Patents

Literature

82results about How to "Minimize investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

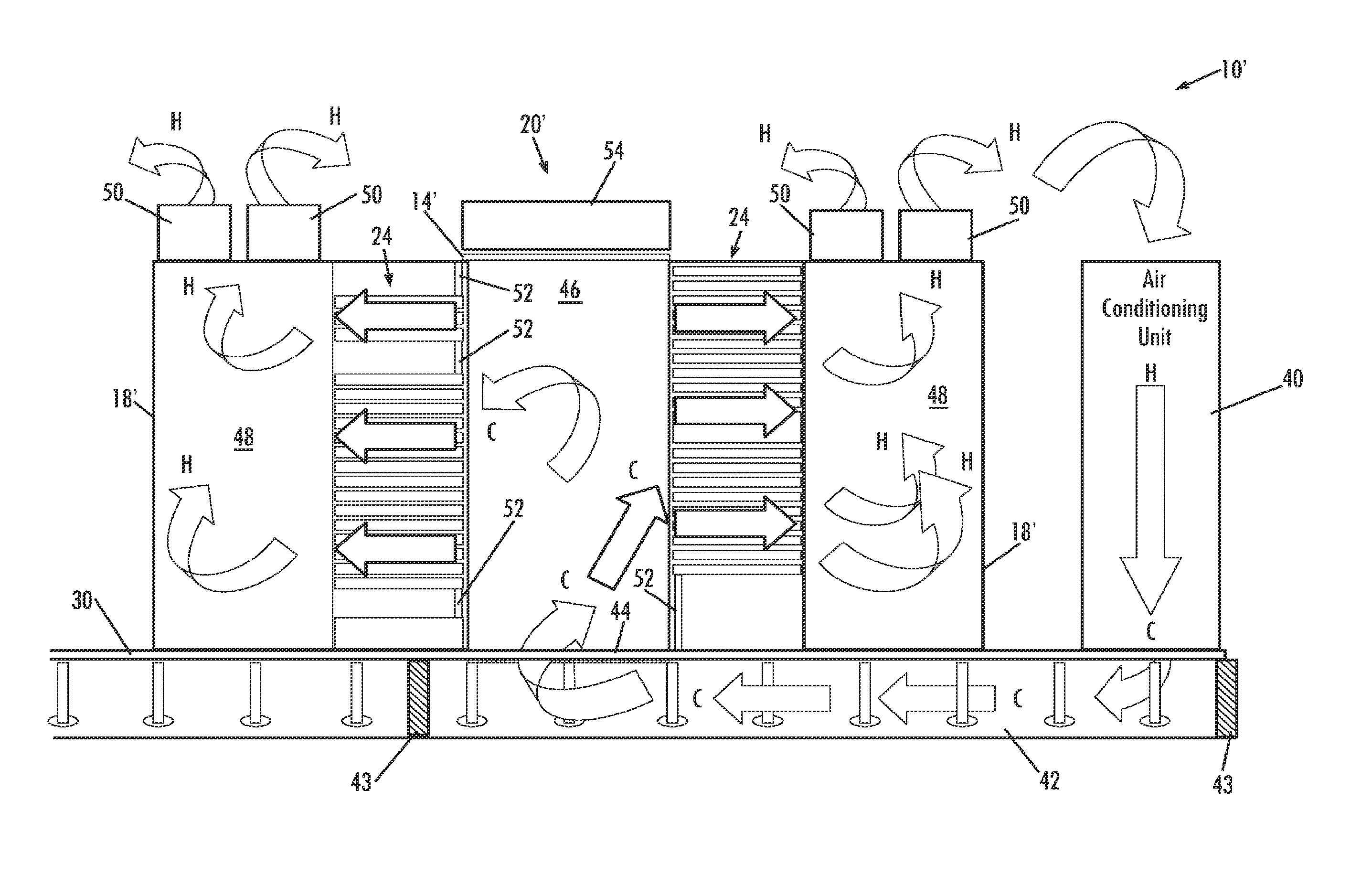

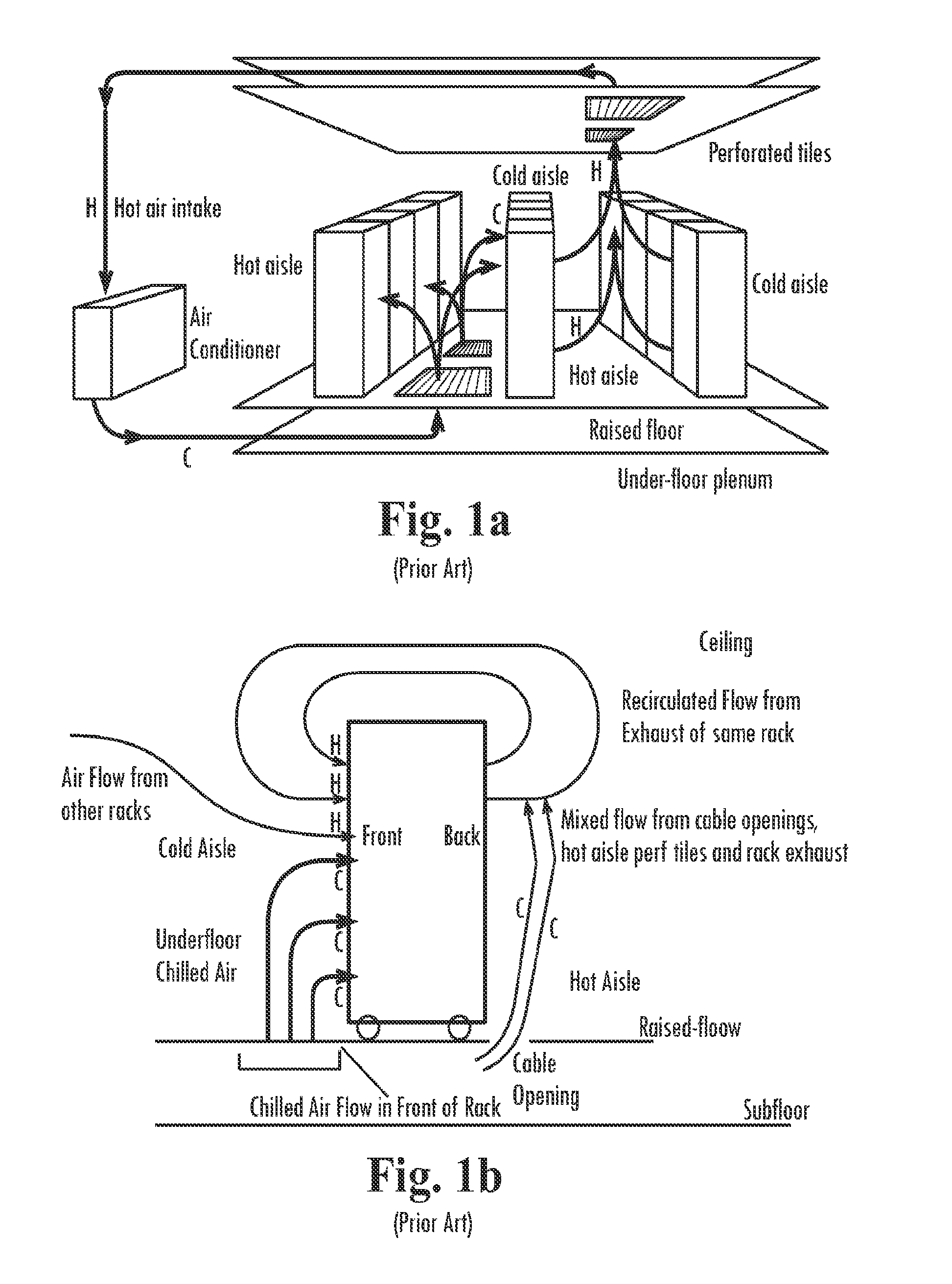

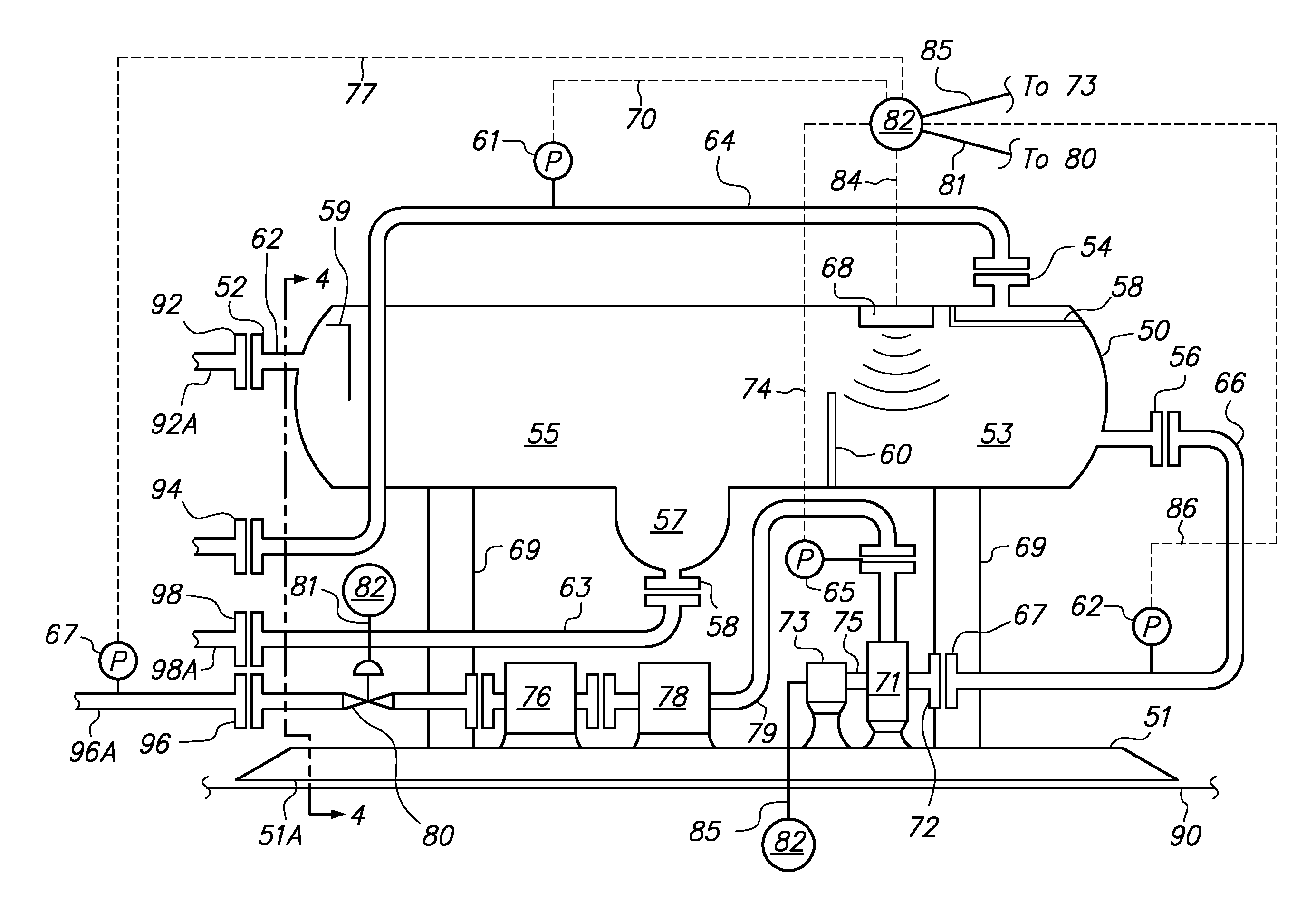

Energy saving system and method for cooling computer data center and telecom equipment

ActiveUS20090168345A1Avoid thermal failureEfficient cooling and heatingMechanical apparatusSpace heating and ventilation safety systemsElectricityData center

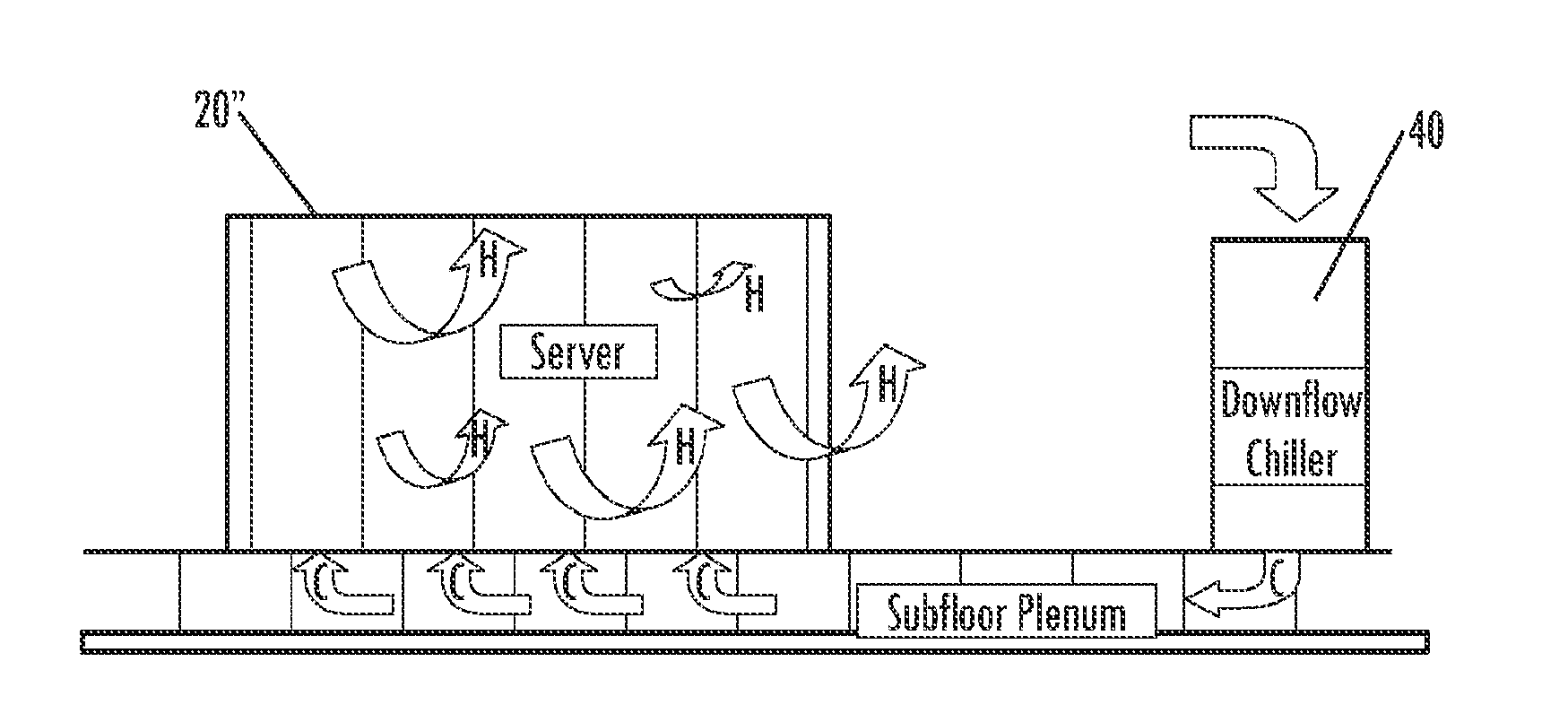

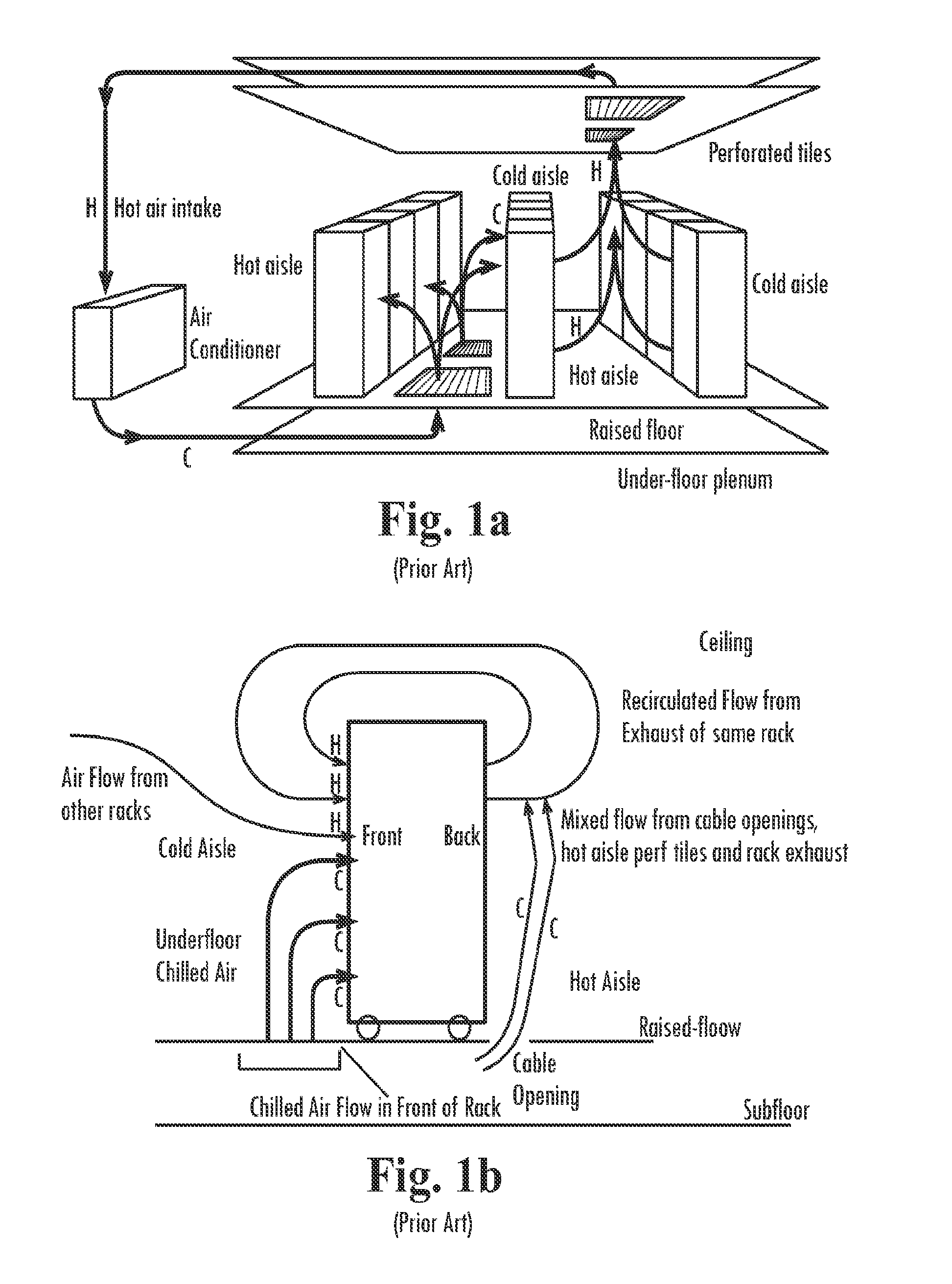

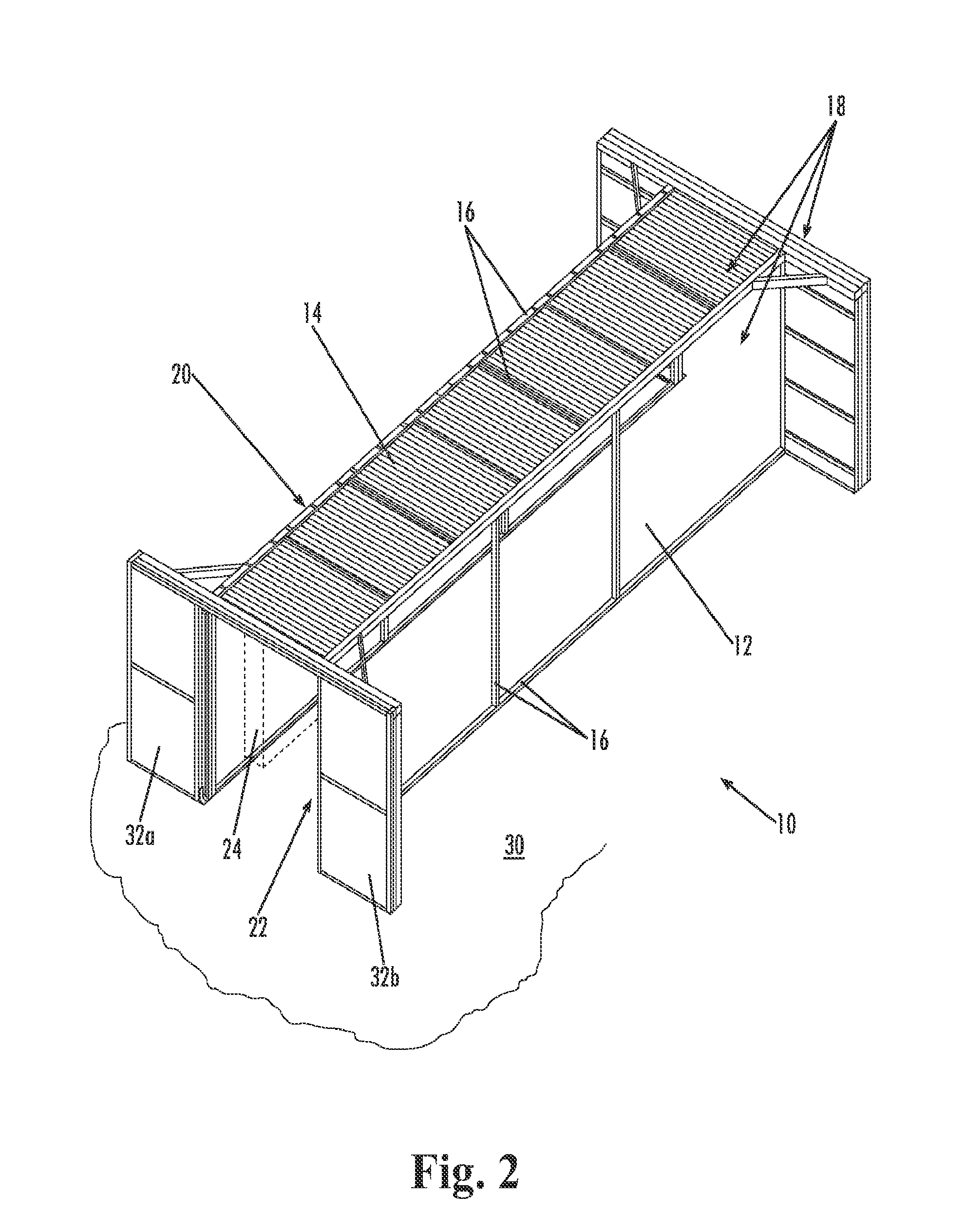

A system and method of reducing consumption of electricity used to cool electronic computer data center, networking, and telecommunications equipment, and to reduce the incidence of thermal failure of electronic components, includes provision of one or more partitions to reduce the volume of the cooled environment supplying coldest possible cooled air from air conditioning systems to a chamber adjacent to racks containing the electronic components, preventing dilution of the supplied cooling airflow by warmer air from outside of the reduced volume environment, and controlling the delivery of cooling air flow through the reduced volume of the cooled environment.

Owner:MARTINI VALAN R

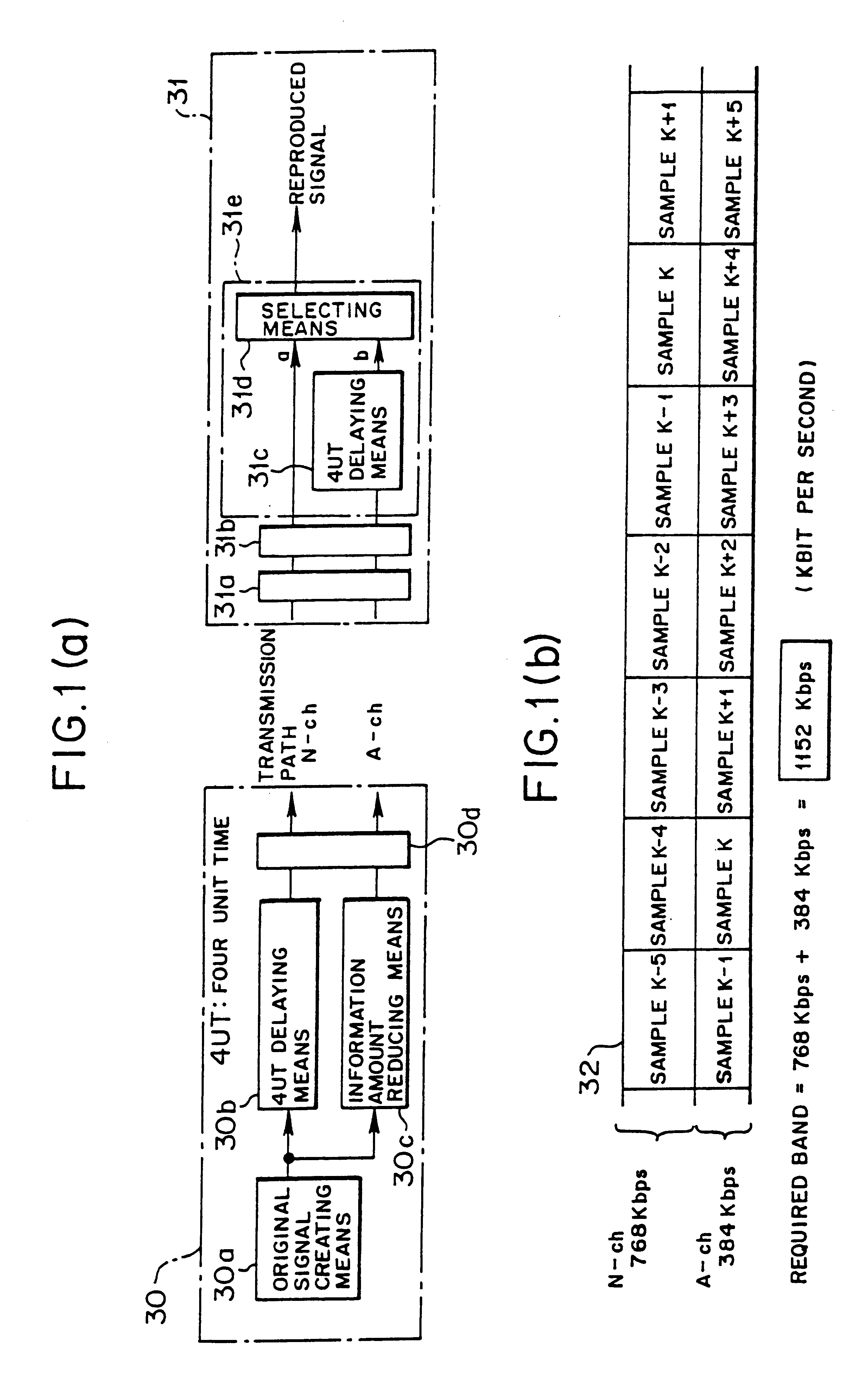

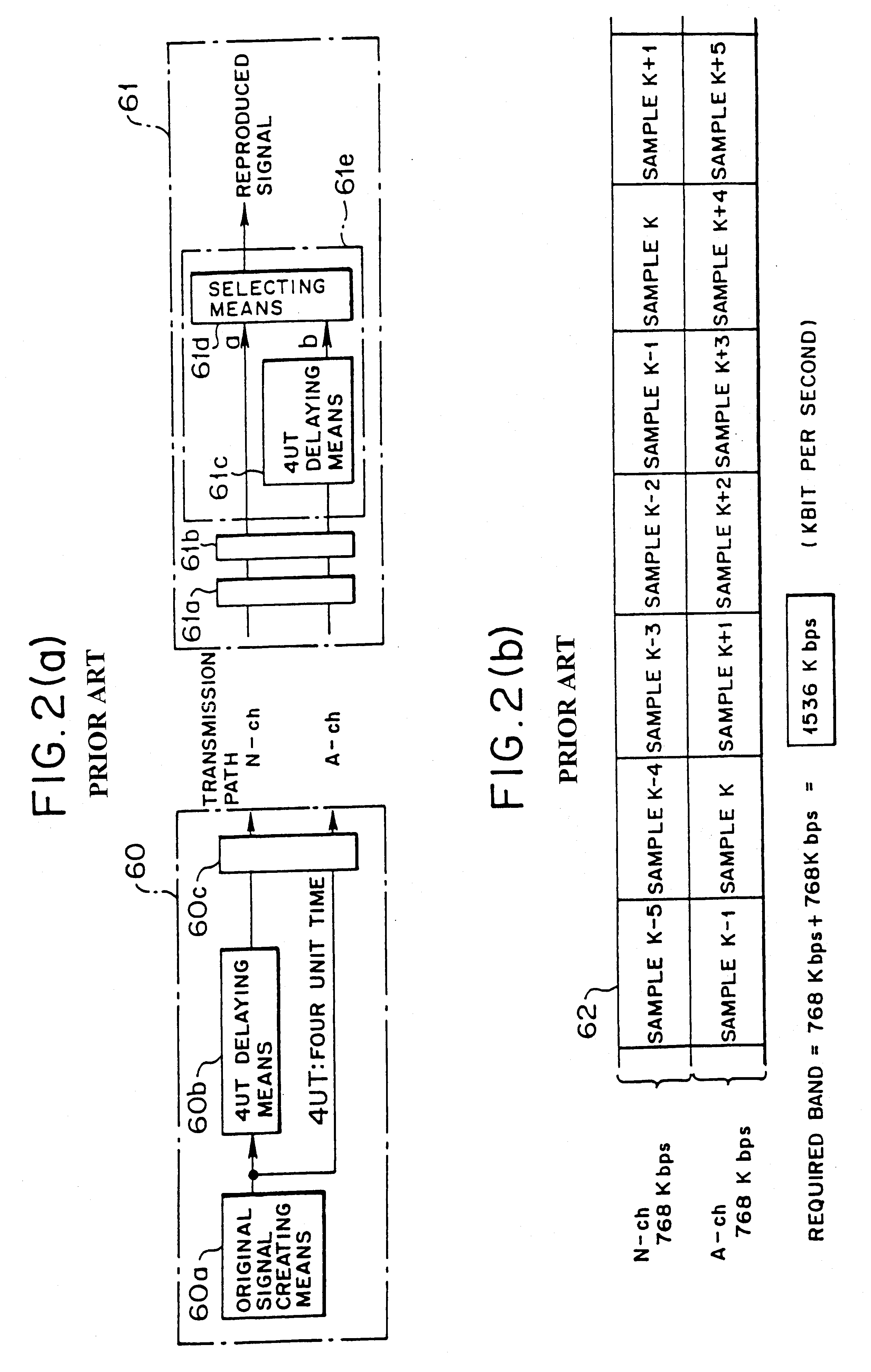

Method, system and apparatus for transmitting, receiving, and reproducing a digital broadcast signal

InactiveUS6535717B1Small bandwidthIncrease the number ofPulse modulation television signal transmissionBroadcast transmission systemsEngineeringDigital broadcasting

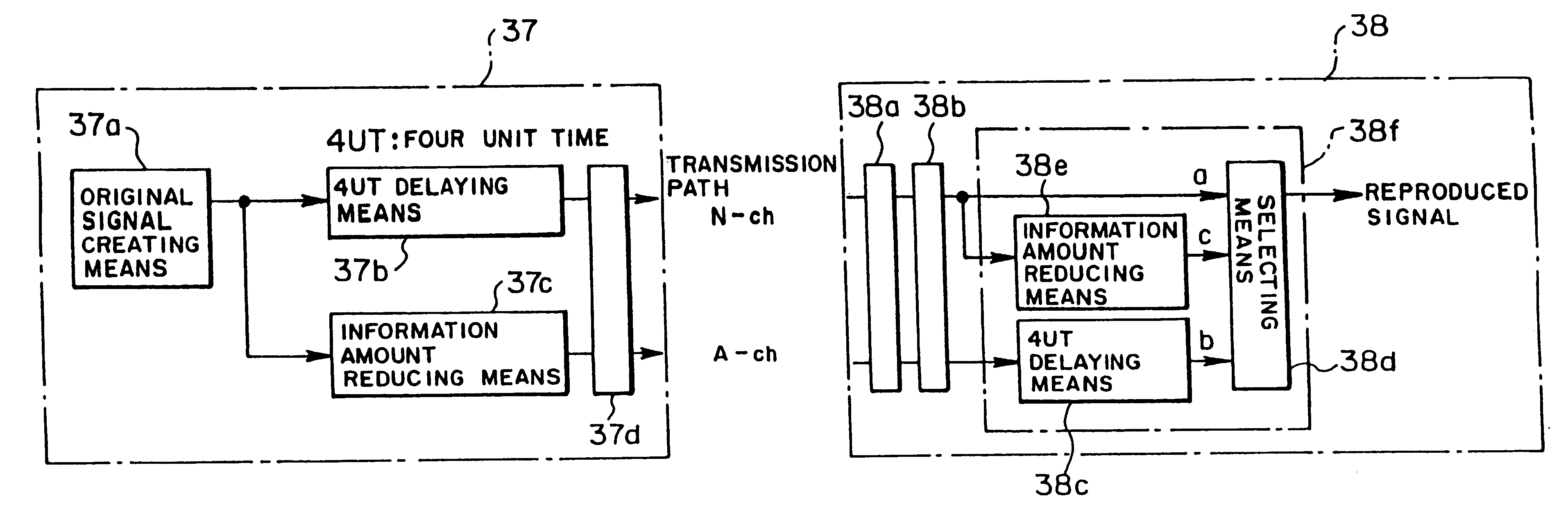

The present system comprises a transmitting apparatus for digital broadcast which includes an original signal generating section, delaying section, information amount reducing section, and transmitting section. A receiving and reproducing apparatus for digital broadcast includes a signal reception front stage unit for receiving a high quality signal and a low quality signal, mode determining section and reproducing section composed of a delaying section and selecting section for selectively reproducing the high quality signal and the low quality signal. By employing time diversity, the transmitting apparatus sends the low quality signal having a smaller bandwidth and the high quality signal so that the low quality signal has a preceding time lag relative to the high quality signal, and the receiving apparatus reproduces broadcasting programs. Utilizing the frequency band for broadcast effectively, many broadcasting programs can be increased, and the investment for providing a gap filler can be minimized.

