Spark plug

a technology of spark plugs and plugs, which is applied in the direction of spark plugs, sparking plugs, basic electric elements, etc., can solve the problems of not having sufficient studies on how to dissipate heat sufficiently, ignition to occur before spark discharge, etc., and achieve the effect of improving heat dissipation through the path from the insulator through the sheet packing to the metallic shell, sufficient deformation allowance, and improving heat dissipation through the path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

A. First embodiment

A-1. Configuration of Spark Plug

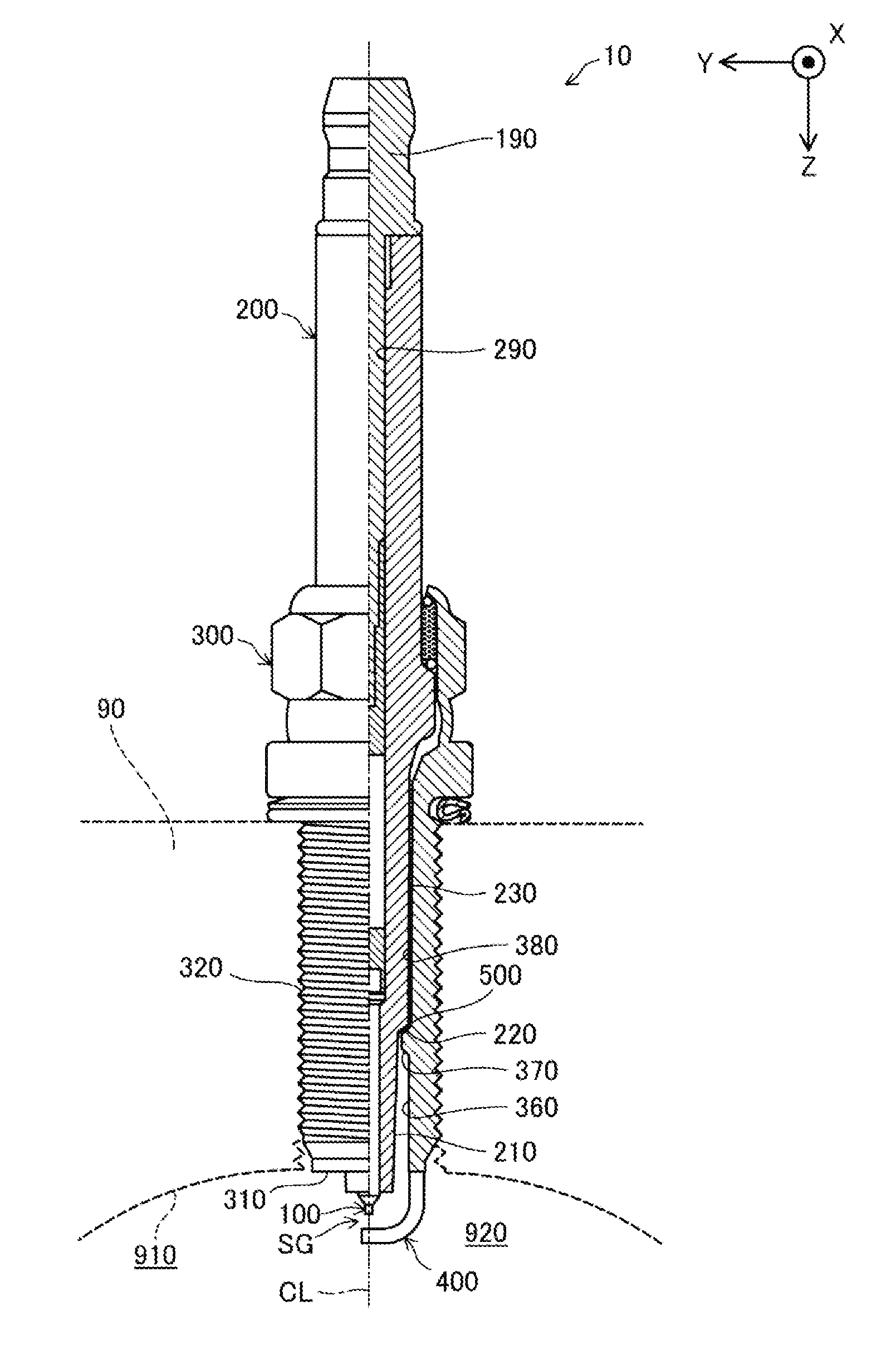

