Three-dimensional ordered macroporous molybdenum disulfide/carbon composite flexible electrode material and preparation method and application thereof

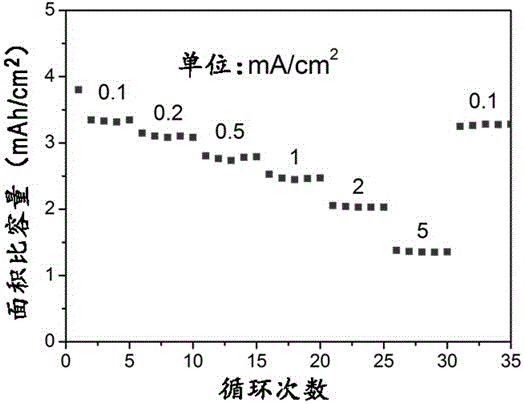

A carbon composite material, molybdenum disulfide technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as dissolution and re-stacking, and achieve excellent electrochemical performance, high rate performance and stability, and good cycle. Effects of performance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

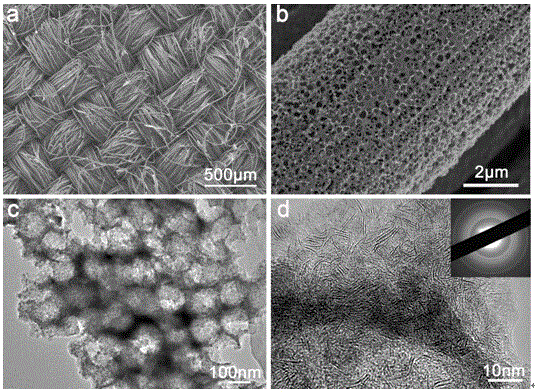

[0024] Dissolve 5ml of styrene, 0.5ml of acrylic acid, and 120mg of sodium bicarbonate in 100ml of water, heat up to 70°C, add 0.1g of ammonium persulfate, stir for 7 hours under an inert atmosphere, and dialyze for 3 days to obtain carboxylated styrene nanospheres.

[0025] 20 mg of sucrose, 40 mg of sodium molybdate, and 0.2 g of carboxylated polystyrene nanospheres were dissolved in 5 ml of deionized water, and stirred for 2 hours to obtain a precursor solution.

[0026] The carbon fiber cloth was immersed in the polyaniline / N,N dimethylpyrrolidone solution with a mass fraction of 0.0025wt% for 1 h, and after drying, it was immersed in the precursor solution for 1 h. Take it out and dry it in a vacuum oven. get the product.

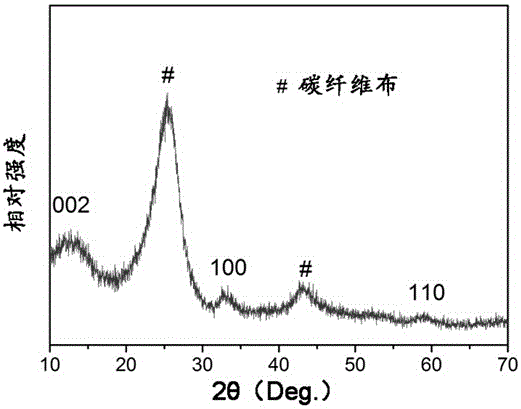

[0027] The product obtained after drying was calcined at high temperature in sulfur vapor, and reacted at 600°C for 2 hours to realize the preparation of three-dimensional ordered macroporous molybdenum disulfide / carbon composite flexible electrode. ...

Embodiment 2

[0030] Dissolve 3ml of styrene, 0.1ml of acrylic acid, and 24mg of sodium bicarbonate in 100m of water, raise the temperature to 60°C, add 0.3g of ammonium persulfate, stir for 5h under the protection of an inert atmosphere, and dialyze for 3 days to obtain carboxylated styrene nanospheres.

[0031] 10 mg of glucose, 80 mg of ammonium molybdate, and 0.1 g of carboxylated polystyrene nanospheres were dissolved in 5 ml of deionized water, and stirred for 3 hours to obtain a precursor solution.

[0032] The carbon fiber cloth was immersed in the dopamine / tromethamine solution with a mass fraction of 0.005wt% for 3 hours, and after drying, it was immersed in the precursor solution for 3 hours. Take it out and dry it in a vacuum oven. get the product.

[0033] The product obtained after drying was calcined at high temperature in thiourea vapor, and reacted at 850° C. for 6 hours to realize the preparation of three-dimensional ordered macroporous molybdenum disulfide / carbon composi...

Embodiment 3

[0035] Dissolve 1ml of styrene, 0.3ml of acrylic acid, and 40mg of sodium bicarbonate in 100m of water, raise the temperature to 70°C, add 0.5g of ammonium persulfate, stir for 10 hours under an inert atmosphere, and dialyze for 3 days to obtain carboxylated styrene nanospheres.

[0036] 40 mg of sucrose, 160 mg of ammonium thiomolybdate, and 0.5 g of carboxylated polystyrene nanospheres were dissolved in 5 ml of deionized water, and stirred for 6 hours to obtain a precursor solution.

[0037] The carbon fiber cloth was immersed in the polyaniline / N,N dimethylpyrrolidone solution with a mass fraction of 0.01wt% for 6 hours, and after drying, it was immersed in the precursor solution for 6 hours. Take it out and dry it in a vacuum oven. get the product.

[0038] The product obtained after drying is calcined at high temperature in sulfur vapor, and reacted at 1000°C for 10 hours to realize the preparation of three-dimensional ordered macroporous molybdenum disulfide / carbon comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com