Owner:FUJITSU LTD

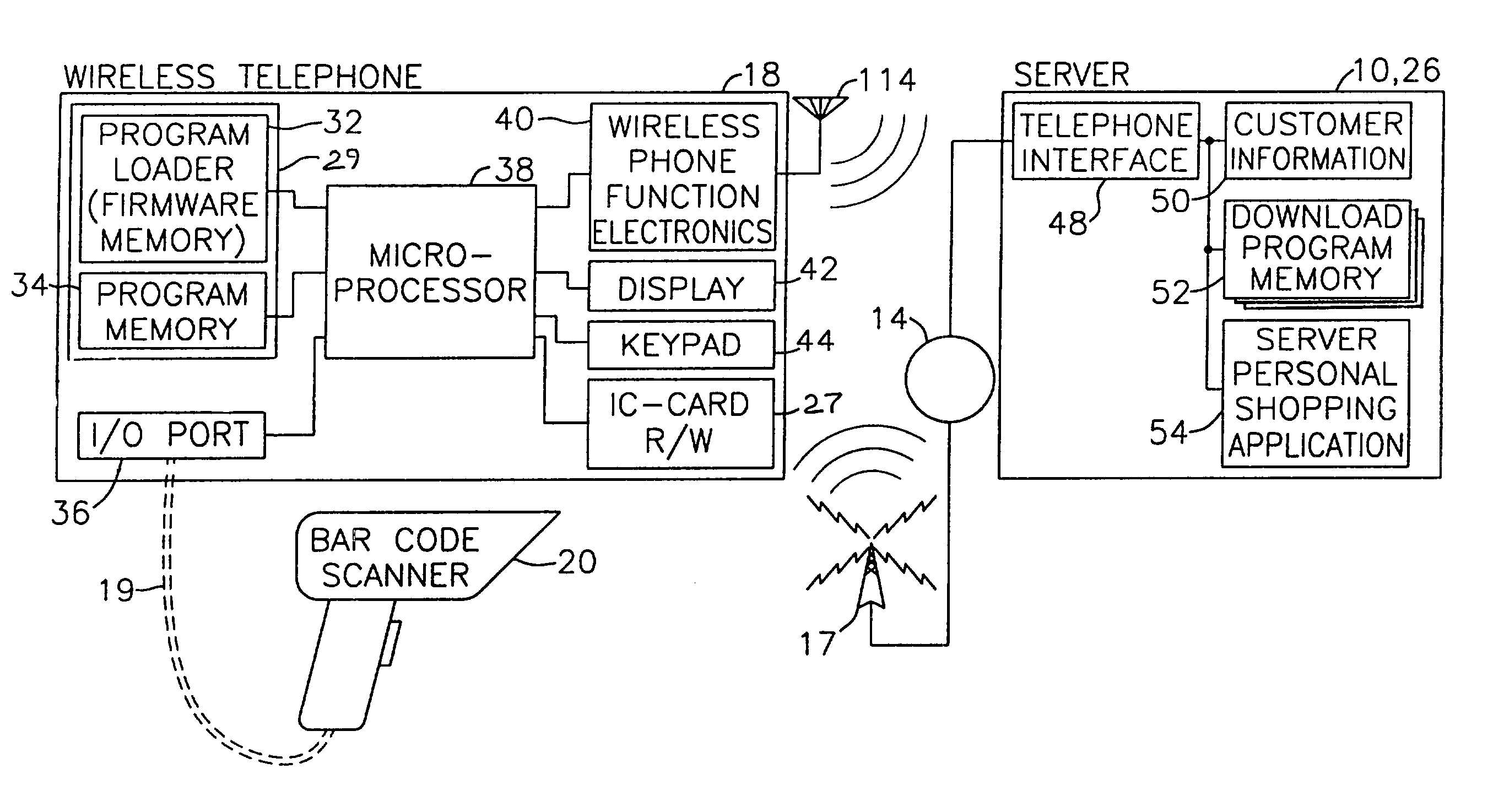

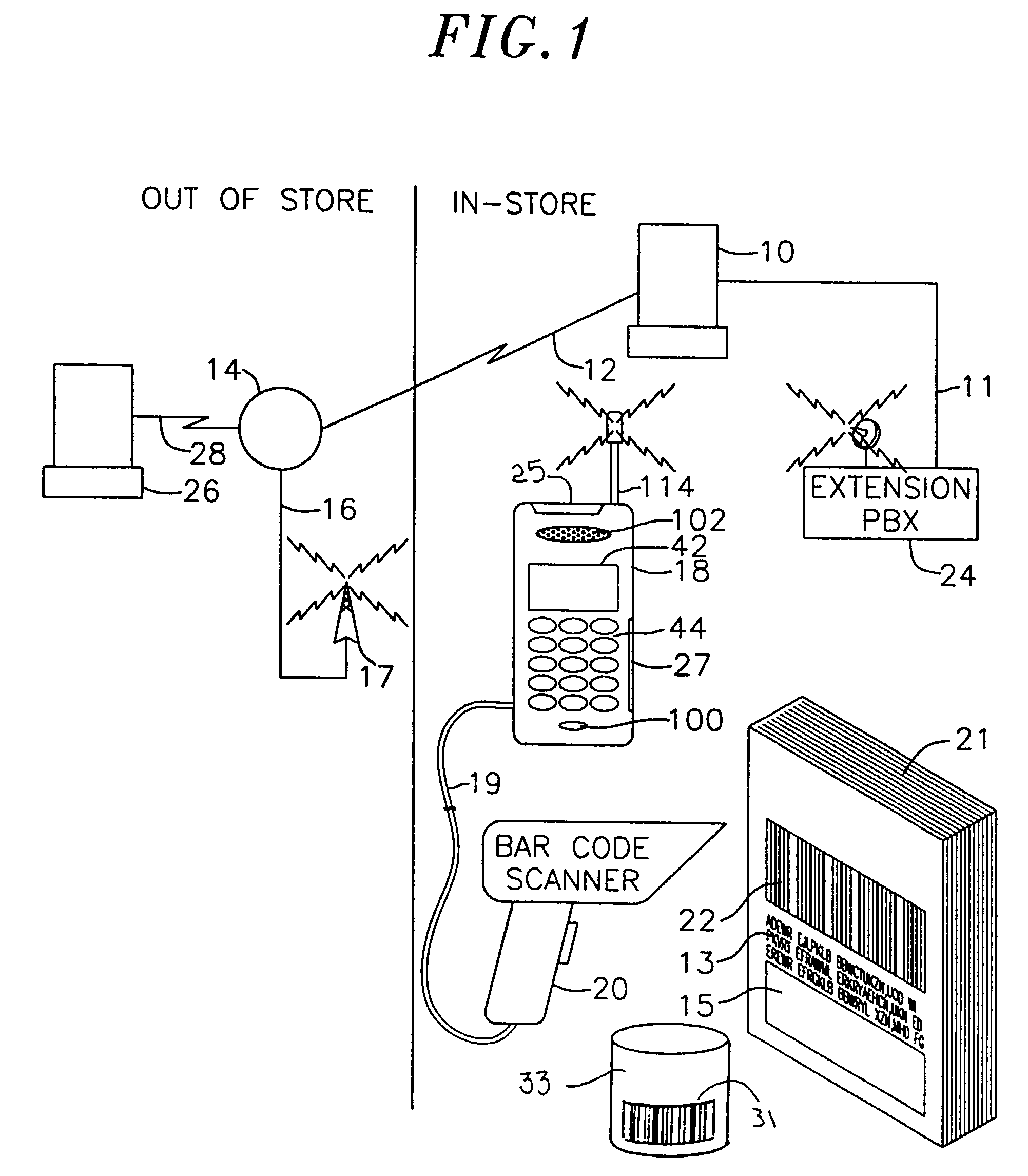

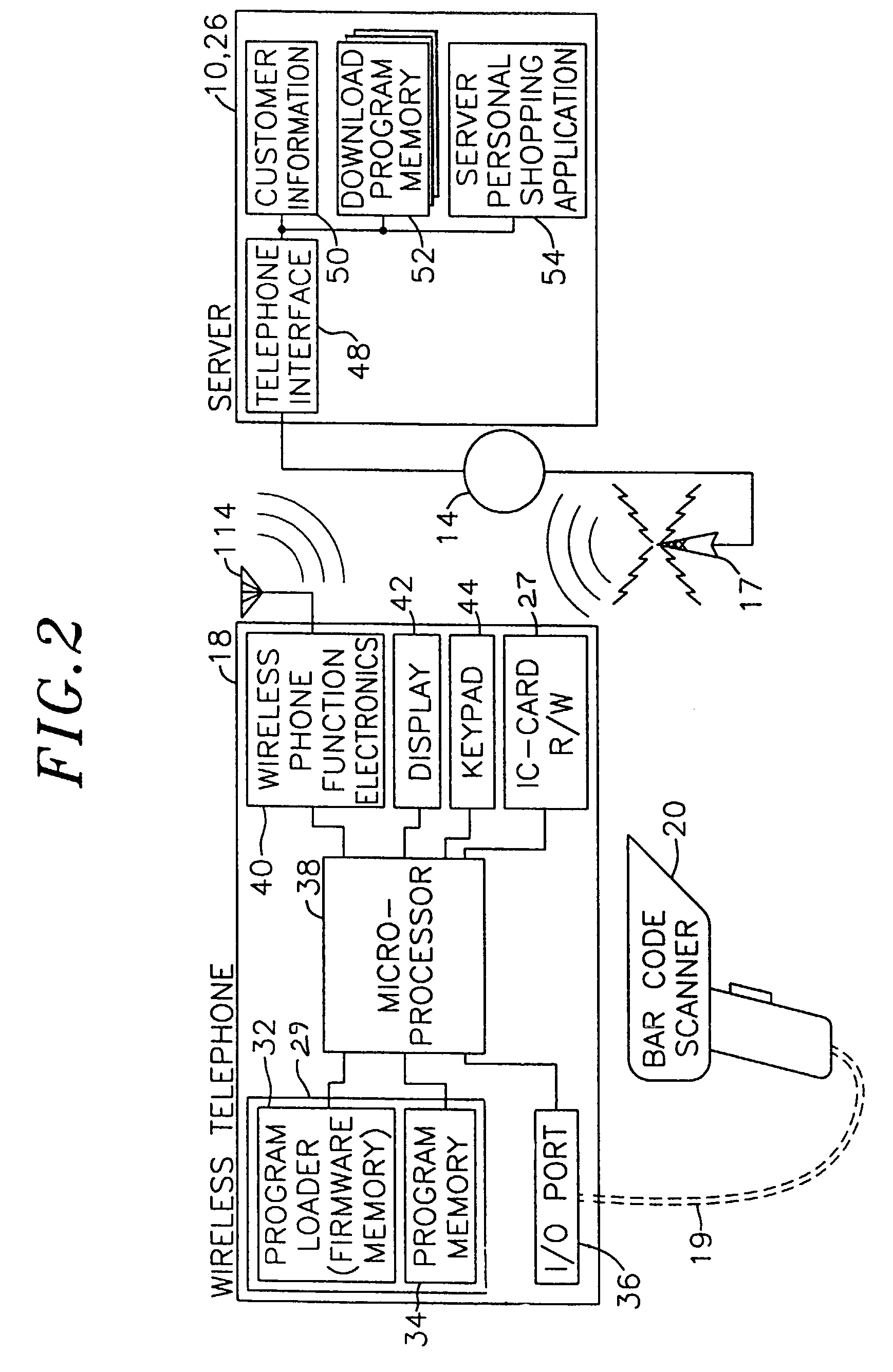

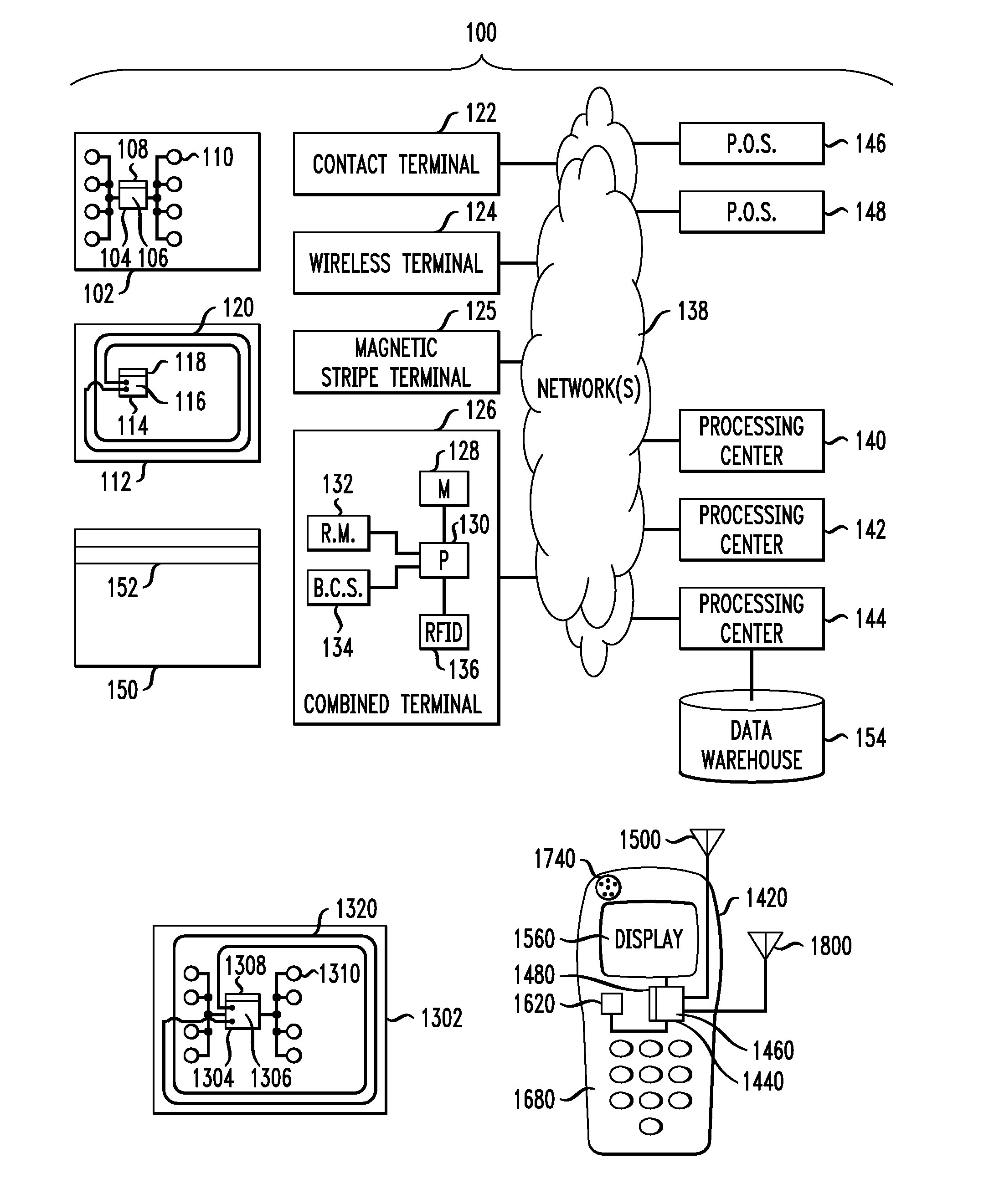

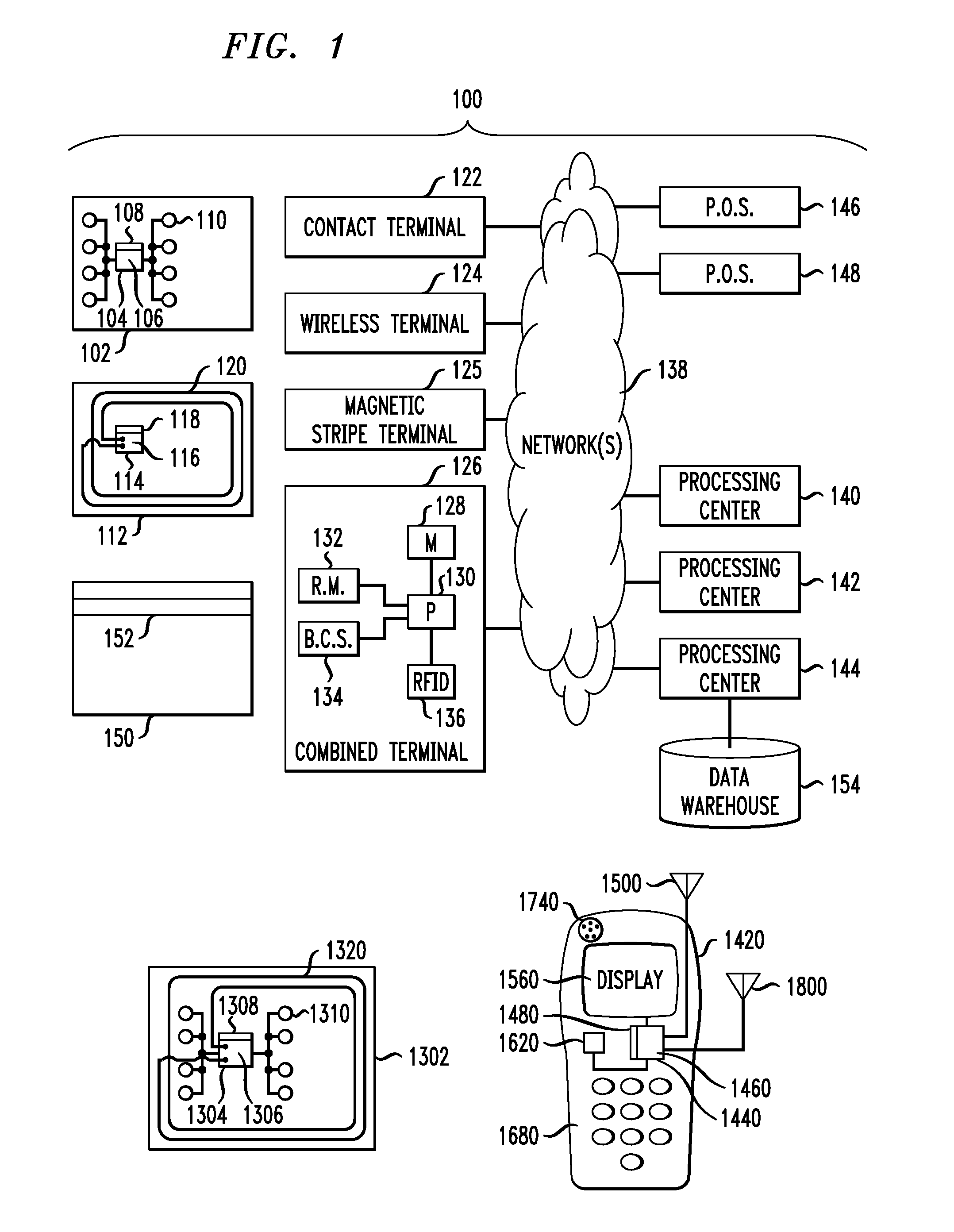

Electronic shopping system utilizing a program downloadable wireless telephone

InactiveUS6975856B2Easily and conveniently performedMinimal investmentCredit registering devices actuationUnauthorised/fraudulent call preventionPaymentBarcode

An electronic shopping system facilitates purchase transactions via a wireless telephone. A purchase transaction program is downloaded from the seller's server to a purchaser's wireless telephone via a program loader contained within the purchaser's wireless telephone. The purchase transaction program is stored in a program memory of the purchaser's wireless telephone. The purchase transaction program is used by the purchaser to facilitate the selection of items to be purchased, as well as payment therefor. An external bar code reader is attached to the wireless telephone to facilitate the selection of items to be purchased and is controlled via the downloaded purchase transaction program.

