Capacitor and method for manufacturing capacitor

A manufacturing method and capacitor technology, applied in the field of capacitors, can solve problems such as high raw material prices and restrictions on raw material production areas, and achieve the effect of preventing the diffusion of oxygen and preventing the deterioration of characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention can be realized in various modifications and various forms, and as an example thereof, a specific embodiment shown in the drawings will be described in detail below. The illustrations and embodiments do not limit the present invention to the specific forms disclosed here, and all modifications, equivalents, and substitutions within the scope of the appended claims are included in the present invention. .

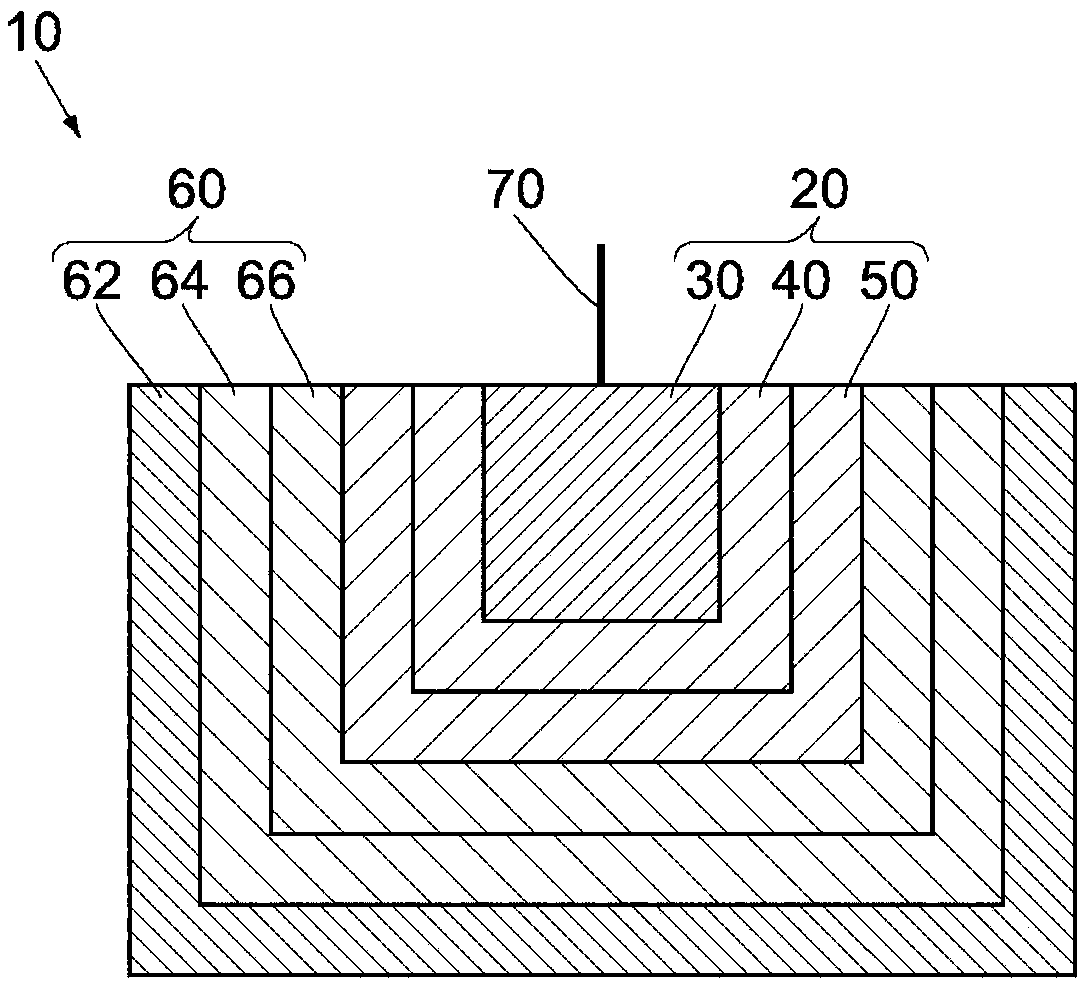

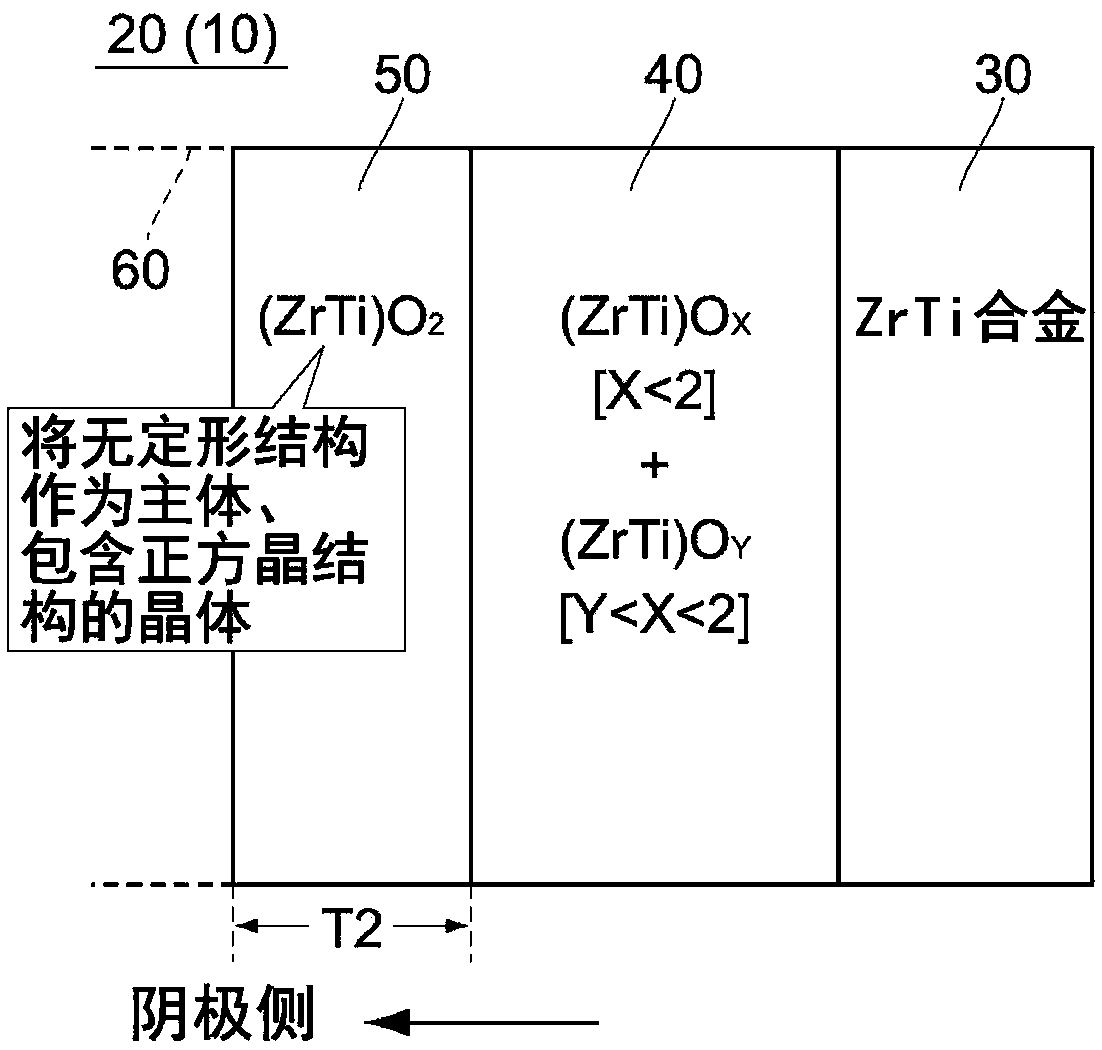

[0036] when referring to figure 1 , the capacitor 10 according to the embodiment of the present invention is a solid electrolytic capacitor having the anode structure 20 formed of a Zr alloy. The Zr alloy of the present embodiment is a binary alloy (ZrTi) in which Ti (titanium) is added to Zr (zirconium) as a main component. However, the present invention is not limited thereto. The Zr alloy of the present invention only needs to contain Zr and a metal element M capable of forming an oxide film in the electrolytic solution. The metal element ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com