Hollow spheroidal mullite material and preparation method thereof

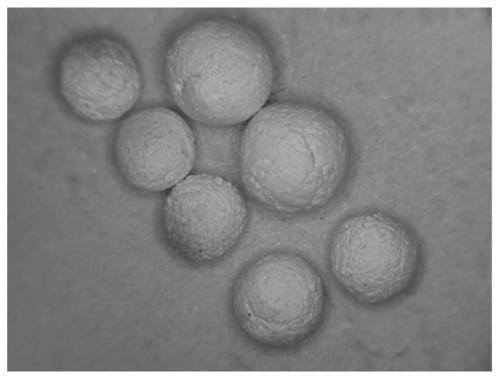

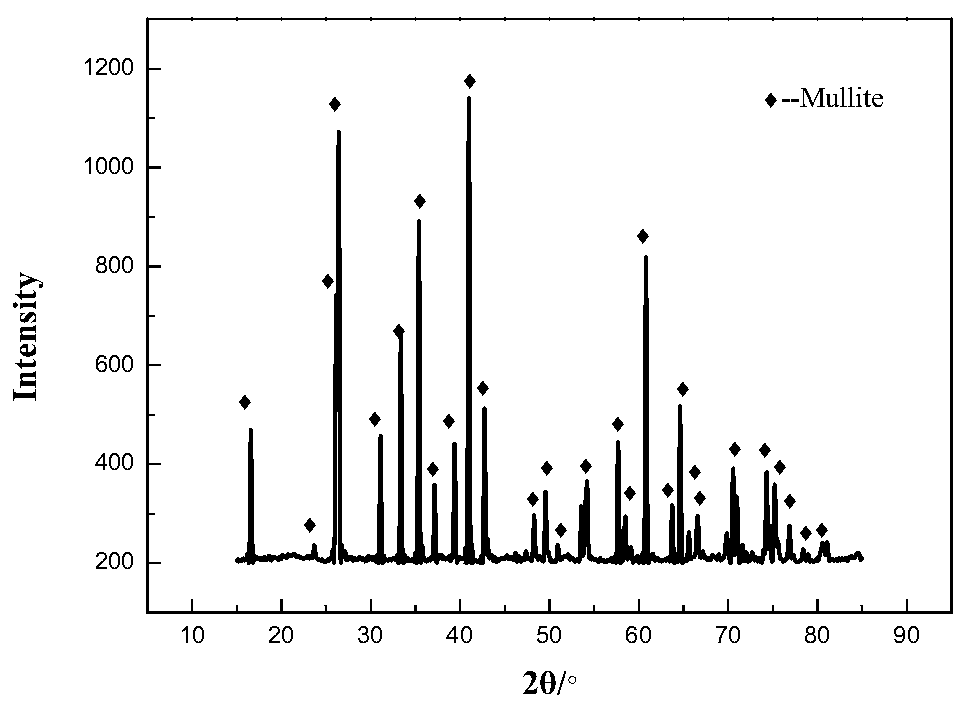

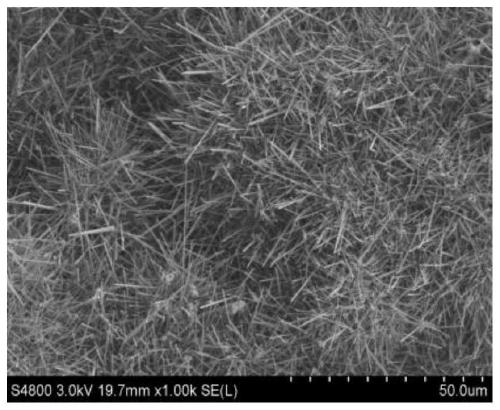

A technology of mullite and mullite whiskers, which is applied in the field of hollow mullite spherical materials and its preparation, can solve the problems of difficulty in obtaining pure whiskers, cost dependence, and difficult control of conditions, and achieve good rolling filling The effect of high capacity, light weight and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of mullite whisker hollow sphere material of the present invention comprises the following steps:

[0031] (1) Add silica sol, water and ethanol to the container in a volume ratio of 1:(4-9):(6-8), stir evenly, adjust the pH value to 2, and form silica sol;

[0032] After mixing alumina powder, aluminum fluoride trihydrate powder, and ethanol at a mass ratio of 1:(0.29-0.67):(3-9), wet milling with zirconia balls for 24-36 hours to make nano-alumina powder and trihydrate The particle diameters of the aluminum fluoride powder are all less than 2000nm to obtain a mixed slurry;

[0033] In the present invention, one or more of calcium aluminate, magnesium oxide, titanium oxide and chromium oxide can be added to promote sintering. Calcium aluminate accounts for 0.1-5% of the solid content of the mixed slurry, magnesium oxide accounts for 0.1-1.2% of the solid content of the mixed slurry, titanium oxide accounts for 0.1-2.0% of the solid content...

Embodiment 1

[0043] (1) Add silica sol, water and ethanol into the container at a volume ratio of 1:4:6, stir evenly, adjust the pH value to 2, and form silica sol A; add alumina powder, aluminum fluoride trihydrate Powder and ethanol were mixed at a mass ratio of 1:0.29:3, and wet milled with zirconia balls for 24 hours. The particle diameters of nano-alumina powder and aluminum fluoride trihydrate powder were both 50nm, and a mixed slurry S was obtained; Calcium aluminate is added to S, and the calcium aluminate accounts for 3% of the solid content of the mixed slurry S to promote sintering.

[0044] (2) Mix the silica sol A and the mixed slurry S in step (1) uniformly at a volume ratio of 1:0.5 to obtain the mullite precursor composite slurry, and then add the coagulant ammonia water to compound the mullite precursor The pH value of the slurry is 7, and it gels in the container to obtain a composite block;

[0045] (3) The composite block was naturally dried at room temperature for 20 ...

Embodiment 2

[0050] (1) Stir the silica sol, water and ethanol in a container at a volume ratio of 1:5:6, adjust the pH value to 2 to form silica sol A; mix alumina powder, aluminum fluoride trihydrate, ethanol After mixing according to the mass ratio of 1:0.35:4, wet milling with zirconia balls for 28 hours, the particle diameters of nano-alumina powder and aluminum fluoride trihydrate powder are both 100nm, and mixed slurry S is obtained; Magnesium oxide, and magnesium oxide accounts for 1% of the solid content of the mixed slurry S, to promote sintering.

[0051] (2) Mix the silica sol A and the mixed slurry S in step (1) uniformly at a volume ratio of 1:0.8 to obtain the mullite precursor composite slurry, and then add the coagulant ammonia water to compound the mullite precursor The pH value of the slurry is 7, and the composite block is obtained by gelling in the container;

[0052] (3) The composite block was naturally dried at room temperature for 40 h, and then heated at 70° C. f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com