Owner:KNAPP INVESTMENT

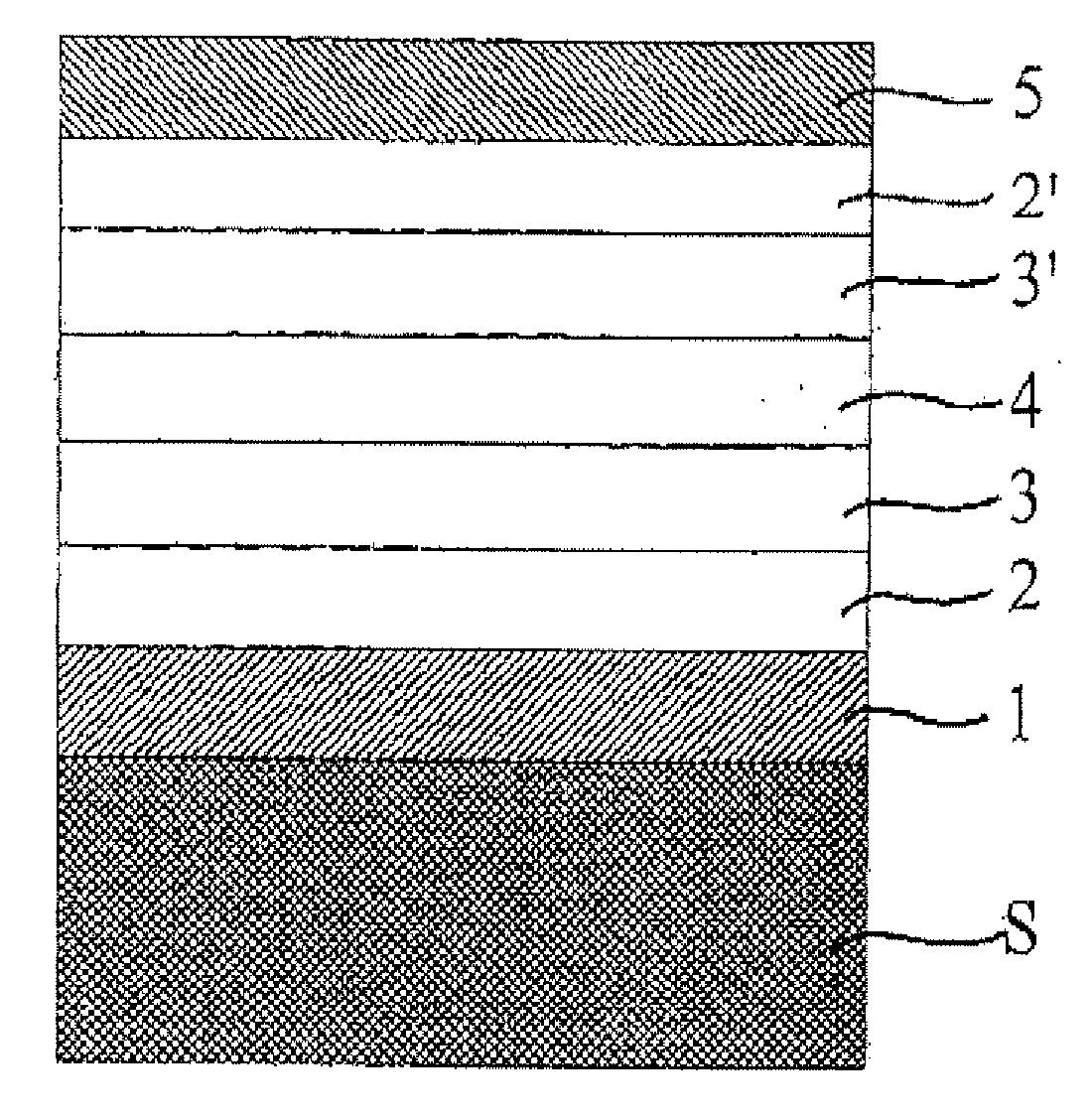

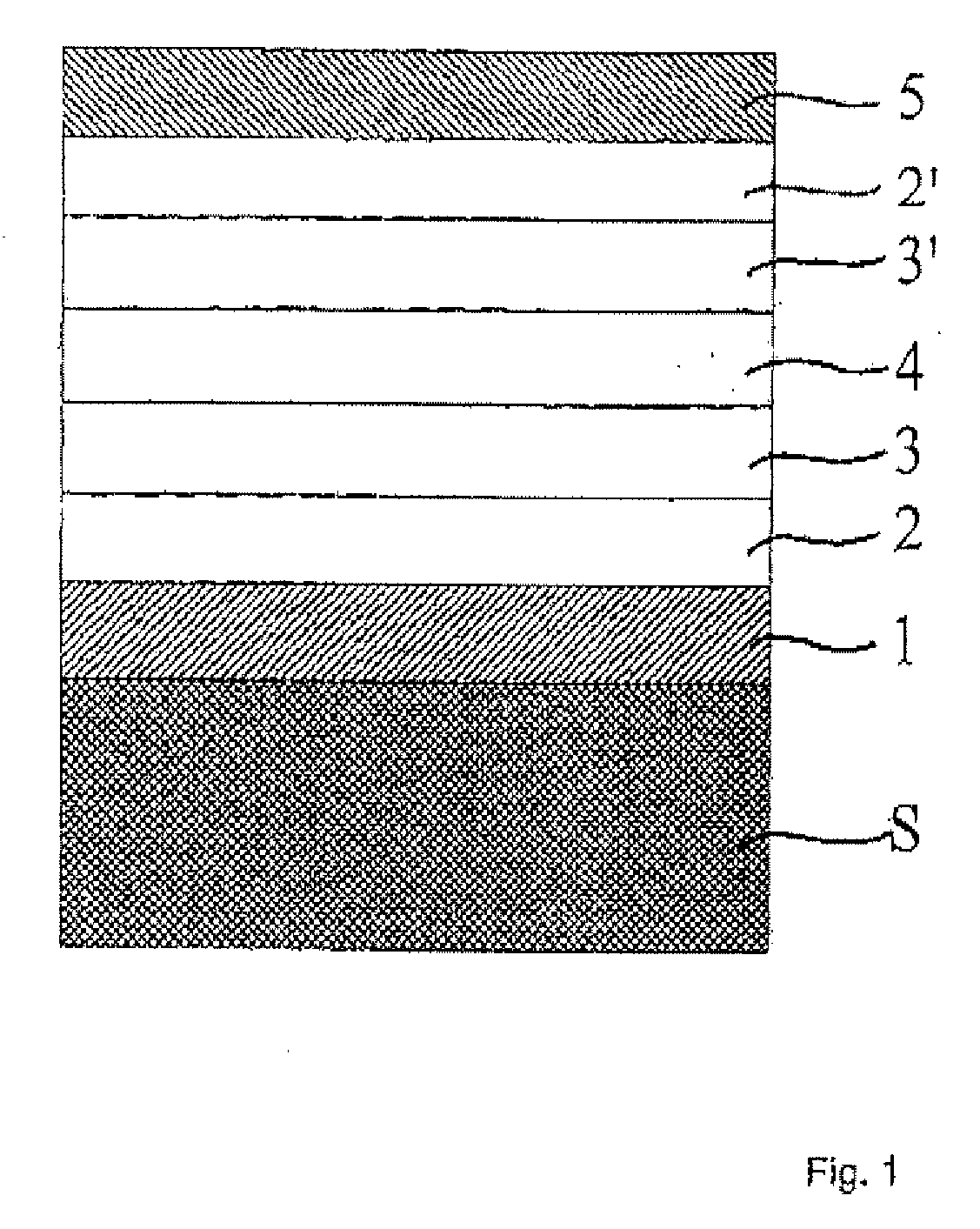

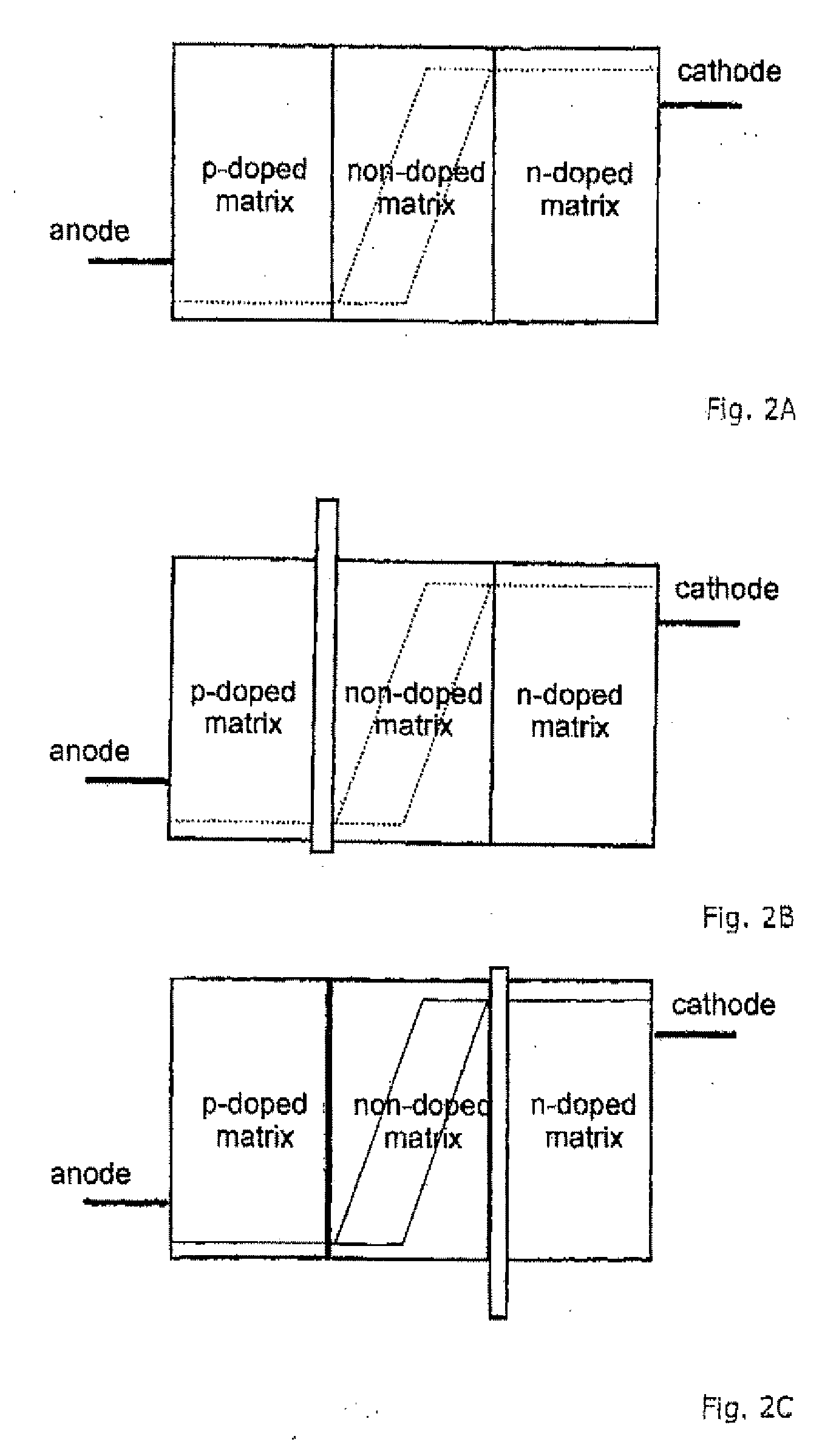

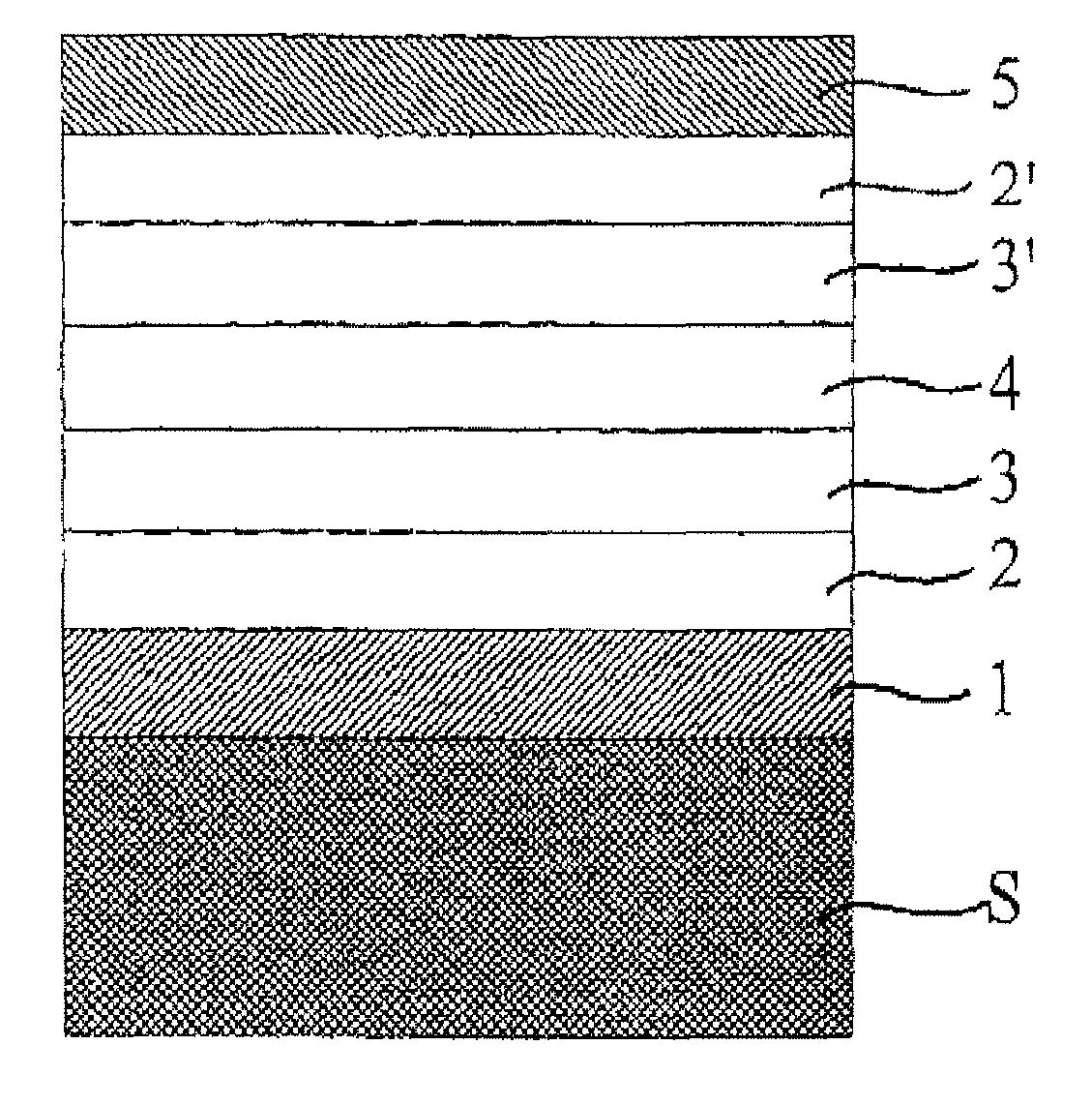

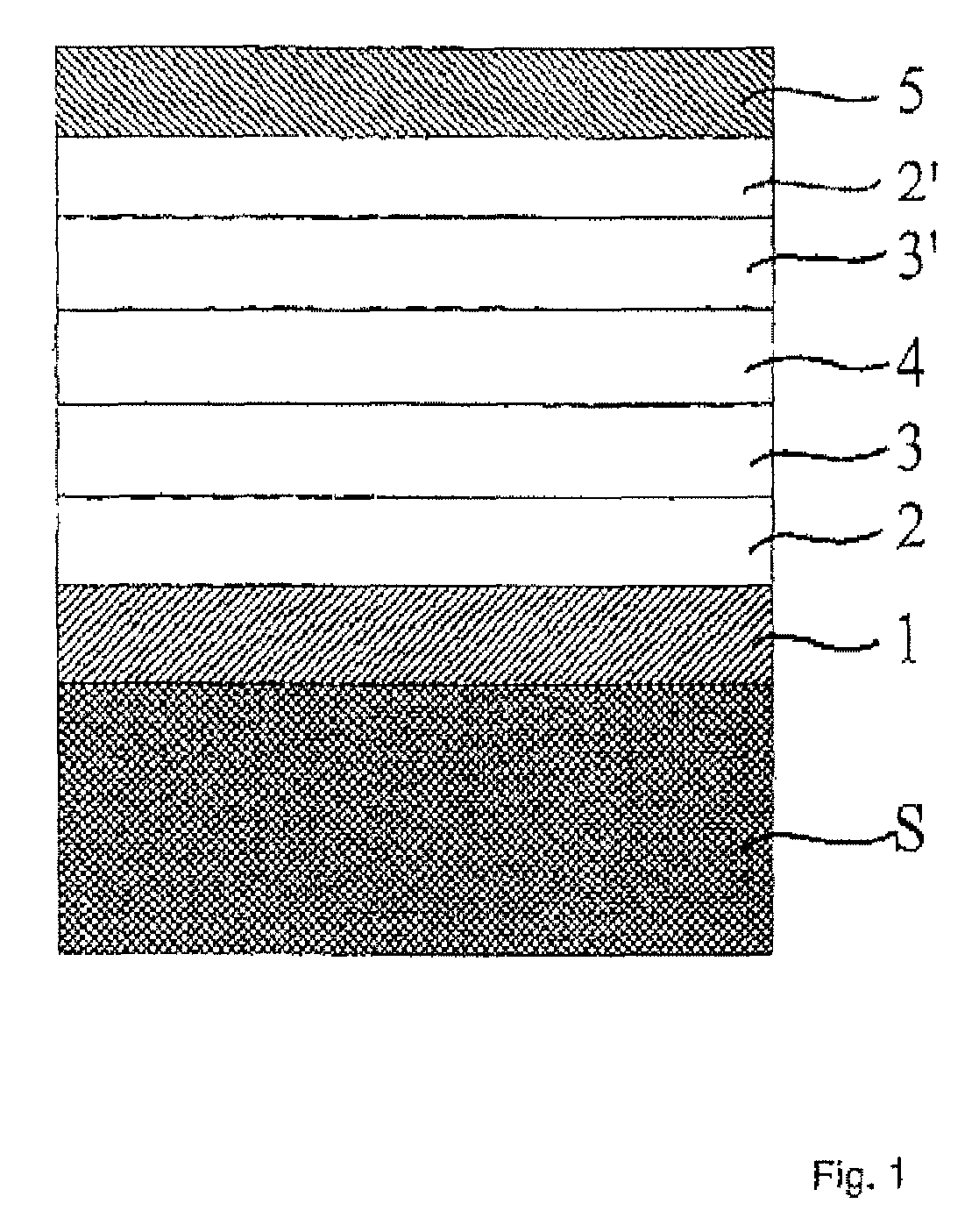

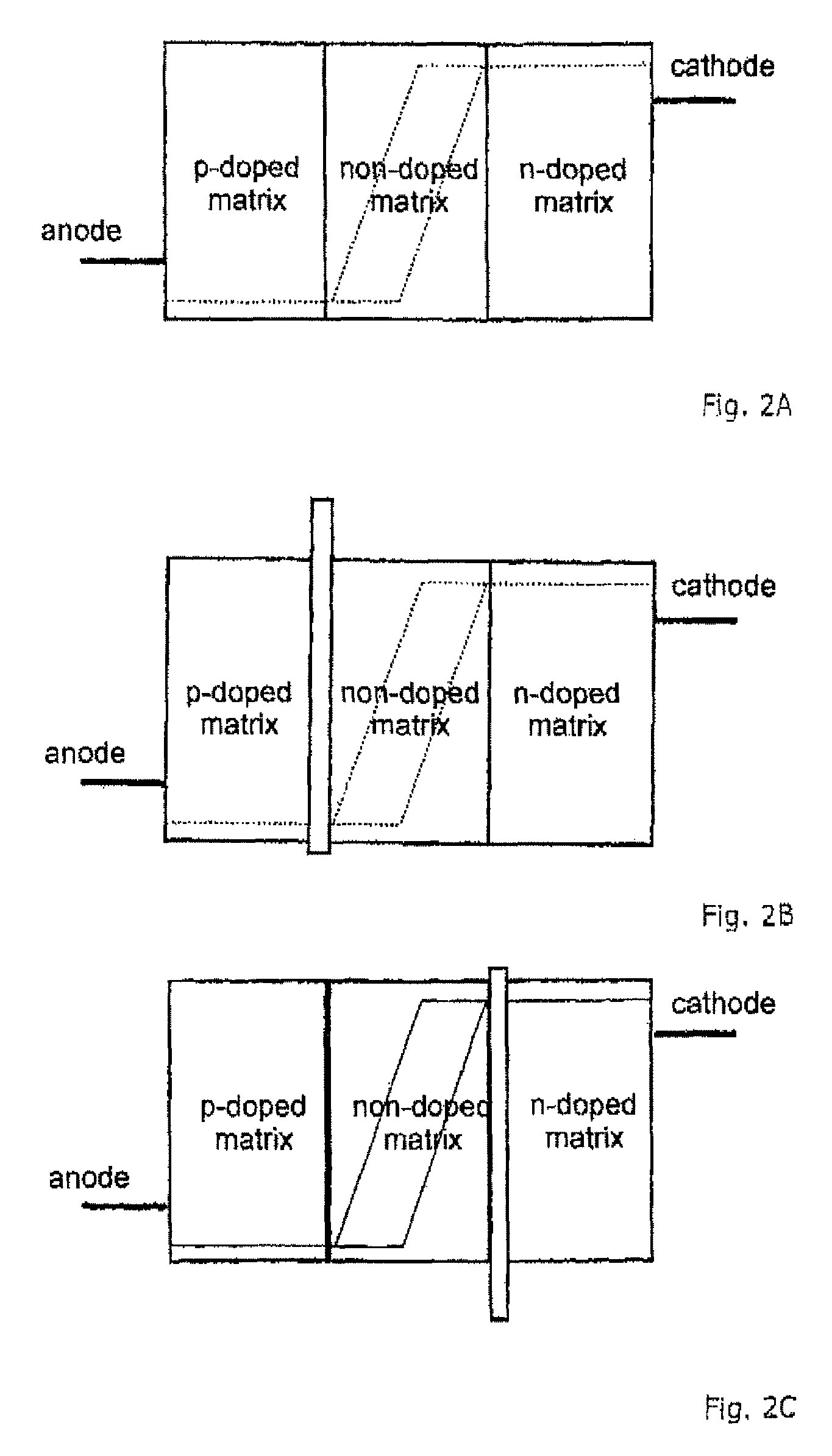

Arrangement for an Organic Pin-Type Light-Emitting Diode and Method for Manufacturing

ActiveUS20060250076A1Simple configurationReduce the number of layersDischarge tube luminescnet screensElectroluminescent light sourcesTransport layerCharge carrier

The invention relates to an arrangement for an organic pin-type light-emitting diode with an electrode and a counter-electrode and a stack with organic layers between the electrode and the counter-electrode, where the stack with the organic layers comprises an emission layer comprising a k (k=1, 2, 3, . . . ) organic matrix materials, a doped charge carrier transport layer, which is arranged between the electrode and the emission layer, a further doped charge carrier transport layer, which is arranged between the counter-electrode and the emission layer, and one block layer, which is arranged between one of the doped charge carrier transport layers and the emission layer. The organic layers of the stack are formed by means of n (n≦k+2) organic matrix materials, where the n organic matrix materials comprise the k organic matrix materials of the emission layer. The stack with the organic layers can also be executed in a block-layer-free manner, where then the emission layer and the doped charge carrier transport layer are formed from an organic matrix material. Furthermore, a method for manufacturing such arrangements is stated.