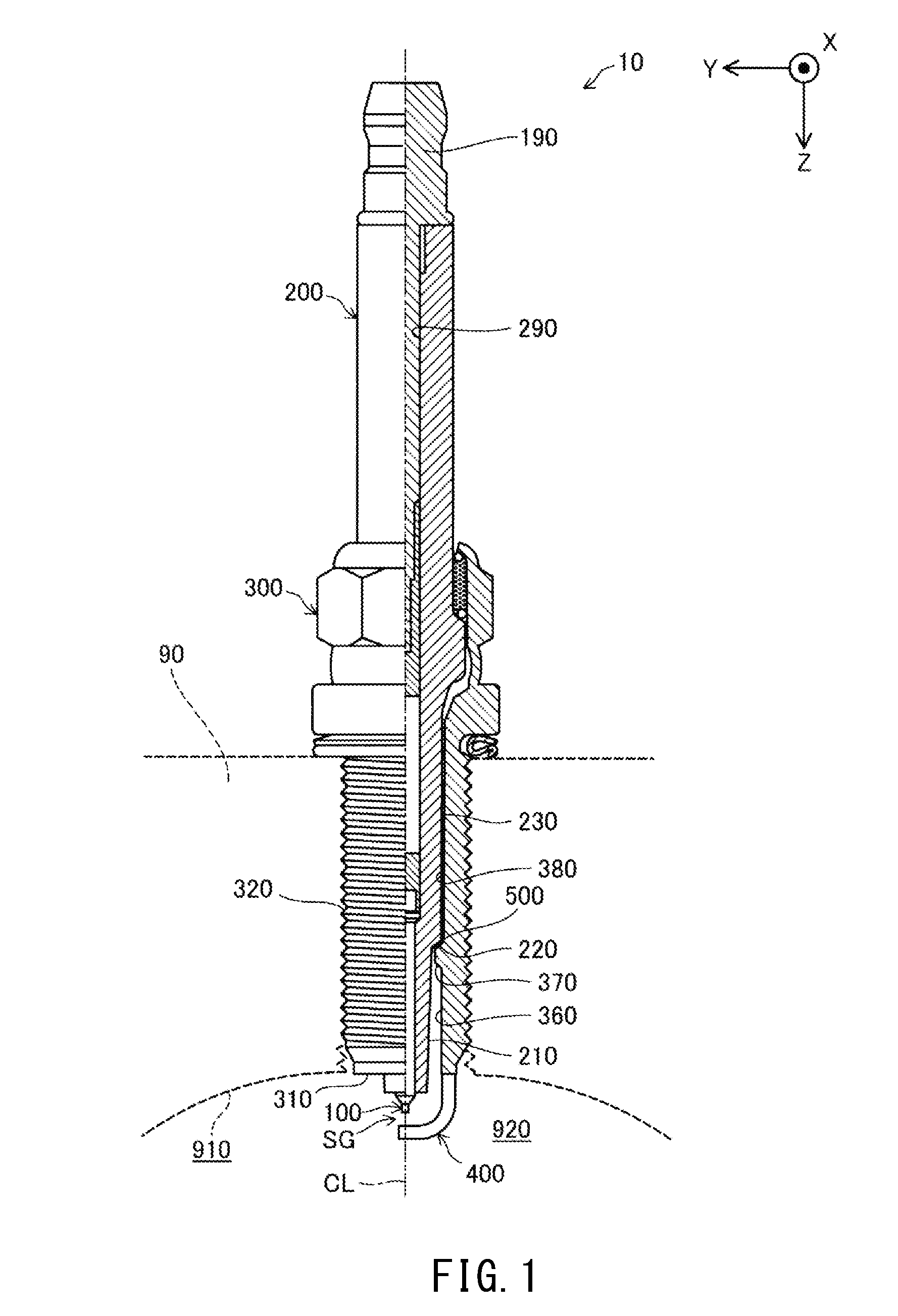

[0027]FIG. 1 is an illustration showing a partial cross section of a spark plug 10. In FIG. 1, the exterior shape of the spark plug 10 is shown on the left side of the sheet with respect to an axial line CL, i.e., the axis of the spark plug 10, and a cross-sectional shape of the spark plug 10 is shown on the right side of the sheet with respect to the axial line CL. In the description of the present embodiment, the lower side in the sheet of FIG. 1 is referred to as a “forward end side” of the spark plug 10, and the upper side in the sheet of FIG. 1 is referred to as a “rear end side.”

