Preparation method of three-dimensional flocculent graphene substrate material and application

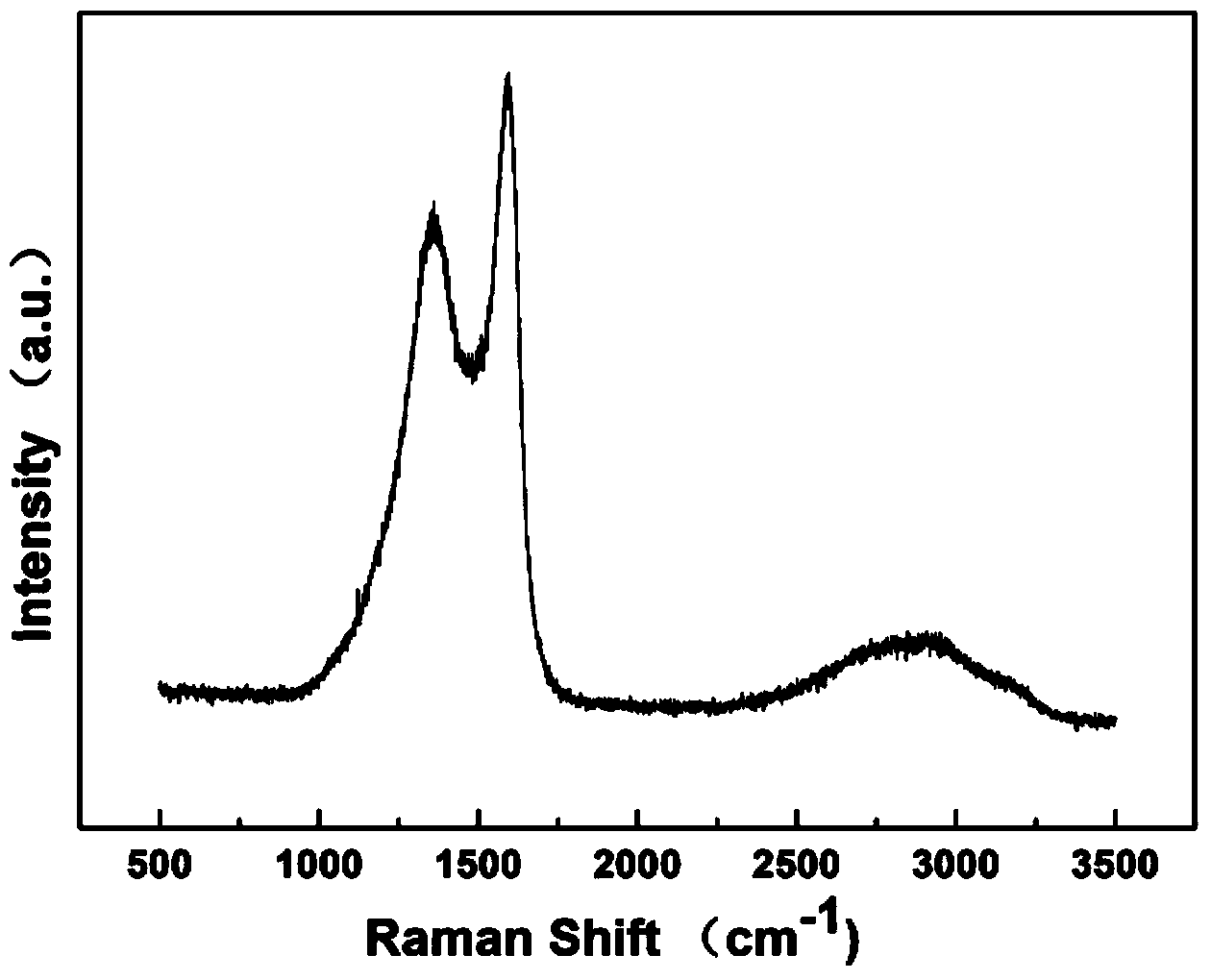

A technology of base material and graphene, applied in the field of preparation of three-dimensional flocculent graphene base material, can solve the problems of carbon structure defects, increase the specific surface area of the material, and the negative effect of the electrical properties of the material, so as to reduce the internal resistance and improve the capacitance performance. , the effect of excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Put graphite oxide in a crucible, heat the muffle furnace at a rate of 5°C / min to a temperature of 1000°C, put the crucible into the muffle furnace and keep it warm for 0.5min, then take out the crucible to obtain expanded graphite .

[0020] (2) Take 20 mg of expanded graphite and disperse it in 10 mL of water, add 800 μL of polystyrene (PS) beads water dispersion with a mass concentration of 2.5 wt % and 2 μm polystyrene (PS) beads, and then sonicate for 4 hours.

[0021] (3) The expanded graphite-polystyrene composite system dispersion liquid is directly sucked onto the foamed nickel at a rate of 4L / s, and after drying at 60°C for 18h, the foamed nickel loaded with expanded graphite-polystyrene is placed in 100mL In a mixed solution containing 100 μL of hydrazine hydrate and 700 μL of concentrated ammonia water with a mass concentration of 26%, react at 95°C for 1 hour, take it out, soak and wash it with deionized water for 5 times, and dry at 60°C for 18 hours t...

