Gold-sliver alloy two-dimensional ordered nano film prepared by in-situ interface transformation and method for preparing gold-sliver alloy two-dimensional ordered nano film

A gold-silver alloy and nano-film technology, which is applied in the field of in-situ interface transformation to prepare a two-dimensional ordered nano-film of gold-silver alloy, can solve the problems of unfavorable recycling and reuse, low utilization rate of effective components, large dependence, etc. The effect of product amplification, simple synthesis method and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing a gold-silver alloy two-dimensional ordered nano-film by an in-situ interface conversion method, the method comprising the following steps:

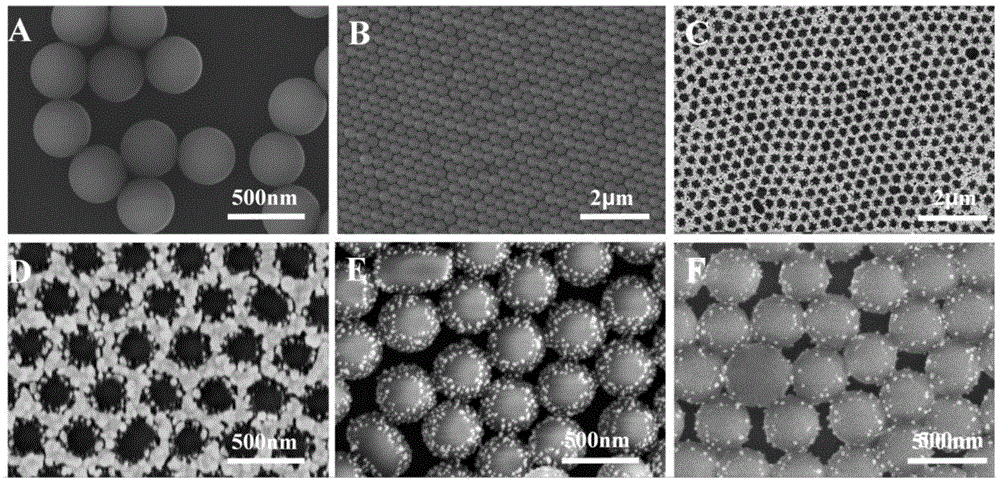

[0022] Take the desiccator as the reaction vessel, put a Petri dish filled with 15 mmol / L silver nitrate solution on its upper layer, and add 30 microliters of polystyrene balls ( figure 1 A) ethanol-water (V ethanol: V water = 1:1) mixed solution, after a while, the single-layer polystyrene sphere self-assembled film ( figure 1 B) The assembly is completed; place about 3.5 grams of finely ground dimethylaminoborane powder and 5 milliliters of nitric acid aqueous solution with a concentration of 5 mol / liter in the lower layer. After about 4 hours of reaction, the silver-polystyrene ball two-dimensional ordered nanonet film ( figure 1 EF); and after 25 hours of reaction, a dense silver-polystyrene sphere two-dimensional ordered nanonet film ( figure 1 CD), in the film, silver nanoparticles are tightly packe...

Embodiment 2

[0024] A method for preparing a gold-silver alloy two-dimensional ordered nano-film by an in-situ interface conversion method, the method comprising the following steps:

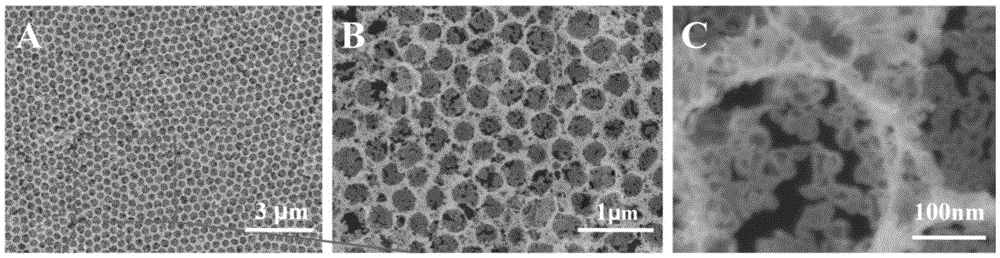

[0025] (1) Get the desiccator as the reaction vessel, and its upper layer is placed flatly to fill the petri dish of 20 mmol / liter silver nitrate solution, and the ethanol-water (V ethanol: V water= 1:1) mixed solution, after a while, the single-layer polystyrene spherical self-assembled membrane was assembled; about 3.5 grams of finely ground dimethylaminoborane powder and 5 milliliters of nitric acid aqueous solution with a concentration of 5 mol / liter were placed in the lower layer . After about 25 hours of reaction, a dense silver-polystyrene ball two-dimensional ordered nano-network film can be obtained.

[0026] (2) Pipette a mixed reaction solution consisting of 10 ml of chloroauric acid (15 mmol / L) and 15 ml of disodium hydrogen phosphate (200 mmol / L) into a clean Petri dish. Take a smooth and clea...

Embodiment 3

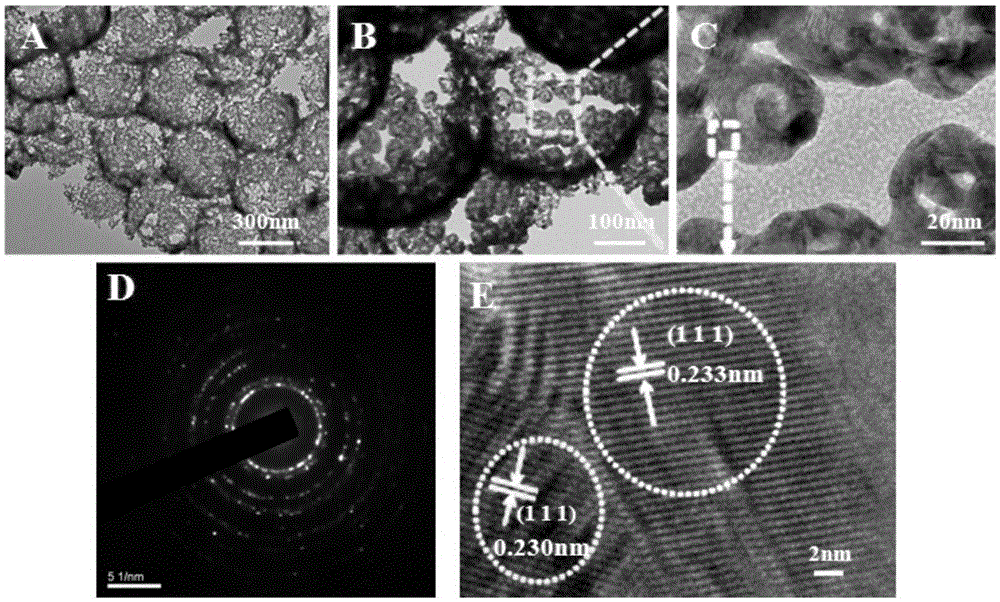

[0029] A method for preparing a gold-silver alloy two-dimensional ordered nano-film by an in-situ interface conversion method, the method comprising the following steps:

[0030](1) Get the desiccator as the reaction vessel, and its upper layer is placed flatly to fill the petri dish of 15 mmol / liter silver nitrate solution, and the ethanol-water (V ethanol: V water= 1:1) mixed solution, after a while, the single-layer polystyrene spherical self-assembled membrane was assembled; about 3.5 grams of finely ground dimethylaminoborane powder and 5 milliliters of nitric acid aqueous solution with a concentration of 5 mol / liter were placed in the lower layer . After about 25 hours of reaction, a dense silver-polystyrene ball two-dimensional ordered nano-network film can be obtained.

[0031] (2) Pipette a mixed reaction solution consisting of 10 ml of chloroauric acid (15 mmol / L) and 15 ml of disodium hydrogen phosphate (100 mmol / L) into a clean petri dish. Take a smooth and clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com