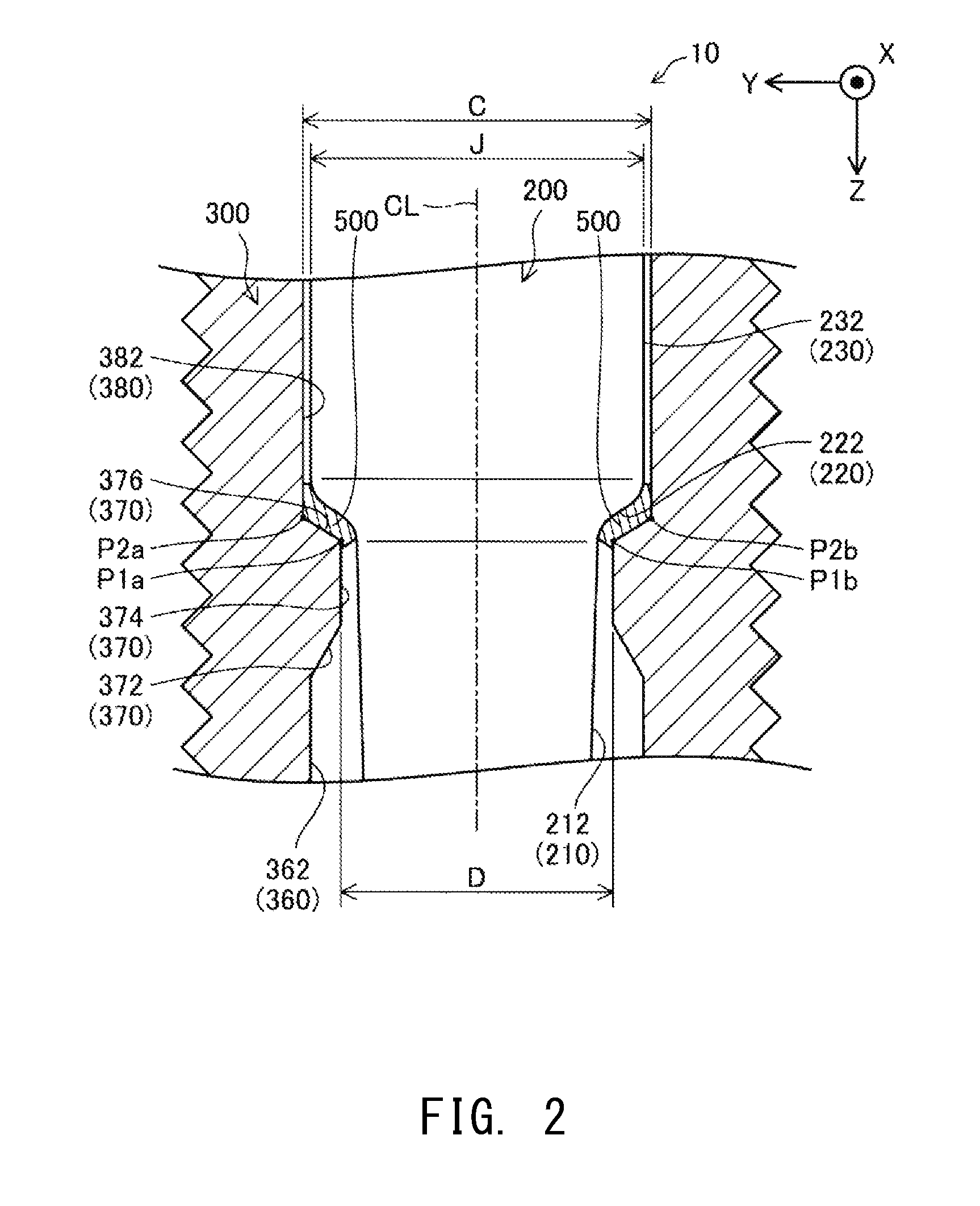

[0028]The spark plug 10 includes a center electrode 100, an insulator 200, a metallic shell 300, a ground electrode 400, and a sheet packing 500. In the present embodiment, the axial line CL of the spark plug 10 is also the axis of the center electrode 100, the axis of the insulator 200, and the axis of the metallic shell 300.

[0029]The spark plug 10 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com