Anti-counterfeit label based on patterned metal nanocomposite and production method of anti-counterfeit label

A nano-composite material and patterned metal technology, applied in the field of anti-counterfeiting signs, can solve the problems of easy forgery of technology, achieve high anti-counterfeiting level, easy to use, and enhance the effect of Raman scattering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

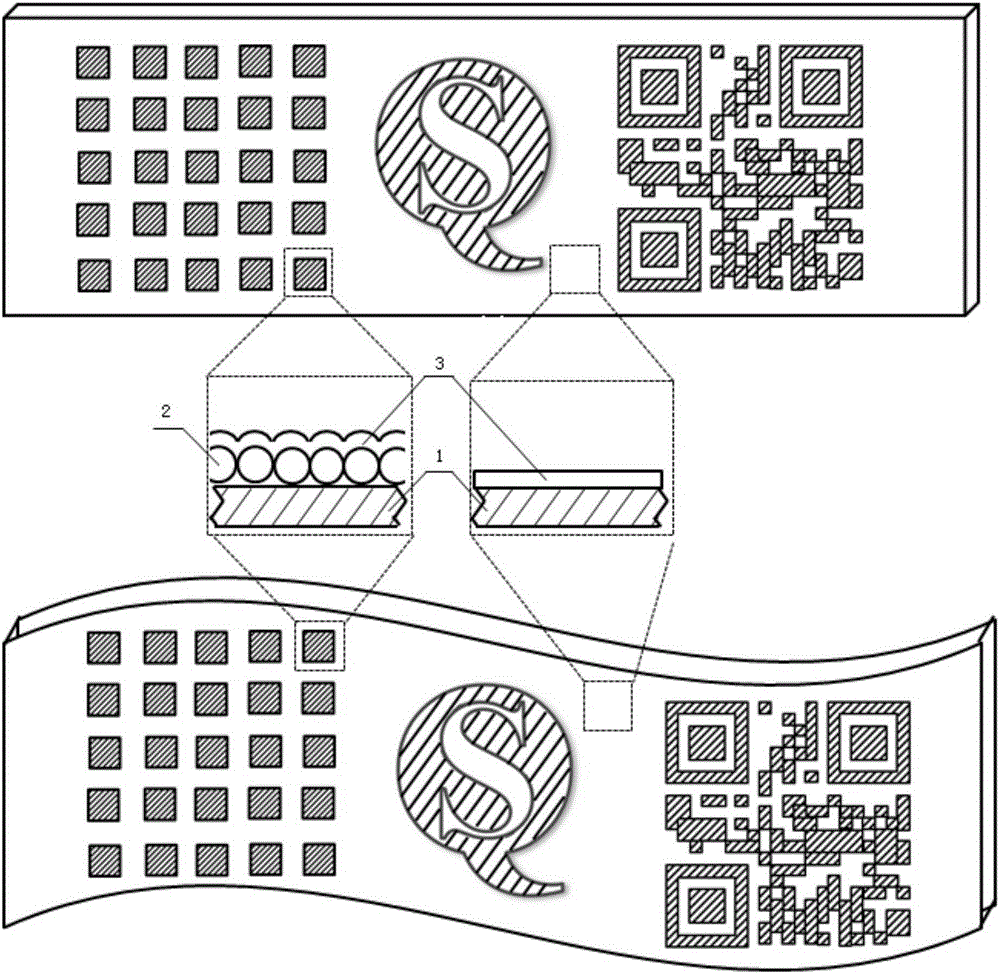

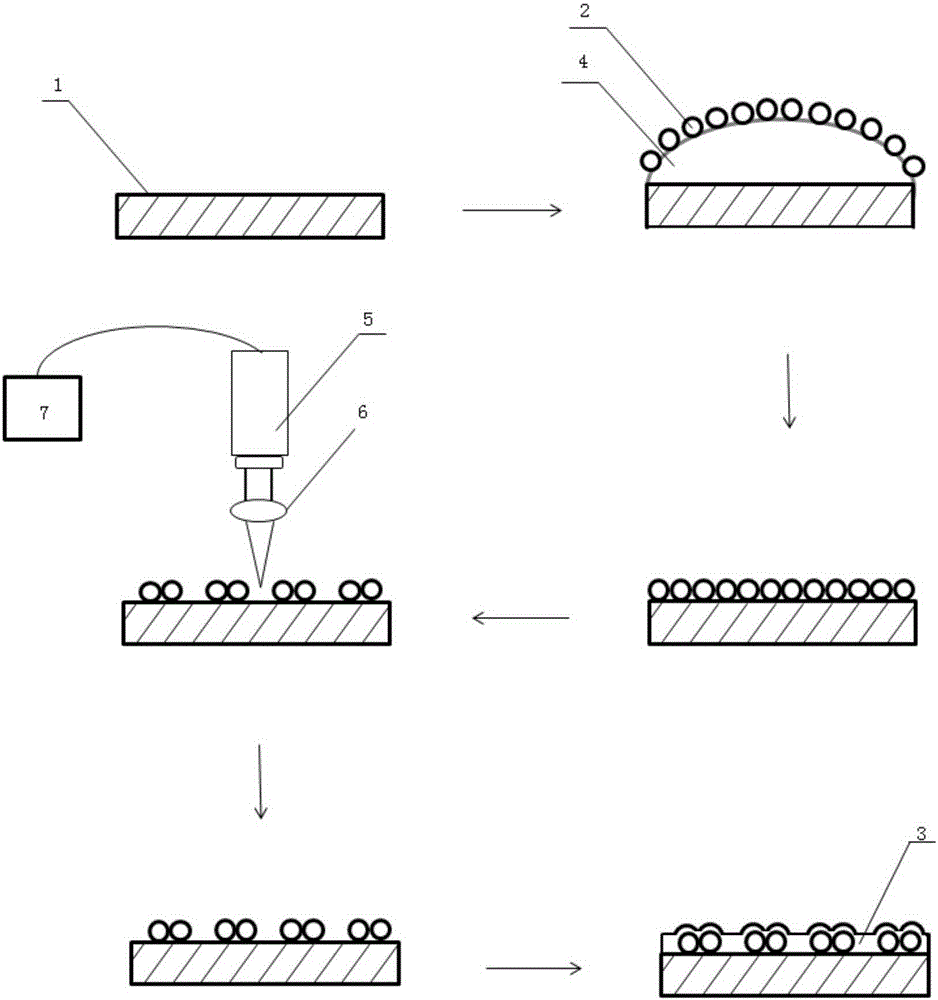

[0054] Embodiment one (as figure 2 shown):

[0055] (1) Substrate cleaning: Clean the glass or silicon wafer with Piranha washing solution (concentrated sulfuric acid / hydrogen peroxide, 4:1, 60°C, 20min) and hydrophilic treatment (hydrogen peroxide / water / concentrated ammonia water, 1:5:1 ,60min) and then ready for use;

[0056] (2) Preparation of polystyrene ball array: place the cleaned substrate surface on a horizontal platform, and add a certain amount of water to form a water film covering the entire substrate surface. On the water film air / liquid interface, use a syringe pump and a microsyringe to slowly inject a monodisperse polystyrene sphere suspension (containing 10 to 20% ethanol) with a diameter of 200 to 1000 nm at a speed of 10 to 30 μL / min. After the water film evaporates, an array of closely arranged polystyrene microspheres can be formed (see Figure 4 );

