waist forks are installed .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com