Vibrating screen mechanism with three-dimensional independent output motion

A vibrating screen and motion technology, applied in the direction of filter screen, manipulator, manufacturing tool, etc., can solve the problems of complex structure, small amplitude, insufficient material turnover, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

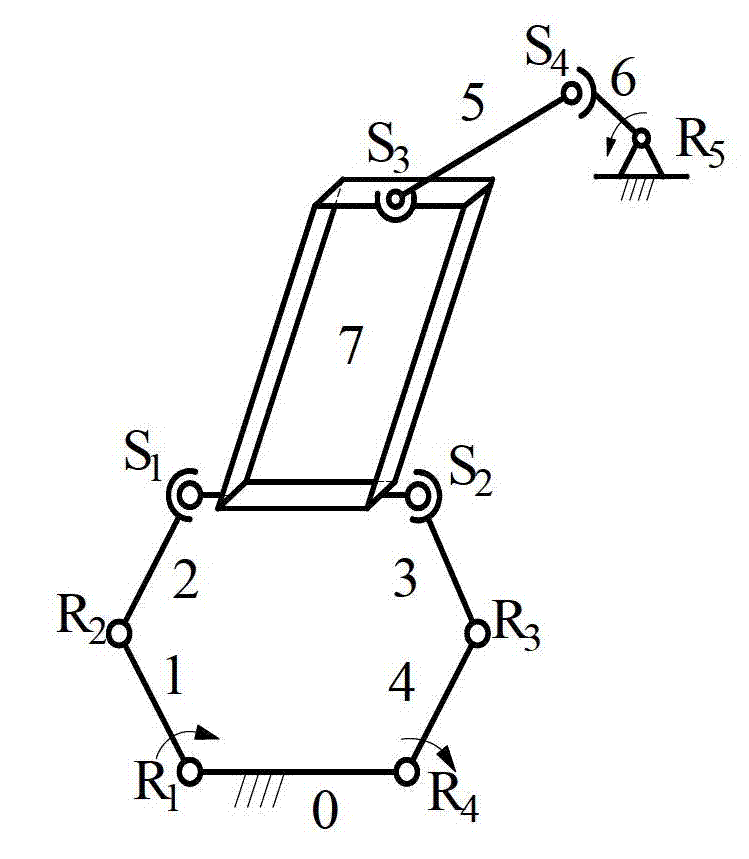

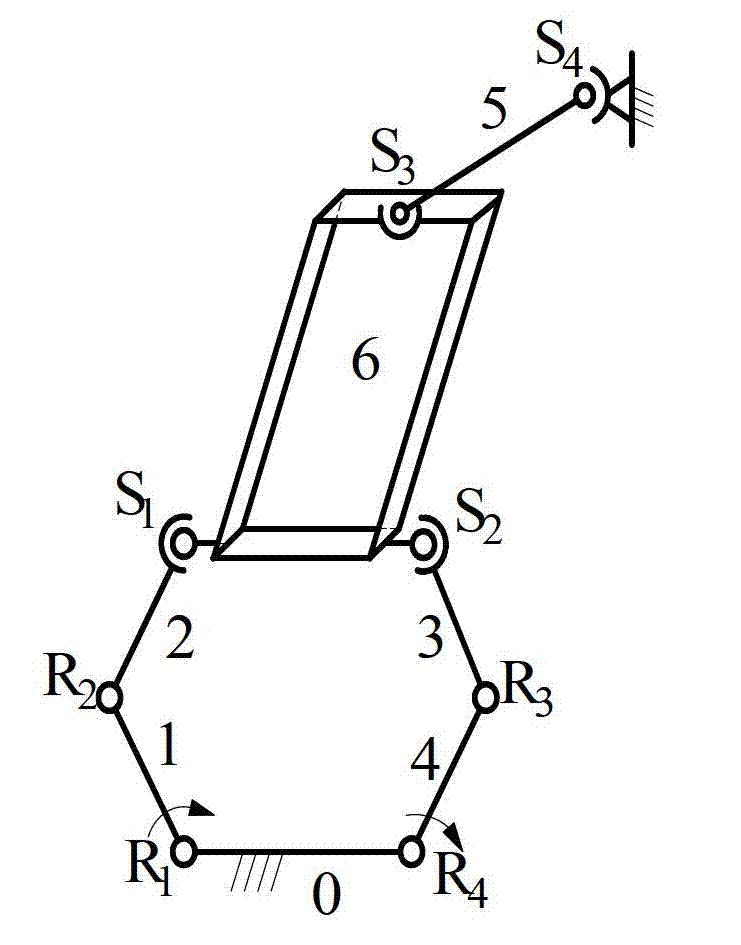

[0008] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0009] attached figure 1 It is a structural schematic diagram of an embodiment of the present invention, which includes a screen frame 7, a frame 0, first and second branch chains with the same structure, and a third branch chain. The pair one S1 is connected to the screen frame 7, the other end is connected to one end of the member one 1 by the rotating pair R2, and the other end of the member one 1 is connected to the frame 0 by the rotating pair R1; one end of the second branched member three 3 is connected by a ball pair The second S2 is connected to the screen frame 7, and the other end is connected to one end of the member 44 with the rotating pair 3 R3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com