A kind of Fischer-Tropsch synthesis reaction device and Fischer-Tropsch synthesis method

A Fischer-Tropsch synthesis and reaction device technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, chemical/physical/physical-chemical processes, etc. To achieve the effect of compact structure, safe equipment operation and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the nano-catalyst is as follows: under the protection of nitrogen, a certain amount of soluble salt containing metal ions and a stabilizer are mixed and dissolved in water, a metal reducing agent is added, and the nano-metal particles are produced after fully stirring. The metal particles are separated by magnetic separation, washed with water, and then dispersed into water containing stabilizers to form a liquid phase medium. The stabilizer is preferably polyvinylpyrrolidone.

[0033] In the Fischer-Tropsch synthesis method provided by the present invention, the liquid phase medium is water, alcohol, refluxing hydrocarbon or ionic liquid. Preferably, the liquid phase medium is water. Preferably, the liquid medium contains a polymer stabilizer to maintain high dispersion of the metal nanoparticles, and the stabilizer is preferably polyvinylpyrrolidone.

[0034] In the Fischer-Tropsch synthesis method provided by the invention, the concentrati...

Embodiment 1

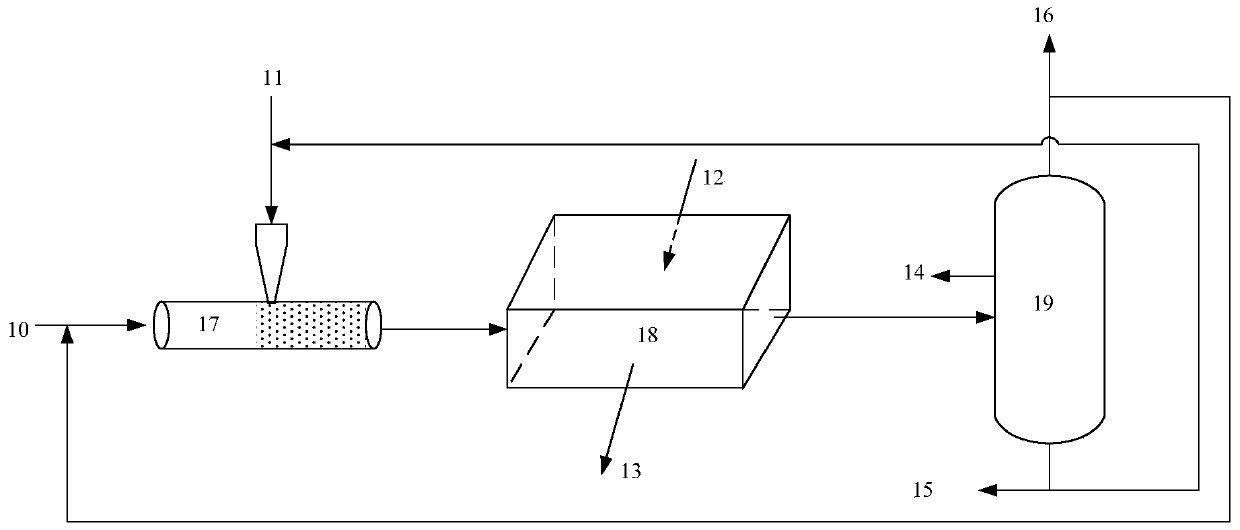

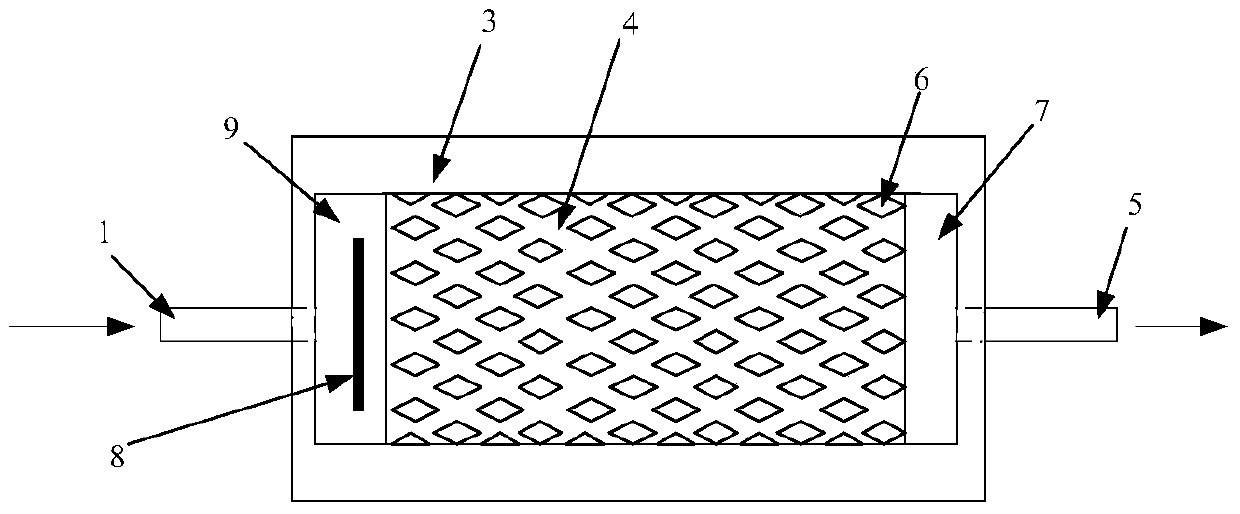

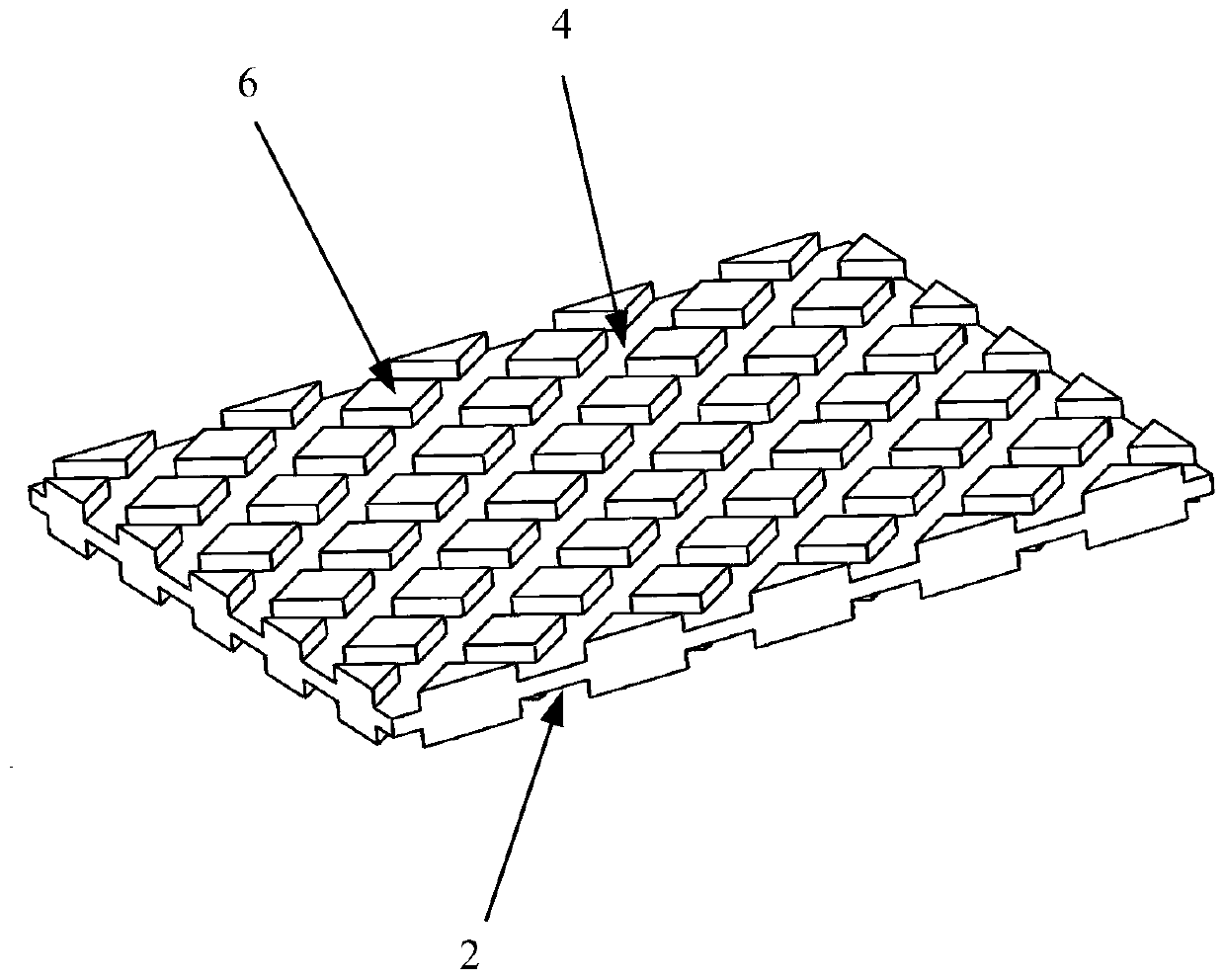

[0049] Use as attached figure 1 The shown Fischer-Tropsch synthesis reaction device, the structure of the microreactor is as attached Figure 2-4 shown. The diameter of the nozzle of the mixer is 0.4 mm. The microchannel reactor includes reaction microchannels and heat exchange microchannels. The dimensions of all microchannels are 1 mm high and 2 mm wide. The flow diverting member 6 is rhombus-shaped, the inner angle of the obtuse angle of the rhombus is 120 degrees, and the inner angle of the acute angle is 60 degrees. The ratio of the volume flow rate of the synthesis gas entering the mixer to the liquid phase (catalyst liquid) containing nano metal catalyst particles is 30:1. The nano particles contained in the catalytic liquid are cobalt catalysts, and polyvinylpyrrolidone is added to maintain the stability of the catalytic liquid. The concentration of cobalt in the catalytic liquid is 0.05mmol / mL. The ratio of synthesis gas tail gas to circulating synthesis gas is 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com