Macro pore/meso pore TiO2 film with high double ordered structure and preparation method thereof

A macroporous and mesoporous technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of difficult access to reactants, easy recombination of photogenerated electrons and holes, and few photocatalytic reaction points, so as to promote effective The formation of ordered structure, shortening aging time, and improving the effect of order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

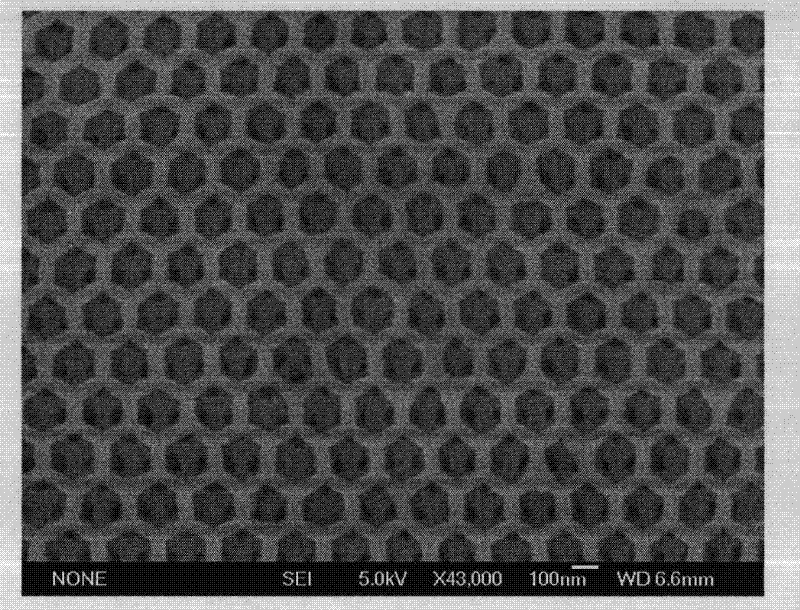

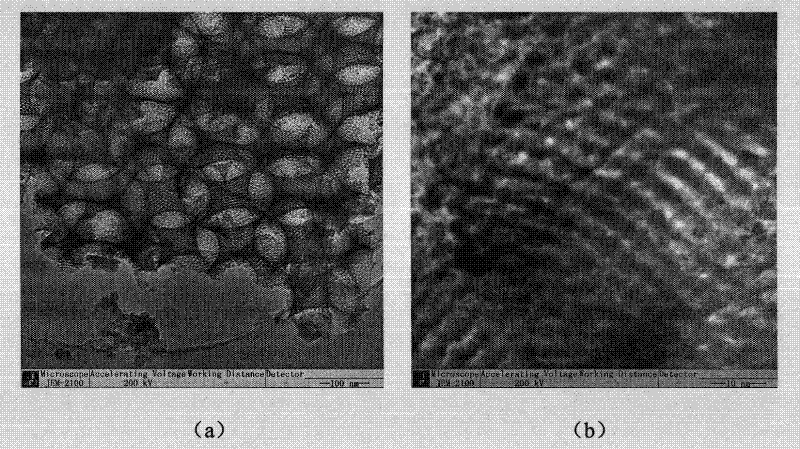

[0030] 80ml H 2 O, 10ml styrene, 0.146g sodium bicarbonate (dissolved in 10mlH 2 O), 0.6ml methacrylic acid, after mixing evenly, heat it in a water bath to 80°C, then quickly add 0.072g of initiator KPS (dissolved in 10mlH 2 O), after reacting for 4h, the temperature was raised to 90°C for another 1h, and the whole process was carried out under N 2 under protection. The product was centrifuged and washed three times with deionized water, and the obtained product was PS spheres with an average diameter of 300 nm.

[0031] After immersing the glass slide in a mixed solution of concentrated sulfuric acid and hydrogen peroxide (volume ratio 7:3) for 24 hours, they were ultrasonically cleaned with acetone and ethanol for 30 min, respectively. The cleaned glass slide is vertically immersed in a 0.3% aqueous solution of PS spheres by mass, and the suspension is evaporated to dryness at 55° C., and a uniform PS sphere colloidal crystal template can be obtained on the glass slide. ...