Owner:NOVALED GMBH

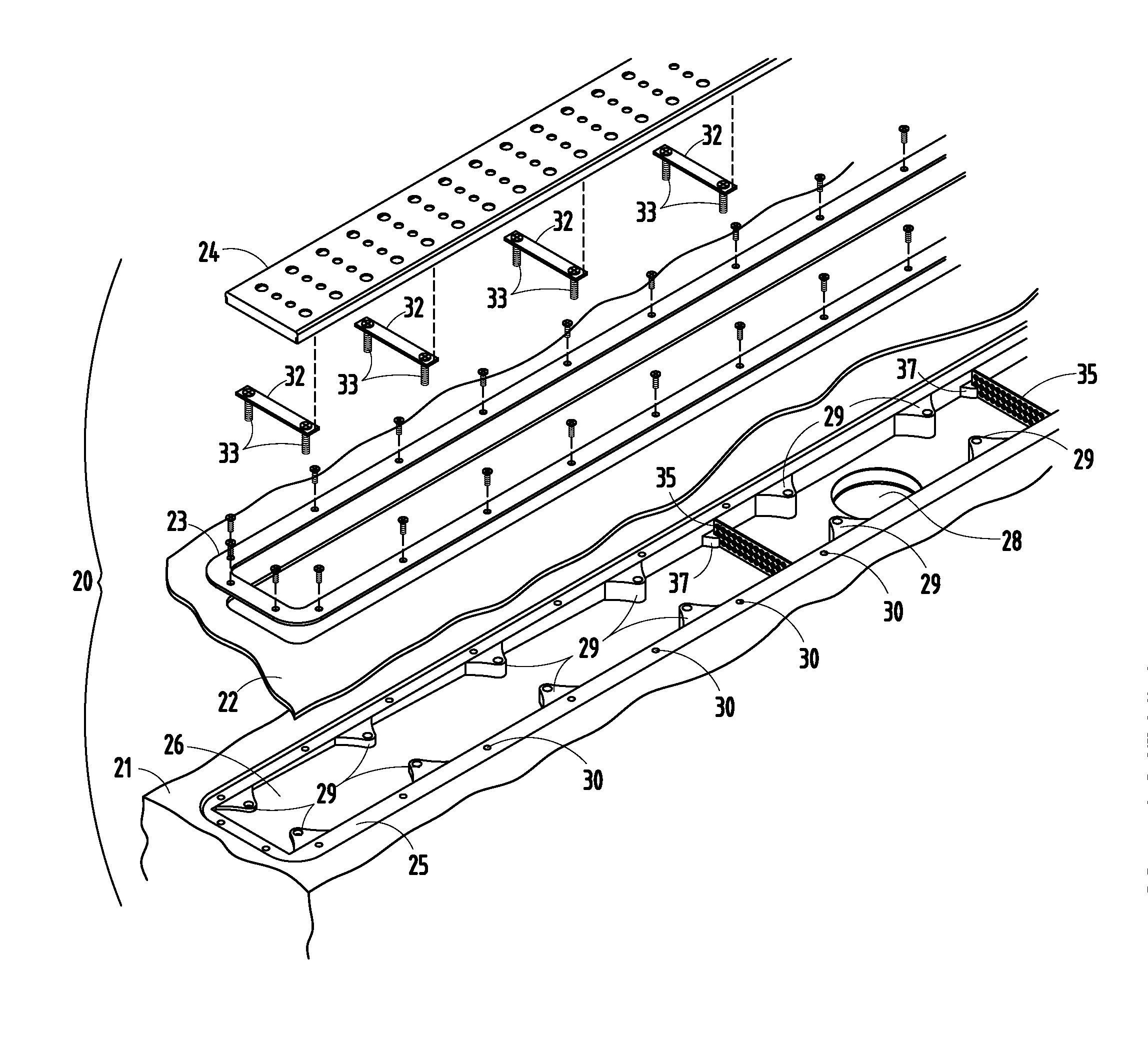

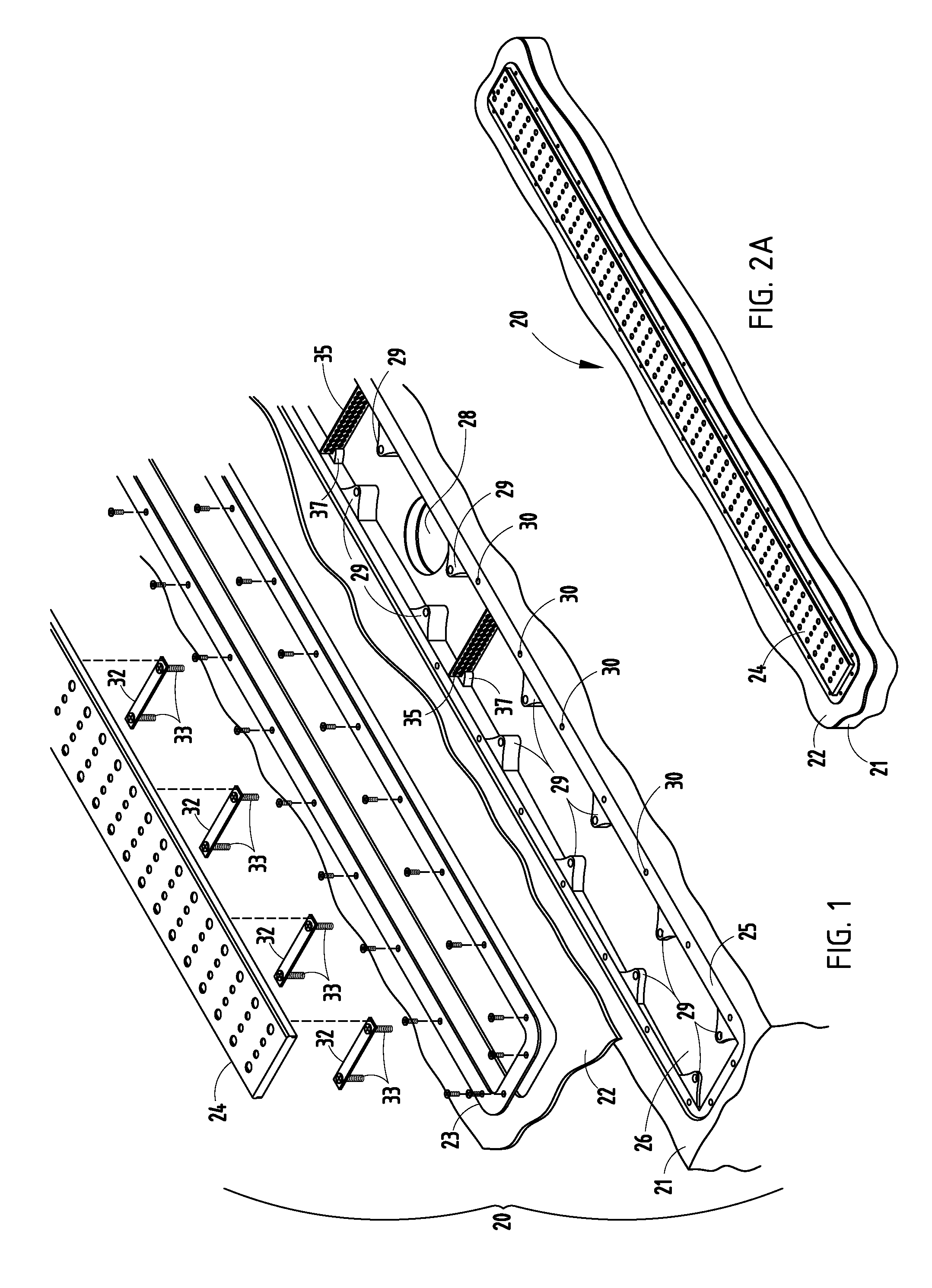

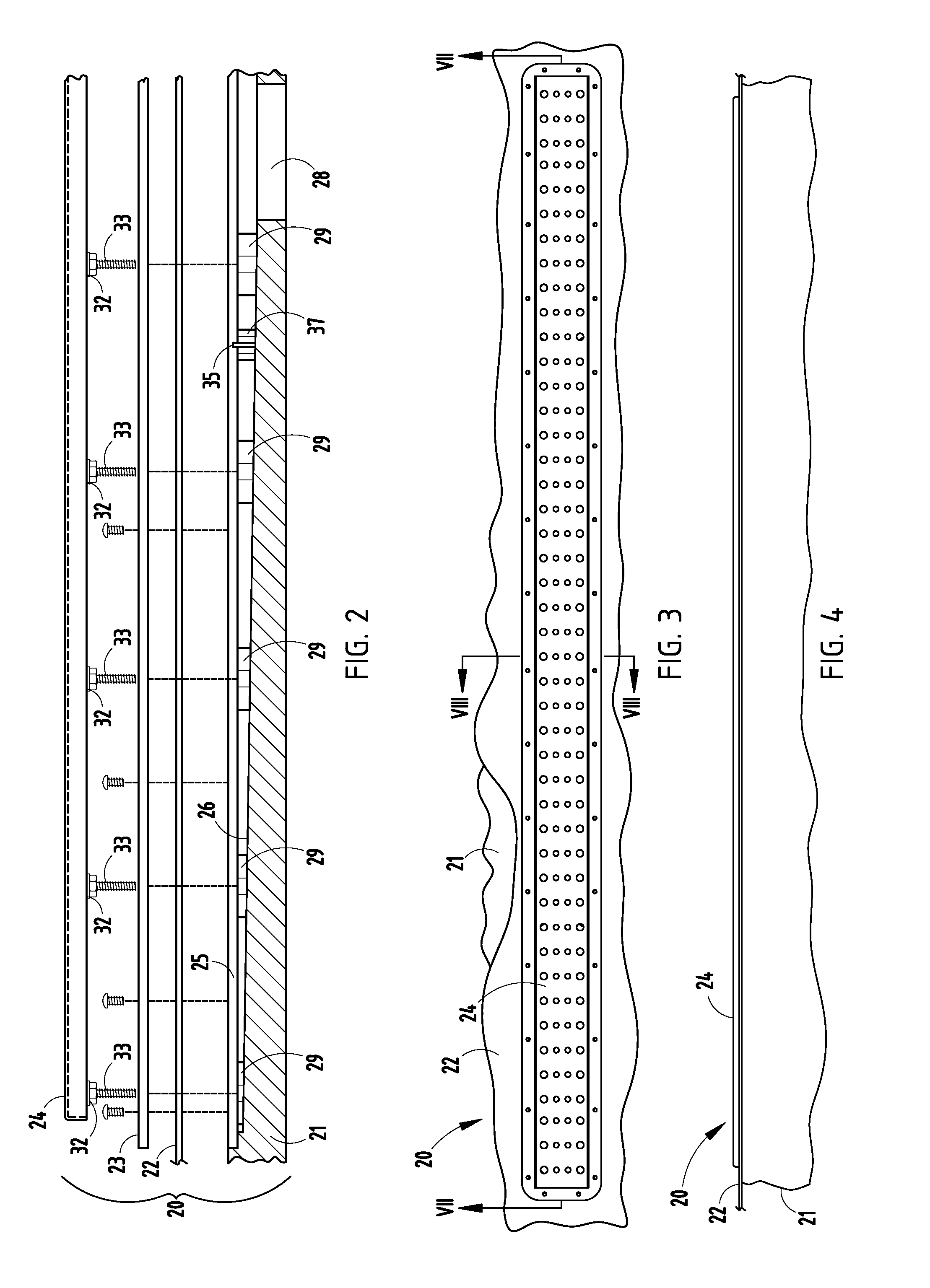

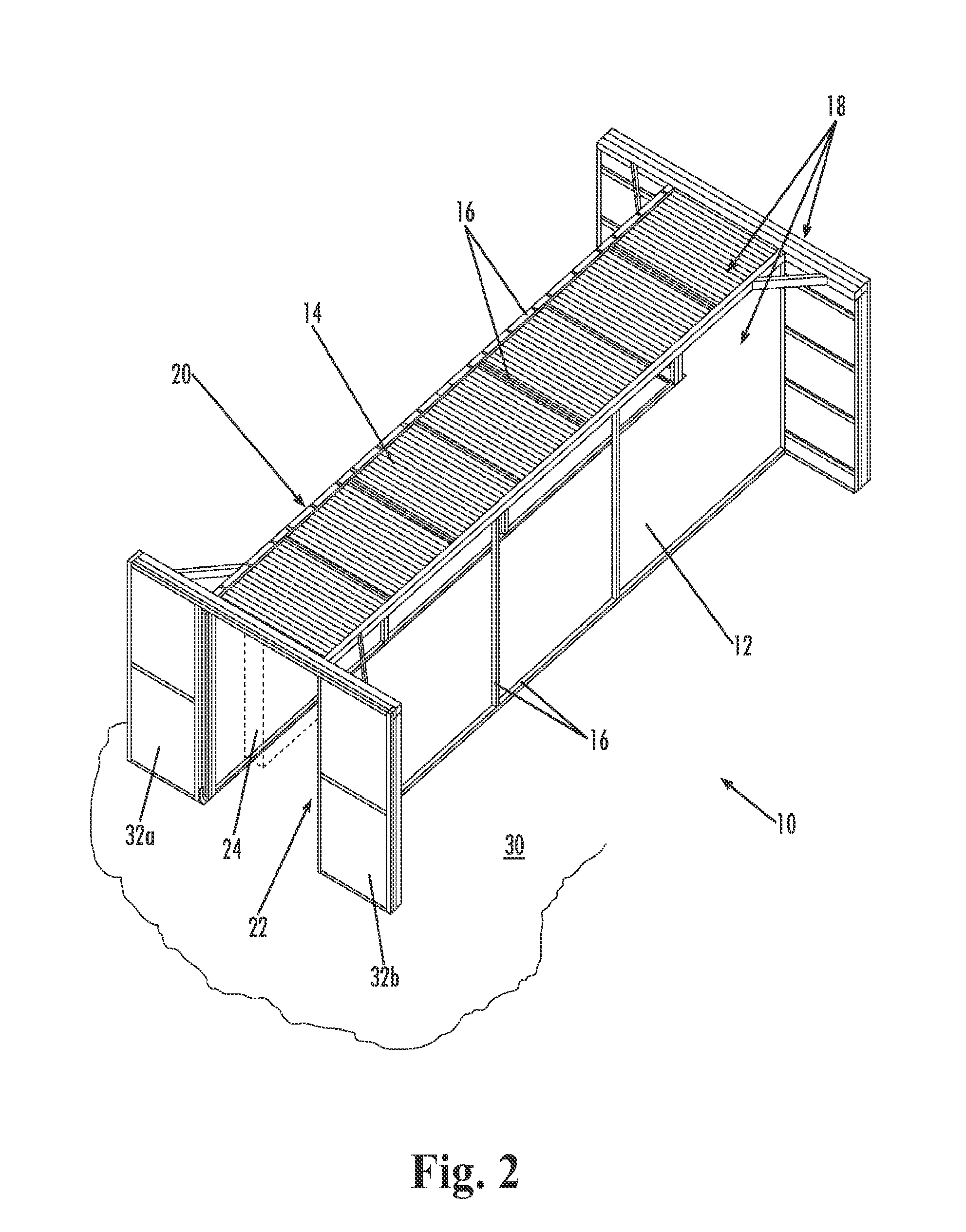

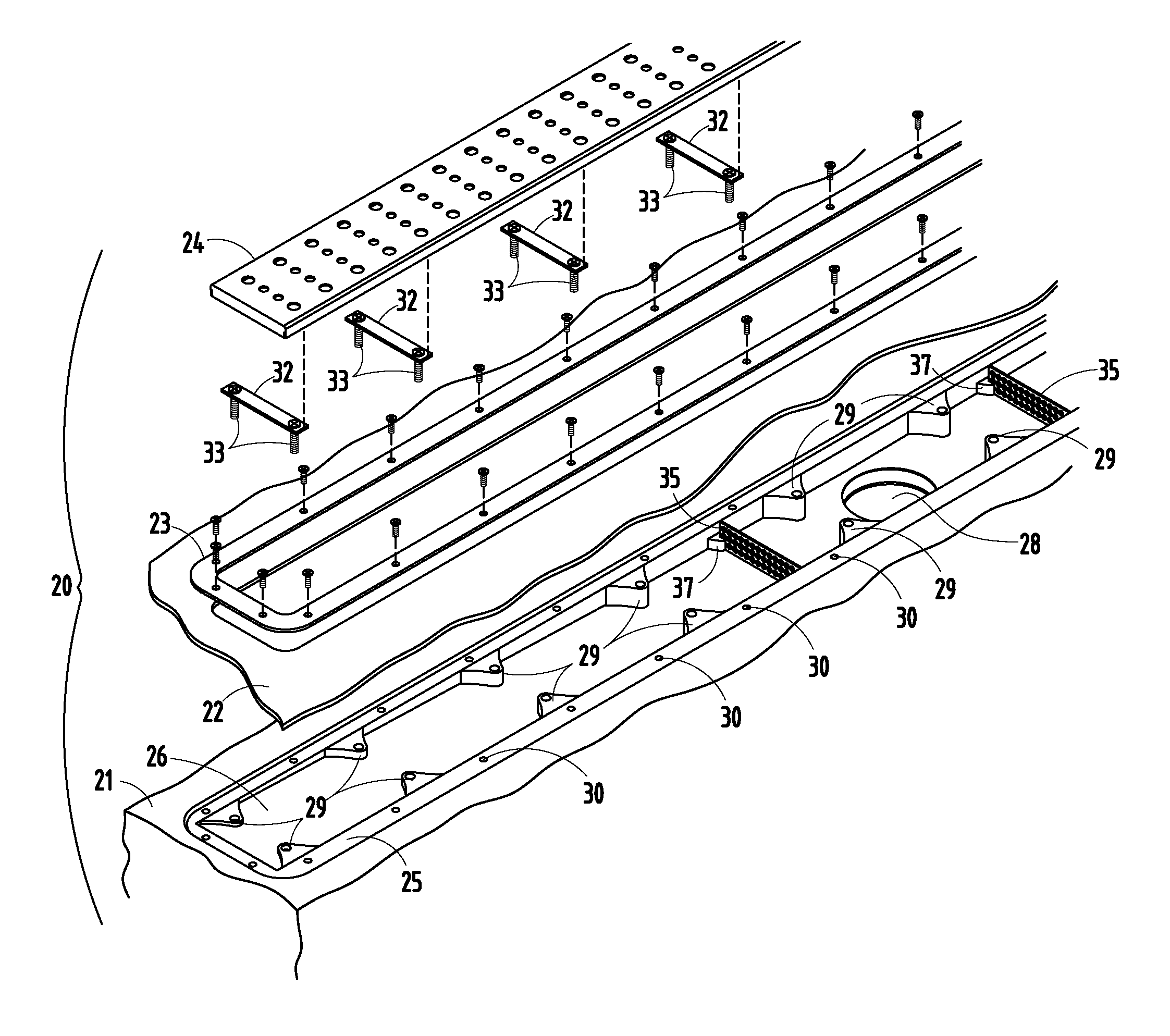

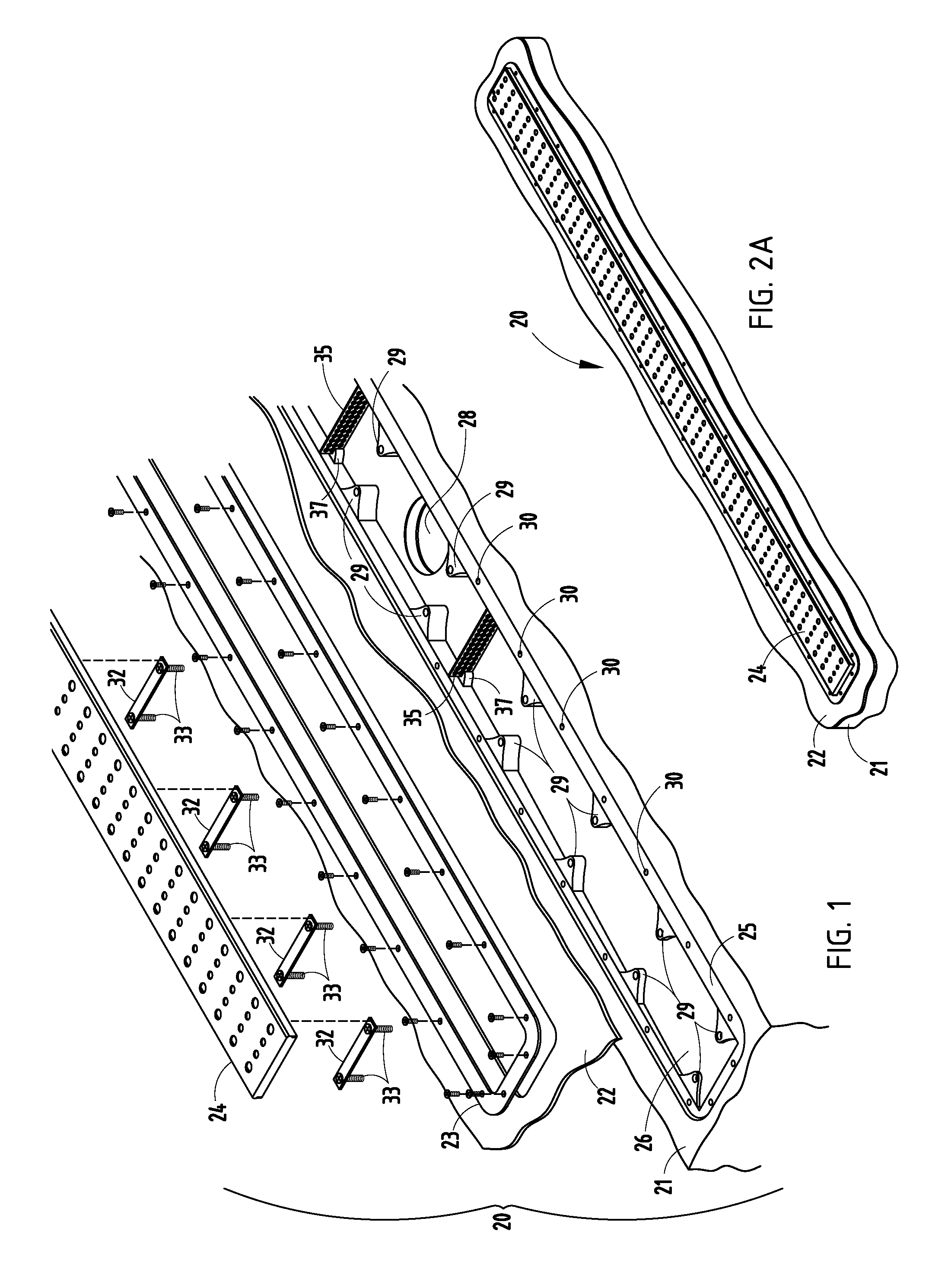

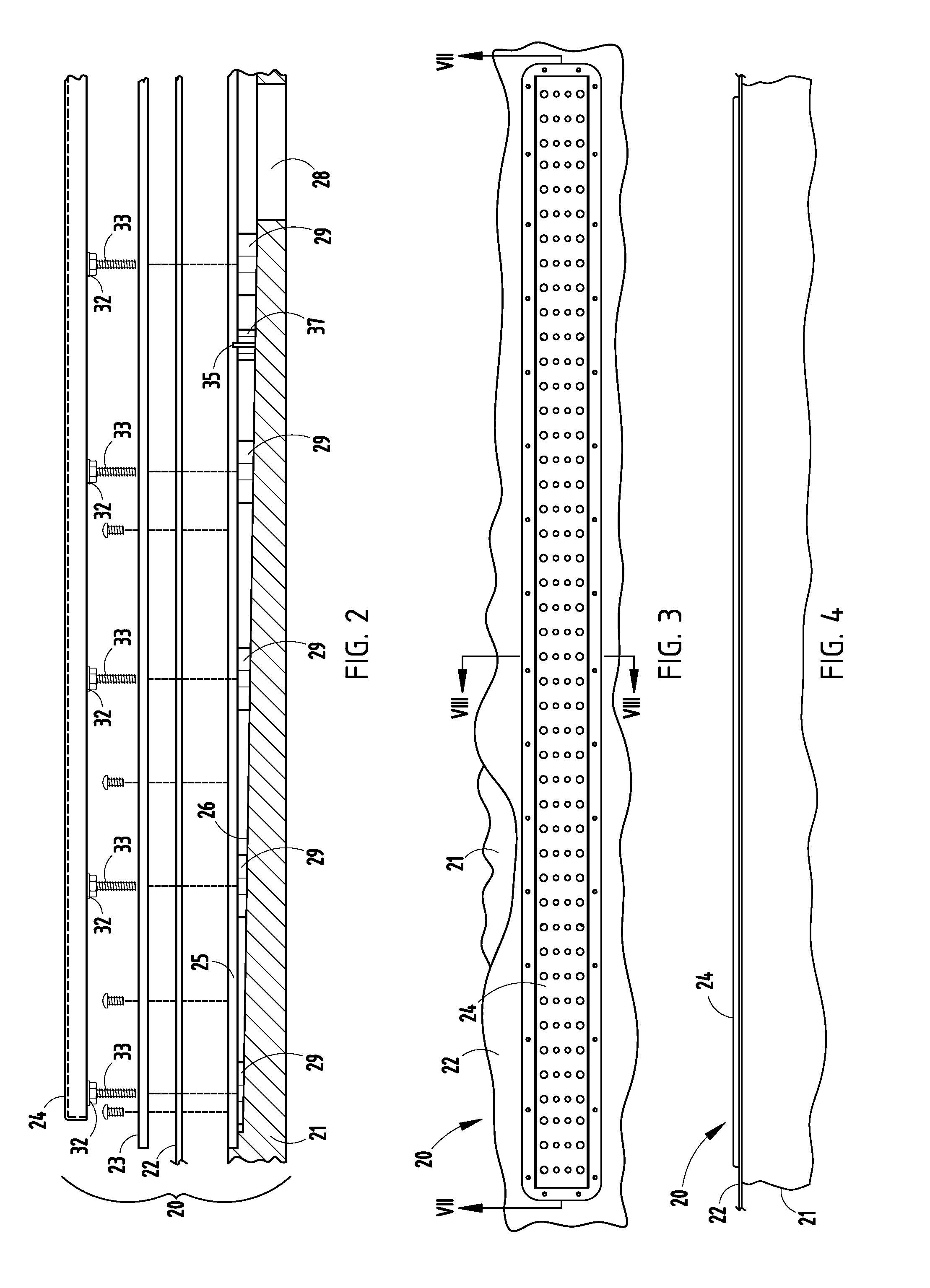

Trench shower drain

ActiveUS20110162137A1Reduce inventory costsMinimizes tooling investmentSewerage structuresClimate change adaptationEngineeringMechanical engineering

A shower trench drain apparatus includes a shower trench drain body of polymeric material having an integrally-formed drain channel with angled bottom surface and drain opening or openings, a waterproof membrane over the drain body, a clamp ring retaining the membrane to the drain body, and a grate adjustably retained to the drain body by a height adjustment mechanism. The trench drain body formed from a block of material such as PVC or ABS, which are compatible with approved plumbing materials and codes. The block has a flat bottom adapted for horizontal support during installation and includes integrally-formed features facilitating adjustment during installation while minimizing components and separate parts and simplicity of installation.

Owner:NOBLE CO LTD

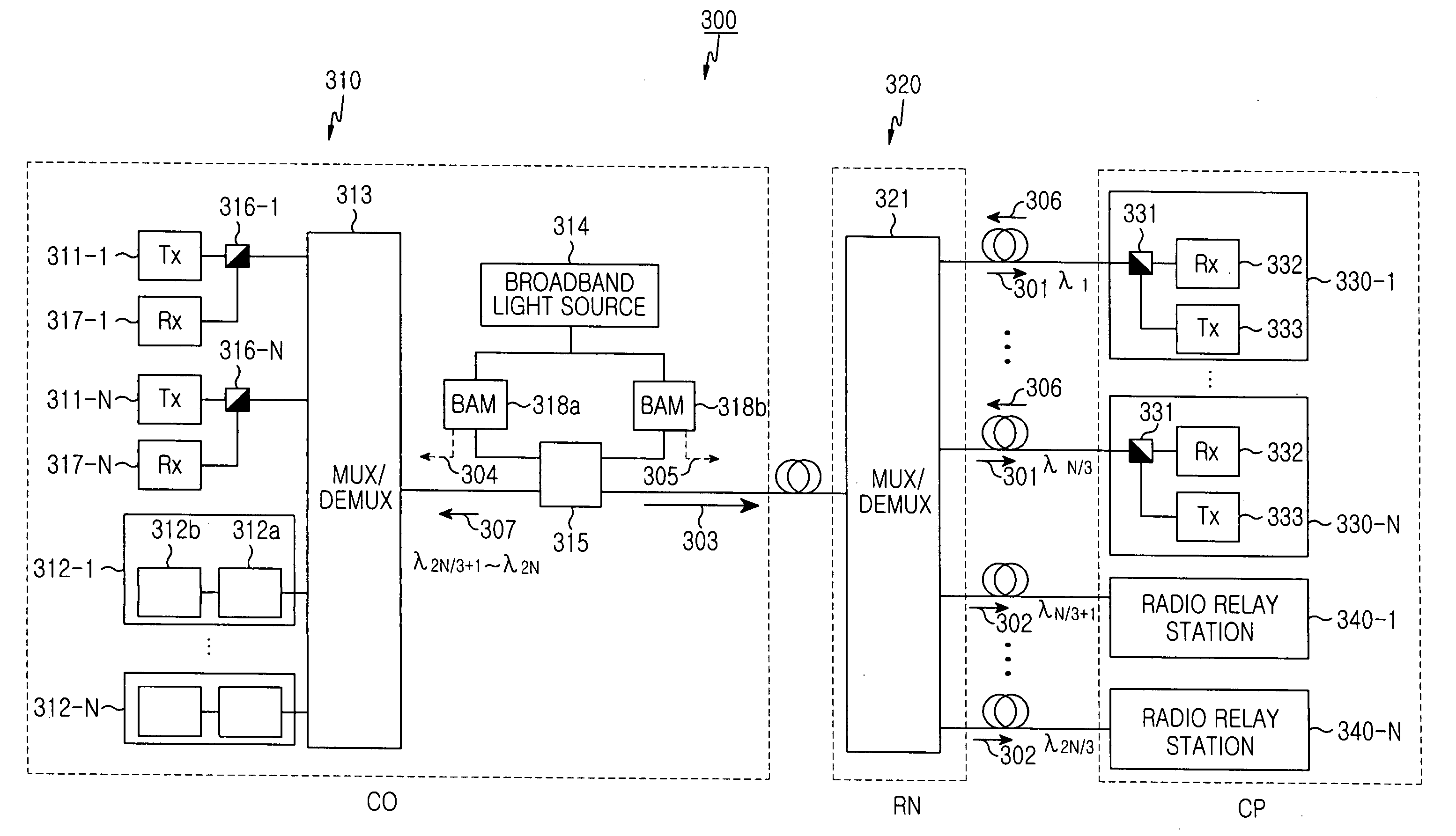

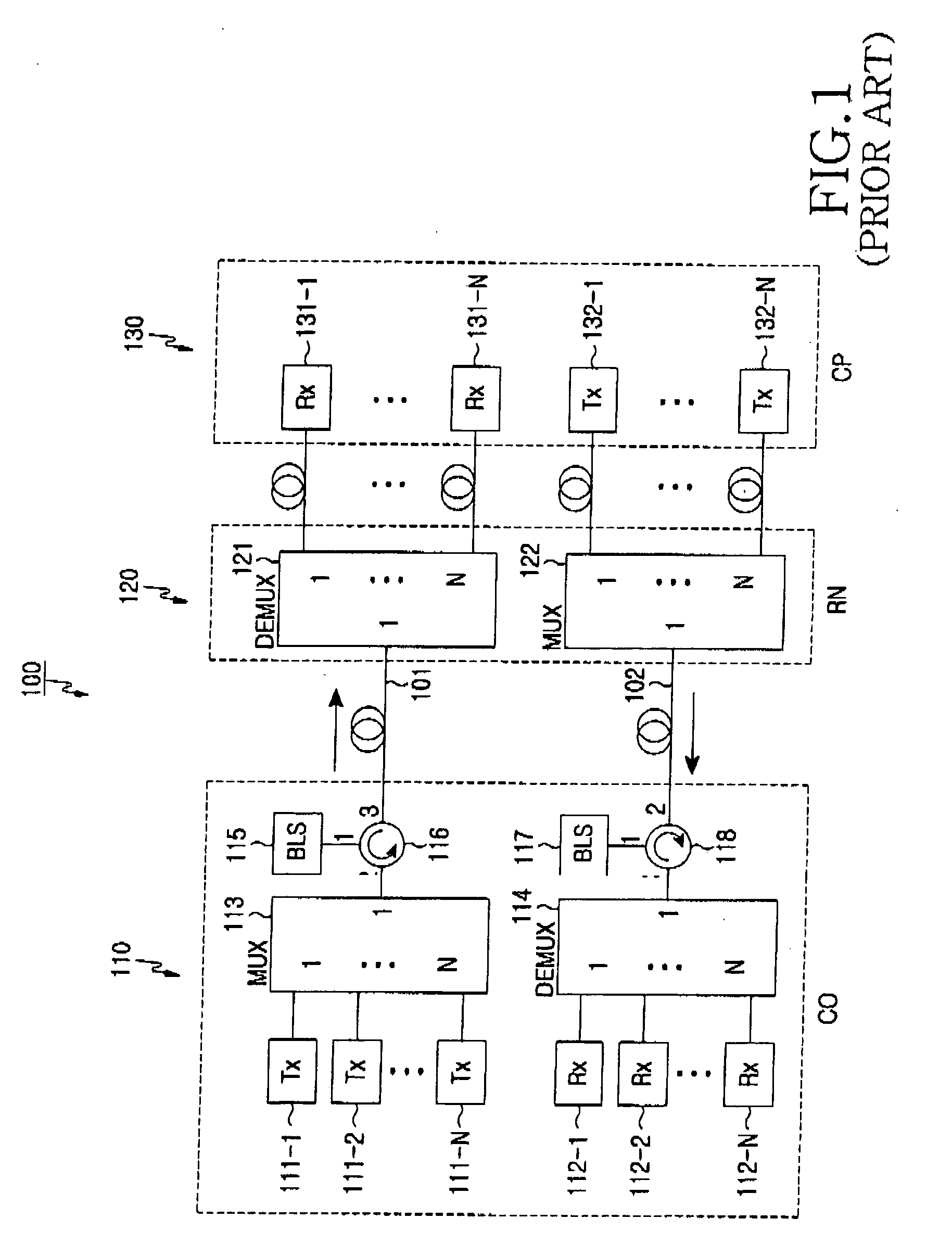

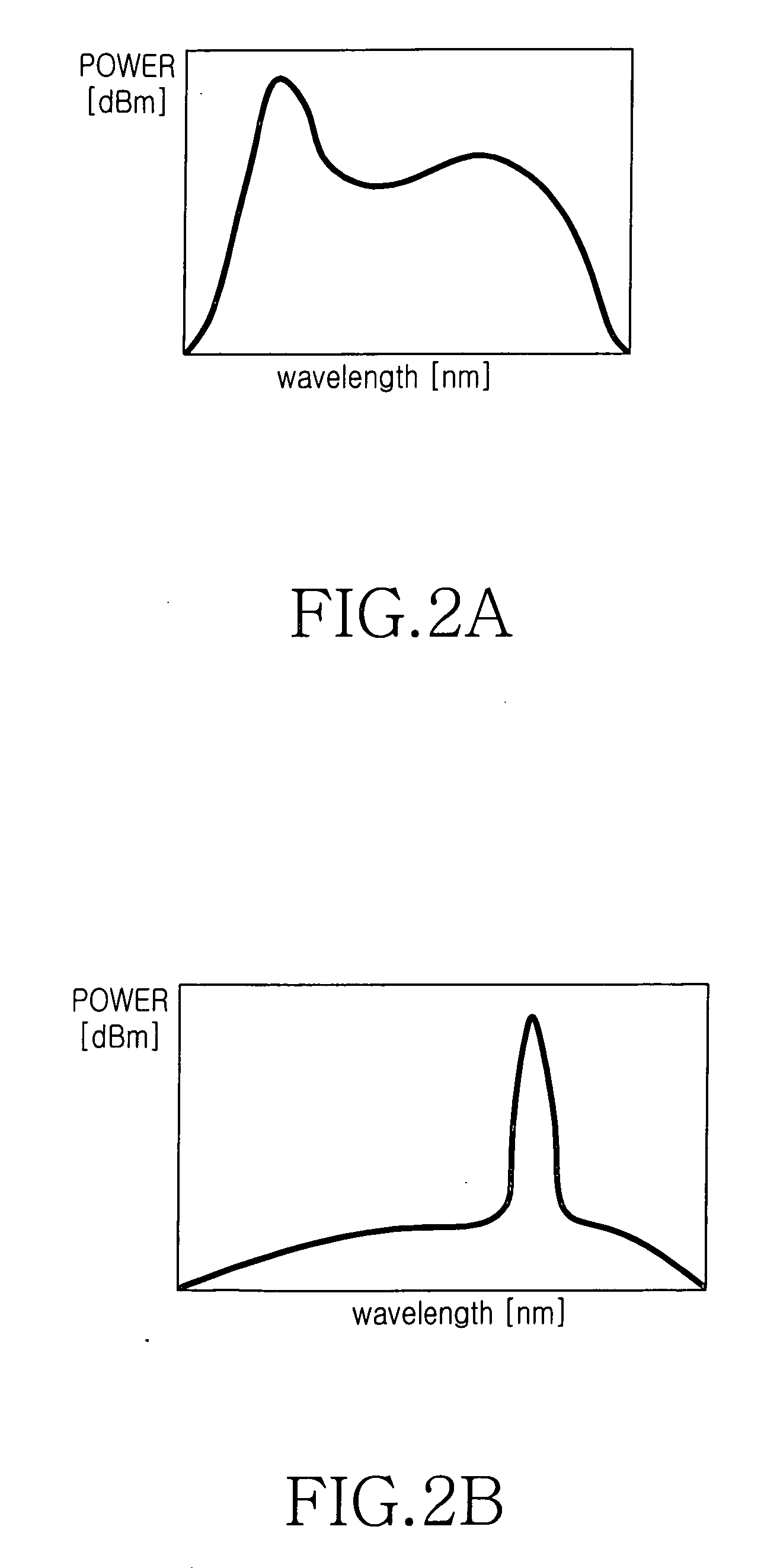

Optical access network of wavelength division method and passive optical network using the same

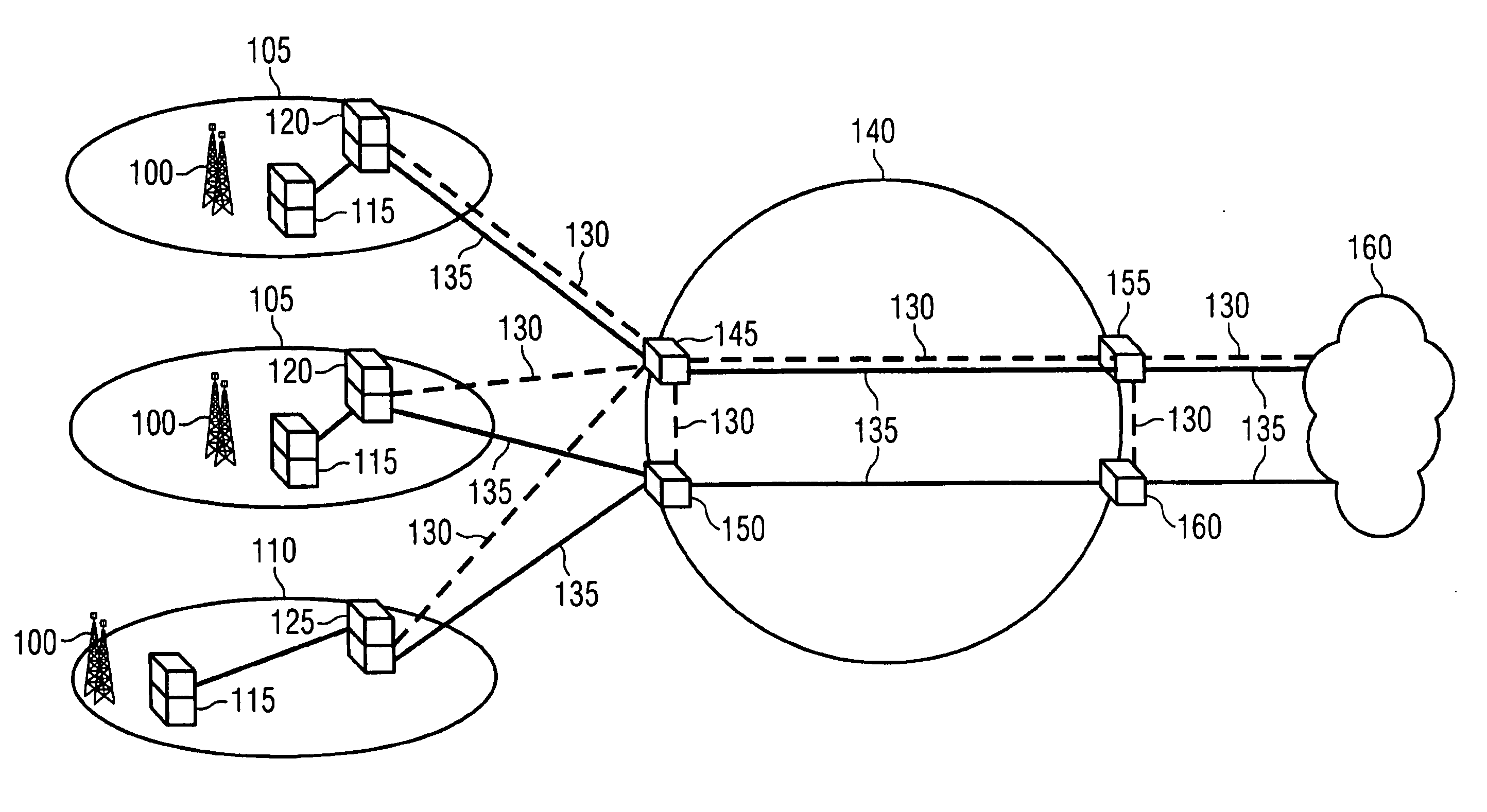

InactiveUS20060045524A1Minimize investmentLow costWavelength-division multiplex systemsMultimode transmissionAccess networkWired communication

An optical access network of wavelength division method and passive optical network using the same are disclosed. The wavelength division multiplexed optical access network includes a central office for multiplexing first optical signals for wire communication and second optical signals for wireless communication and a remote node connected to the central office through an optical fiber and for demultiplexing a multiplexed optical signal received from the central office. A plurality of subscribers may be connected to the remote node. Each subscriber receives a first optical signal having a corresponding wavelength from among the demultiplexed first optical signals. The network also includes a plurality of radio relay stations connected to the remote node, each radio relay station converting a second optical signal having a corresponding wavelength from among the demultiplexed second optical signals into a radio electric signal and wirelessly transmitting the radio electric signal.

Owner:SAMSUNG ELECTRONICS CO LTD

Energy saving system and method for cooling computer data center and telecom equipment

ActiveUS8498114B2Effective spaceEfficient use ofMechanical apparatusSpace heating and ventilation safety systemsElectricityData center

