Preparation method for alumina hollow spheres

A technology for alumina hollow spheres and alumina powder, which is applied in the field of preparation of alumina hollow spheres, can solve the problems of complex process, poor practicability, easy collapse and broken, etc., and achieve simple preparation equipment and process, good product performance, The effect of sintering temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

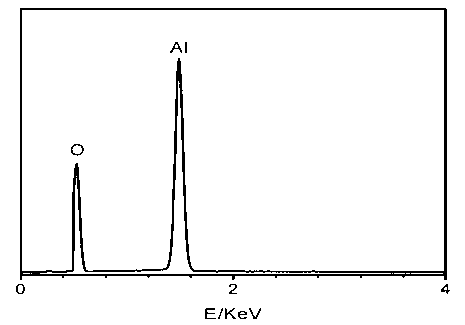

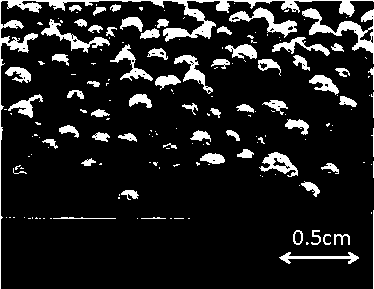

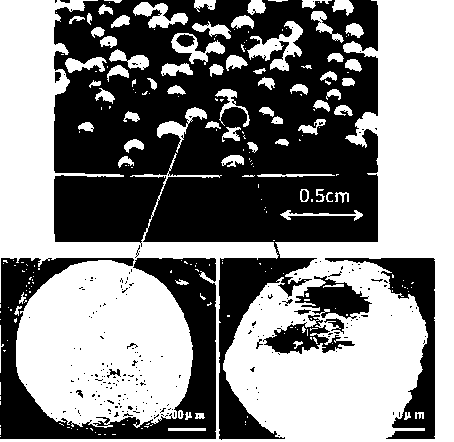

[0024] A preparation method of aluminum oxide hollow spheres, comprising the following steps:

[0025] A, batching: by chitosan: water is the mass ratio of 0.5:100, acetic acid: water is the mass ratio of 0.5:100, get chitosan, water and acetic acid and mix and be mixed with chitosan-acetic acid-water solution; Styrene balls: chitosan-acetic acid-water solution is a mass ratio of 8:1, and polystyrene balls: α-alumina powder is a mass ratio of 1:5, and polystyrene (which can be cheap polystyrene) Styrene) balls, chitosan-acetic acid-water solution and α-alumina powder;

[0026] b. Preparation of core-shell spheres: mix and stir polystyrene spheres with chitosan-acetic acid-water solution, so that the surface of polystyrene spheres is evenly coated with a layer of chitosan-acetic acid-water solution; Put the polystyrene balls of sugar-acetic acid-water solution and α-alumina powder into a ball mill (it can be a ball mill, a ball mill tank, etc.), and rotate and coat at a speed ...

Embodiment 2

[0030] A preparation method of aluminum oxide hollow spheres, comprising the following steps:

[0031] a. Ingredients: According to the mass ratio of chitosan: water 0.5:100~5:100, acetic acid: water 0.5:100~5:100 mass ratio, chitosan, water and acetic acid are mixed to prepare chitosan Sugar-acetic acid-water solution; according to the mass ratio of polystyrene ball: chitosan-acetic acid-water solution is 5:1~10:1, according to polystyrene ball: α-alumina powder is 1:5~1: The mass ratio of 15, get polystyrene ball, chitosan-acetic acid-water solution and α-alumina powder;

[0032] b. Preparation of core-shell spheres: mix and stir polystyrene spheres with chitosan-acetic acid-water solution, so that the surface of polystyrene spheres is evenly coated with a layer of chitosan-acetic acid-water solution; Put the polystyrene balls of sugar-acetic acid-water solution and α-alumina powder into a ball mill (it can be a ball mill, a ball mill tank, etc.), and rotate and coat at a s...

Embodiment 3

[0035] A preparation method of aluminum oxide hollow spheres, comprising the following steps:

[0036] A, batching: by chitosan: water is the mass ratio of 5:100, acetic acid: water is the mass ratio of 5:100, get chitosan, water and acetic acid and mix and be mixed with chitosan-acetic acid-water solution; Styrene ball: chitosan-acetic acid-water solution is a mass ratio of 10:1, according to the mass ratio of polystyrene ball: α-alumina powder is 1:15, take polystyrene ball, chitosan-acetic acid - aqueous solution and α-alumina powder;

[0037]b. Preparation of core-shell spheres: mix and stir polystyrene spheres with chitosan-acetic acid-water solution, so that the surface of polystyrene spheres is evenly coated with a layer of chitosan-acetic acid-water solution; Put the polystyrene balls of sugar-acetic acid-water solution and α-alumina powder into a ball milling device (which can be a ball mill, a ball milling tank, etc.), and rotate at a speed of 30r / s (rev / sec) for 2h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com