Pressurized hot water sterilization process and equipment pipeline configuration of continuous sterilization system for aerobic microbe fermentation culture medium or fed-batch material

A fermentation medium and aerobic microorganism technology, which is applied in the field of process and equipment pipeline configuration, can solve the problems of restricting the promotion and application of technology, and the inability of water elimination system to be widely used, so as to reduce energy consumption, prevent scaling, and reduce operating temperature. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

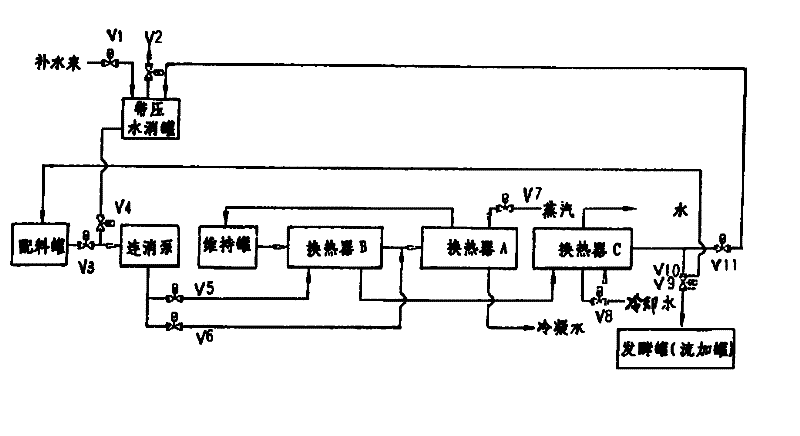

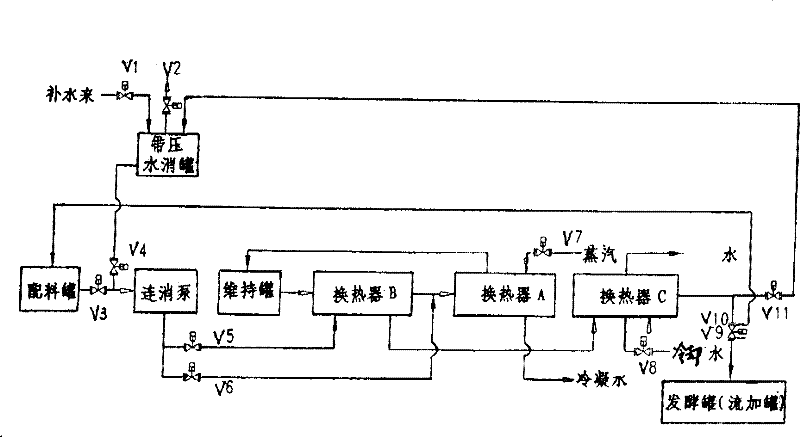

[0025] An equipment pipeline configuration for the pressurized water elimination process, which includes: a pressure water elimination tank, a water inlet valve V1 on the water elimination tank, which is connected to the water supply pipe of the workshop, and an exhaust valve on the water elimination tank V2, the valve is connected to the emptying pipeline; the outlet valve V4 on the water elimination tank is connected to the inlet of the continuous elimination pump of each continuous elimination system; the inlet of the continuous elimination pump is also connected to the discharge valve V3 on the supply pipe of the batching tank The exit connects.

[0026] The equipment pipeline configuration also includes heat exchanger A (heating), heat exchanger B (preheating), heat exchanger C (cooling) and maintenance tank. Heat exchanger A water inlet valve V6, one end of the valve is connected to the water inlet pipe, and the other end is connected to the material passage inlet of hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com