Embodiment 2

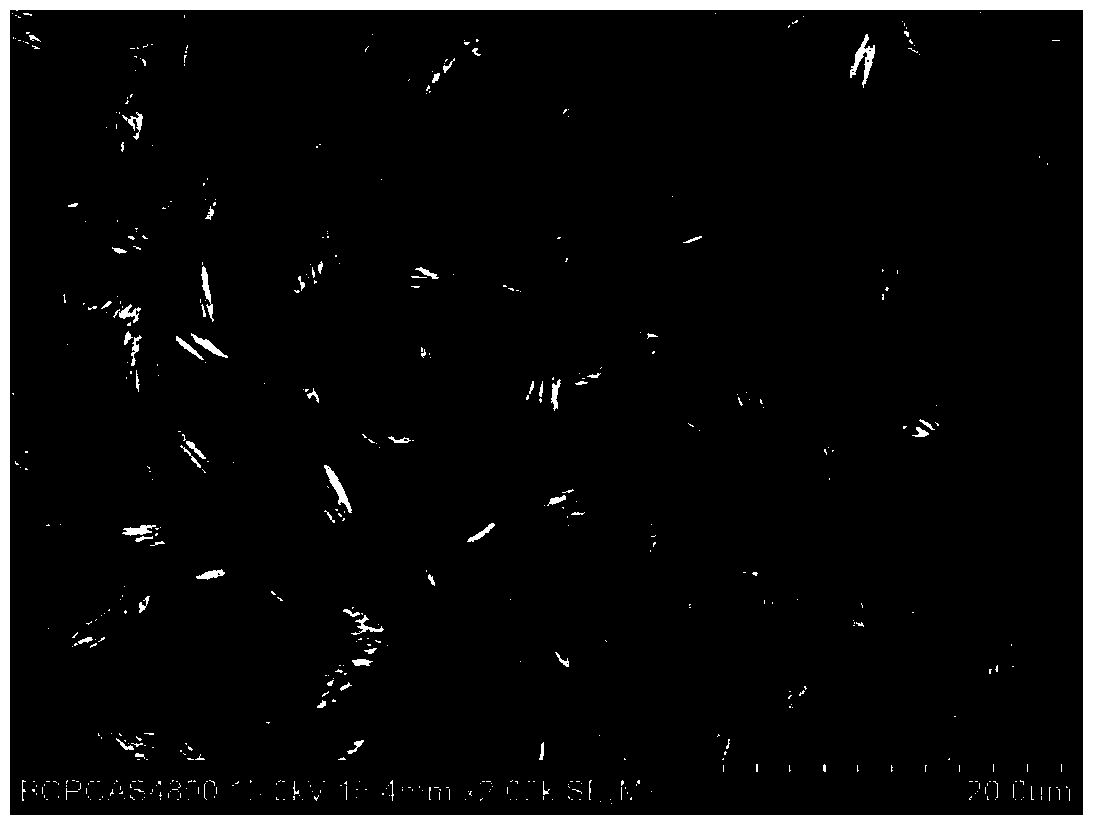

[0029] (1) Put graphite oxide in a crucible, heat the muffle furnace at a rate of 2°C / min to a temperature of 1100°C, put the crucible into the muffle furnace and keep it warm for 1min, then take out the crucible to obtain expanded graphite.

[0030] (2) Take 20 mg of expanded graphite and disperse it in 20 mL of water, add 600 μL of polystyrene (PS) beads water dispersion with a mass concentration of 5 wt % and 2 μm polystyrene (PS) beads, and then sonicate for 4 hours.

[0031] (3) The expanded graphite-polystyrene composite system dispersion liquid is directly sucked onto the foamed nickel at a rate of 4L / s, and after drying at 50°C for 15h, the foamed nickel loaded with expanded graphite-polystyrene is placed in 100mL In a mixed solution containing 100 μL of hydrazine hydrate and 700 μL of concentrated ammonia water with a mass concentration of 26%, react at 95°C for 1 hour, take it out, soak and wash it with deionized water for 5 times, and dry at 60°C for 15 hours to obta...

Embodiment 3

[0035] (1) Put graphite oxide in a crucible, heat the muffle furnace at a rate of 5°C / min to a temperature of 900°C, put the crucible into the muffle furnace and keep it warm for 1min, then take out the crucible to obtain expanded graphite.

[0036] (2) Take 20 mg of expanded graphite and disperse it in 10 mL of water, add 500 μL of polystyrene (PS) beads aqueous dispersion with a mass concentration of 3 wt % and a polystyrene (PS) bead of 2 μm, and then sonicate for 4 h.

[0037] (3) The expanded graphite-polystyrene composite system dispersion liquid is directly sucked onto the foamed nickel at a rate of 3L / s, and after drying at 40°C for 18h, the foamed nickel loaded with expanded graphite-polystyrene is placed in 100mL In a mixed solution containing 100 μL of hydrazine hydrate and 800 μL of concentrated ammonia water with a mass concentration of 25%, react at 95°C for 1 hour, take it out, soak and wash it with deionized water for 5 times, and dry at 60°C for 18 hours to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com