Owner:MARTINI VALAN R

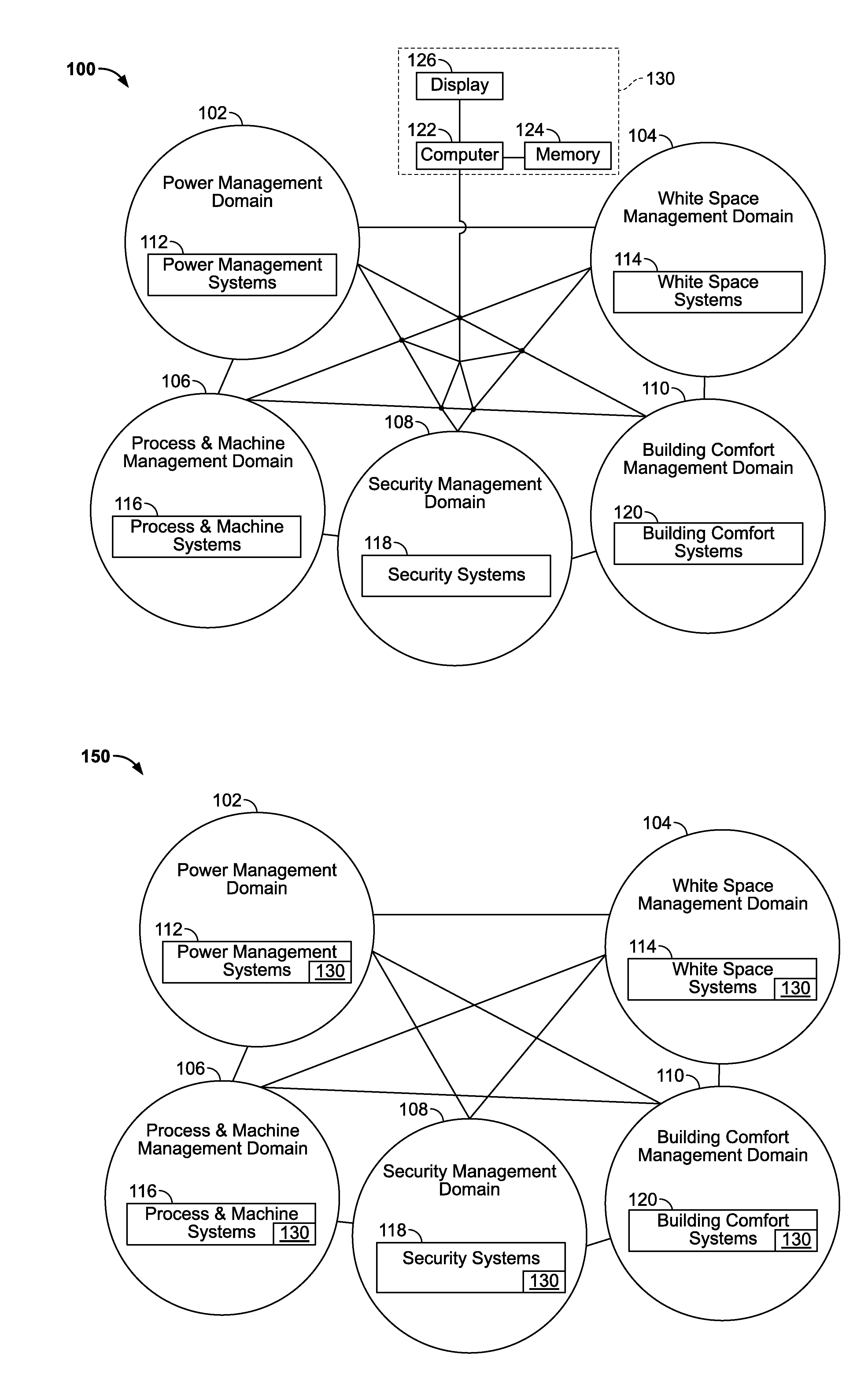

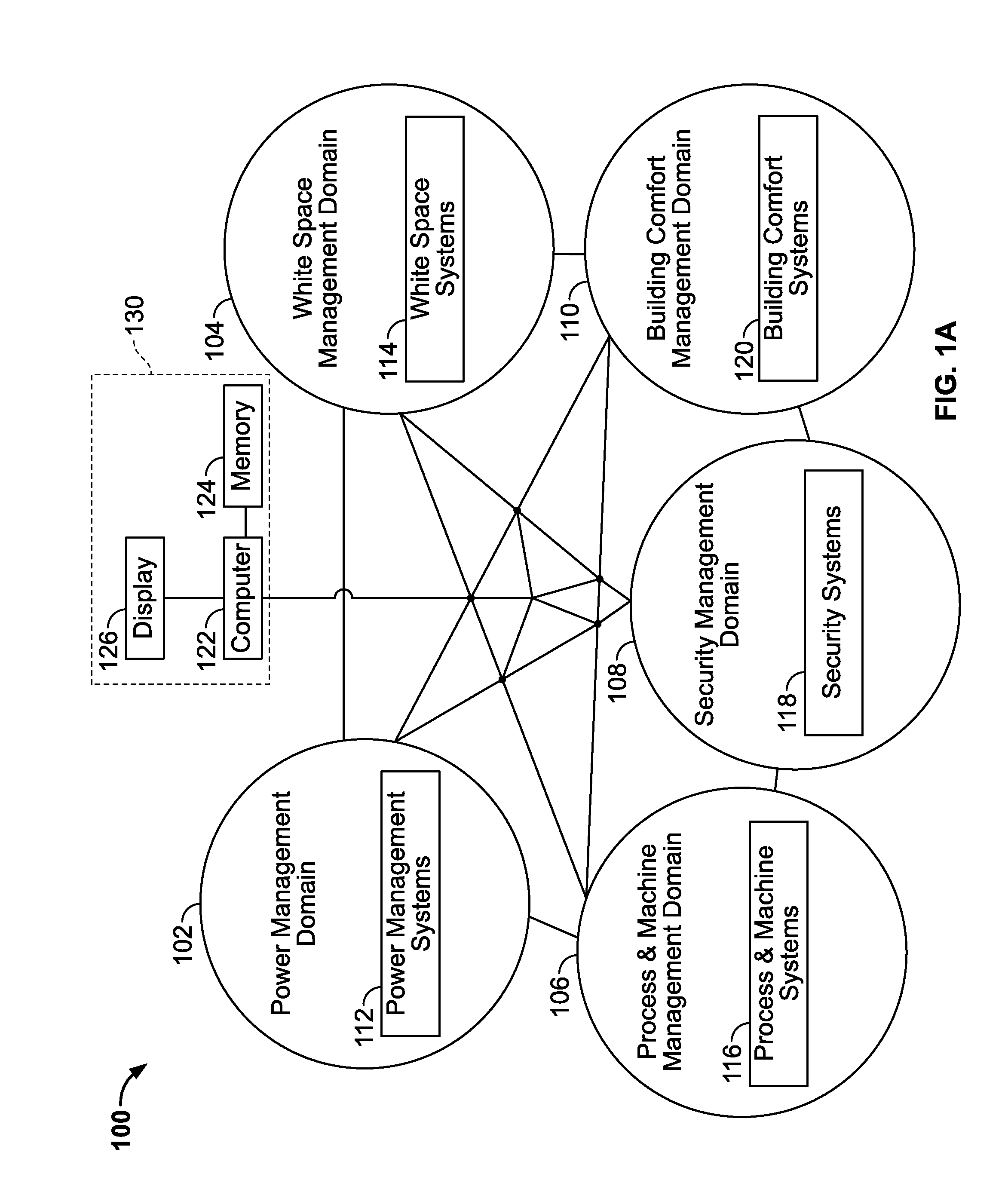

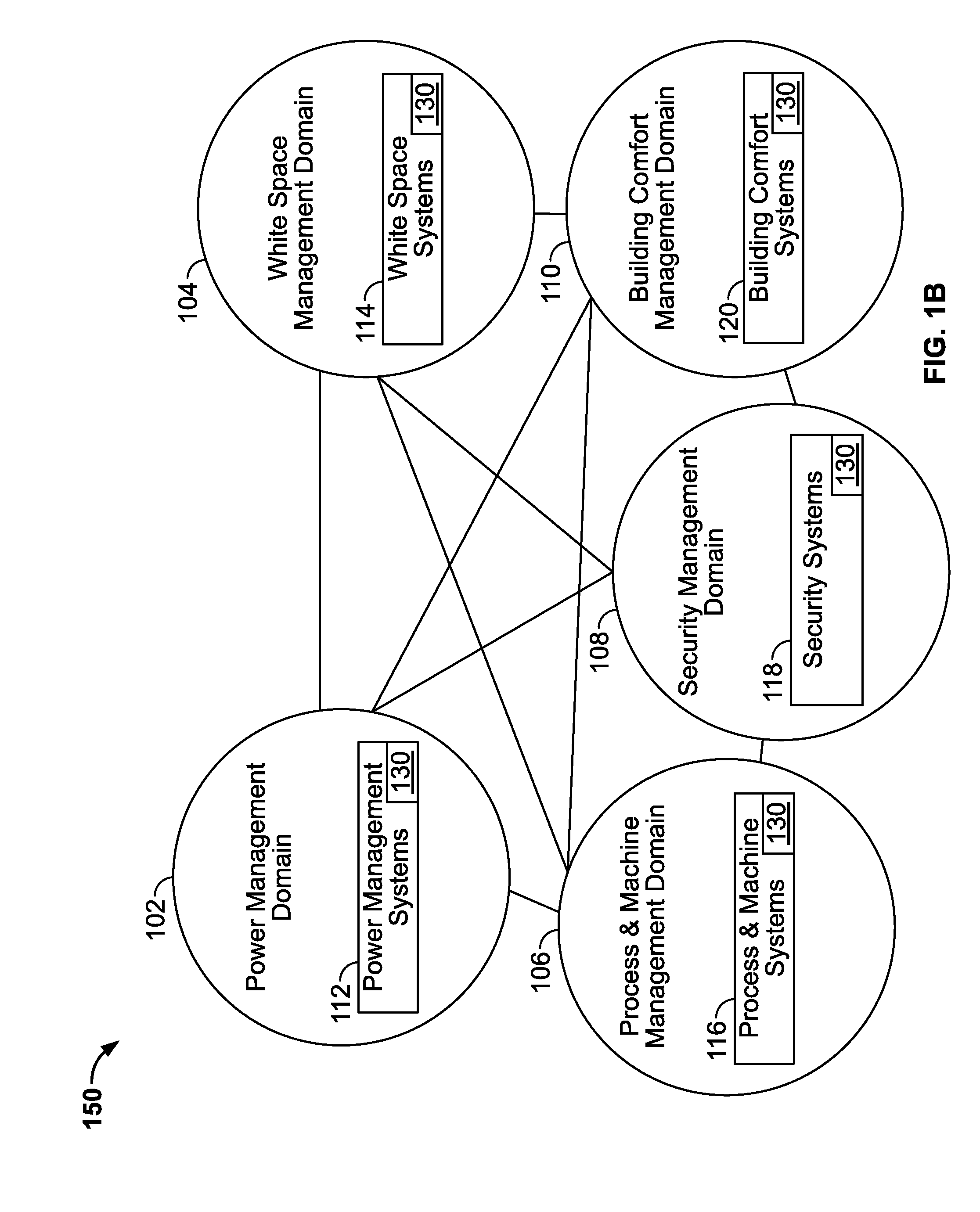

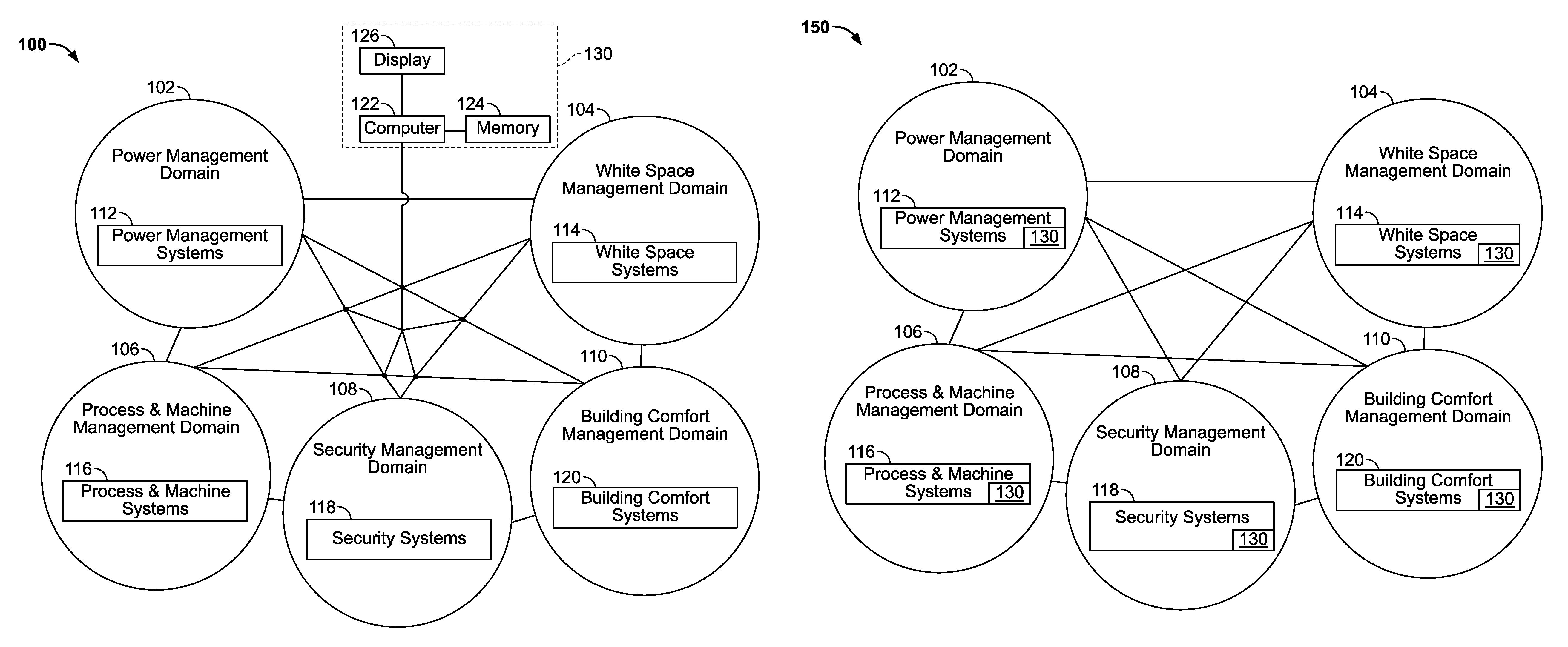

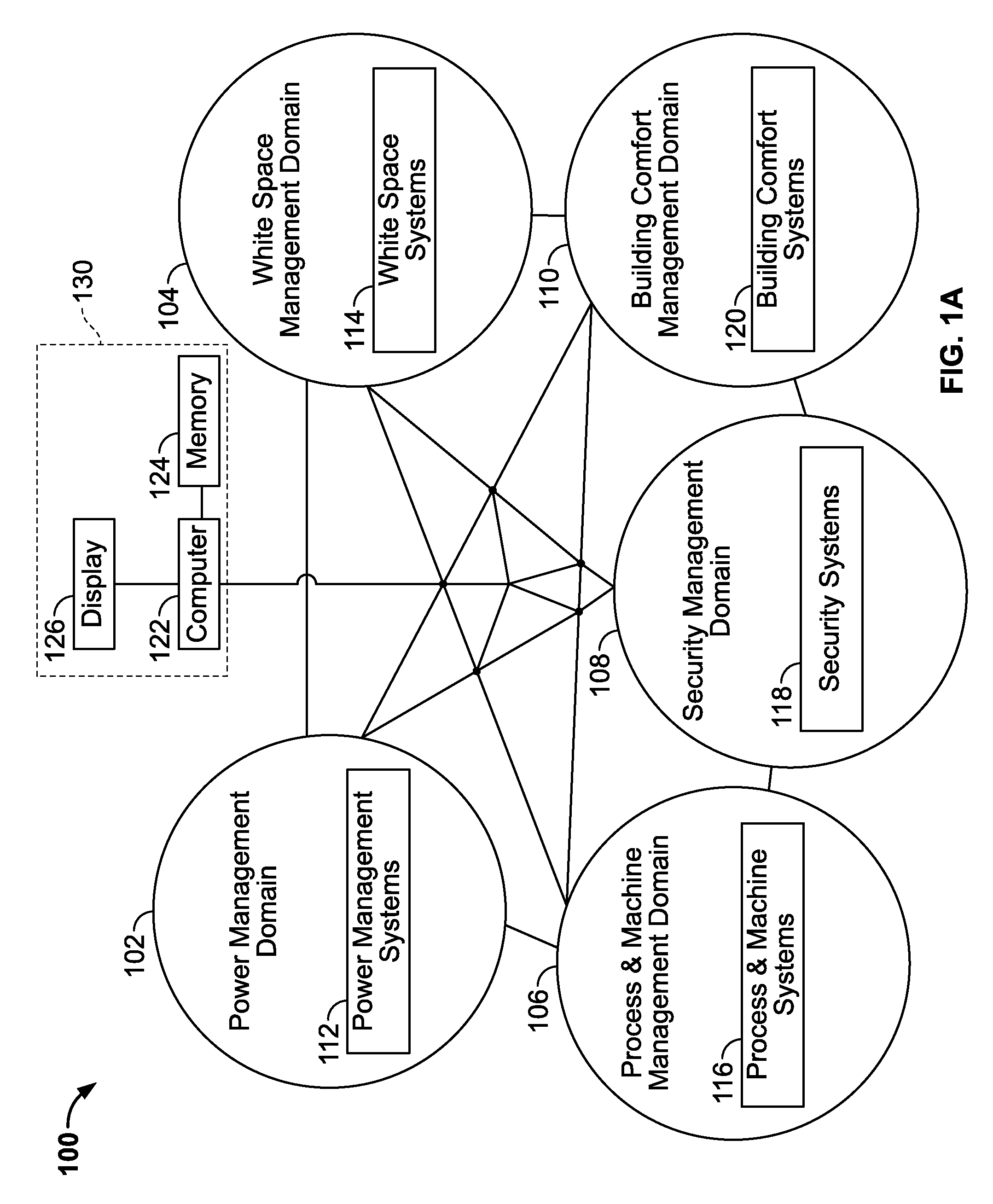

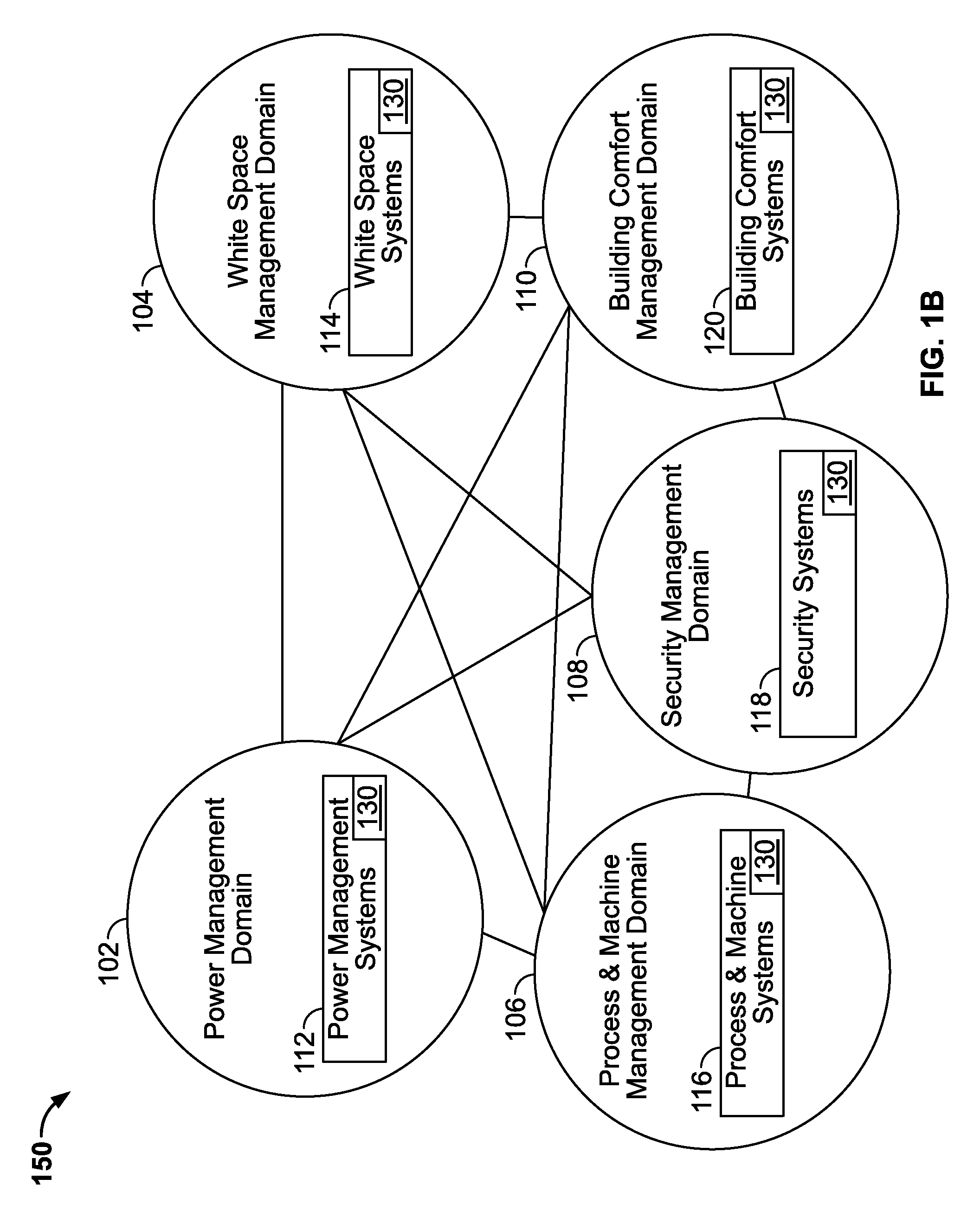

Methods of integrating multiple management domains

ActiveUS20120131217A1Increase controlReduce energy usageMechanical apparatusSpace heating and ventilation safety systemsPower usage effectivenessIntegrated approach

An integrated solution strategy that integrates multiple domains together in a seamless and standardized way for increasing a users control over facilities and equipment. This integrated approach can lead to a reduction of energy usage, more efficient energy usage, increased safety, health, and security of a facility and its occupants, optimized production in industrial settings, and associated and other economic advantages. Accurate, reliable information about a facility or equipment is essential to making timely, informed decisions. Enhanced automation provides a reliable means of collecting and assembling a variety of operating data and archiving that data into a central database for evaluation, reporting, forecasting, and negotiation with resource marketers.

Owner:SCHNEIDER ELECTRIC USA INC

Trench shower drain

ActiveUS8474068B2Very waterproofLow costSewerage structuresClimate change adaptationEngineeringDrainage tubes

Owner:NOBLE CO LTD

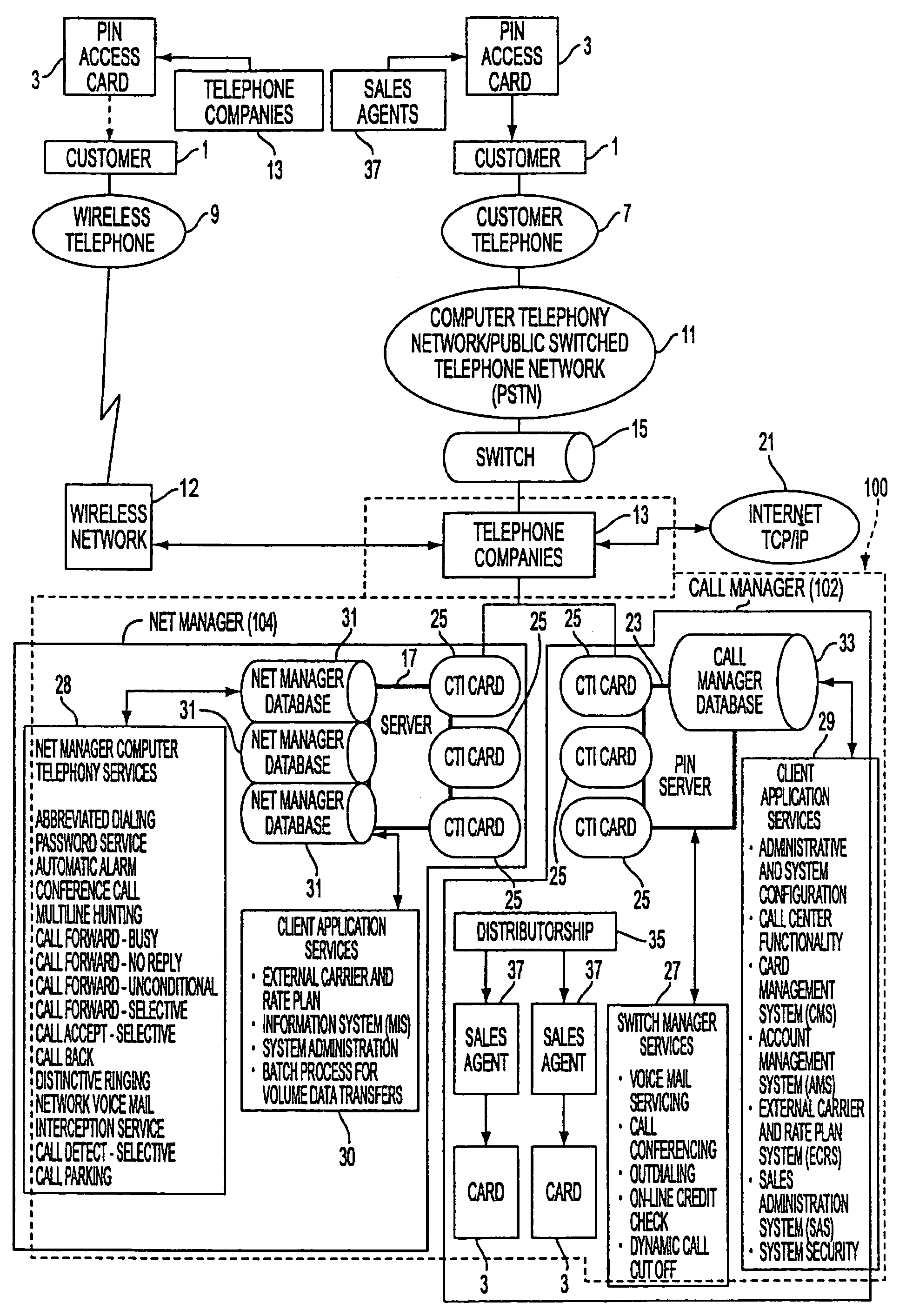

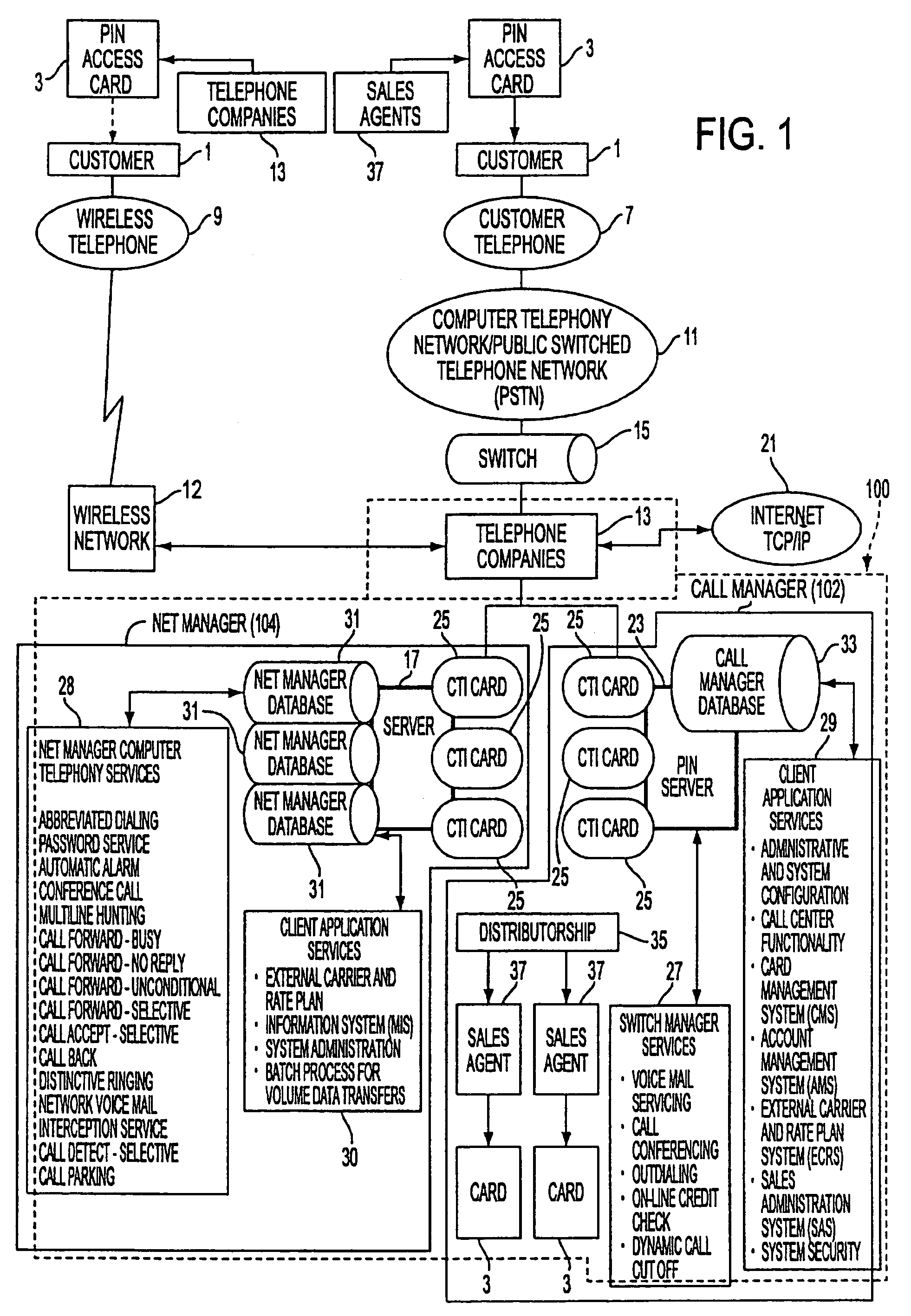

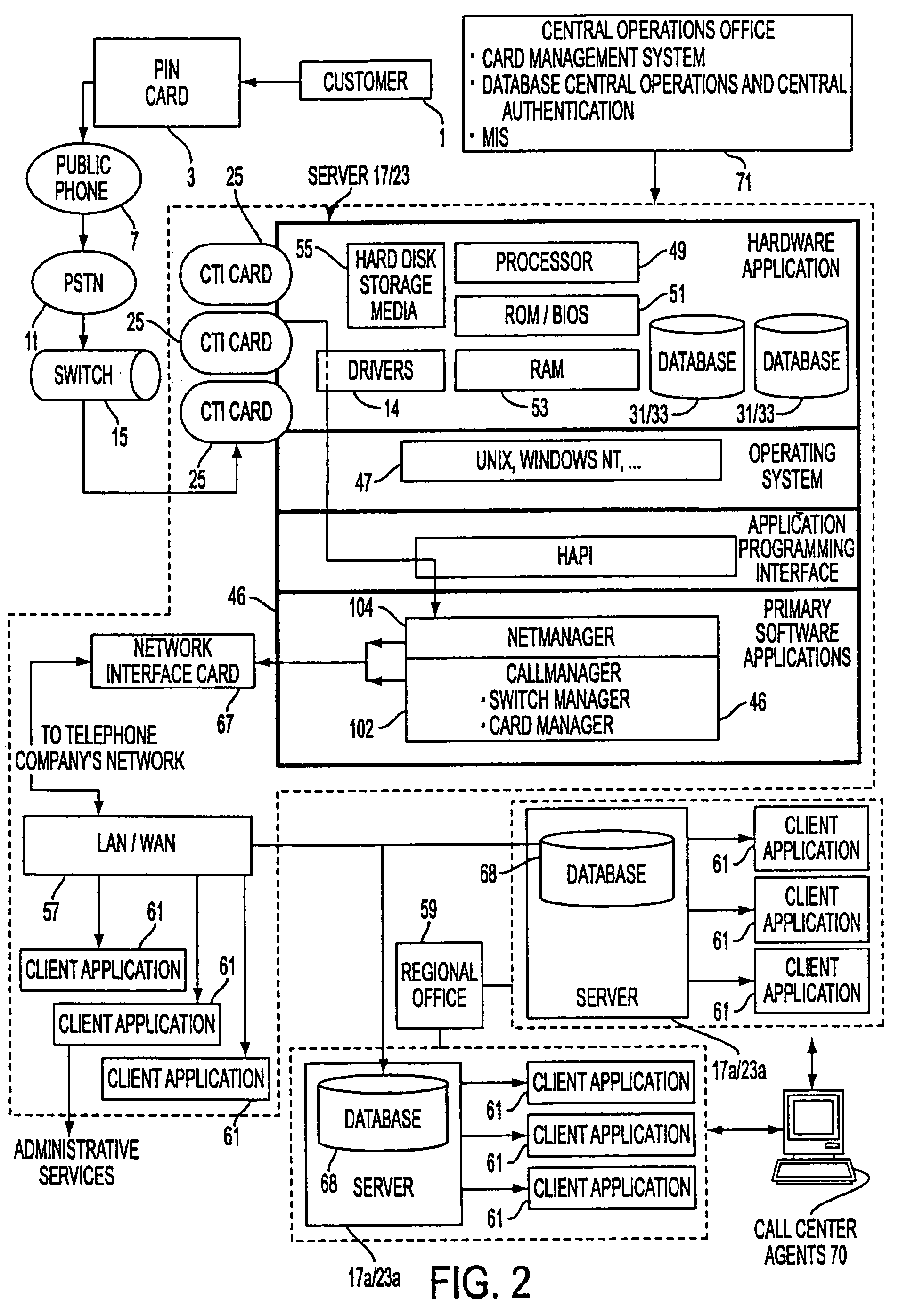

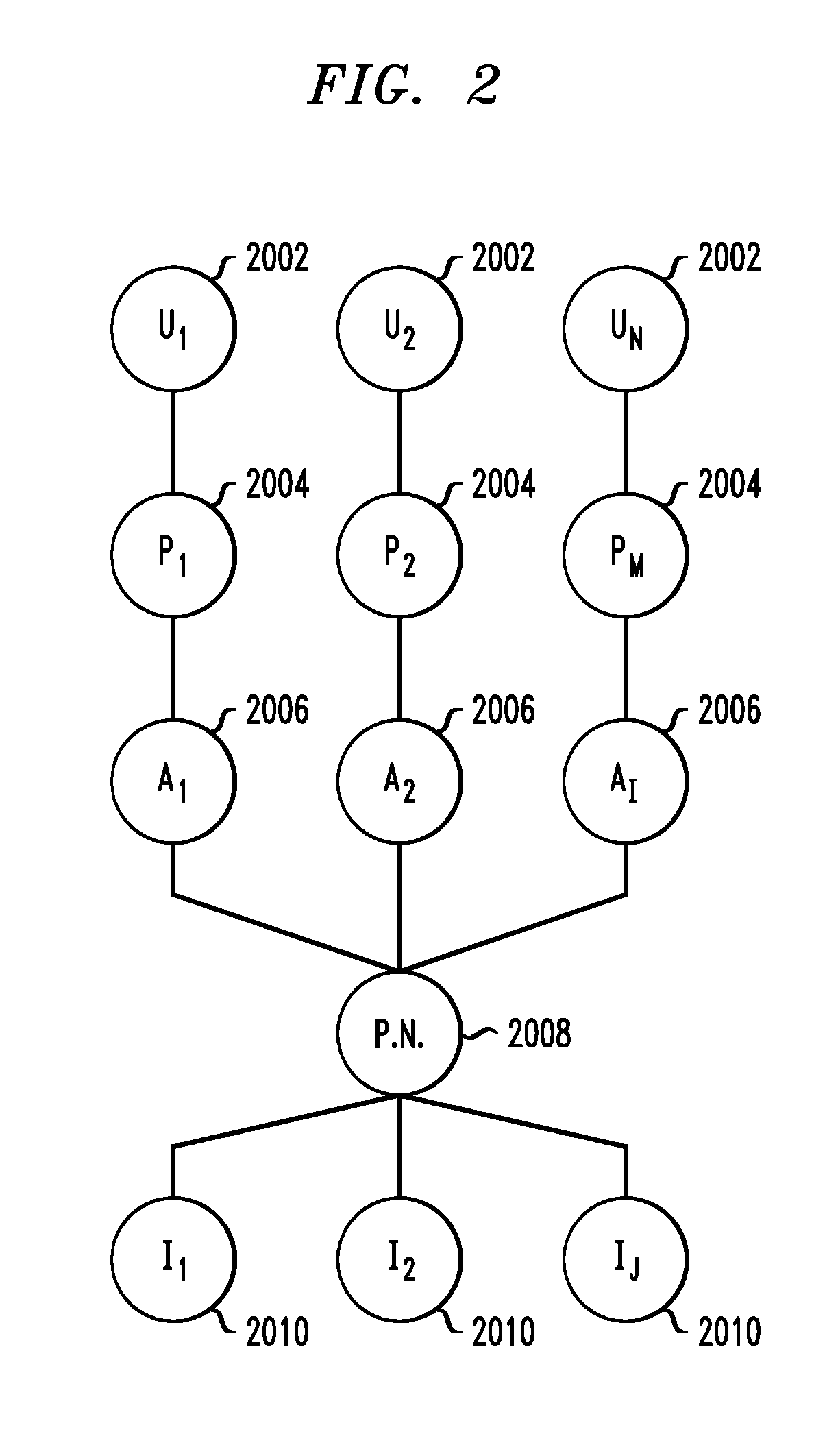

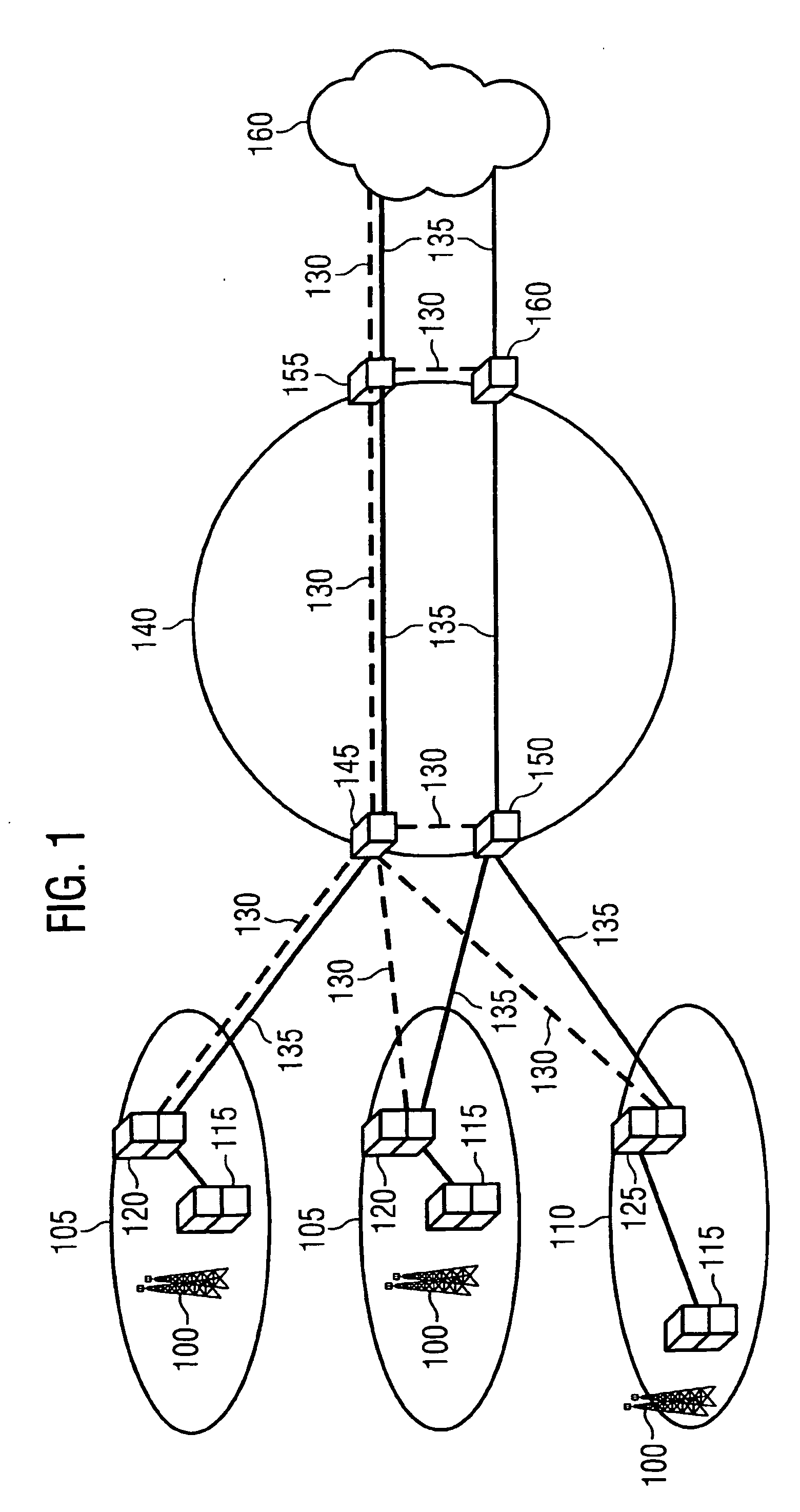

Enhanced communication platform and related communication method using the platform

InactiveUS7308087B2Minimize investmentImprove communication serviceMultiplex system selection arrangementsAccounting/billing servicesPayment

A method of providing pre-authorized communication services and / or transactions via a plurality of networks, including accepting and processing a request from a user to provide at least one of a communication service, a transaction and user account information via a plurality of networks of different types, verifying that the user is authorized to receive the at least one of the communication service, the transaction, and the user account information, and that an account associated with the user has a sufficient amount currently available for payment of the at least one of the communication service and the transaction and charging, in real time, an authorized account associated with the user as the at least one of the communication service and the transaction is provided.

