Flat shunting operation hook planning system

A technology of hook planning and shunting, which is applied to railway car body components, railway signals and safety, and locking devices in stations, etc. It can solve the problems of manual compilation, the inability to guarantee the quality and speed of compilation, etc., and achieve practical operation and extended functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

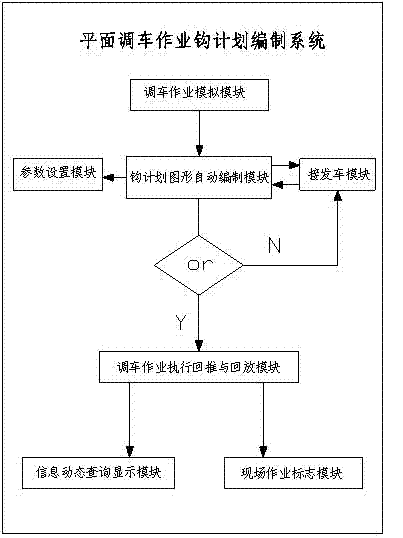

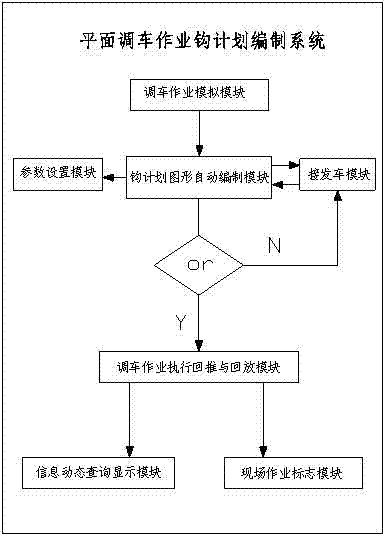

[0020] As shown in the figure, the plane shunting operation hook planning system described in the present invention is a modular structure, and the main modules include:

[0021] A. Parameter setting module: It is used to uniformly set the parameters required by the system, including the selection and change settings of the current station, station structure settings, vehicle length change and machine adjustment maximum number of traction vehicles, printer and paper type settings, Screen format and size settings;

[0022] B. Information dynamic query display module: used for dynamic information display and query of station storage status (vehicle types, light and heavy vehicles, loaded goods, departure and arrival, loading and unloading status, arrival time), overtime parking vehicles (old-brand vehicles) ), closed car, special standard car informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com