Preparation method of mesoporous carbon sphere material

A mesoporous carbon and carbon source technology, applied in the field of materials, can solve the problems of time-consuming and cumbersome process, and achieve the effects of simple and easy preparation method, avoiding pollution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] According to the literature (Chinese patent, publication number CN101293936A), polystyrene spheres with a diameter of 1000 nm were prepared and used as templates.

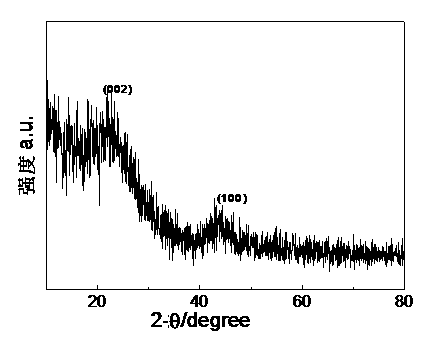

[0033] 0.12g polystyrene spheres were added to a 250ml round bottom flask followed by 90ml ethanol. After ultrasonication for 30 min, 10 g of phenolic resin was added. And continue to react under ultrasound for 6 hours (190w, 40kHZ), centrifuge the above-mentioned solution, take the precipitate, wash it several times, and dry it in a 50°C oven overnight to obtain the polystyrene sphere / carbon source core-shell structure composite. The resulting polystyrene sphere / carbon source composite was loaded into a porcelain boat and heated in a resistance furnace at 2 °C min -1 Heated to 600°C and kept at this temperature for 5h. The whole synthesis process is in N 2 Finished in atmosphere. N 2 The mesoporous carbon sphere material can be obtained by lowering the temperature in the atmosphere with the furnace. T...

Embodiment 2

[0035] Polystyrene spheres with a diameter of 350 nm were prepared according to the literature (Chinese patent, publication number CN101293936A), and used as templates.

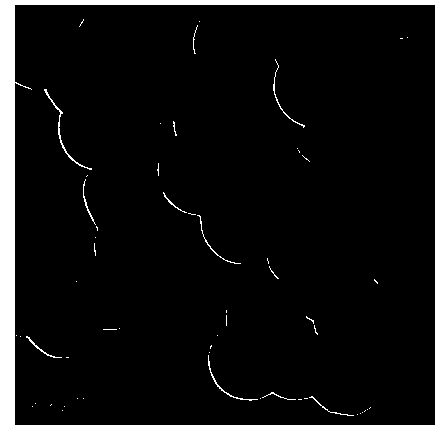

[0036] 0.12 g of polystyrene spheres were added to a 250 ml round bottom flask, followed by 90 ml of ethanol. After ultrasonication for 30 min, 10 g of phenolic resin was added. And continue to react under ultrasound for 6 hours (190w, 40kHZ), centrifuge the above-mentioned solution, wash the precipitate several times and dry it in a 50°C oven overnight to obtain the polystyrene sphere / carbon source core-shell structure composite. Put the obtained polystyrene sphere / carbon source composite into a porcelain boat, and heat it in a resistance furnace at 2°C min -1 Heated to 600°C and kept at this temperature for 5h. The whole synthesis process is in N 2 Finished in atmosphere. N 2 The mesoporous carbon sphere material can be obtained by lowering the temperature in the atmosphere with the furnace. The SEM a...

Embodiment 3

[0038] According to the literature (Chinese patent, publication number CN101293936A), polystyrene spheres with a diameter of 1000 nm were prepared and used as templates.

[0039] 0.12 g of polystyrene pellets were added to a 250 ml round bottom flask followed by 90 ml of ethanol. After ultrasonication for 30 min, 10 g of furfuryl alcohol was added. And continue to react under ultrasound for 6 hours (190w, 40kHZ), centrifuge and wash the above-mentioned solution several times, and then dry it in an oven at 50°C overnight to obtain the polystyrene sphere / carbon source core-shell structure composite. Put the obtained polystyrene sphere / carbon source composite into a porcelain boat, and heat it in a resistance furnace at 2°C min -1 Heat to 600°C for 5h. The whole synthesis process is in N 2 Finished in atmosphere. N 2The atmosphere cools down with the furnace. The mesoporous carbon sphere material can be obtained. Measured by SEM and TEM photos, the diameter of the obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com