High temperature resistant lightweight heat insulation castables

A technology of high temperature resistance and castable, applied in the field of refractory materials, can solve the problems of poor construction performance, poor thermal shock stability, high temperature resistance and light insulation castables are not mentioned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

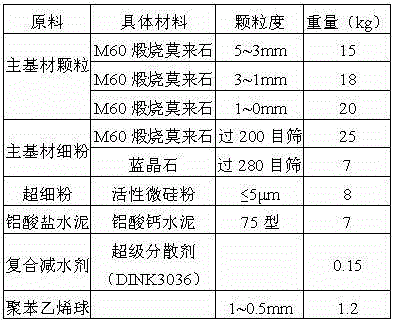

[0019] Manufacture a furnace cover working lining for an aluminum melting furnace (ρ=1.3g / cm 3 ), the long-term working temperature of the furnace cover fluctuates between 1000~1300 °C, the raw materials used and the weight of each raw material are shown in Table 1, and the raw materials in the table can be mixed together.

[0020] Table 1

[0021]

Embodiment 2

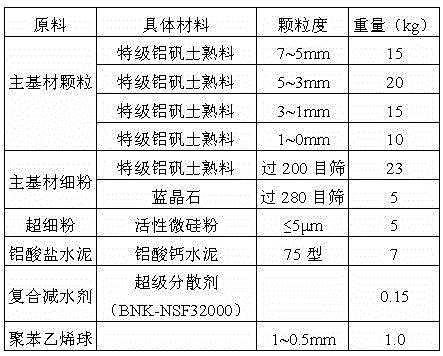

[0023] Manufacture a high-aluminum lightweight heat-insulating castable (ρ=1.5g / cm 3 ), the long-term working temperature of the furnace cover is stable at 1450°C, the raw materials used and the weight of each raw material are shown in Table 2, and the raw materials in the table can be mixed together.

[0024] Table 2

[0025]

Embodiment 3

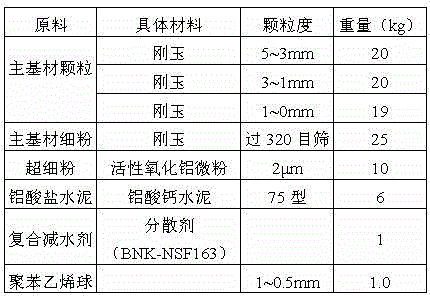

[0027] Manufacture a corundum lightweight heat-insulating castable (ρ=1.2g / cm2) for the ethylene cracking furnace of a petrochemical company 3 ), its long-term working temperature is stable at 1350°C, requiring the material SiO 2 Content≯0.2%, the raw materials used and the weight of each raw material are shown in Table 3, and the raw materials in the table can be mixed together.

[0028] table 3

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com