Cooler for several heating elements

A technology for heating elements and cooling devices, which is applied to electrical components, cooling/ventilation/heating transformation, electrical solid-state devices, etc., and can solve problems such as burnout, difficult positioning of cooling blocks and heating elements, and poor heat dissipation capability of microprocessors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

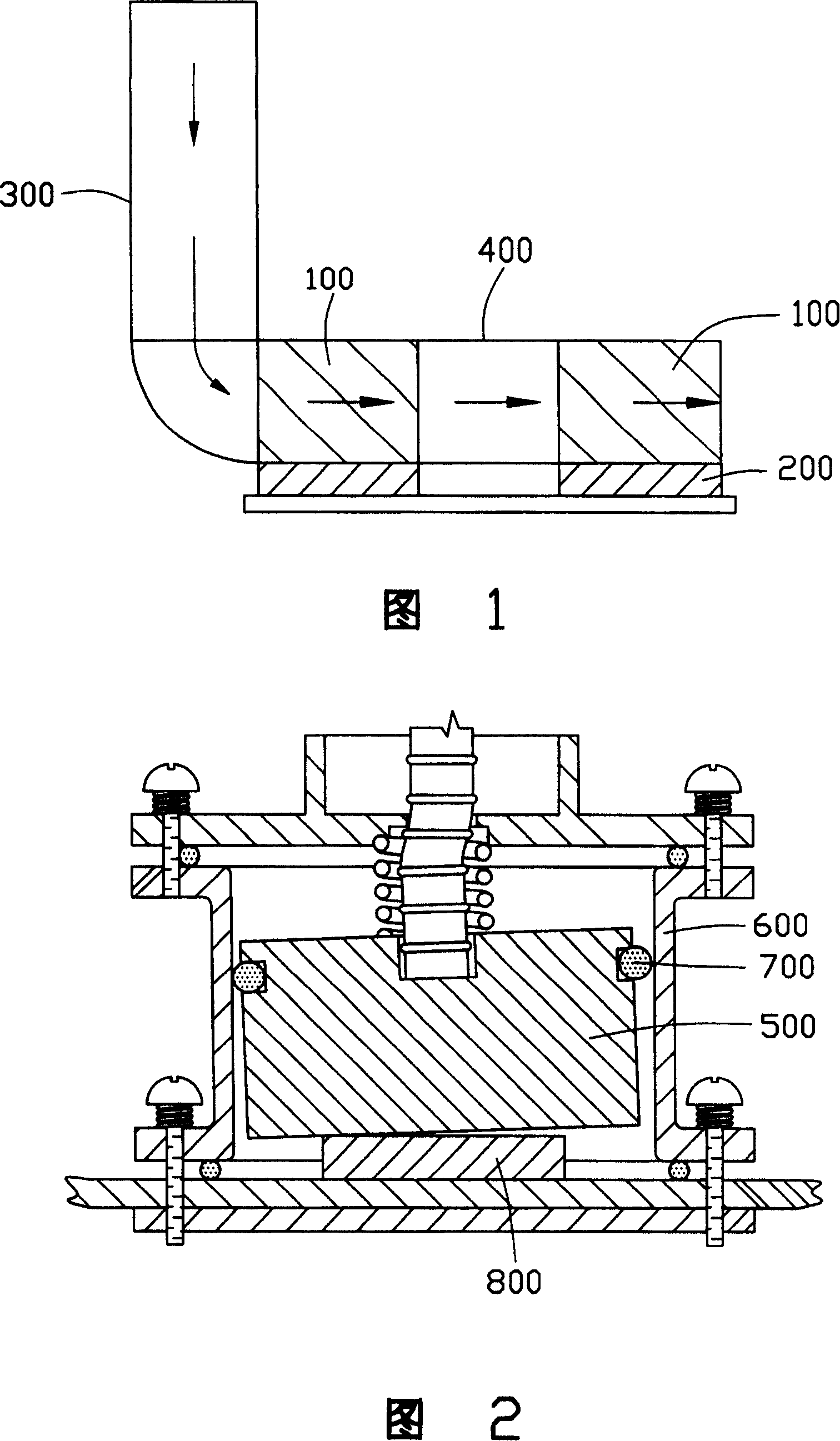

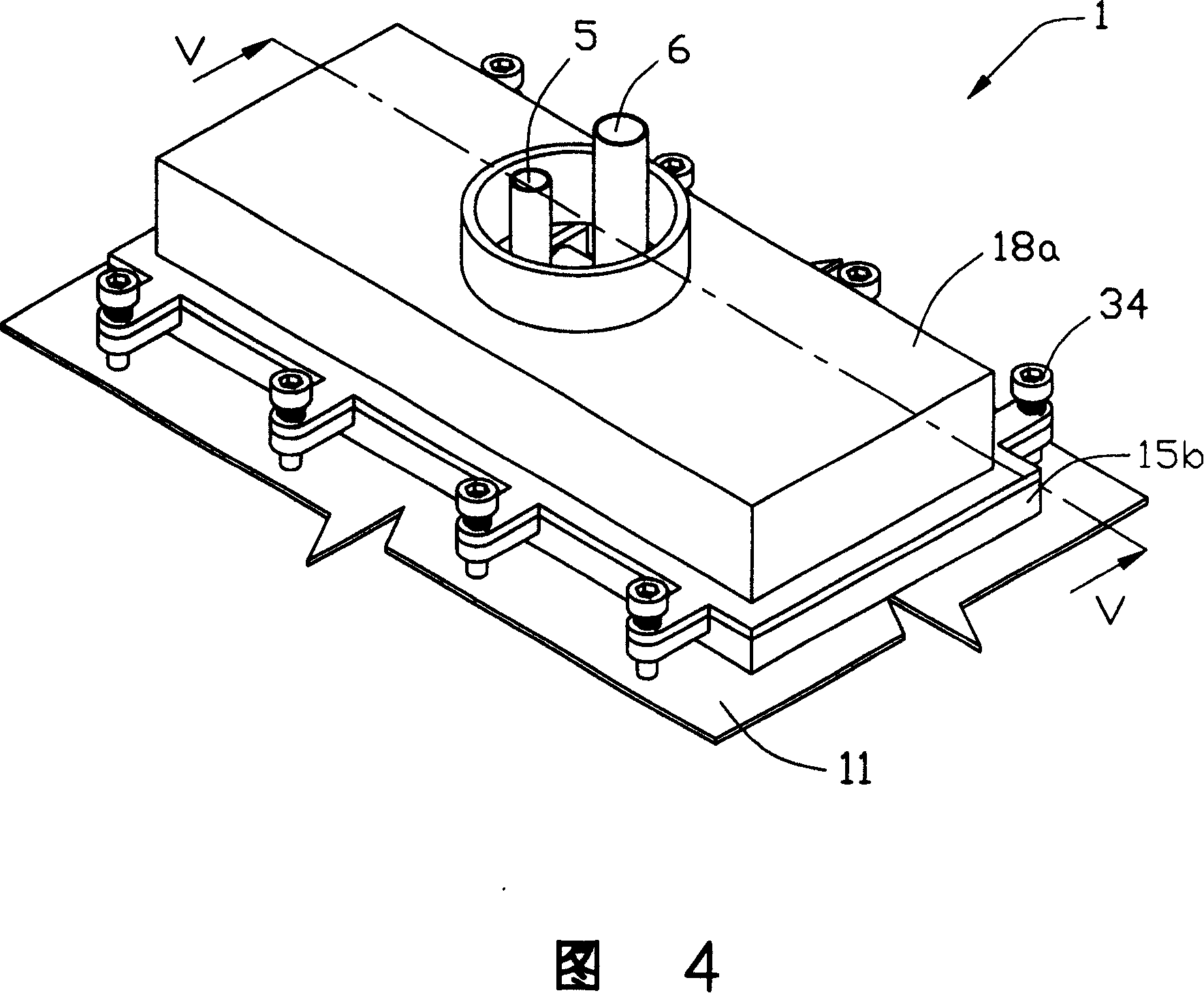

[0036] FIG. 3 is a schematic diagram of the principle of the compression refrigeration cycle system used in the cooling device for several heating elements (for simplicity of description, hereinafter referred to as the cooling device) in this embodiment. The cooling device of this embodiment is used to remove the heat generated by the microprocessor 10 disposed on a circuit board 11 . It can be understood that the cooling device of this embodiment can also be used to cool other electronic components and non-electronic components with several heat sources. In order to simplify the description, two microprocessors are taken as examples for illustration below.

