Polystyrene/calcium alginate composite gel microsphere in nuclear shell structure and preparation method thereof

A technology of calcium alginate gel and polystyrene microspheres, which can be used in the preparation of microspheres, microcapsule preparations, medical preparations of non-active ingredients, etc., and can solve the problems of easy agglomeration, large size, and blockage of products. Achieve the effect of low production equipment requirements, controllable shell thickness, and mild synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

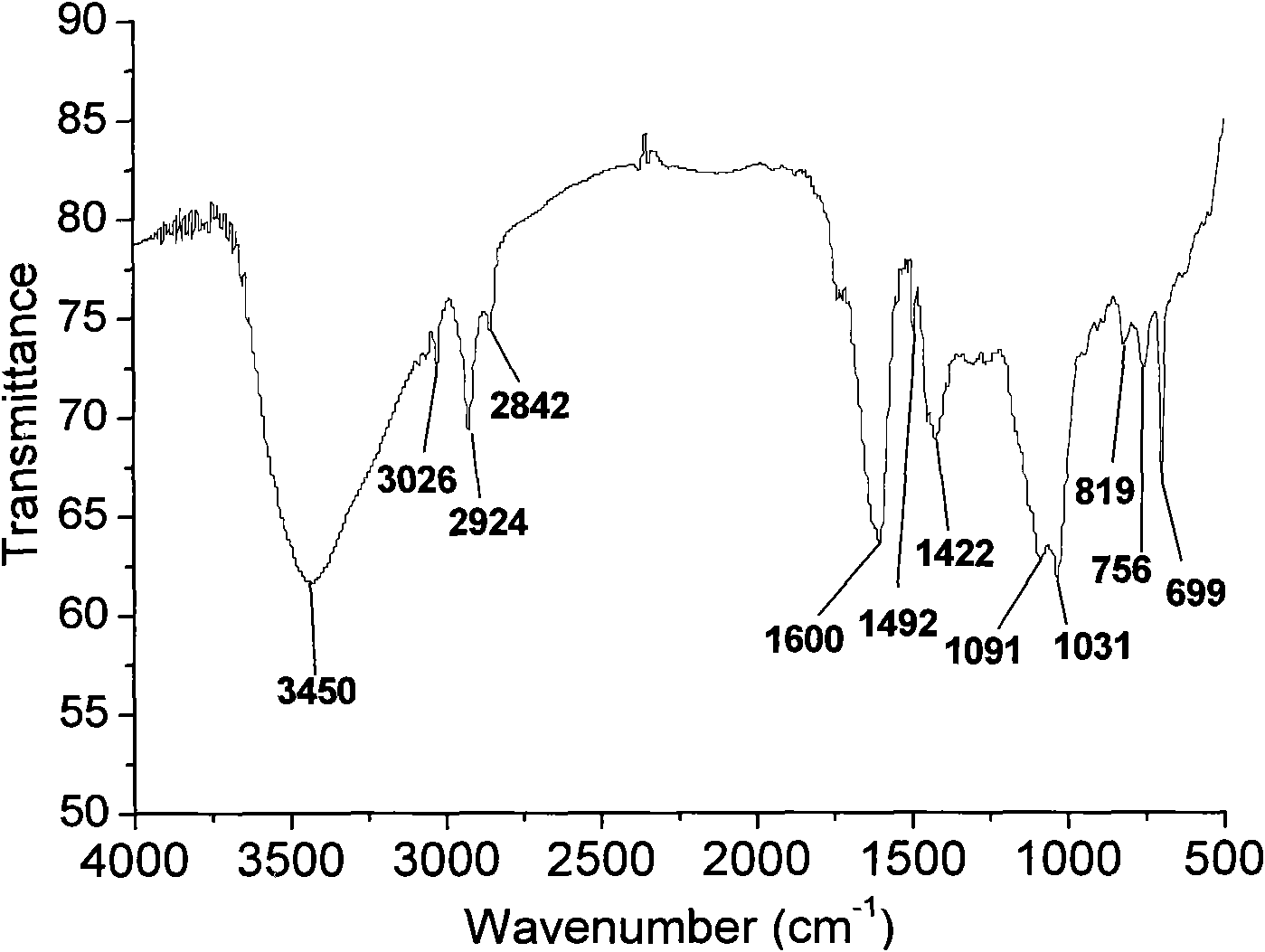

[0023] Example 1: Mix 1g of polystyrene microspheres with 20mL at a concentration of 2.8×10 -2 Mix g / L Tween-60 aqueous solution, after ultrasonic emulsification for 1h, add 2mL sodium alginate solution with a concentration of 30g / L under the action of magnetic stirring, stir 40ml n-heptane solution with 0.036g Span-80 after stirring for 3h Pour into the above system, stir at room temperature for 2 hours, slowly add 2 mL of calcium chloride solution with a mass fraction of 10%, and react for 1 hour, then use a Buchner funnel to carry out suction filtration, and repeatedly rinse with distilled water until no calcium ions remain on the surface. Dry, disperse the obtained product into water, centrifuge at a speed of 3000r / min for 20min, pour out the supernatant, and take out the precipitate as the final product. From SEM photographs (see figure 1 ) It can be seen that the product has a core-shell structure, the white spherical matrix in the figure is polystyrene with a particle ...

Embodiment 2

[0025] Example 2: The steps are the same as in Example 1, but the concentration of the sodium alginate solution is changed to 50g / L, and finally polystyrene / calcium alginate composite gel microspheres with a core-shell structure can be obtained, and the shell thickness can reach 600nm.

Embodiment 3

[0026] Example 3: The steps are the same as in Example 1, but the concentration of the sodium alginate solution is changed to 10g / L, and finally polystyrene / calcium alginate composite gel microspheres with a core-shell structure can be obtained, and the shell thickness can reach 50nm.

[0027] Example 3: The steps are the same as in Example 1, but the amount of Span-80 is changed to 0.032g, so that the concentration is 0.8 times the critical micelle concentration, and finally a polystyrene / calcium alginate composite gel with a core-shell structure can be obtained The shell thickness of the microsphere is 300nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com