Traction device for wire drawing machine

A technology of a traction device and a wire drawing machine, which is applied in the field of traction devices for wire drawing machines, can solve problems such as broken wires, low wire drawing efficiency, and few functions of the traction mechanism, so as to reduce the possibility of damage, reduce the degree of wear, The effect of stabilizing the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

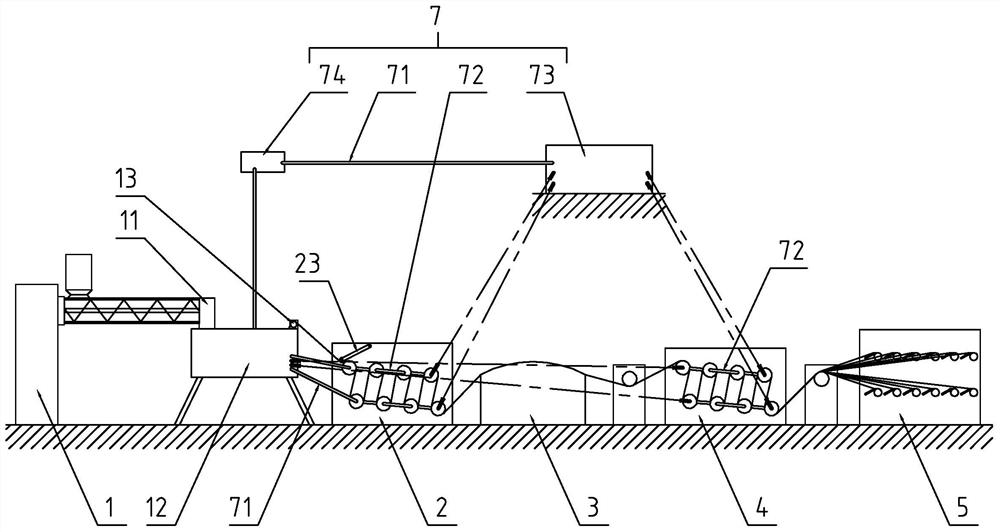

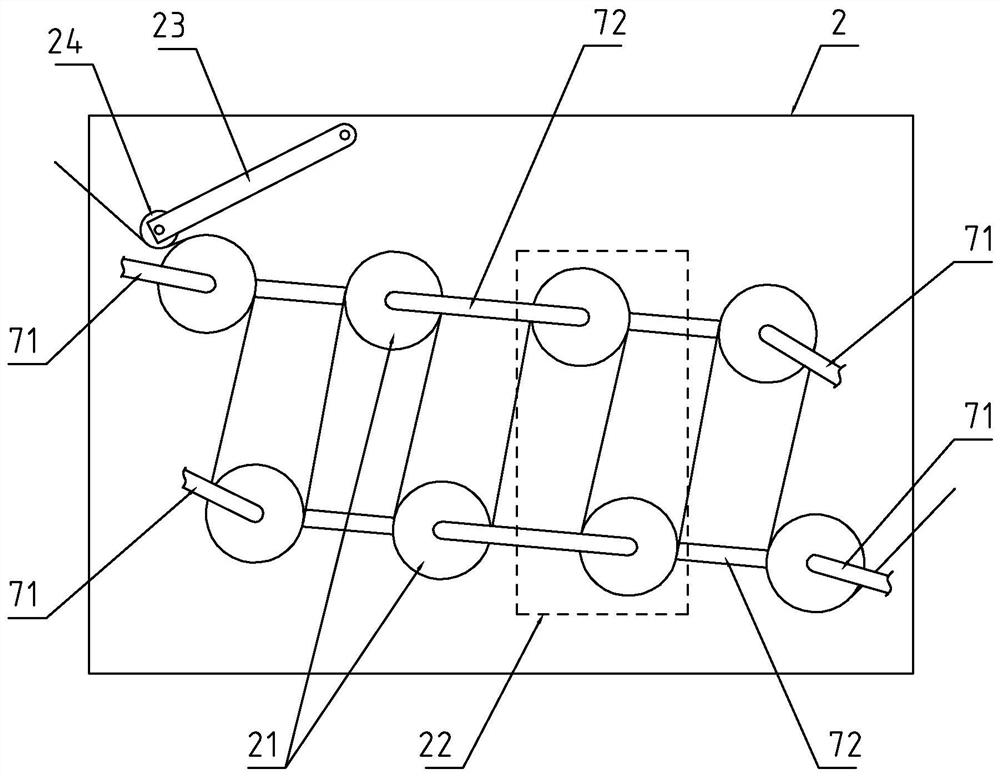

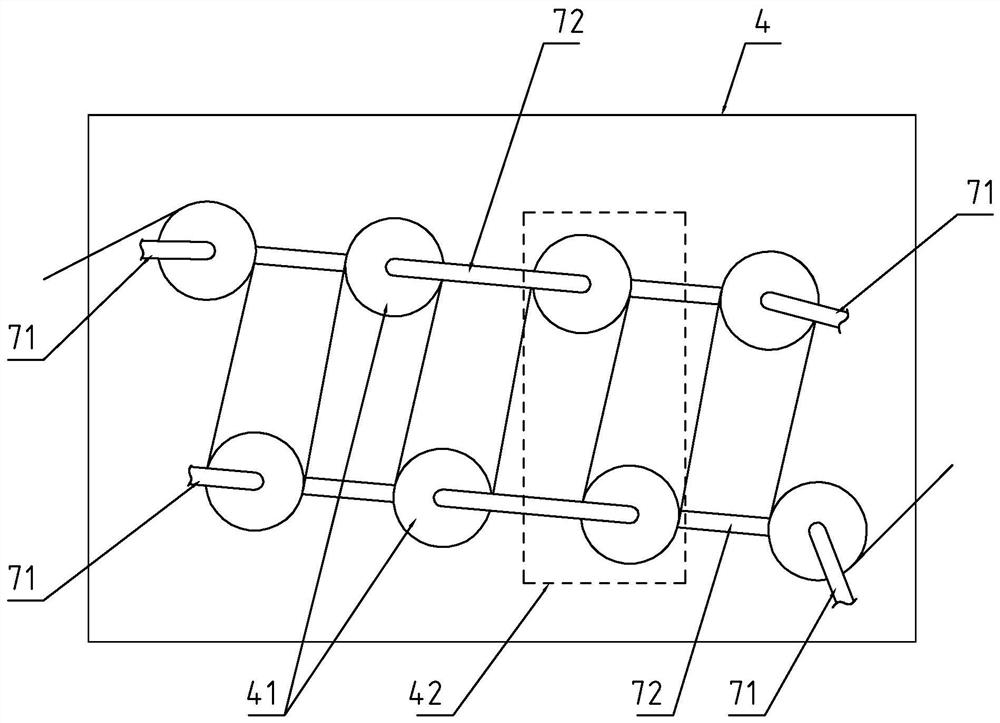

[0027] refer to Figure 1-4Shown, a kind of pulling device for wire-drawing machine comprises the wire-drawing host 1 that can heat and draw the polypropylene raw material into plastic flat film, and the flat-film pulling mechanism 2 that is used for pulling plastic flat film, and can draw plastic flat film A cutting mechanism 3 for cutting into filaments, a flat wire traction mechanism 4 for pulling plastic flat wires, and a winding mechanism 5 for w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com