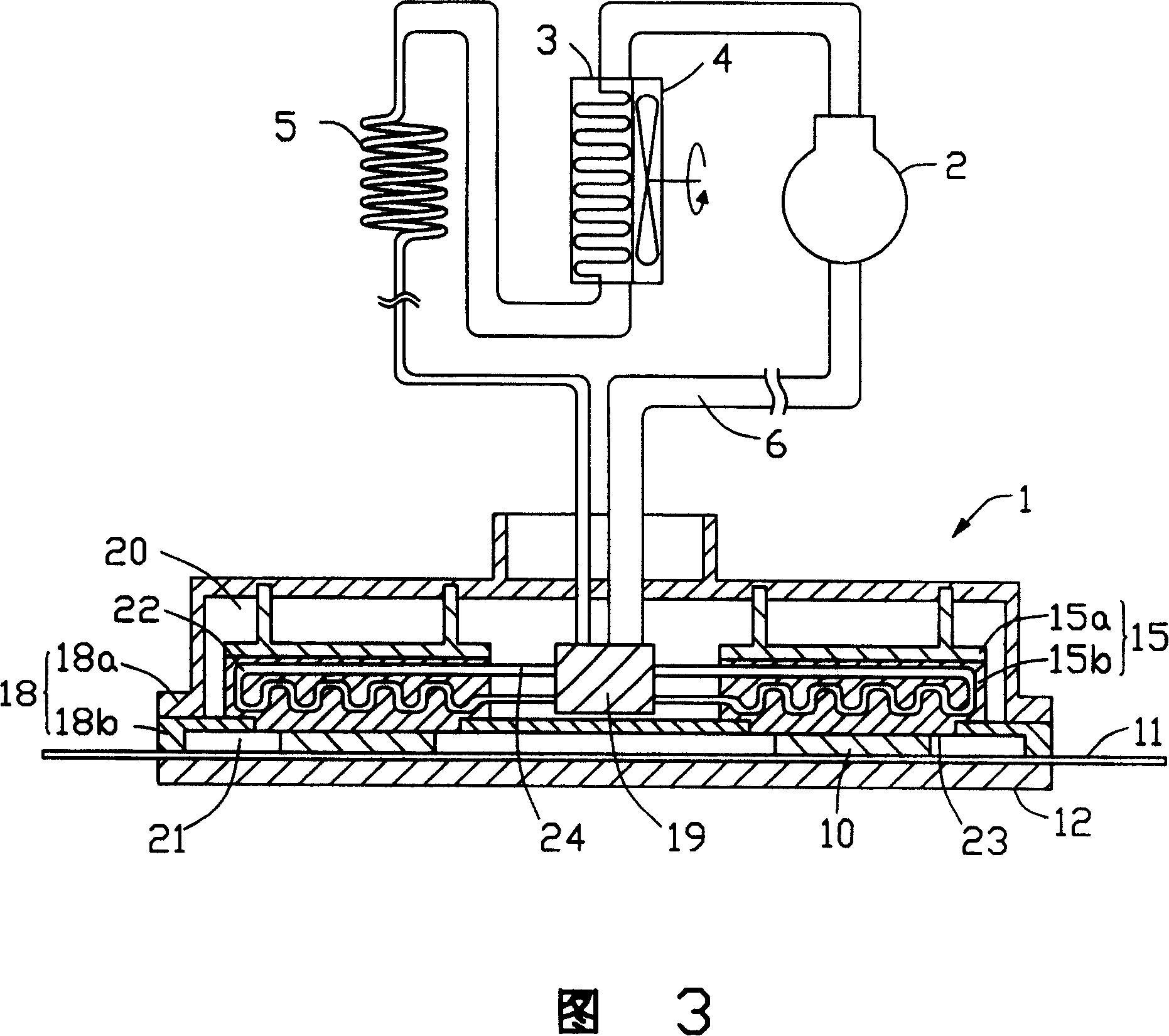

[0037] The cooling device includes an evaporator 1 , a compressor 2 , a condenser 3 and a pipeline for transporting refrigerant, and the pipeline for refrigerant includes a capillary liquid inlet pipe 5 and an air outlet pipe 6 .

[0038] The evaporator 1 includes two cooling blocks 15 , it can be understood that the num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com