Owner:UPAID SYST LTD

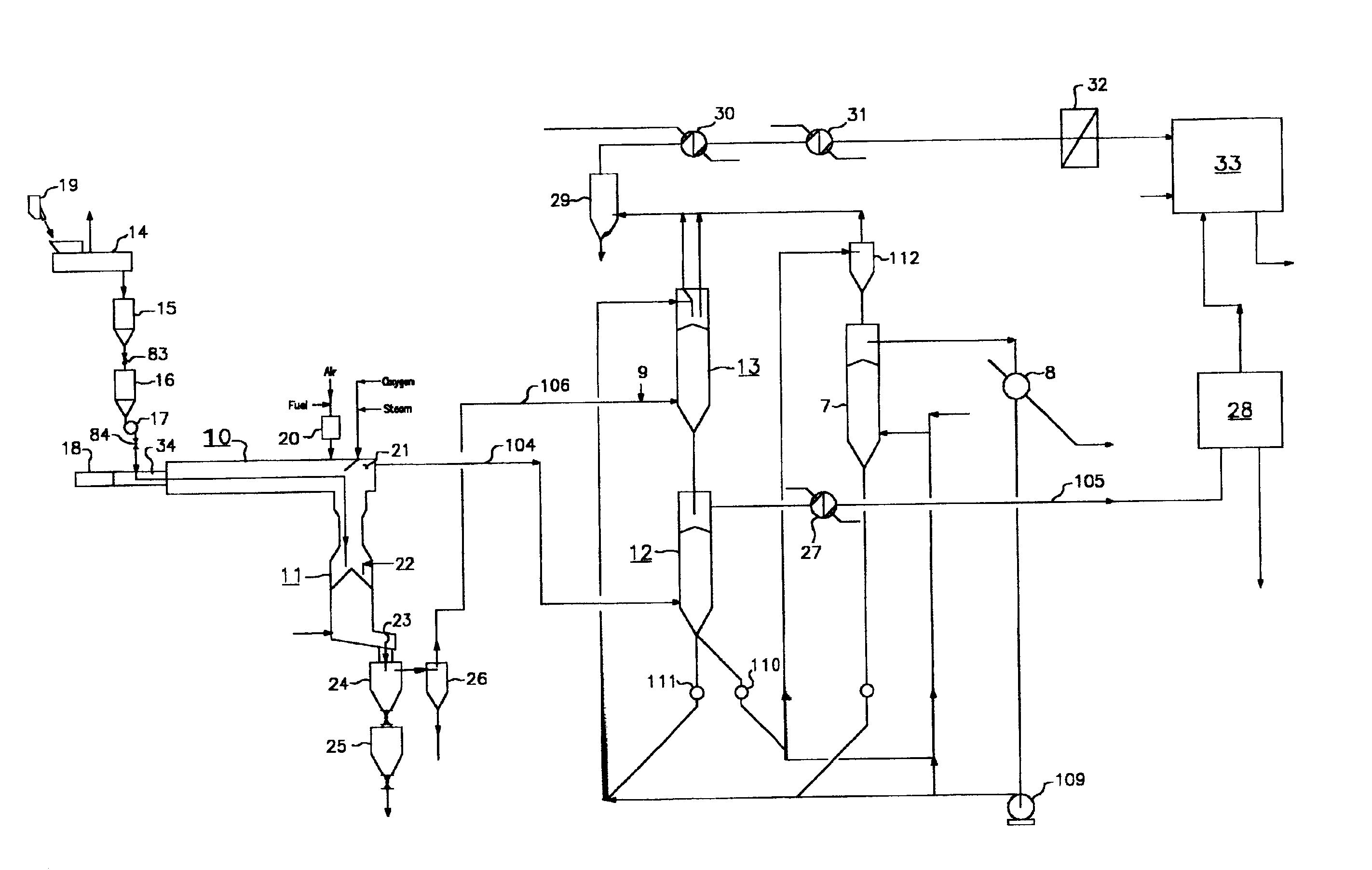

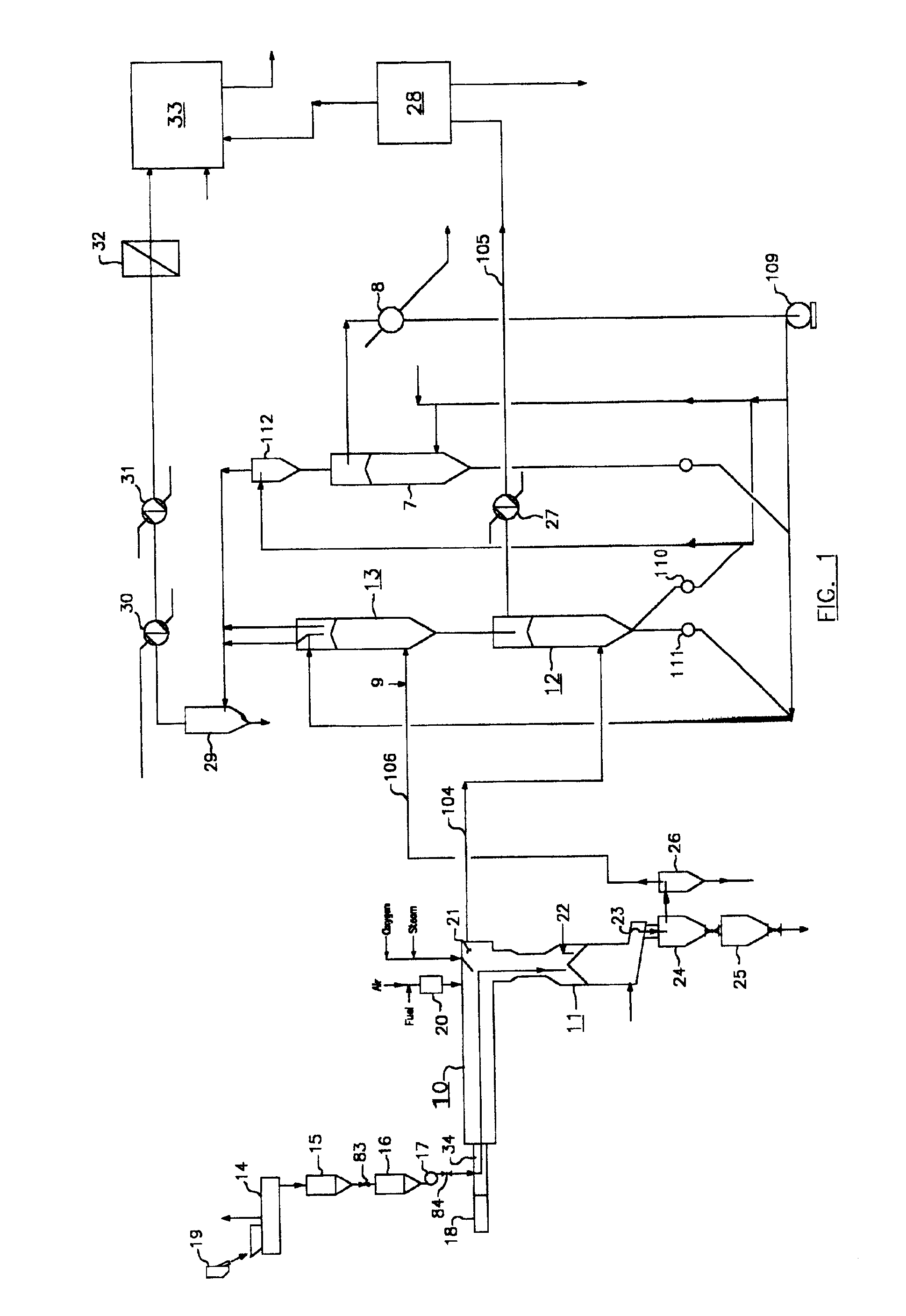

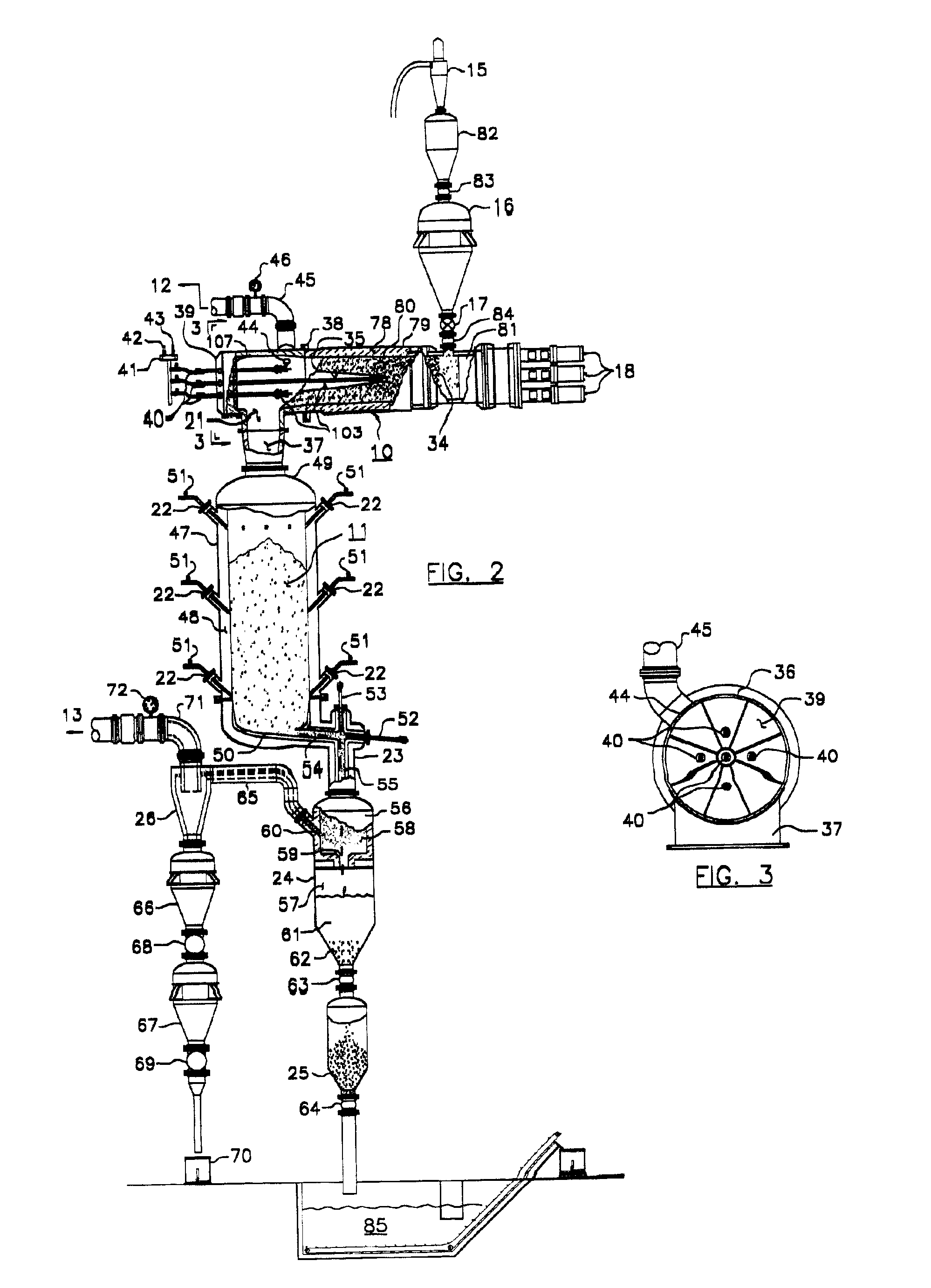

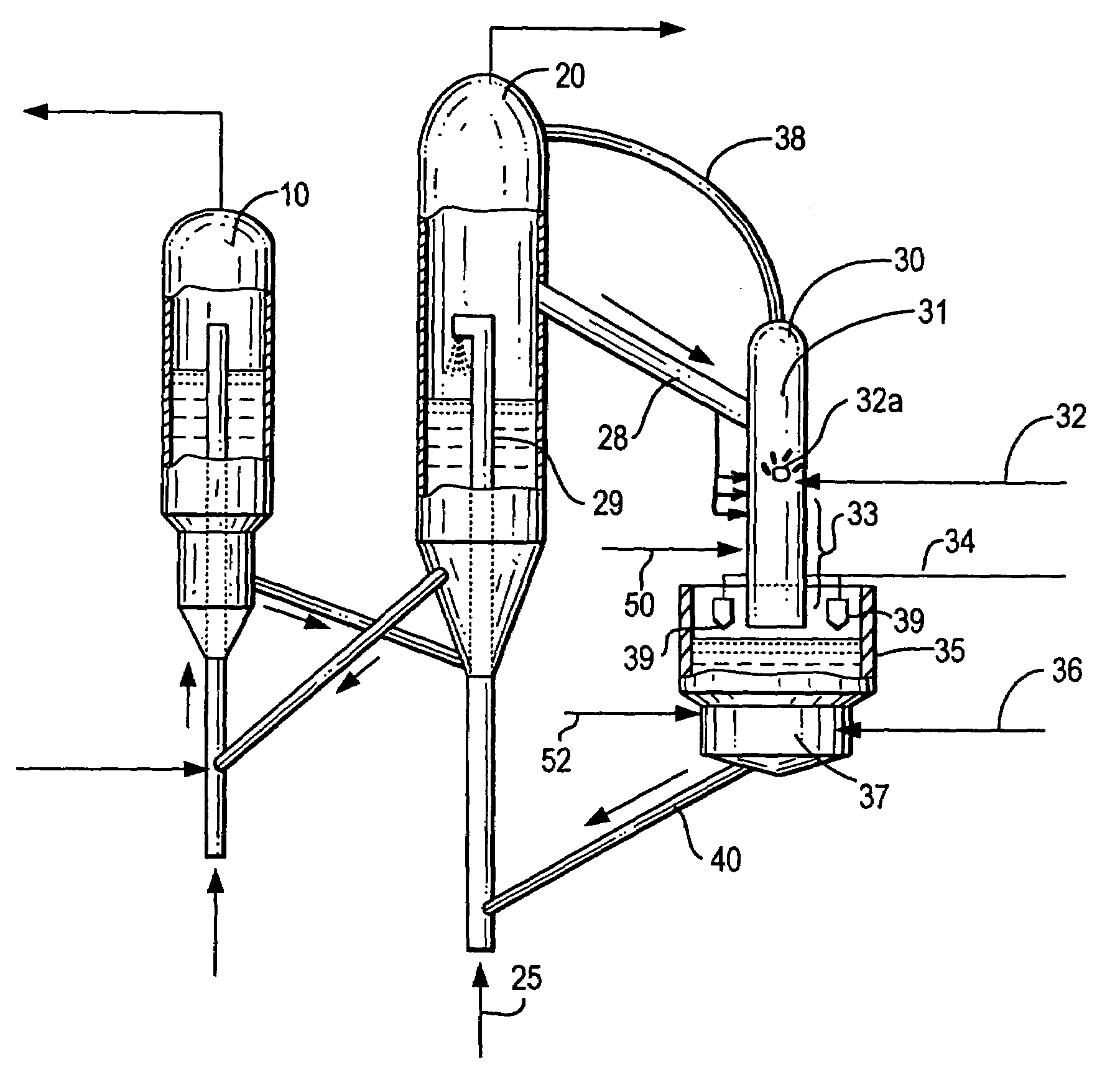

Method for producing clean energy from coal

InactiveUS6911058B2Produce energyImprove efficiencyThermal non-catalytic crackingMuffle furnacesActivated carbonGas turbines

