A kind of Fischer-Tropsch synthesis microreactor and Fischer-Tropsch synthesis method

A micro-reactor, Fischer-Tropsch synthesis technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, preparation of liquid hydrocarbon mixtures, etc. problems, to achieve the effect of safe operation, compact structure, and enhanced heat exchange process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

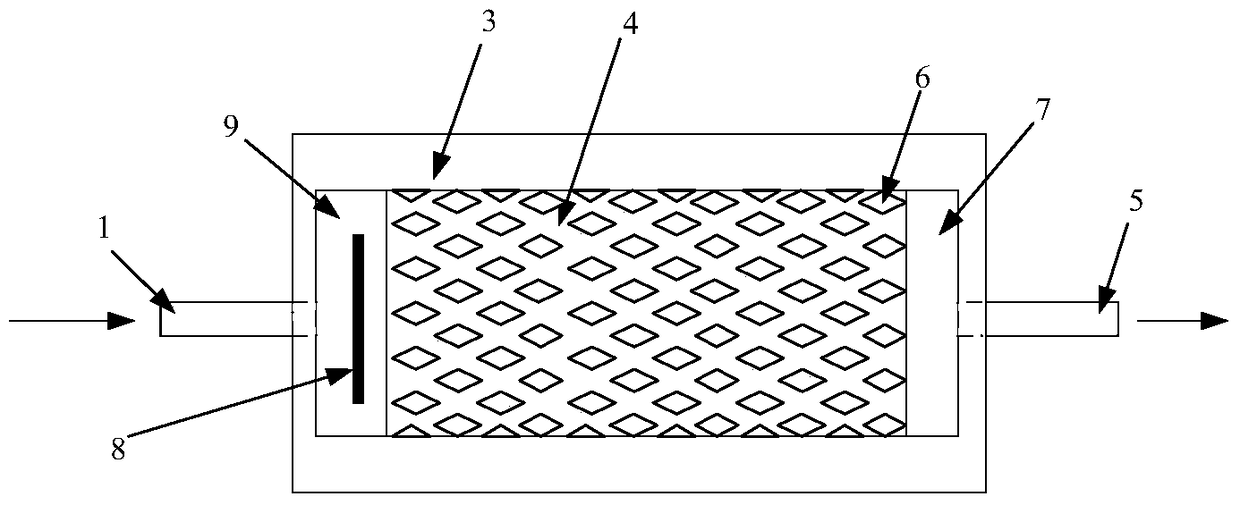

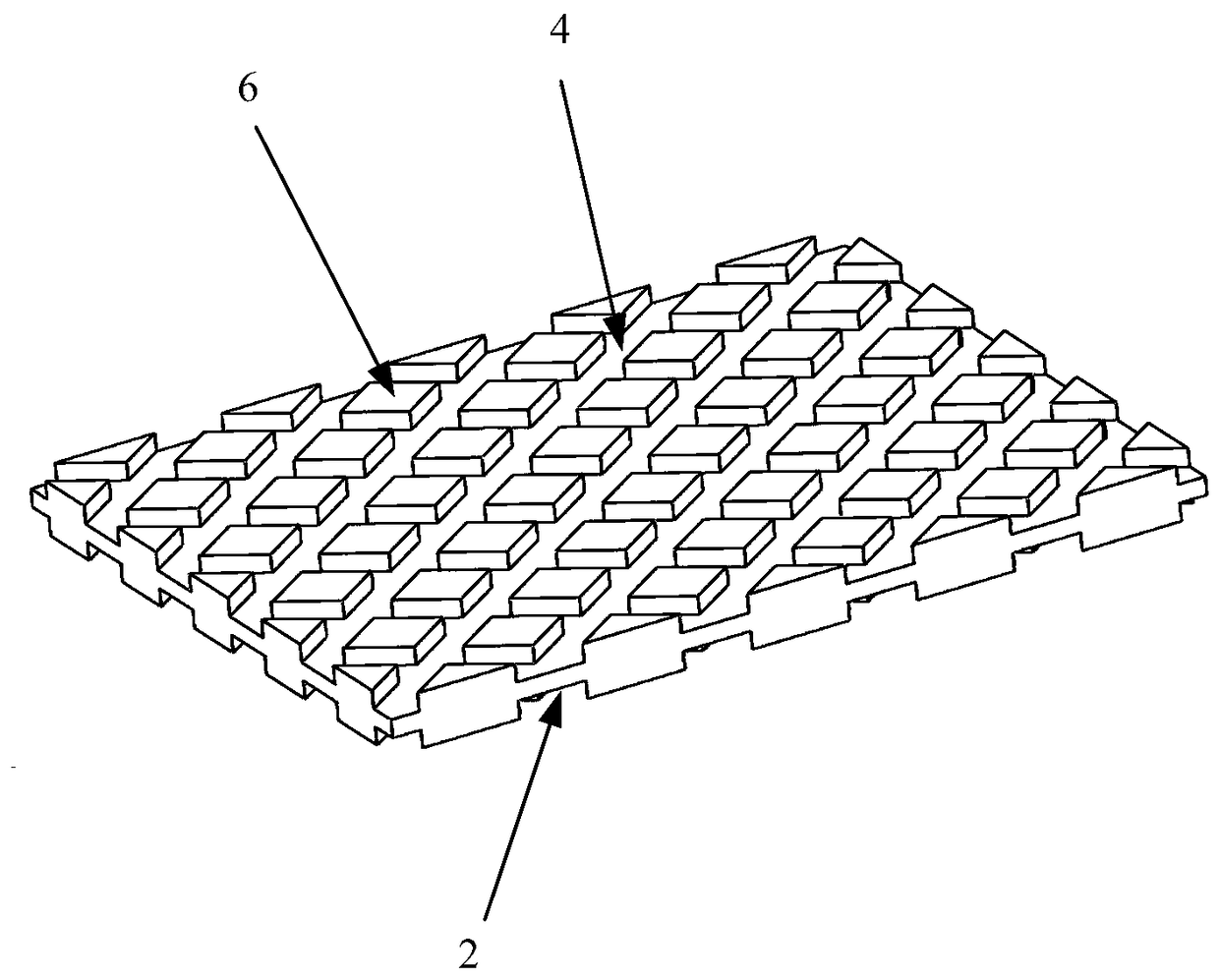

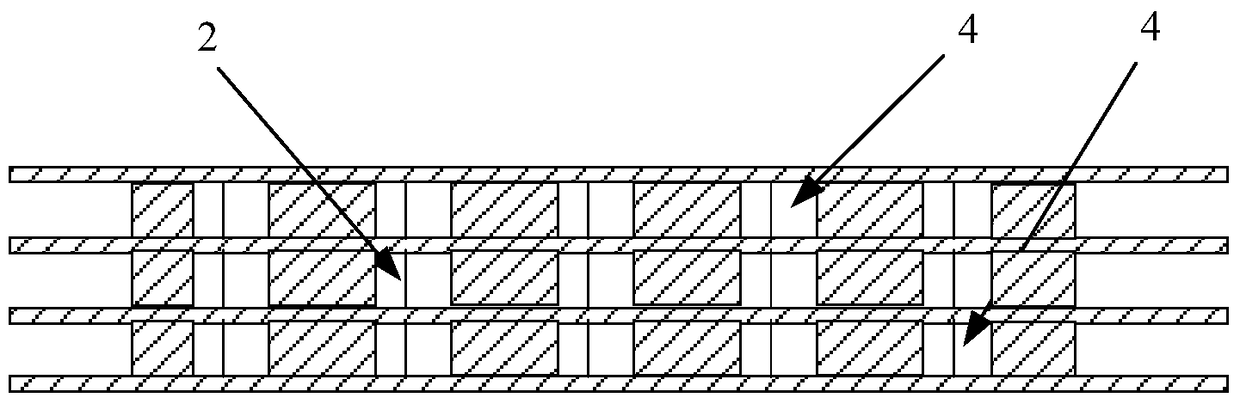

[0035] The microreactor uses figure 1 The structure shown, such as figure 1 As shown, the synthesis gas enters the reaction microchannel 4 of the microreactor from the gas phase inlet 1. The width of the reaction microchannel 4 is 2mm, the height is 1mm, and the length of the region including all the reaction microchannels is 1000mm. The flow diverting member 6 is rhombus-shaped, the inner angle of the obtuse angle of the rhombus is 120 degrees, and the inner angle of the acute angle is 60 degrees. In the reaction microchannel 4, the catalyst coated on the surface of the channel is a Co-based catalyst. For the coating method of the catalyst carrier, see patent CN103212450A. After the catalyst layer is conventionally impregnated, dried, calcined and reduced, the loading of the metal active component Co is completed. The thickness of the catalyst layer is about 100 μm, and the content of Co is about 35%.

[0036] Syngas reacts with a Co-based catalyst coated on the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com