Method for preparing fatty alcohol through fixed bed hydrogenation by using fatty acid methyl ester

A technology of fatty acid methyl ester and fixed bed, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., to achieve the effects of inhibiting the formation of cyclic polymers and alkanes, stabilizing operating temperature, and saving heating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

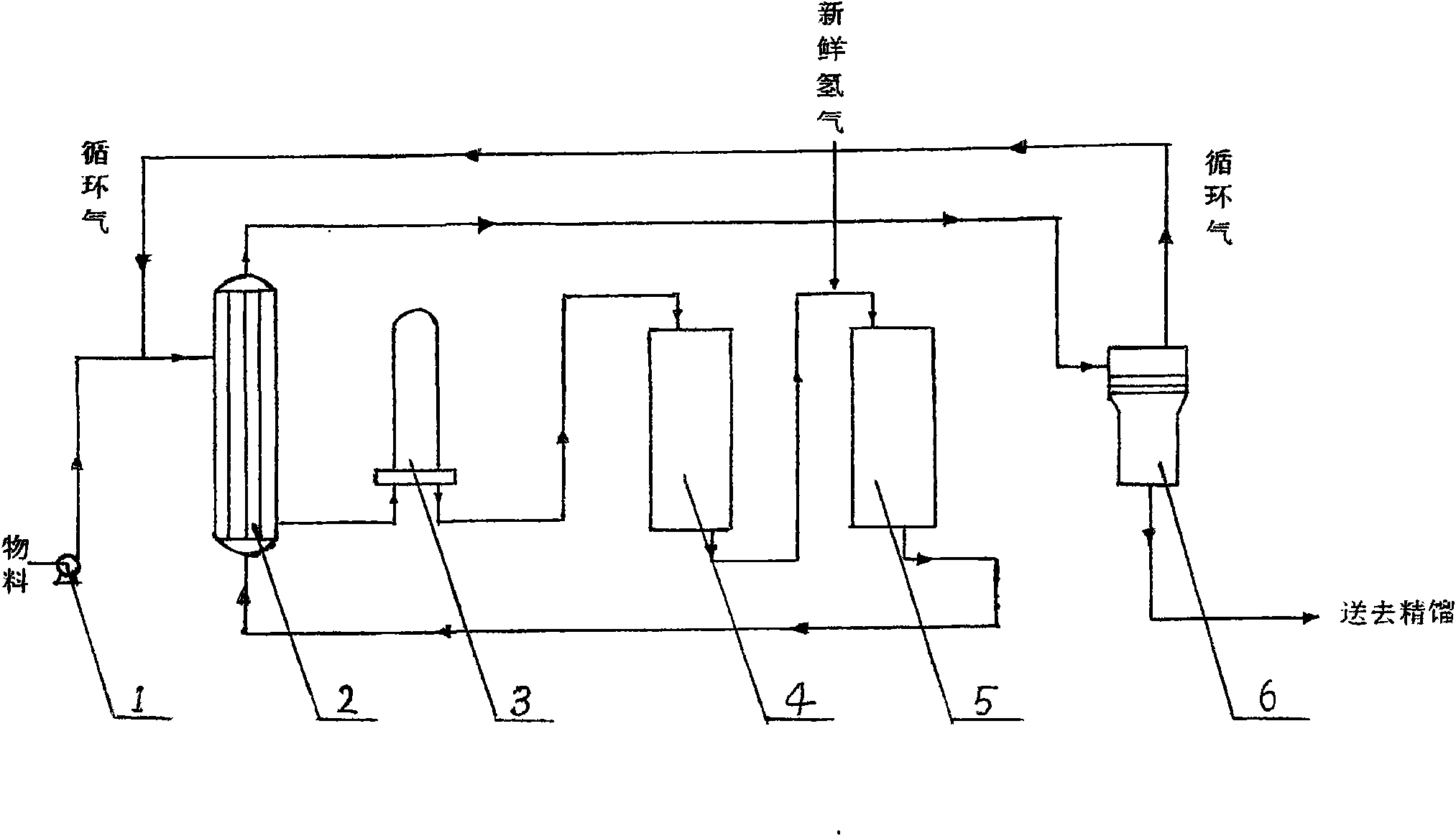

[0024] Methyl n-octanoate with an acid value of 0.70% KOHmg / g and methanol with a purity of 99.81 wt % are mixed into a mixed solution in a volume ratio of 9:1, and the mixed solution is pressurized to 20-25 MPa with a high-pressure pump [1], It is sent to the heat exchanger [2] to be preheated to 180-190 °C. In the heat exchanger [2], the mixed liquid is mixed with the circulating hydrogen separated by the high pressure cyclone from the hydrogenation reactor B[5], and the hydrogen is mixed with fatty acid methyl alcohol. The molar ratio of the ester is 120:1, and the formed two-phase mixture is sent to the heater [3] and heated to 205 to 225° C. After being heated to 205 to 225° C., a composite catalyst of copper oxide and zinc oxide is installed, wherein CuO: Zno=9: 1 (weight). ratio), the top of the circular capsule-shaped fixed-bed hydrogenation reactor A[4] with a particle size of Φ6×6mm enters, and flows through the composite catalyst fixed bed from top to bottom. For 0....

Embodiment 2

[0026] Methyl n-octanoate with an acid value of 0.73% KOHmg / g and methanol with a purity of 99.85% by weight are mixed into a mixed solution in a volume ratio of 12:1, and the mixed solution is pressurized to 20-25MPa with a high-pressure pump [1], It is sent to the heat exchanger [2] to be preheated to 180-190 °C. In the heat exchanger [2], the mixed liquid is mixed with the circulating hydrogen separated by the high pressure cyclone from the hydrogenation reactor B[5], and the hydrogen is mixed with fatty acid methyl alcohol. The molar ratio of the ester is 150:1, and the formed two-phase mixture is sent to the heater [3] and heated to 205 to 225 ° C, and then a composite catalyst of copper oxide and zinc oxide is installed, wherein CuO: Zno=9: 1 (weight). ratio), the top of the circular capsule-shaped fixed-bed hydrogenation reactor A[4] with a particle size of Φ6×6mm enters, and flows through the composite catalyst fixed bed from top to bottom. For 0.1 to 2 hours, the reac...

Embodiment 3

[0028] Use methyl laurate to replace methyl n-octanoate, other conditions and operations are the same as in Example 1, the purity of the obtained lauryl alcohol is 99.6% by weight, and the yield of methyl laurate is 97.0%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com