[0057] (3) Preparation of patterned polystyrene microsphere templates Use laser engraving to evapora...

Embodiment 2

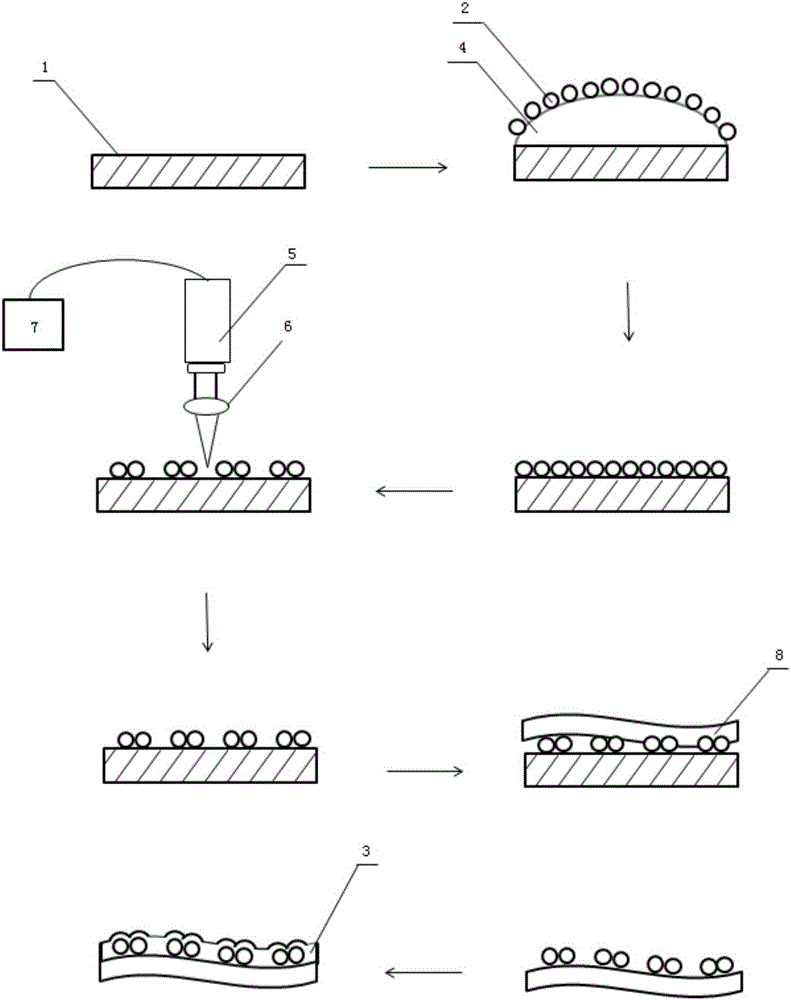

[0063] Such as image 3 , the above-mentioned polystyrene template can also be transferred to the adhesive flexible substrate 8 by using an adhesive material to form a flexible patterned metal nanocomposite anti-counterfeiting material. The specific operations are as follows: steps (1) to (3) are the same as above, Adhesive acrylic tape on the prepared polystyrene ball template, peel off after light pressure, the polystyrene ball template can be transferred to these flexible materials. After coating, a flexible patterned metal nanocomposite anti-counterfeiting material can be prepared.

Embodiment example 3

[0065] In the above-mentioned embodiments, the 200 thick silver film is taken as an example to make this product, and other effect films that can generate surface plasmon resonance can also be used to make this product. Such as Figure 11 As shown in a, the thin film can be Au, Ag, Pt, Cu, Al, Cr pure metal, or a mixed metal layer of the above metals ( Figure 11 b), or non-metallic (SiO 2 、TiO 2 ) and metal composite coating ( Figure 11 c), or a multi-layer composite coating of non-metal and metal, with a total thickness between 20 and 1000 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com