Owner:CALDERON SYNGAS CO

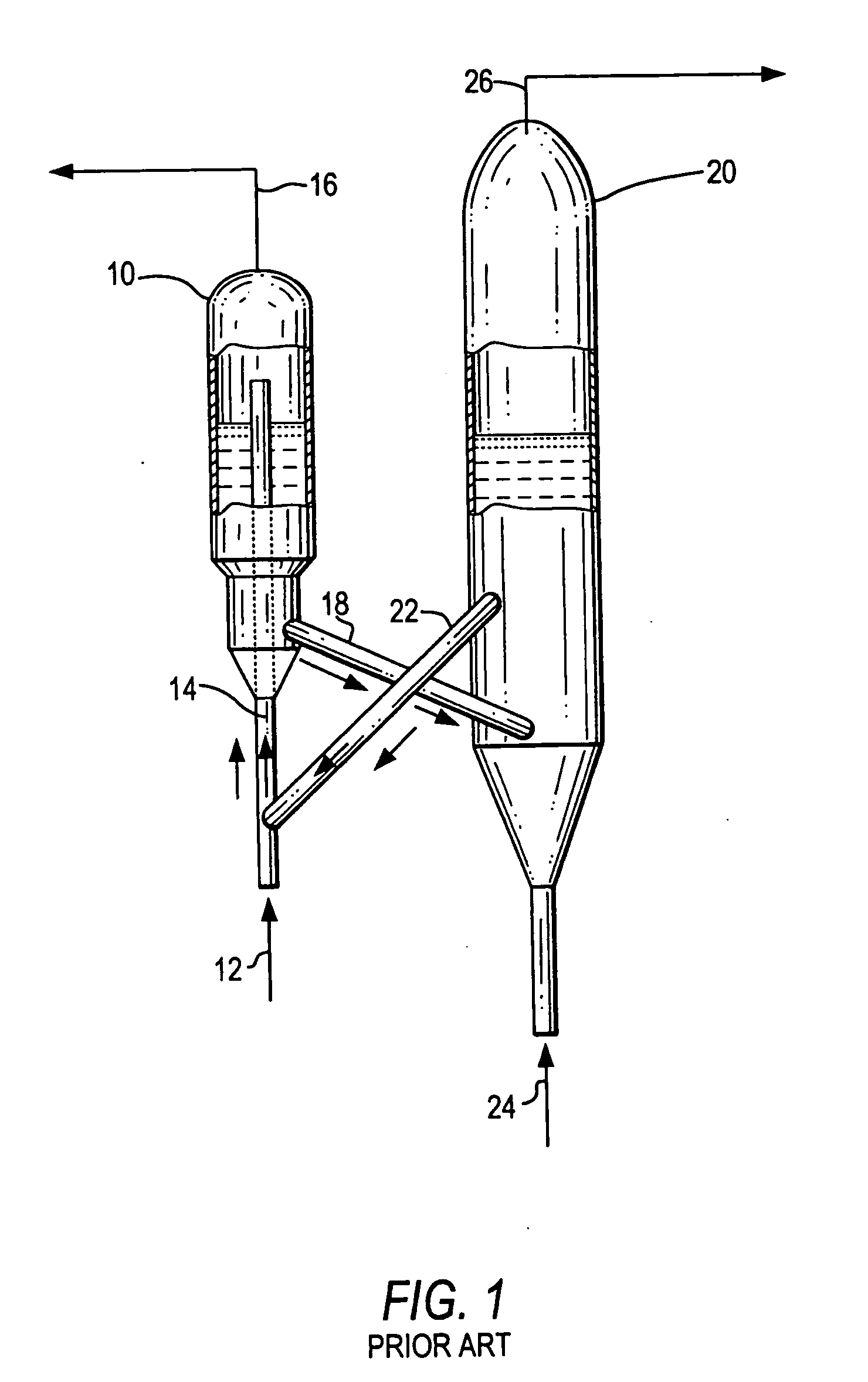

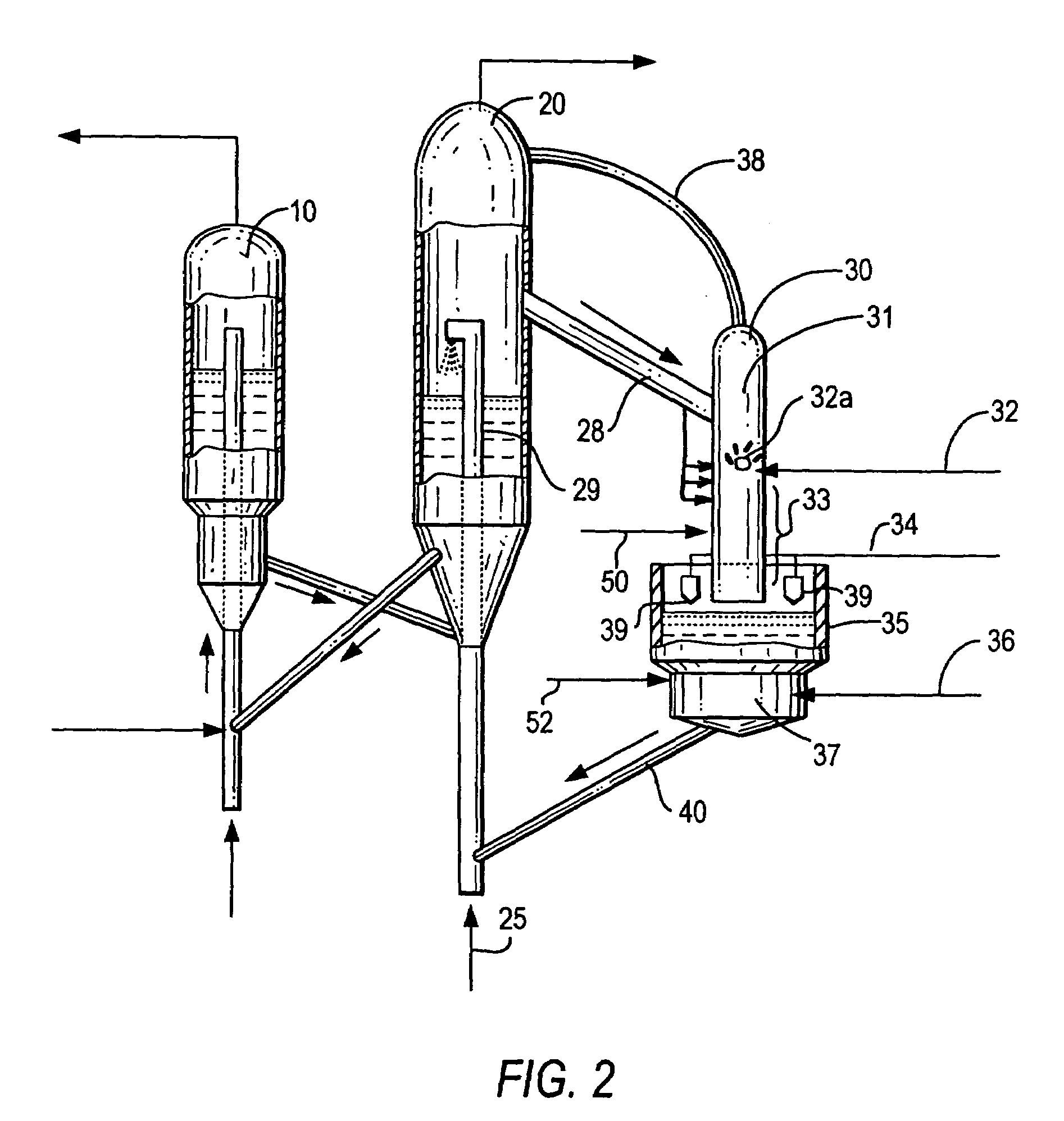

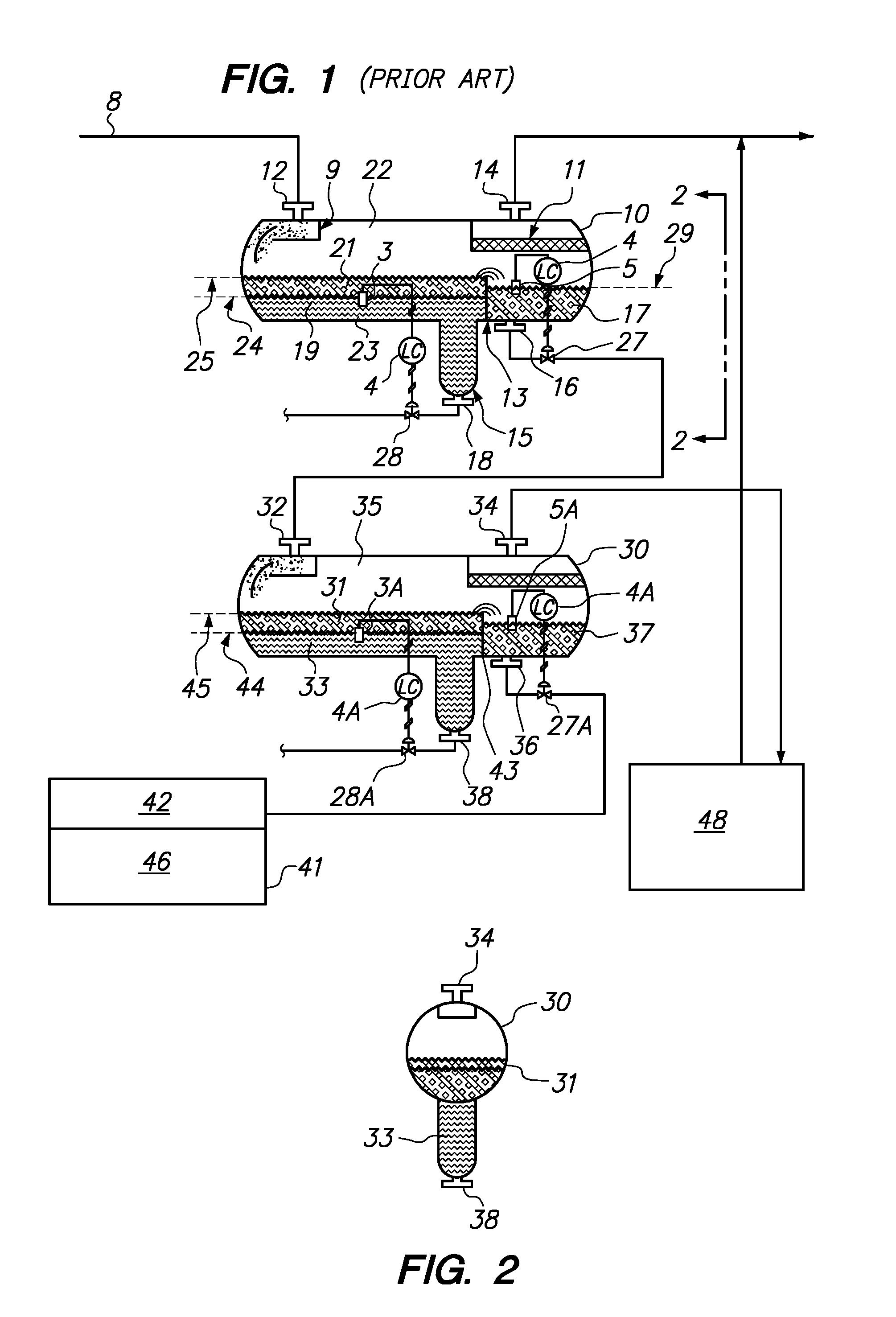

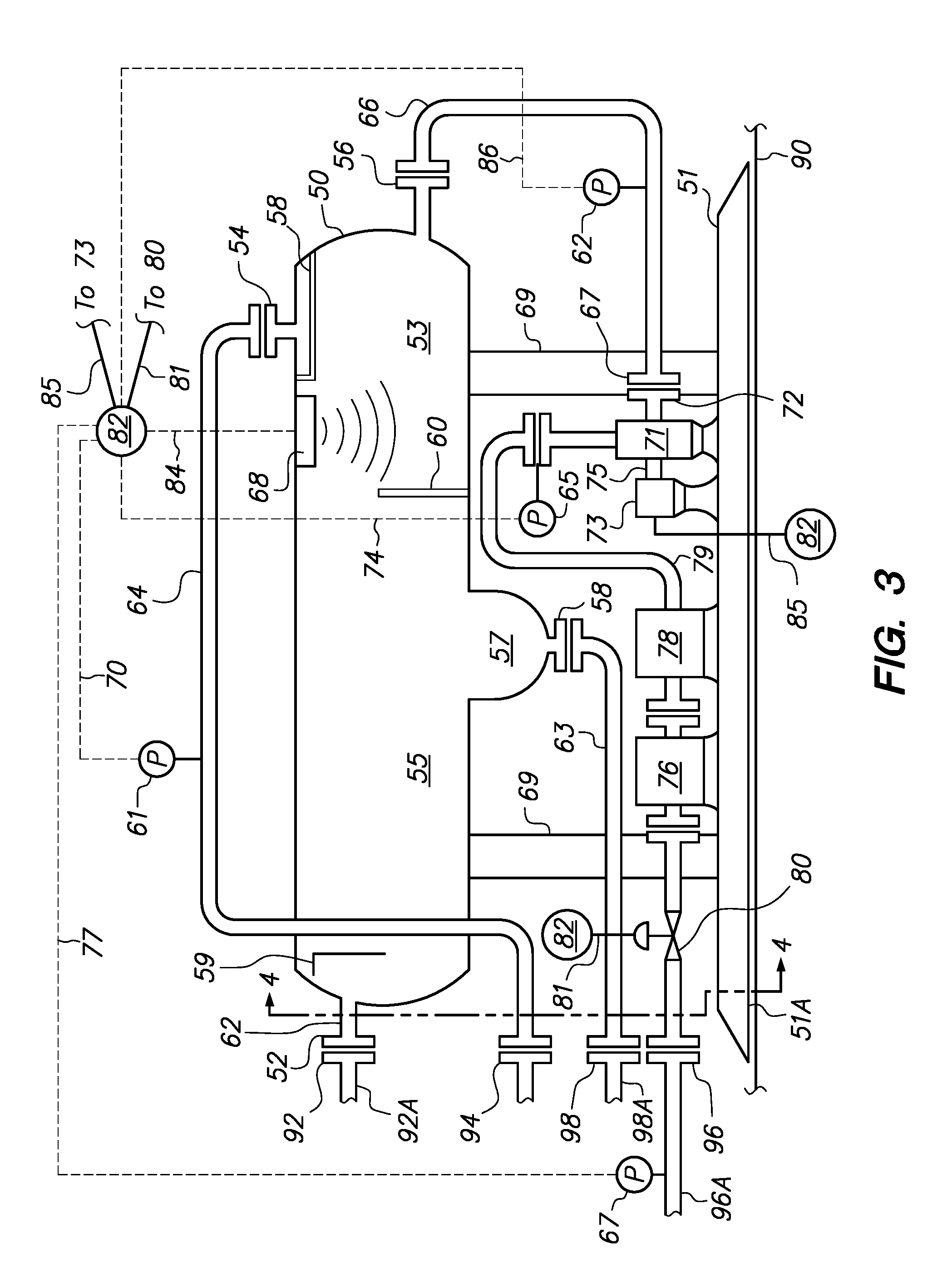

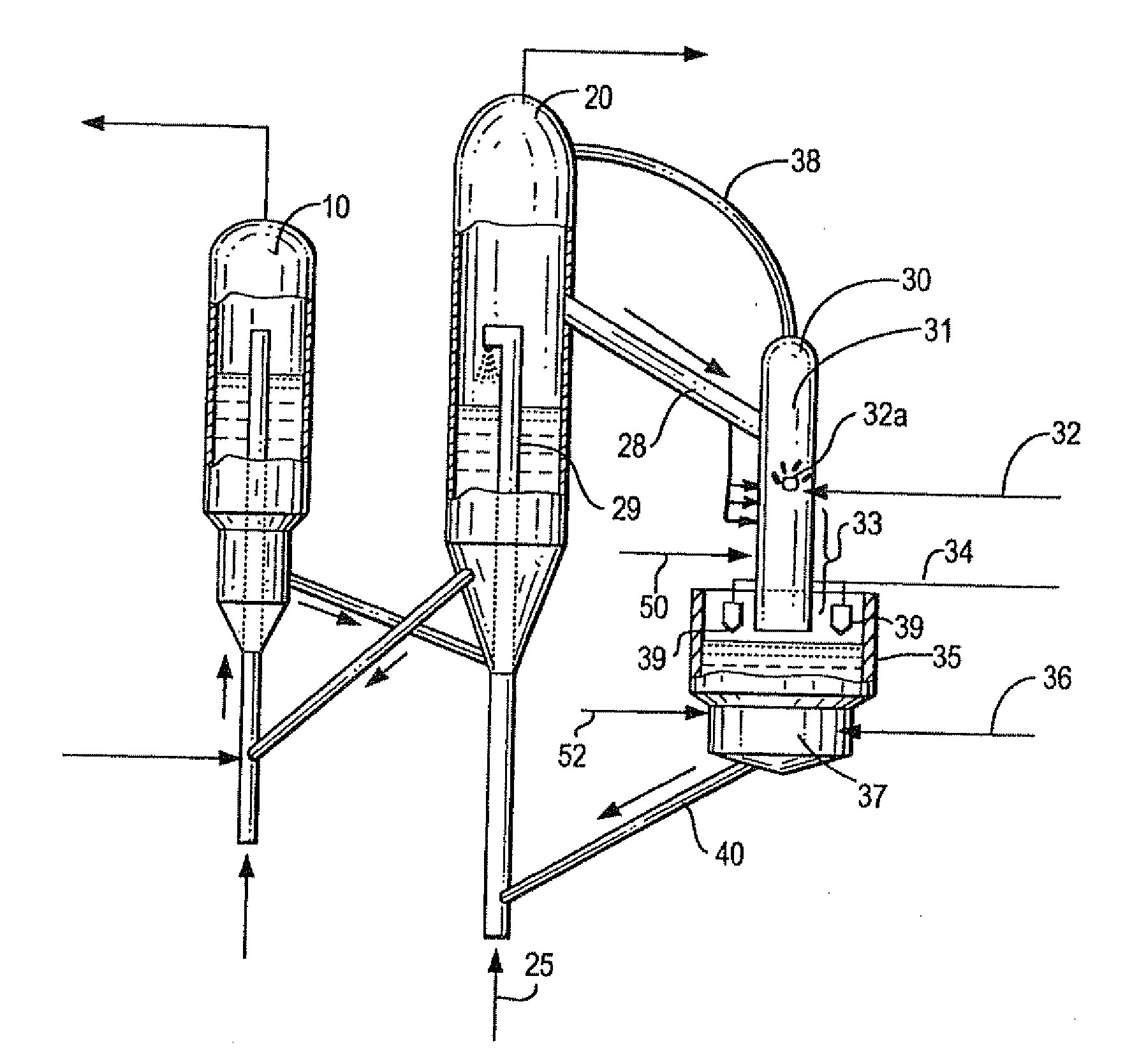

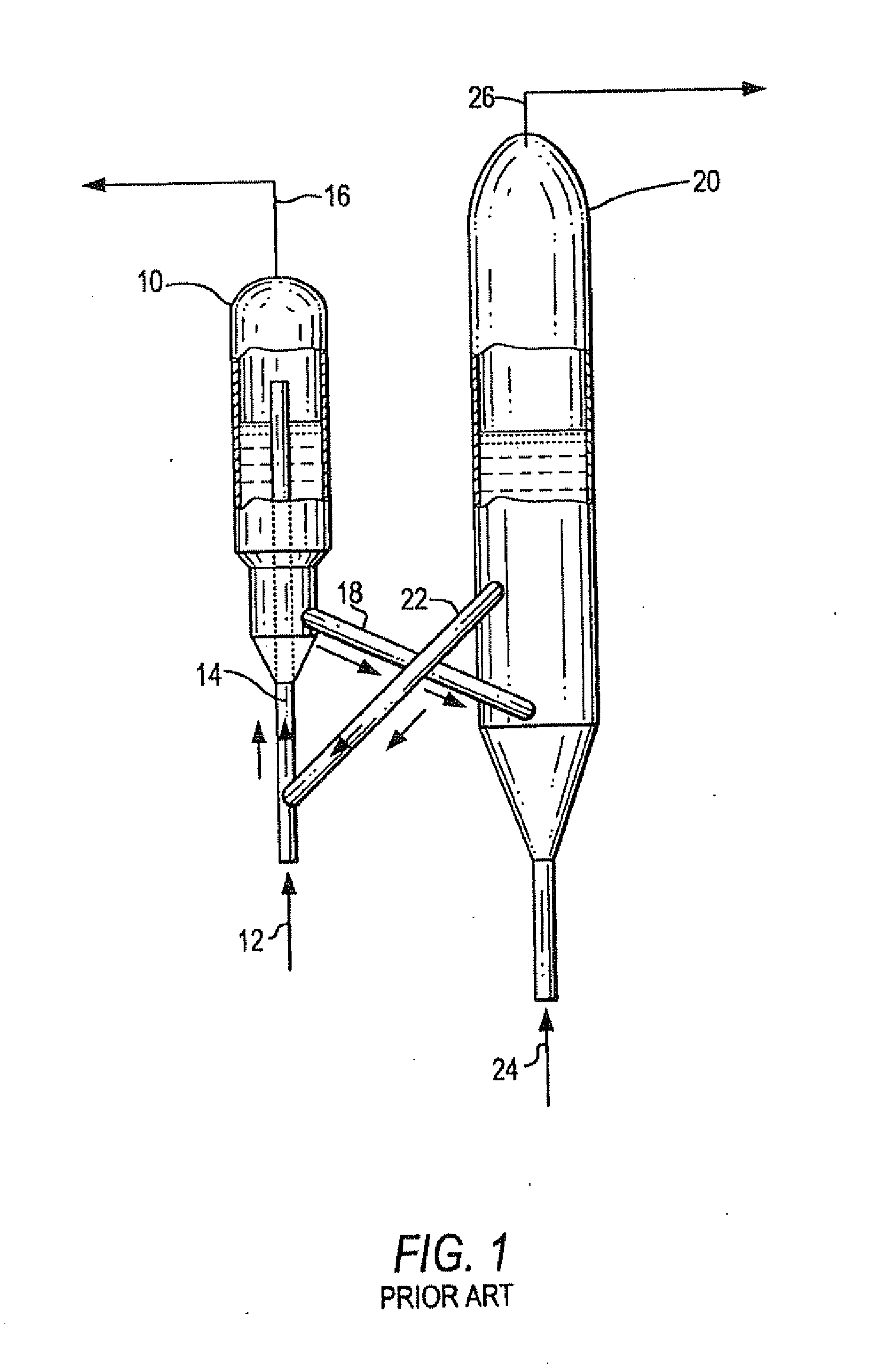

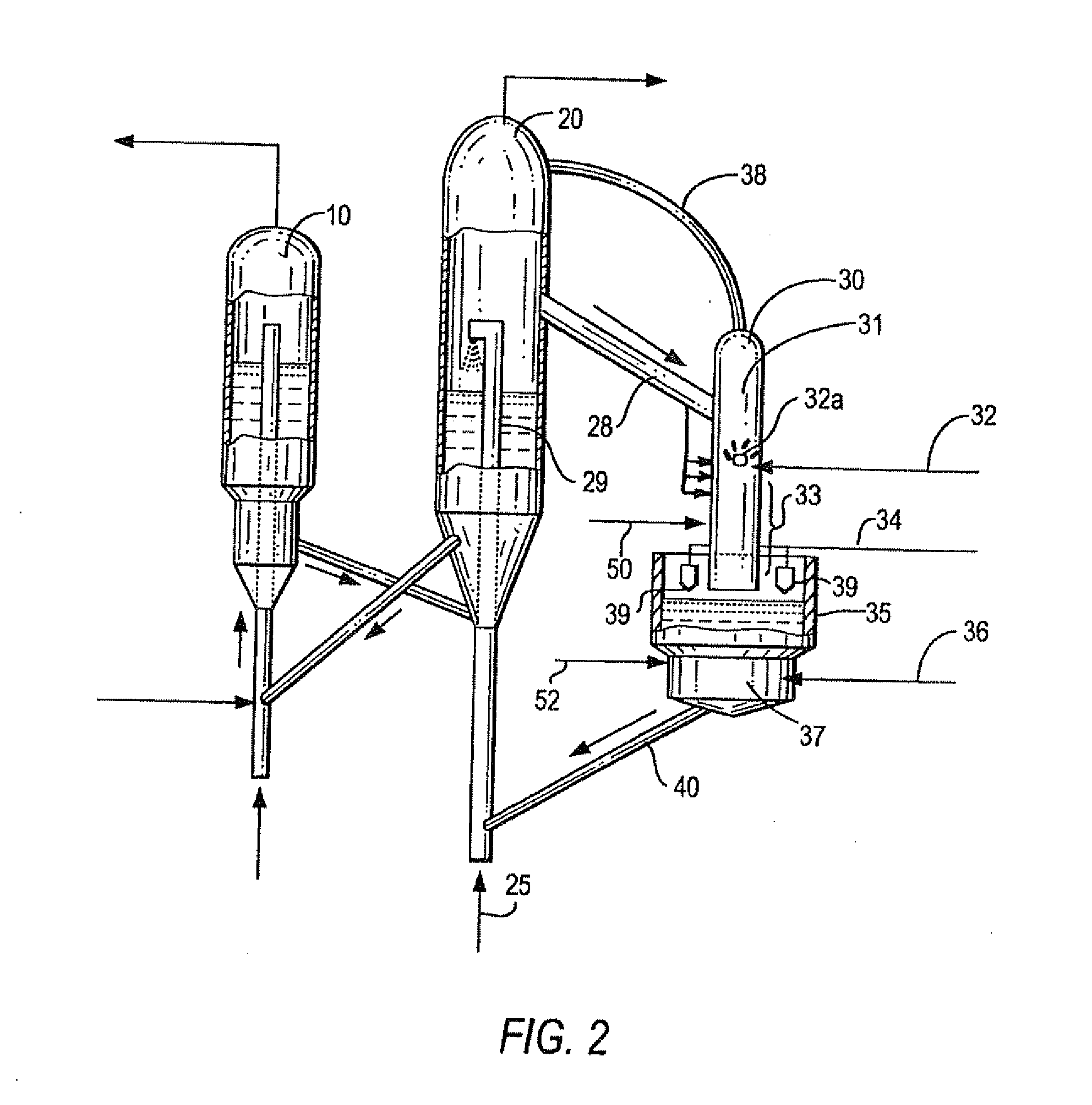

Ancillary cracking of heavy oils in conjuction with FCC unit operations

InactiveUS20080011644A1Minimize investmentShort stayCatalytic crackingTreatment with plural parallel cracking stages onlyUnit operationGasoline

The production of light hydrocarbons consisting of ethylene, propylene, butylenes, and of gasoline is enhanced by introducing a heavy oil feedstream derived from an external source into an ancillary downflow reactor that utilizes the same catalyst composition as an adjacent FCC unit for cracking the heavy oil and withdrawing the desired lighter hydrocarbon reaction product stream from the downflow reactor and regenerating the catalyst in the same regeneration vessel that is used to regenerate the spent catalyst from the FCC unit. The efficiency of the recovery of the desired lighter olefinic hydrocarbons is maximized by limiting the feedstream to the downflow reactor to heavy oils that can be processed under relatively harsher conditions, while minimizing production of undesired by-products.

Owner:NIPPON OIL CORP +1

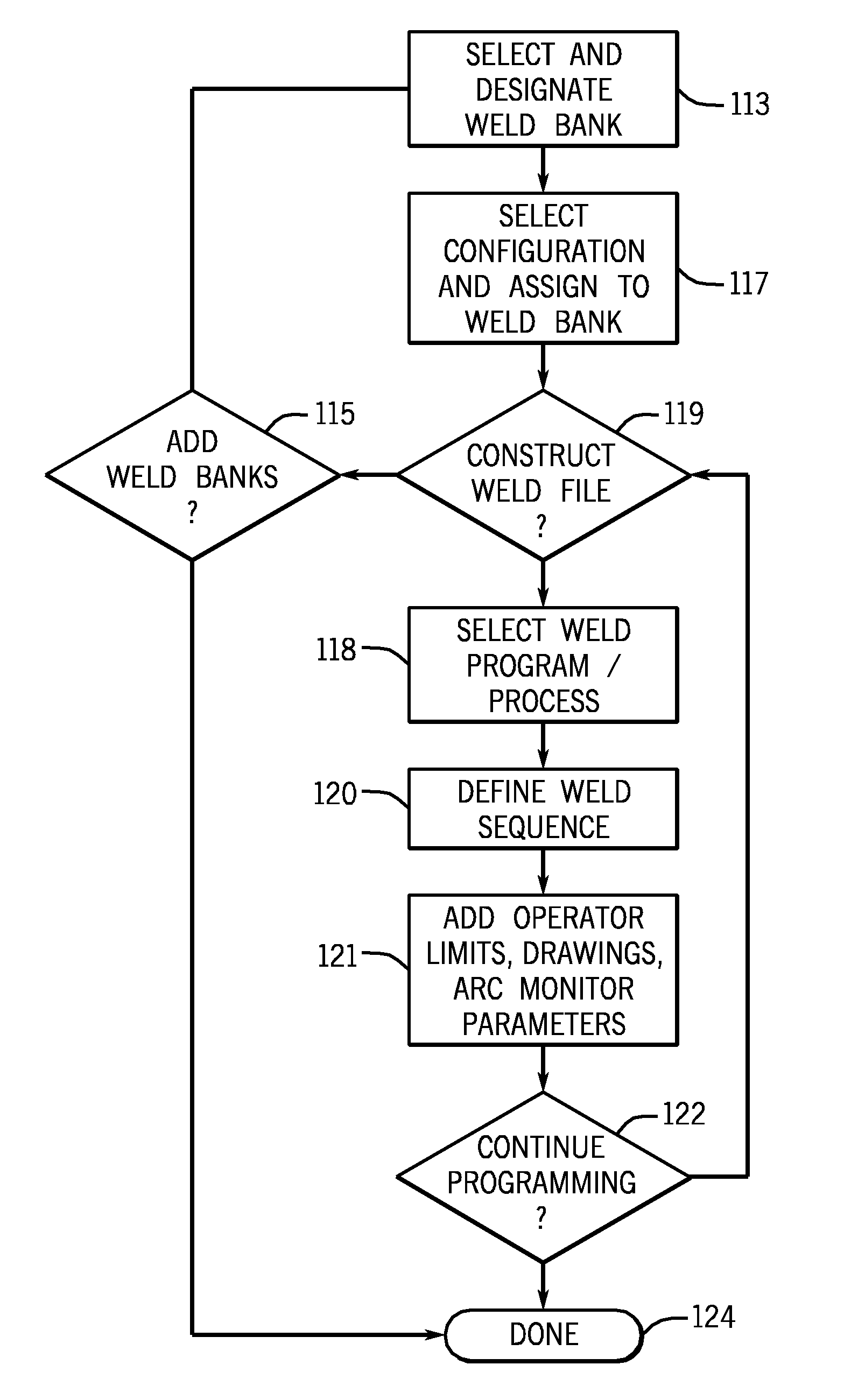

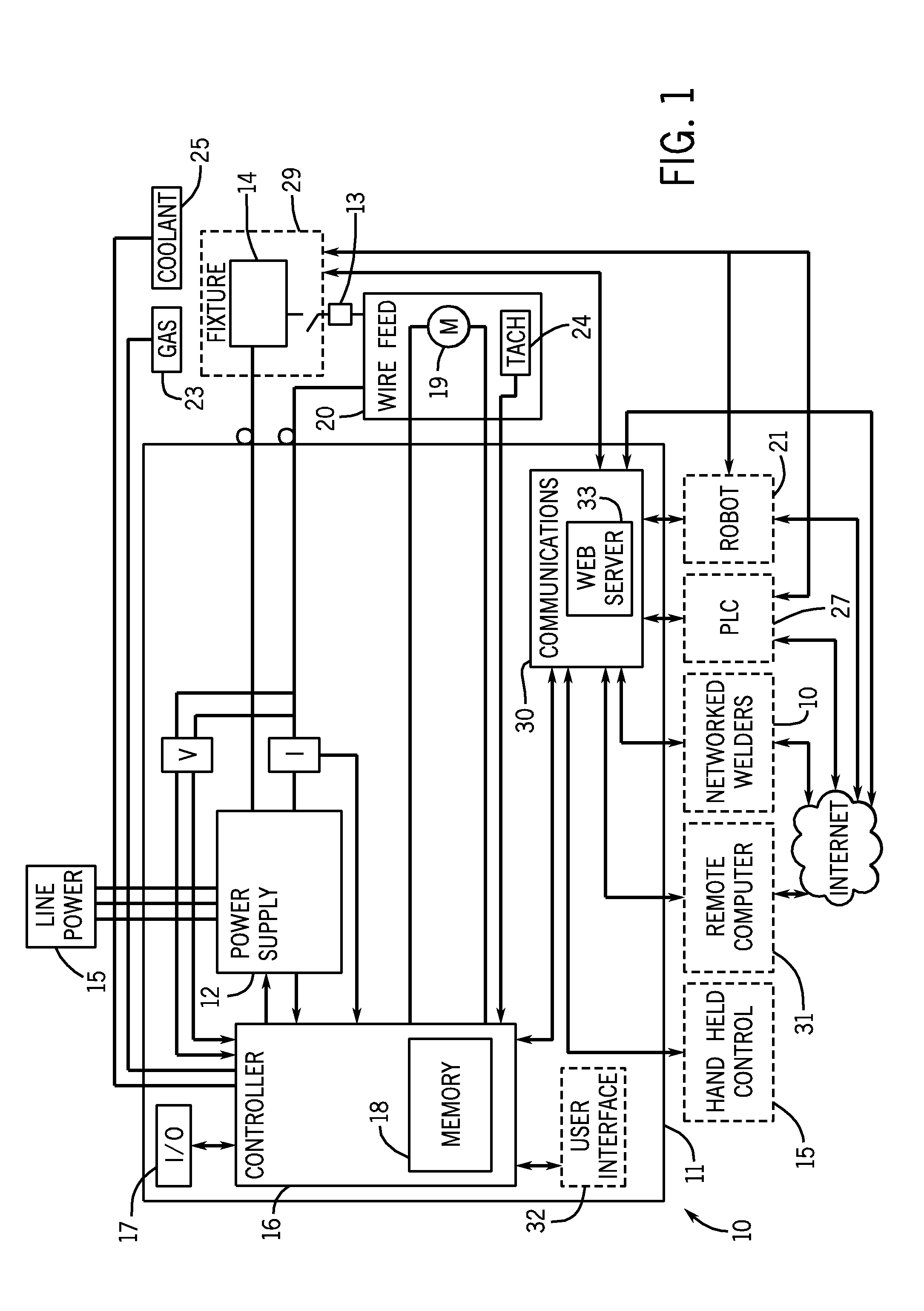

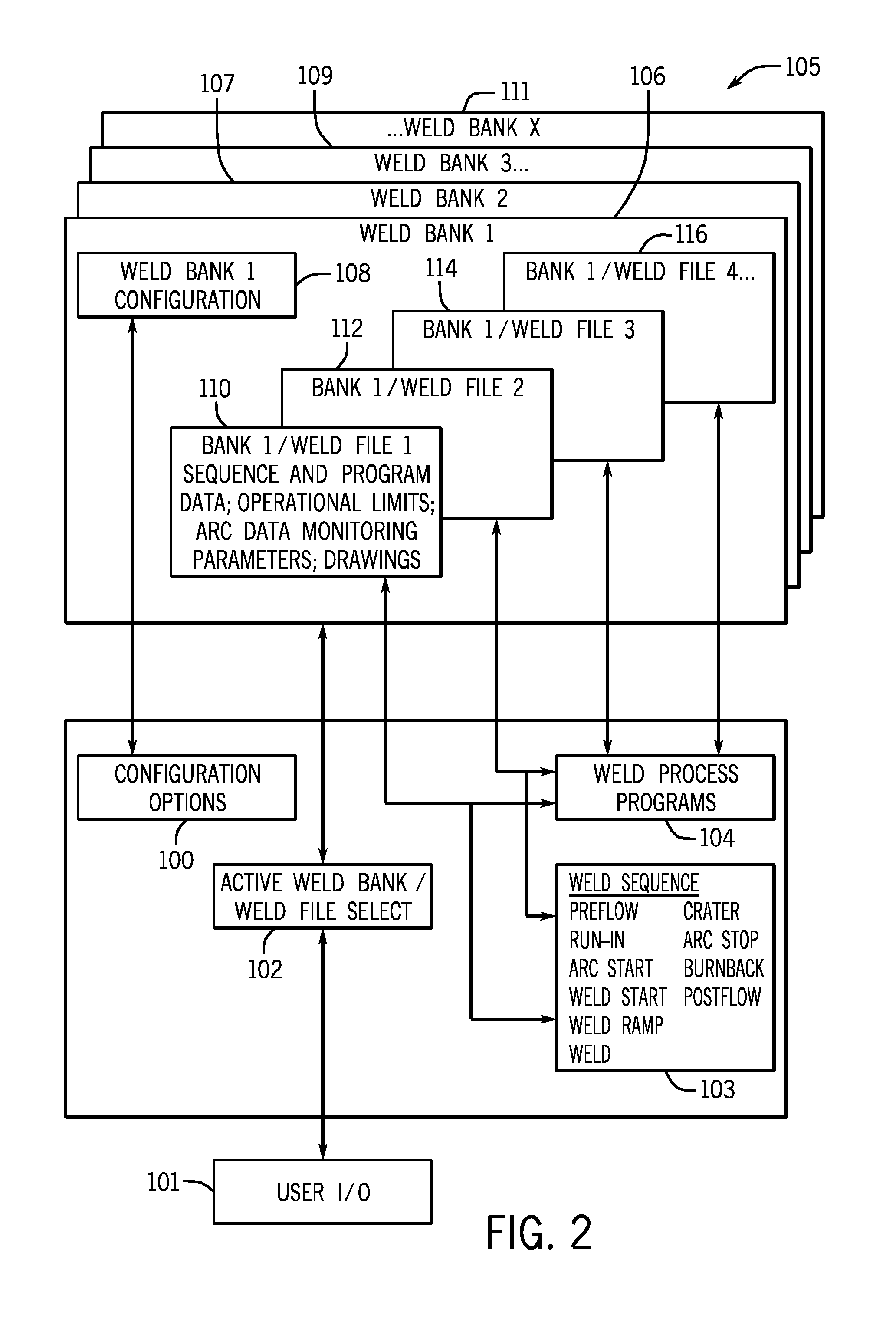

Weld bank data structures for welding applications

ActiveUS8592723B2Easy to reconfigureEasy to useElectron beam welding apparatusSpecial data processing applicationsEngineeringSequencing data

A data structure for weld programs associates configuration data for a welding system with a plurality of weld programs and weld sequence data. The data structure allows the welding system to be configured for a particular part, operator, or stage in a welding process, and to be easily reconfigured when the part, operator, or stage changes, providing improved efficiency and flexibility in operation.

