Process for manufacturing bionic gecko structure material

A structural material and manufacturing process technology, applied in the field of manufacturing process of imitation gecko foot structural materials, can solve the problems of complex process, poor hydrophobicity, high cost of hierarchical micro-nano structure, and achieve simple equipment requirements, simple operation and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

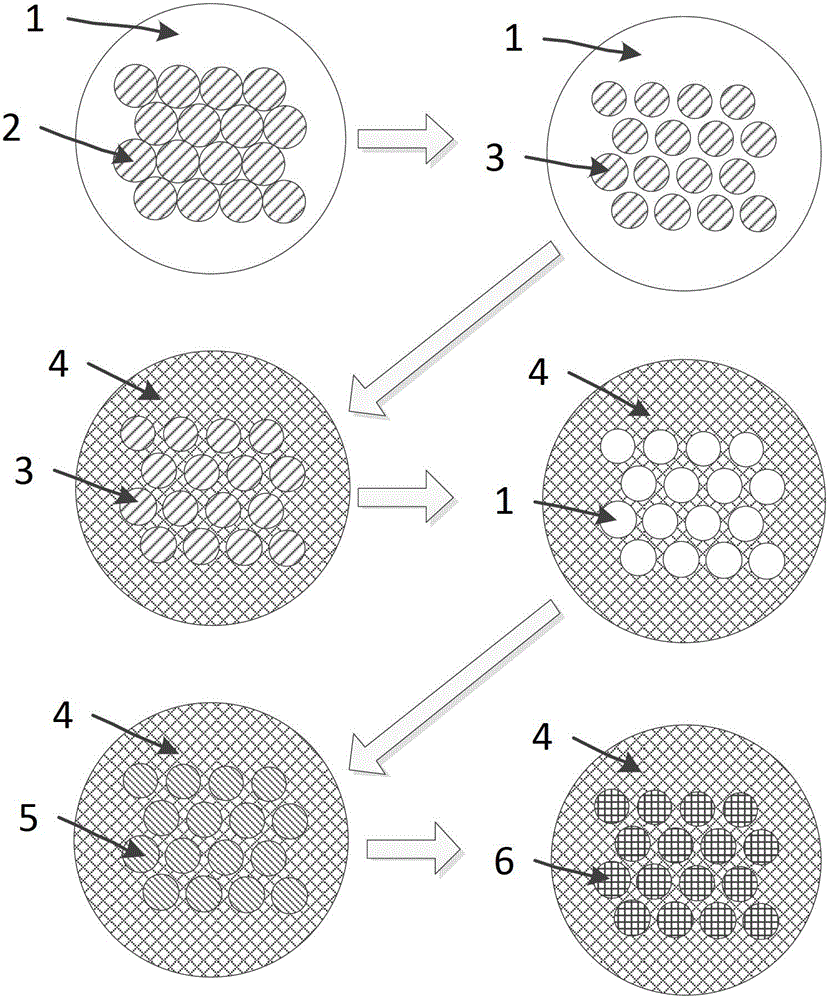

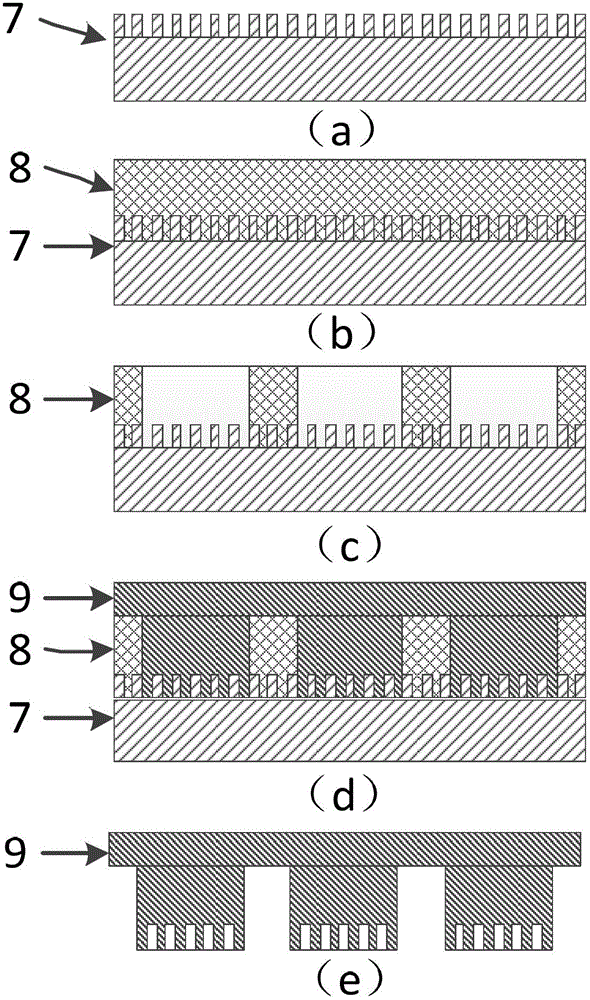

[0040] 1. Self-assembled polystyrene pellets

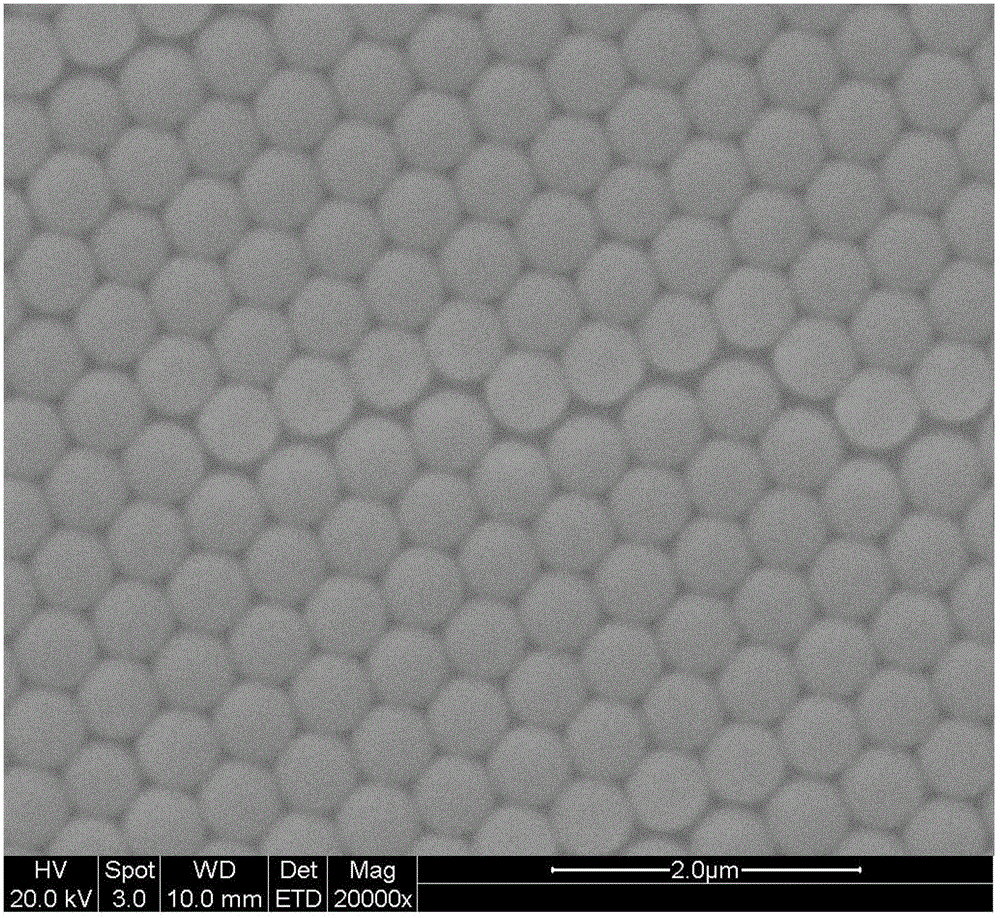

[0041] Self-assemble a single layer of closely arranged polystyrene spheres on a clean silicon wafer, and the diameter of the polystyrene spheres is 500nm.

[0042] 2. Plasma etching polystyrene beads

[0043] Using plasma etching equipment, with O 2 The polystyrene balls on the surface of the silicon wafer are etched to reduce their diameters, and the tightly arranged polystyrene balls become separate and orderly arranged polystyrene balls.

[0044] 3. Plating protective layer

[0045] The silicon wafer treated in step 2 is coated with a layer of chromium film as a protective layer.

[0046] 4. Remove polystyrene pellets

[0047] Put the silicon wafer coated with protective layer into toluene to completely remove the polystyrene pellets on the surface of the silicon wafer. Then use deionized water to wash, remove residual organic solvent, and dry.

[0048] 5. Plating catalyst layer

[0049] A layer of silver film is coated...

example 2

[0057] The operation steps are the same as Example 1, and the parameters are as follows:

[0058]

[0059] In the example of the present invention, various organic solvents capable of dissolving polystyrene can be used in the fourth step to remove polystyrene pellets, such as toluene and dichlorotoluene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com