Method for purifying benzene containing waste gas and recycling benzene and system thereof

A technology for waste gas and emulsion, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of wasting energy and high cost of benzene-containing waste gas, and achieve safe operation, good economic benefits, and solve high-cost problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

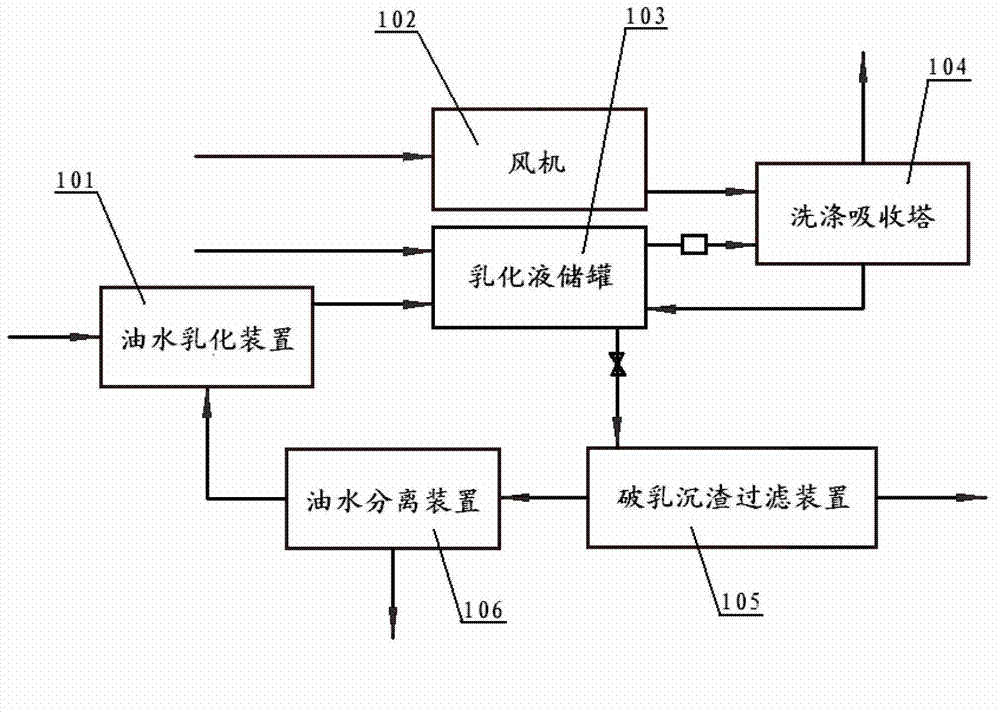

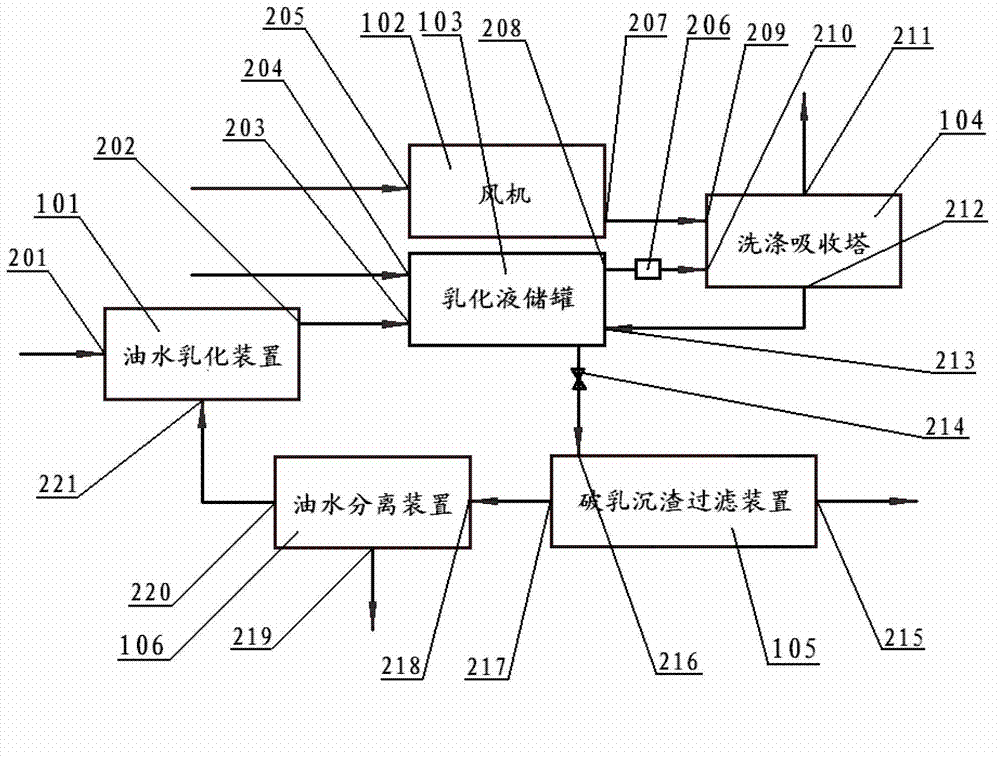

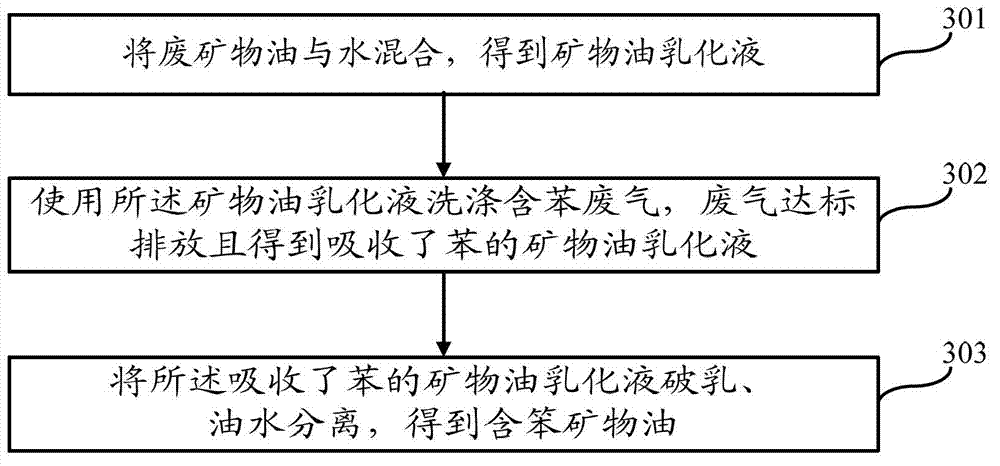

[0020] Such as image 3 Shown, a kind of method for purifying waste gas containing benzene and reclaiming benzene may further comprise the steps:

[0021] 301, mixing waste mineral oil with water to obtain a mineral oil emulsion;

[0022] 302. Use the mineral oil emulsion to wash and absorb benzene-containing waste gas, discharge the waste gas up to the standard and obtain a mineral oil emulsion that has absorbed benzene;

[0023] 303. Demulsify the mineral oil emulsion that has absorbed benzene, and separate oil and water to obtain benzene-containing mineral oil.

[0024] In the method for purifying benzene-containing waste gas of the present invention, waste mineral oil is mixed with water to obtain a mineral oil emulsion, and the mineral oil emulsion is used to wash the benzene-containing waste gas to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com