Method for preparing shell fluorescent microsphere

A technology of fluorescent microspheres and shell layers, which is applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of difficult adjustment of size, uneven diameter, etc., and achieves good solubility, simplified preparation process, The effect of good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] Specific embodiment one: the preparation method of a kind of shell fluorescent microsphere of the present embodiment is carried out according to the following steps:

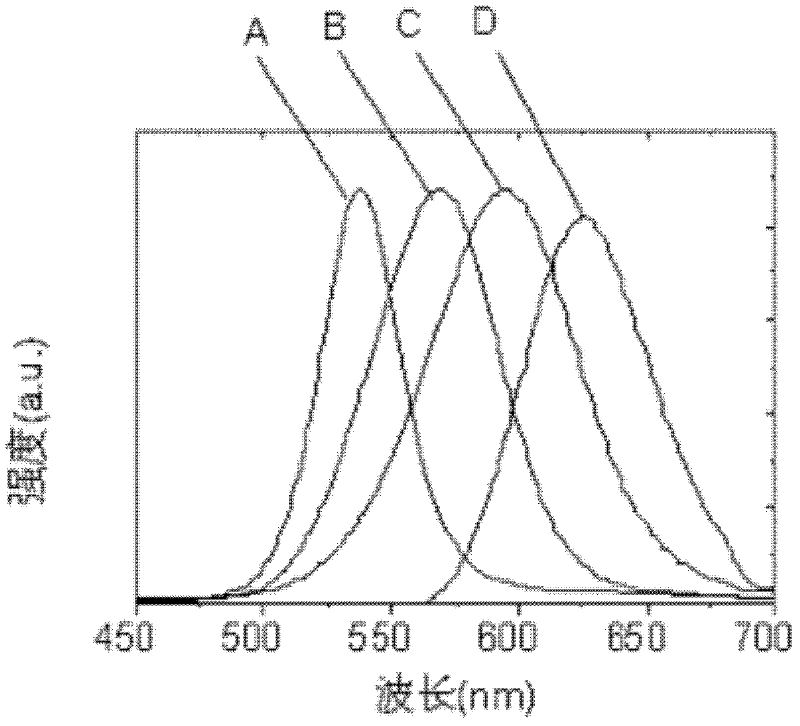

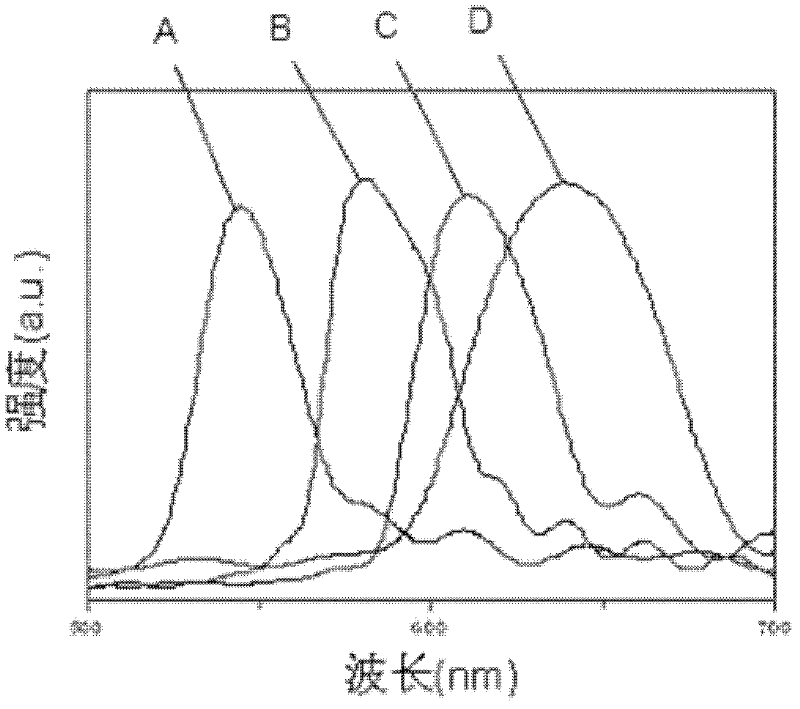

[0030] 1. Preparation of CdTe quantum dots by aqueous phase synthesis method;

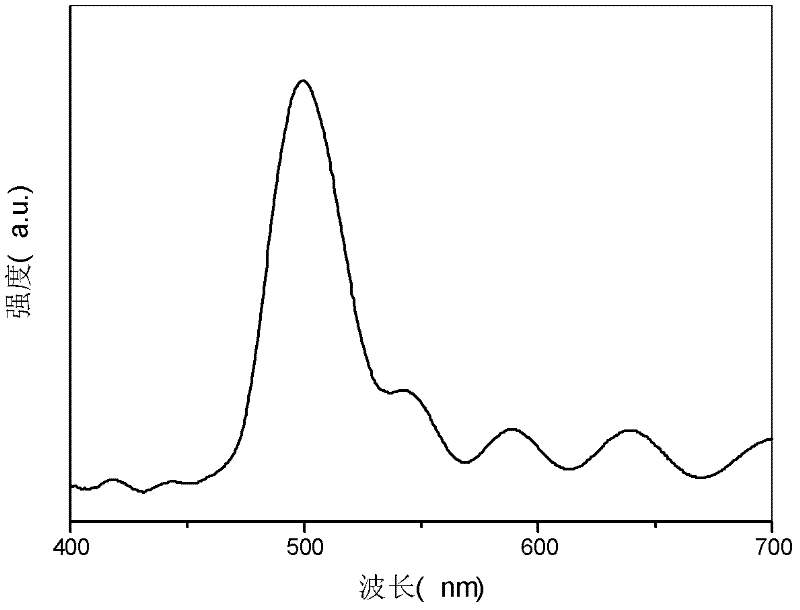

[0031] Two, utilize soap-free emulsion method to prepare polystyrene (PS) ball;

[0032] 3. Weigh 155 to 165 parts of absolute ethanol, 2 to 6 parts of polystyrene balls made in step 2, 2 to 4 parts of ammonia water and 30 to 40 parts of polystyrene balls made in step 1 according to the ratio of parts by volume. Add CdTe quantum dots into a three-necked flask, and stir for 4-6 minutes to obtain a mixture C;

[0033] 4. Weigh 6-7 parts of ethyl orthosilicate and 10-15 parts of absolute ethanol according to the ratio of parts by volume, and mix them evenly at room temperature to obtain the mixed solution E; ~0.8 parts of ammonia water, 10~14 parts of absolute ethanol and 7~7.5 parts of water are mixed uniformly at room tempera...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment is different from Embodiment 1 in that: the diameter of the CdTe quantum dots described in Step 1 is 2-5 nm. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment differs from Embodiments 1 to 2 in that: the diameter of the polystyrene sphere described in Step 2 is 180-220 nm. Other steps and parameters are the same as those in Embodiments 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com