Method for preparing potassium ferrate by using waste liquid from acid washing steel

A technology for iron and steel pickling waste liquid, potassium ferrate, applied in chemical instruments and methods, iron compounds, sodium/potassium compounds, etc., can solve problems such as environmental pollution and resource waste, achieve a wide range of use, eliminate pollution, and The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

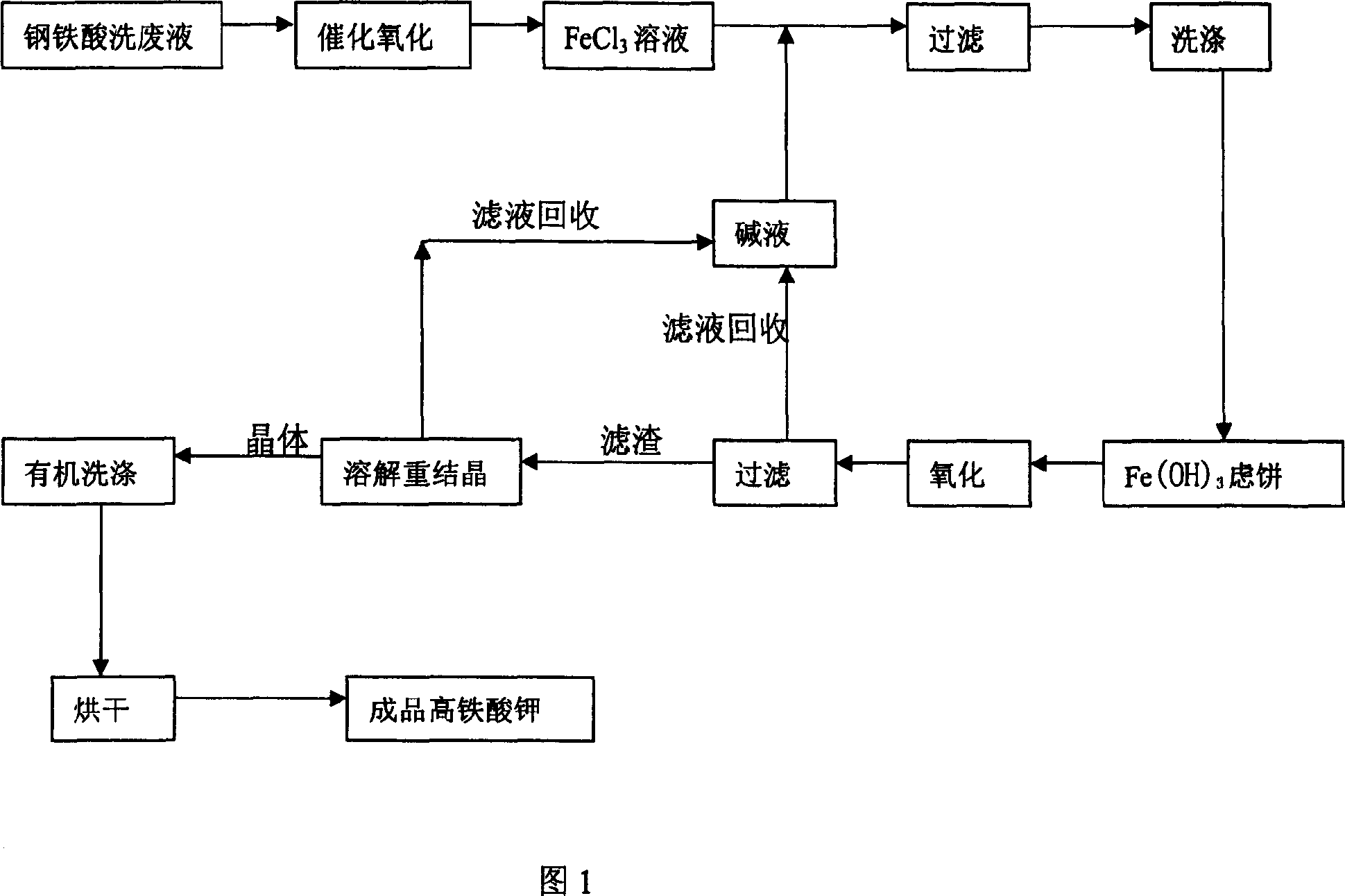

Image

Examples

Embodiment 1

[0022] A method for preparing potassium ferrate by utilizing iron and steel pickling waste liquor, it comprises the steps:

[0023] 1) Iron and steel pickling waste liquid (containing Fe 2+ The mass percentage is 0.1%, Fe 3+ The mass percentage is 0.1%, Cl - The mass percentage is 0.1%, and the acidity is 0mol / l) and the hydrochloric acid that the mass fraction is 21% is mixed with the volume ratio of 1000:6, and the mixed solution is aerated with an aerator, and heated to 40°C; when the temperature reaches 40°C , add NaNO with a weight concentration of 1‰ 2 , NaNO with a weight concentration of 1‰ 2 The dosage is 0.1% of the mass of the mixed liquid, continue to aerate, and maintain the system at 40°C for 1 hour; the reaction equation involved:

[0024] ,

[0025] ,

[0026] After the reaction was completed, the reaction solution was added to the alkali solution, and the Fe 3+ with Fe(OH) 3 Precipitated in the form of, among them, OH - The total amount of...

Embodiment 2

[0033] A method for preparing potassium ferrate by utilizing iron and steel pickling waste liquor, it comprises the steps:

[0034] 1) Iron and steel pickling waste liquid (containing Fe 2+ The mass percentage is 10%, Fe 3+ The mass percentage is 10%, Cl - The mass percentage is 20%, and the acidity is 3mol / l) and the hydrochloric acid that the mass fraction is 10% is mixed with the volume ratio of 1000:30, and the mixed solution is aerated with an aerator, and heated to 70°C; when the temperature reaches 70°C , add NaNO with a weight concentration of 30‰ 2 , NaNO with a weight concentration of 30‰ 2 The dosage is 2% of the mass of the mixture, continue to aerate, and maintain the system at 70°C for 4 hours; the reaction equation involved:

[0035] ,

[0036] ,

[0037] After the reaction was completed, the reaction solution was added to the alkali solution, and the Fe 3+ with Fe(OH) 3 Precipitated in the form of, among them, OH - The total amount of matte...

Embodiment 3

[0044] A method for preparing potassium ferrate by utilizing iron and steel pickling waste liquor, it comprises the steps:

[0045] 1) Iron and steel pickling waste liquid (containing Fe 2+ The mass percentage is 20%, Fe 3+ The mass percentage is 20%, Cl - The mass percentage is 35%, acidity 6mol / l) is mixed with the hydrochloric acid that mass fraction is 21% with the volume ratio of 1000:40, the mixed solution is aerated with an aerator, and heated to 90 ℃; when the temperature reaches 90 ℃ , add NaNO with a weight concentration of 50‰ 2 , NaNO with a weight concentration of 50‰ 2 The dosage is 5% of the mass of the mixed liquid, continue to aerate, and maintain the system at 90°C for 6 hours; the reaction equation involved:

[0046] ,

[0047] ,

[0048] After the reaction was completed, the reaction solution was added to the alkali solution, and the Fe 3+ with Fe(OH) 3 Precipitated in the form of, among them, OH - The total amount of matter is Fe 3+ 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com