Water purifying agent for aquaculture, and preparation method thereof

A technology of aquaculture and purification agent, which is applied in the direction of chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc. It can only solve problems such as flocculation, and achieve the effect of obvious coagulation effect, fast adsorption speed, and guaranteed quality and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

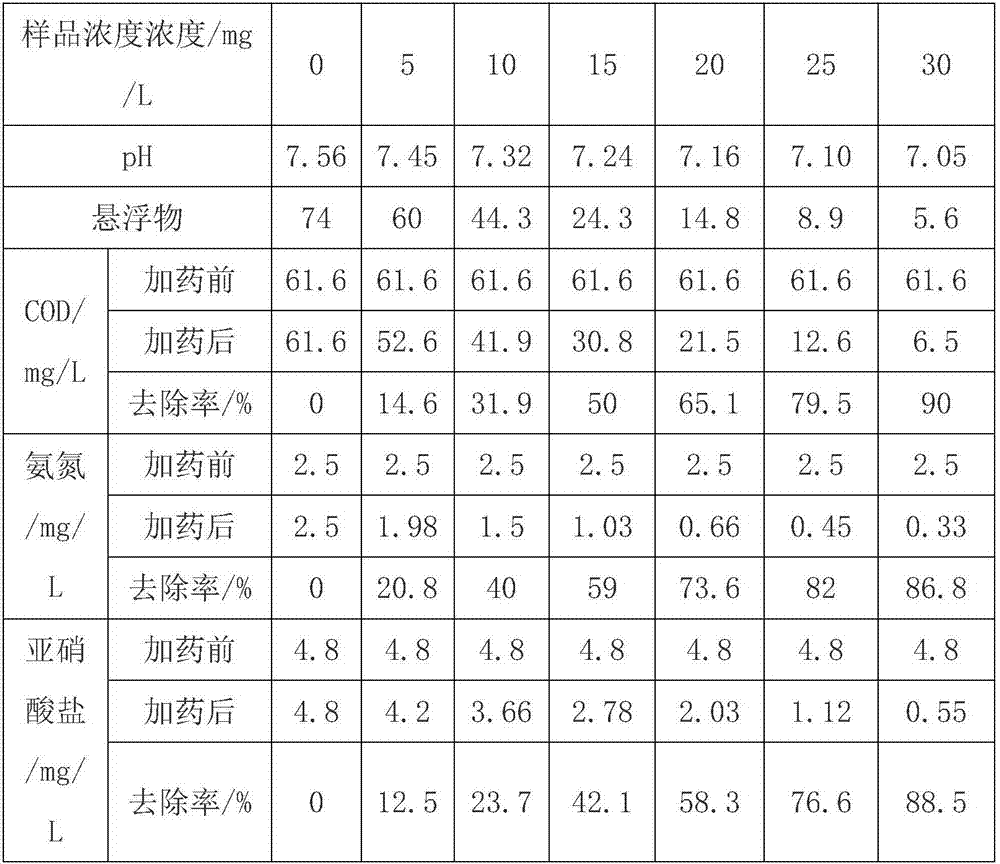

Examples

Embodiment 1

[0022] A water quality purifier for aquaculture, comprising the following components in parts by weight: 55 parts of tourmaline particles, 40 parts of modified zeolite, 25 parts of polyaluminum chloride, 20 parts of potassium ferrate, 15 parts of copper sulfate, carbon black 5 parts, 20 parts of activated carbon fiber, 5 parts of diatomaceous earth, 5 parts of calcium oxide and 3 parts of magnesium oxide.

[0023] Wherein, the particle size of the tourmaline particles is 300 mesh.

[0024] Wherein, the modified zeolite is made of the following raw materials in parts by weight: 70 parts of zeolite, 5 parts of cerous chloride and 3 parts of lanthanum chloride; its preparation method: according to parts by weight, cerous chloride and Dissolve lanthanum chloride in water, stir evenly, adjust the pH to 10, add crushed zeolite to it, filter and wash with water until neutral, dry, and roast at 600°C for 5.5 hours to obtain modified zeolite.

[0025] A preparation method of an aquacu...

Embodiment 2

[0030] A water quality purifier for aquaculture, comprising the following components in parts by weight: 50 parts of tourmaline particles, 30 parts of modified zeolite, 20 parts of polyaluminum chloride, 15 parts of potassium ferrate, 10 parts of copper sulfate, carbon black 3 parts, 10 parts of activated carbon fiber, 2 parts of diatomaceous earth, 3 parts of calcium oxide and 1 part of magnesium oxide.

[0031] Wherein, the particle size of the tourmaline particles is 200 mesh.

[0032] Wherein, the modified zeolite is made of the following raw materials in parts by weight: 60 parts of zeolite, 3 parts of cerous chloride and 1 part of lanthanum chloride; its preparation method: according to parts by weight, cerous chloride and Dissolve lanthanum chloride in water, stir evenly, adjust the pH to 9, add crushed zeolite to it, filter and wash with water until neutral, dry, and roast at 550°C for 5 hours to obtain modified zeolite.

[0033] A preparation method of an aquaculture...

Embodiment 3

[0038] A water quality purifier for aquaculture, comprising the following components in parts by weight: 60 parts of tourmaline particles, 50 parts of modified zeolite, 30 parts of polyaluminum chloride, 25 parts of potassium ferrate, 20 parts of copper sulfate, carbon black 8 parts, 30 parts of activated carbon fiber, 8 parts of diatomaceous earth, 8 parts of calcium oxide and 5 parts of magnesium oxide.

[0039] Wherein, the particle size of the tourmaline particles is 400 mesh.

[0040] Wherein, the modified zeolite is made of the following raw materials in parts by weight: 80 parts of zeolite, 8 parts of cerous chloride and 5 parts of lanthanum chloride; its preparation method: according to parts by weight, cerous chloride and Dissolve lanthanum chloride in water, stir evenly, adjust the pH to 11, add crushed zeolite to it, filter and wash with water until neutral, dry, and roast at 650°C for 6 hours to obtain modified zeolite.

[0041] A preparation method of an aquacult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com