Potassium ferrate preparation method

A technology of potassium ferrate and sodium ferrate, applied in cells, electrolysis process, diaphragm and other directions, can solve problems such as instability of sodium ferrate, influence on current efficiency, easy passivation of metallic iron, etc., and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

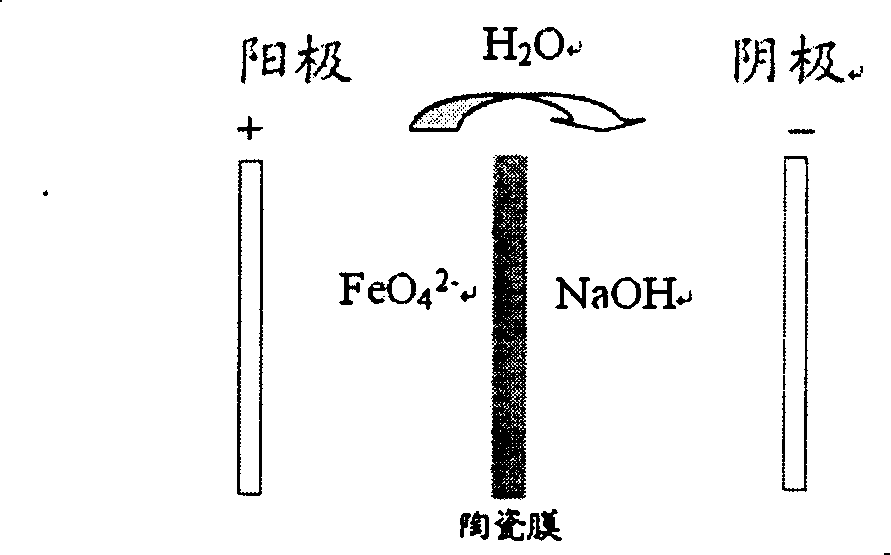

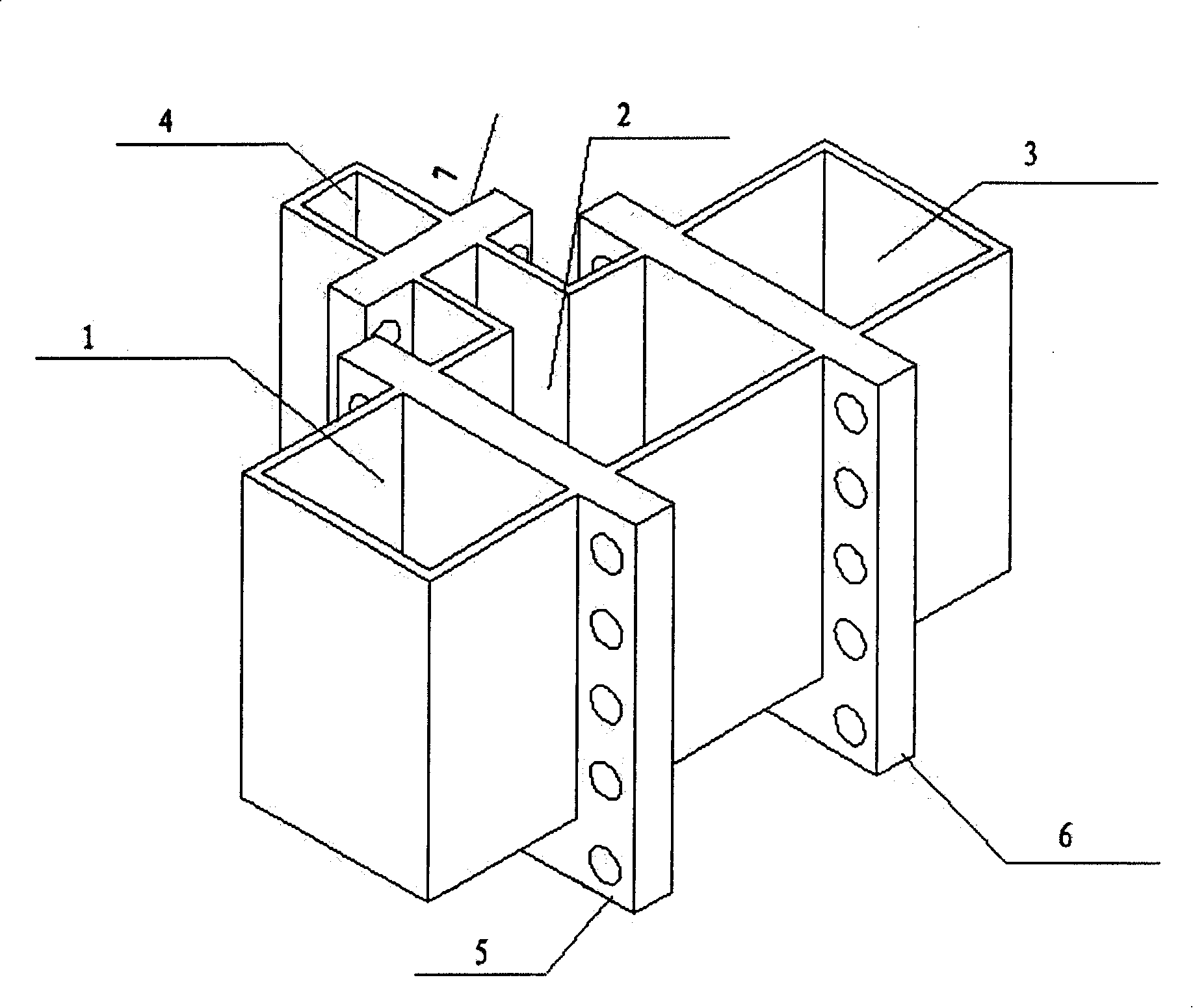

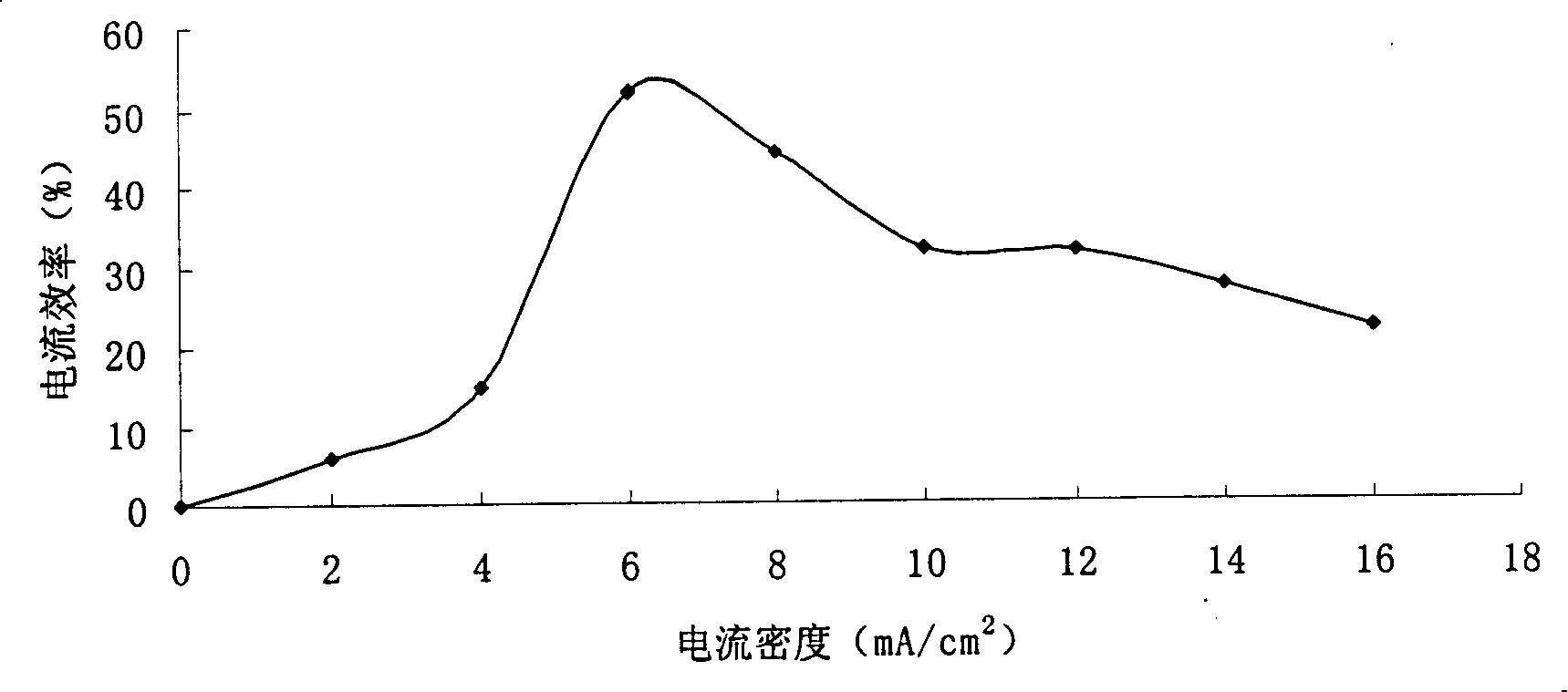

[0022] The present invention is further described in detail below by accompanying drawing, a kind of preparation method of potassium ferrate, comprising the following steps: a. the preparation of potassium ferrate takes place in the electrolyzer, as figure 2 As shown in the figure, the electrolytic cell is composed of 4 cells (wherein cell 4 is reserved), the cell 1 and cell 2 are separated by a porous ceramic membrane 5, and the cell 2 and cell 3, and cell 2 and cell 4 are separated by a cation exchange membrane respectively. 6 and 7 are separated, the electrolytic cell is placed in a water bath with a constant temperature of 20°C, the white cast iron is put into the anode chamber tank 2 of the electrolytic cell, the nickel mesh is put into the tank 1 and the tank 3 as a negative electrode, and the electrolyte is 14mol / L NaOH, feed N into the cathode compartment 2 Take away the hydrogen produced by the cathode reaction and add 0.1% KIO 4 and 3% NaCl at 6mA / cm 2 Direct cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com