Embodiment 2

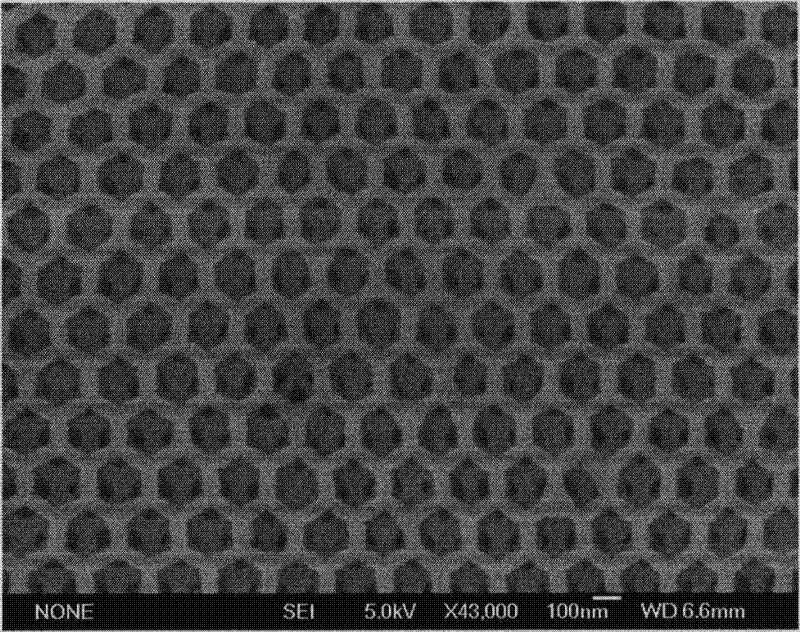

[0034] 80ml H 2 O, 10ml styrene, 0.146g sodium bicarbonate (dissolved in 10mlH 2 O), 0.6ml methacrylic acid, after mixing evenly, heat it in a water bath to 80°C, then quickly add 0.144g of initiator KPS (dissolved in 10mlH 2 O), after reacting for 4h, the temperature was raised to 90°C for another 1h, and the whole process was carried out under N 2 under protection. The product was centrifuged and washed three times with deionized water, and the obtained product was PS spheres with an average diameter of 240 nm.

[0035] After immersing the glass slide in a mixed solution of concentrated sulfuric acid and hydrogen peroxide (volume ratio 7:3) for 24 hours, they were ultrasonically cleaned with acetone and ethanol for 30 min, respectively. The cleaned glass slide is vertically immersed in a 0.3% aqueous solution of PS spheres by mass, and the suspension is evaporated to dryness at 55° C., and a uniform PS sphere colloidal crystal template can be obtained on the glass slide. ...

Embodiment 3

[0038] 80ml H 2 O, 10ml styrene, 0.146g sodium bicarbonate (dissolved in 10mlH 2 O), 0.6ml methacrylic acid, after mixing evenly, heat it in a water bath to 80°C, then quickly add 0.072g of initiator KPS (dissolved in 10mlH 2 O), after reacting for 4h, the temperature was raised to 90°C for another 1h, and the whole process was carried out under N 2 under protection. The product was centrifuged and washed three times with deionized water, and the obtained product was PS spheres with an average diameter of 300 nm.

[0039] After immersing the glass slide in a mixed solution of concentrated sulfuric acid and hydrogen peroxide (volume ratio 7:3) for 24 hours, they were ultrasonically cleaned with acetone and ethanol for 30 min, respectively. The cleaned glass slide is vertically immersed in a 0.3% aqueous solution of PS spheres by mass, and the suspension is evaporated to dryness at 55° C., and a uniform PS sphere colloidal crystal template can be obtained on the glass slide. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com