Owner:ILLINOIS TOOL WORKS INC

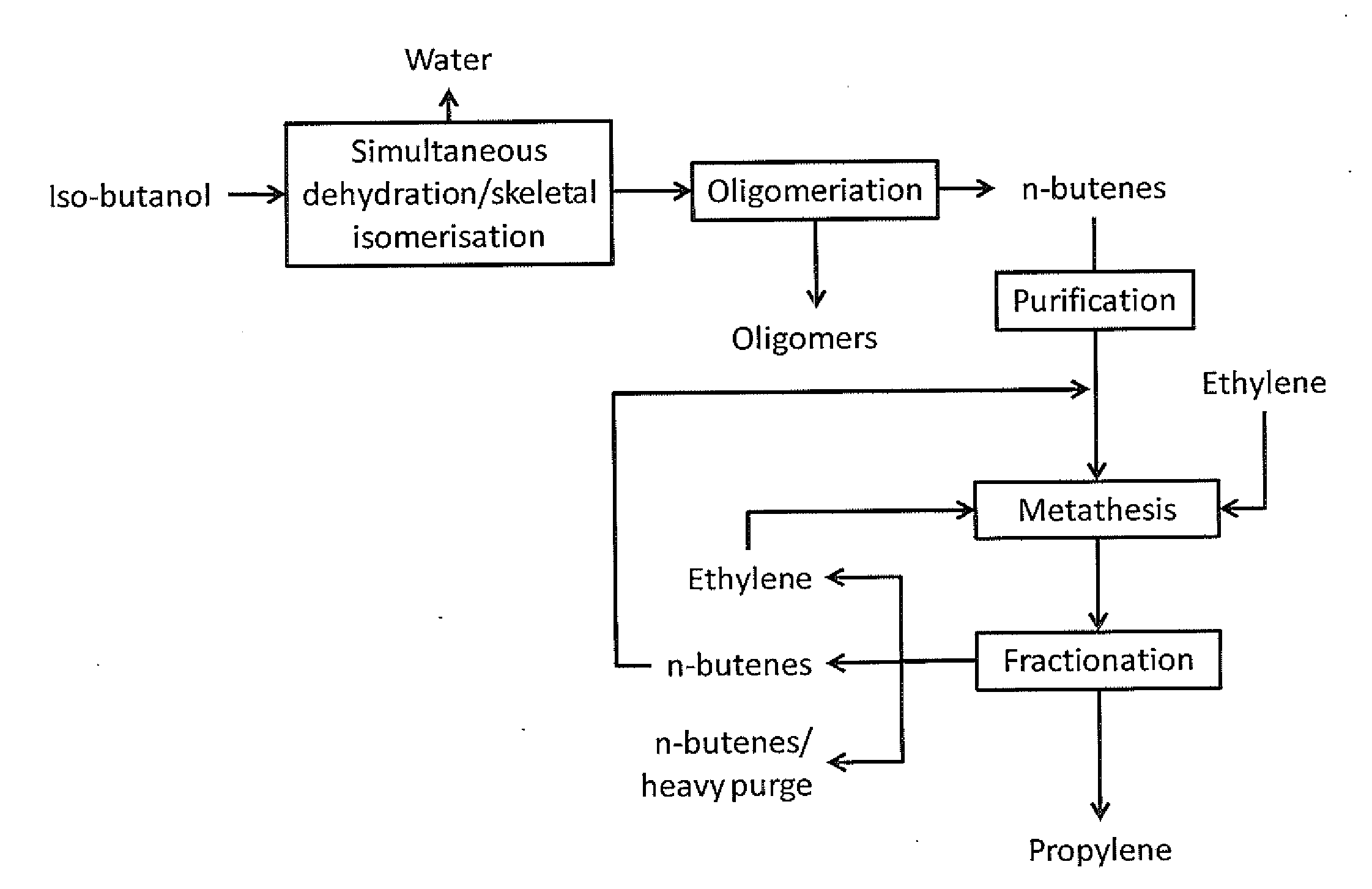

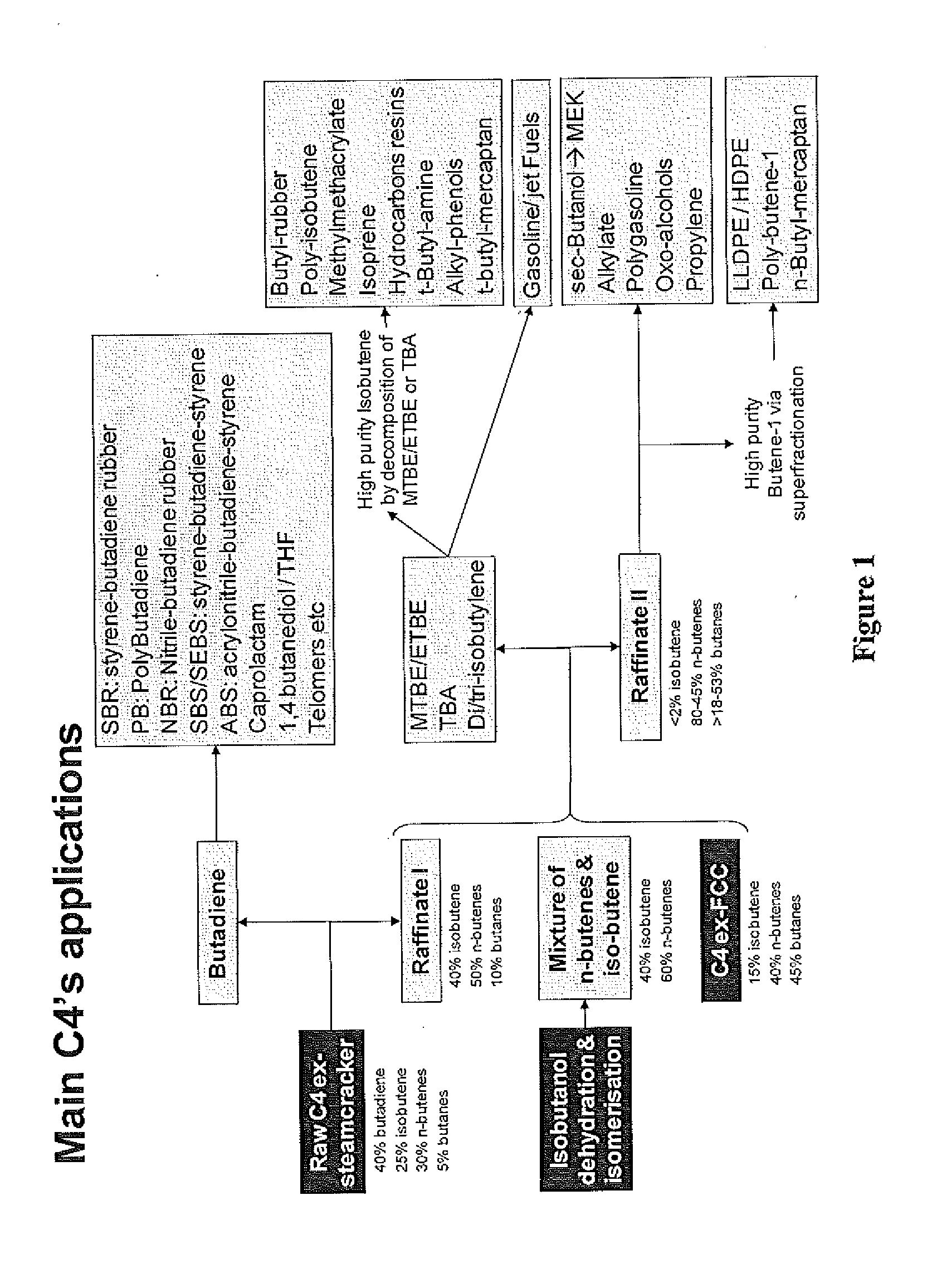

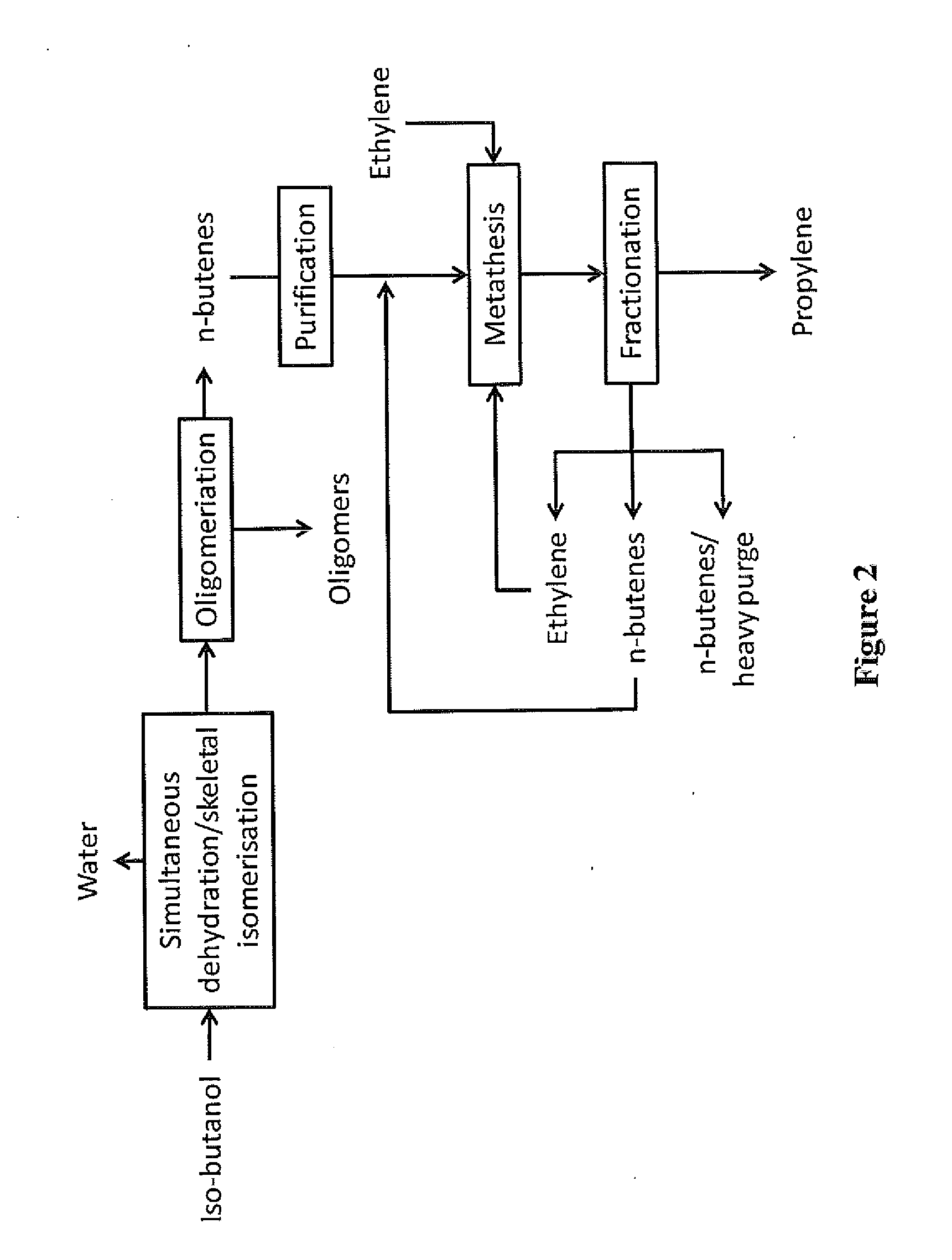

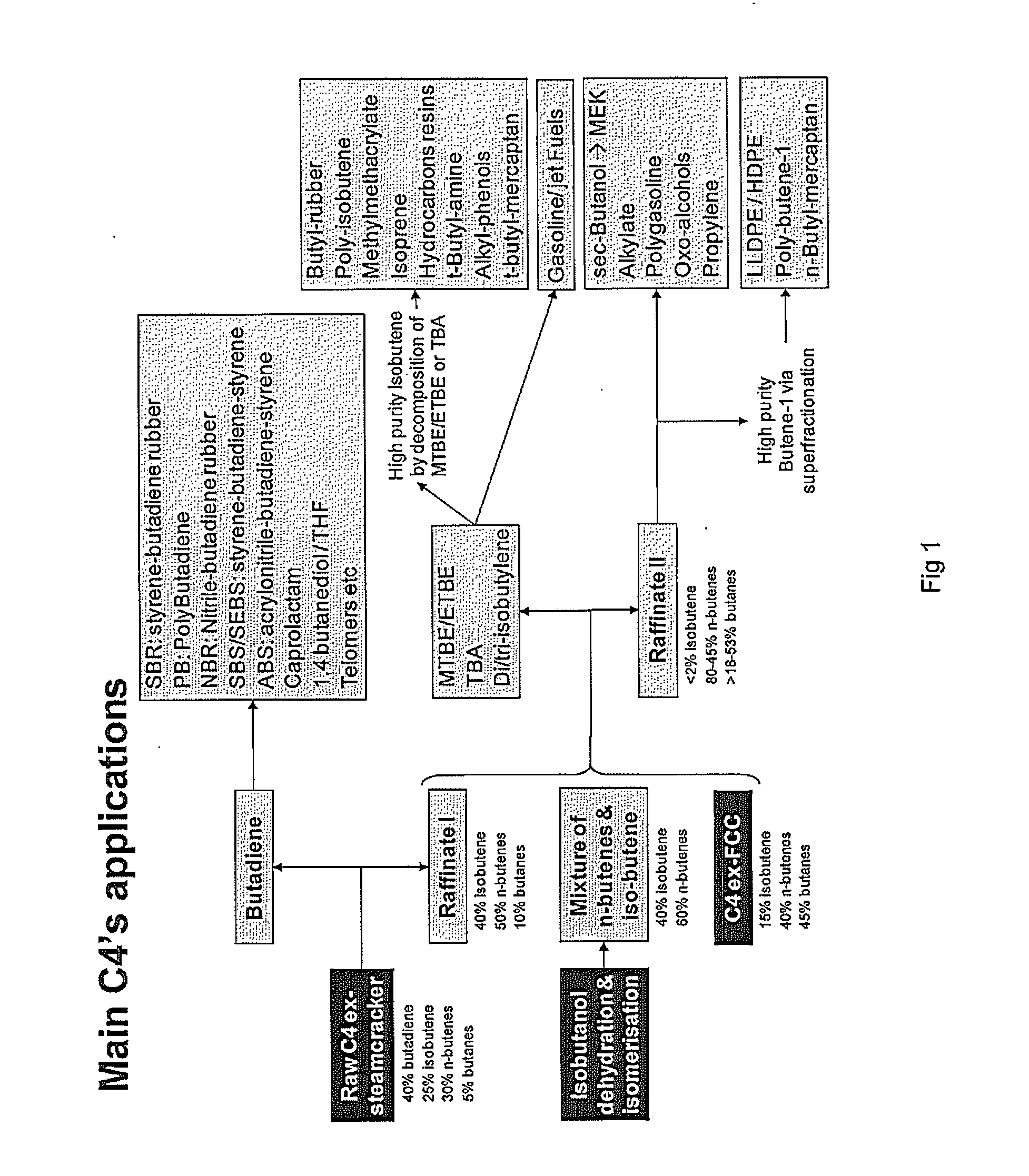

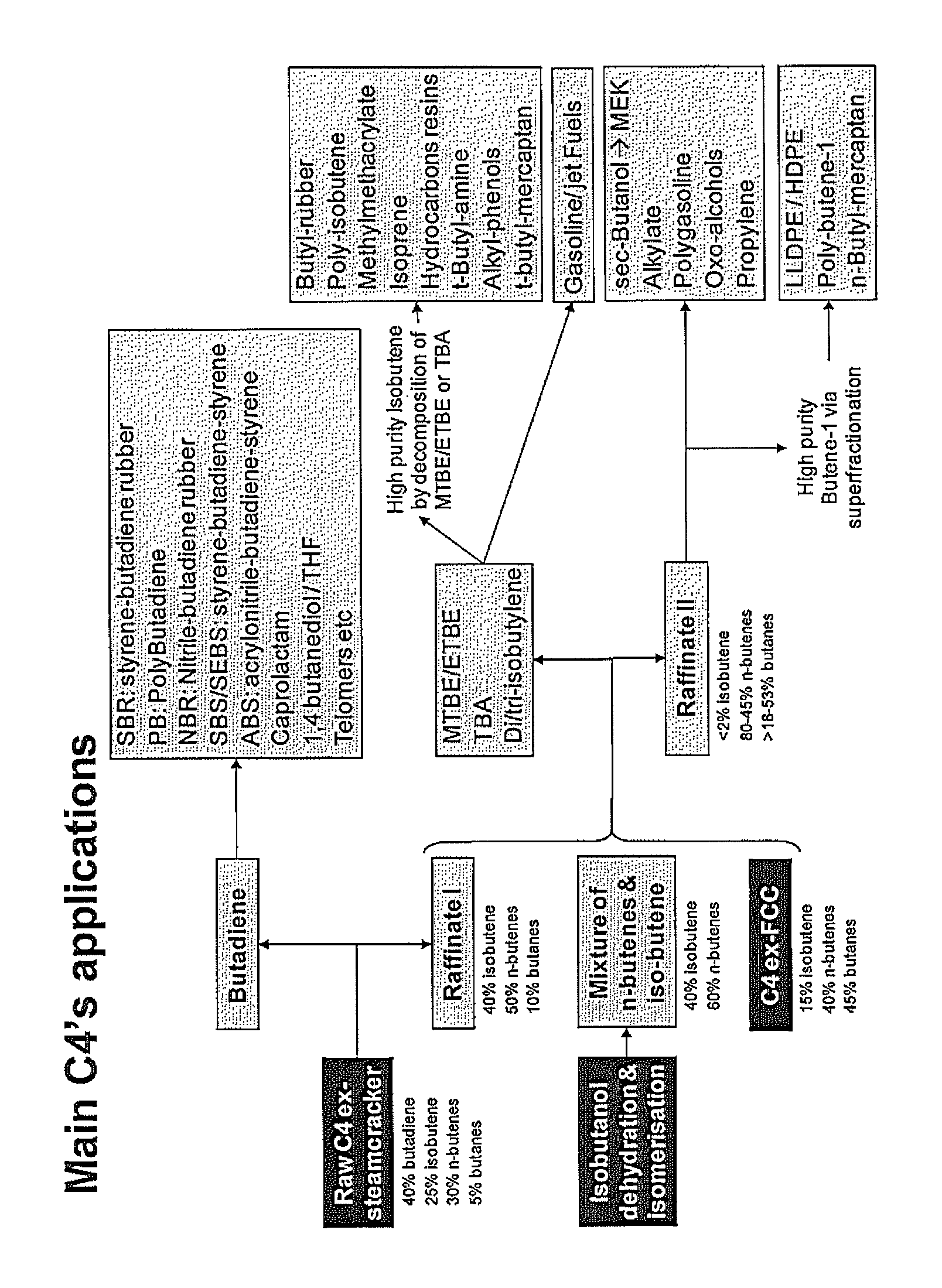

Production of propylene via simultaneous dehydration and skeletal isomerisation of isobutanol on acid catalysts followed by metathesis

ActiveUS20130245348A1High yieldCapital investment can be minimizedMolecular sieve catalystHydrocarbon purification/separationButeneIsobutanol

The present invention relates to a process for the production of propylene in which in a first step isobutanol is subjected to a simultaneous dehydration and skeletal isomerisation to make substantially corresponding olefins, having the same number of carbons and consisting essentially of a mixture of n-butenes and iso-butene and in a second step n-butenes are subjected to methathesis, said process comprising:a) introducing in a reactor a stream (A) comprising isobutanol, optionally water, optionally an inert component,b) contacting said stream with a catalyst in said reactor at conditions effective to dehydrate and skeletal isomerase at least a portion of the isobutanol to make a mixture of n-butenes and iso-butene,c) recovering from said reactor a stream (B), removing water, the inert component if any and unconverted isobutanol if any to get a mixture of n-butenes and iso-butene,d) fractionating said mixture to produce a n-butenes stream (N) and to remove the essential part of isobutene optionally recycled with stream (A) to the dehydration / isomerization reactor of step b),e) sending the stream (N) to a methathesis reactor and contacting stream (N) with a catalyst in said methathesis reactor, optionally in the presence of ethylene, at conditions effective to produce propylene,f) recovering from said methathesis reactor a stream (P) comprising essentially propylene, unreacted n-butenes, heavies, optionally unreacted ethylene,g) fractionating stream (P) to recover propylene and optionally recycling unreacted n-butenes and unreacted ethylene to the methathesis reactor.

Owner:TOTAL RES & TECH FELUY

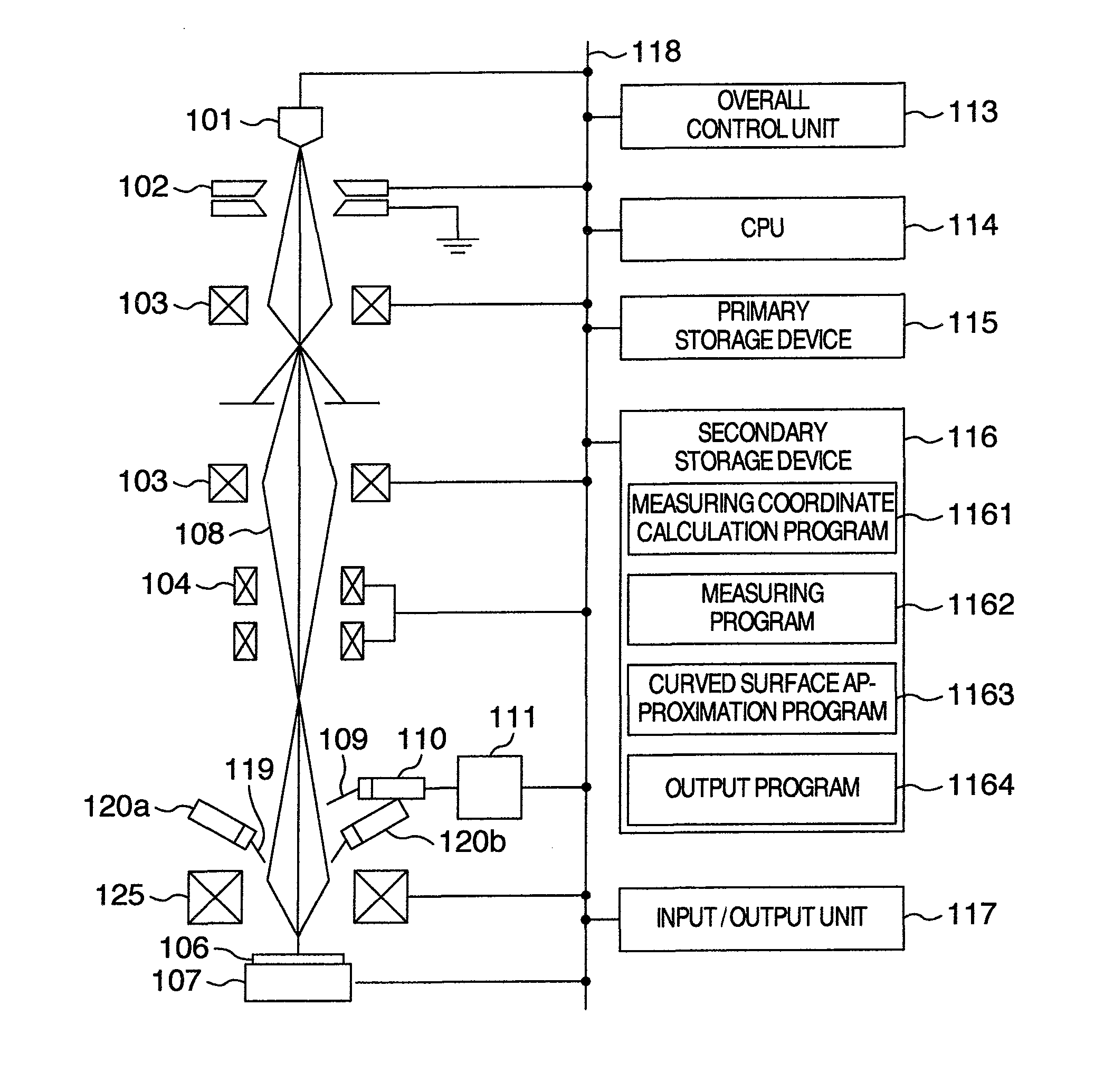

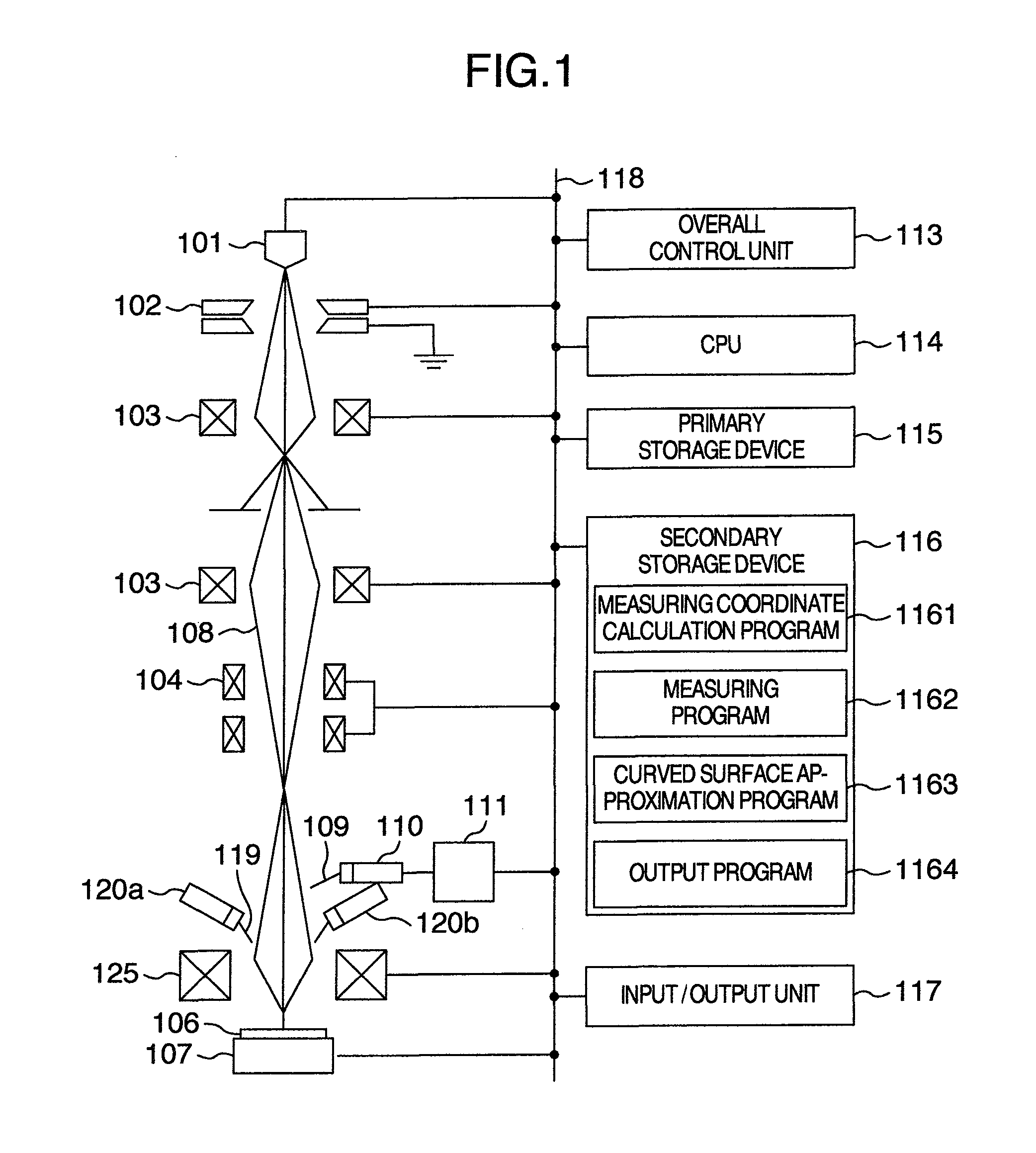

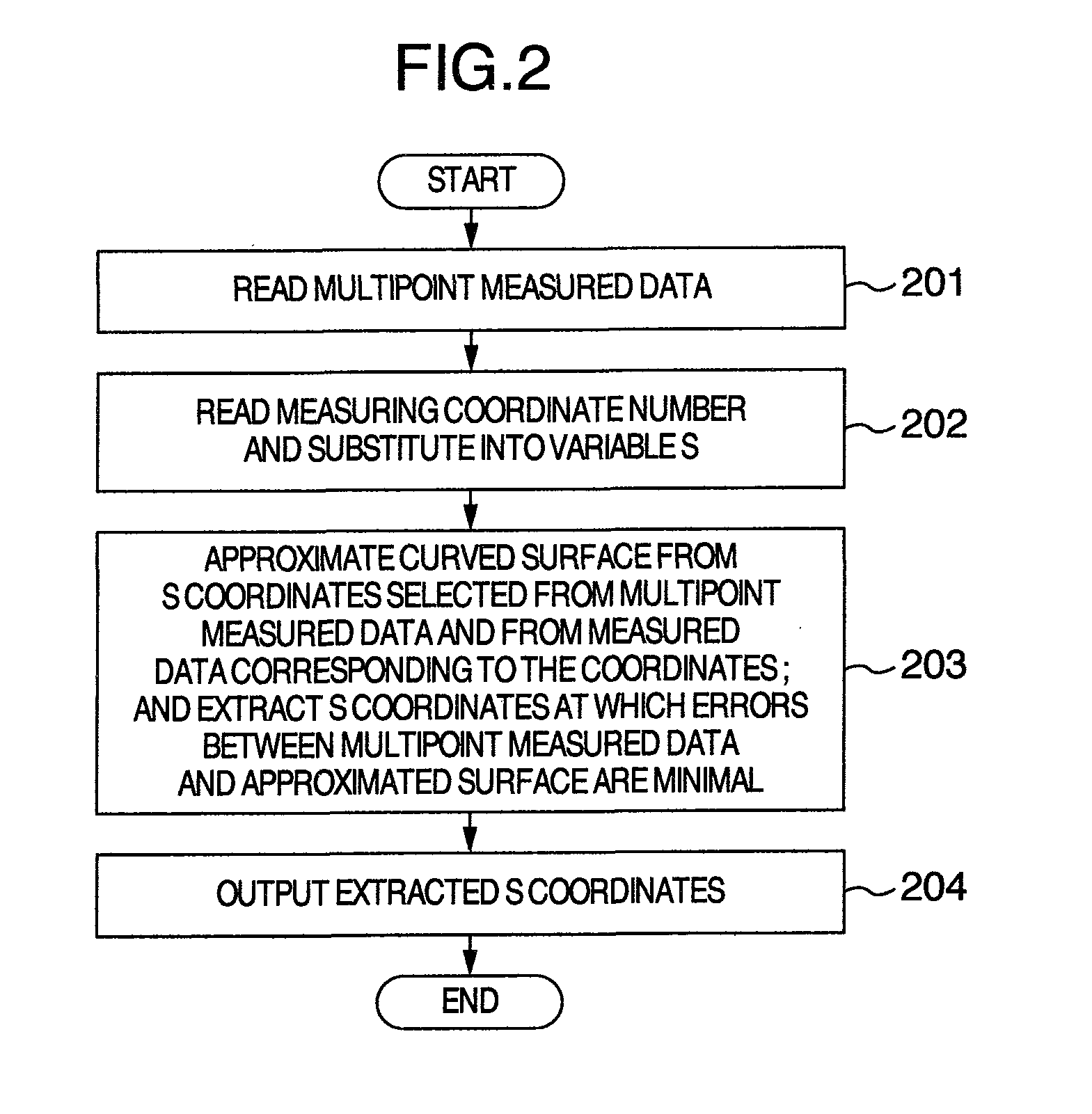

Measuring Apparatus, Measuring Coordinate Setting Method and Measuring Coordinate Number Calculation Method

InactiveUS20110060552A1Improve accuracyImprove device performanceElectric discharge tubesFeeler-pin gaugesEtchingEngineering

With little cost and time, this invention makes high-precision measurements over an entire surface of a substrate to check how well devices are fabricated. The devices include integrated circuits, magnetic heads, magnetic discs, solar cells, optical modules, light emitting diodes and liquid crystal display panels—the ones that are fabricated on a substrate by repetitively performing deposition, resist application, exposure, development and etching. The method of this invention involves inputting multipoint measured data and a number of points used for measurement and calculating measuring coordinates by the measuring coordinate calculation program 1161. Next, based on the calculated measuring coordinates, the measuring program 1162 measures device characteristics, such as dimensions of the devices. Next, the curved surface approximation program 1163 calculates approximated values of device characteristics over the entire surface of the substrate, followed by the output program 1164 outputting the approximated values.

Owner:HITACHI LTD

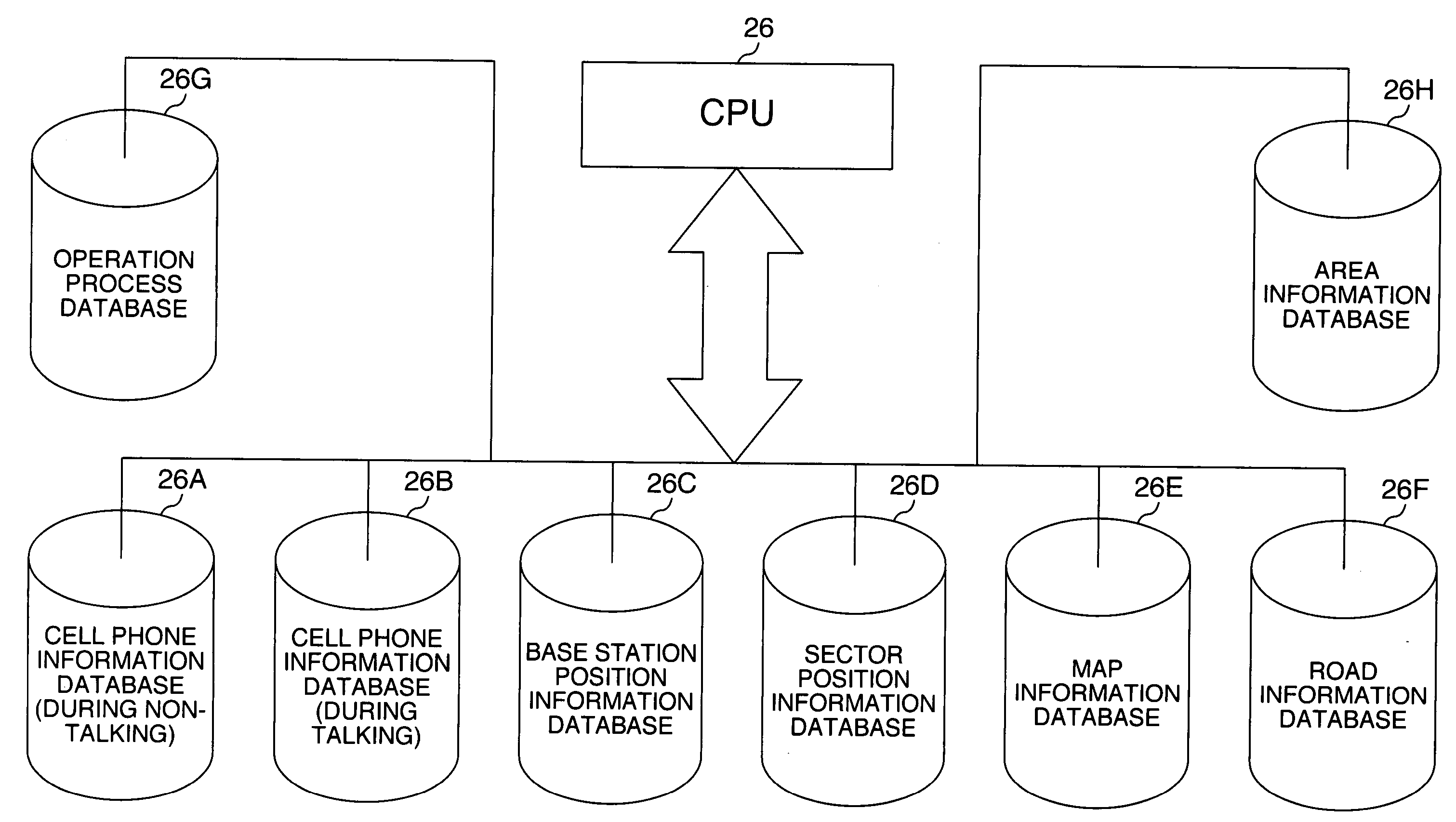

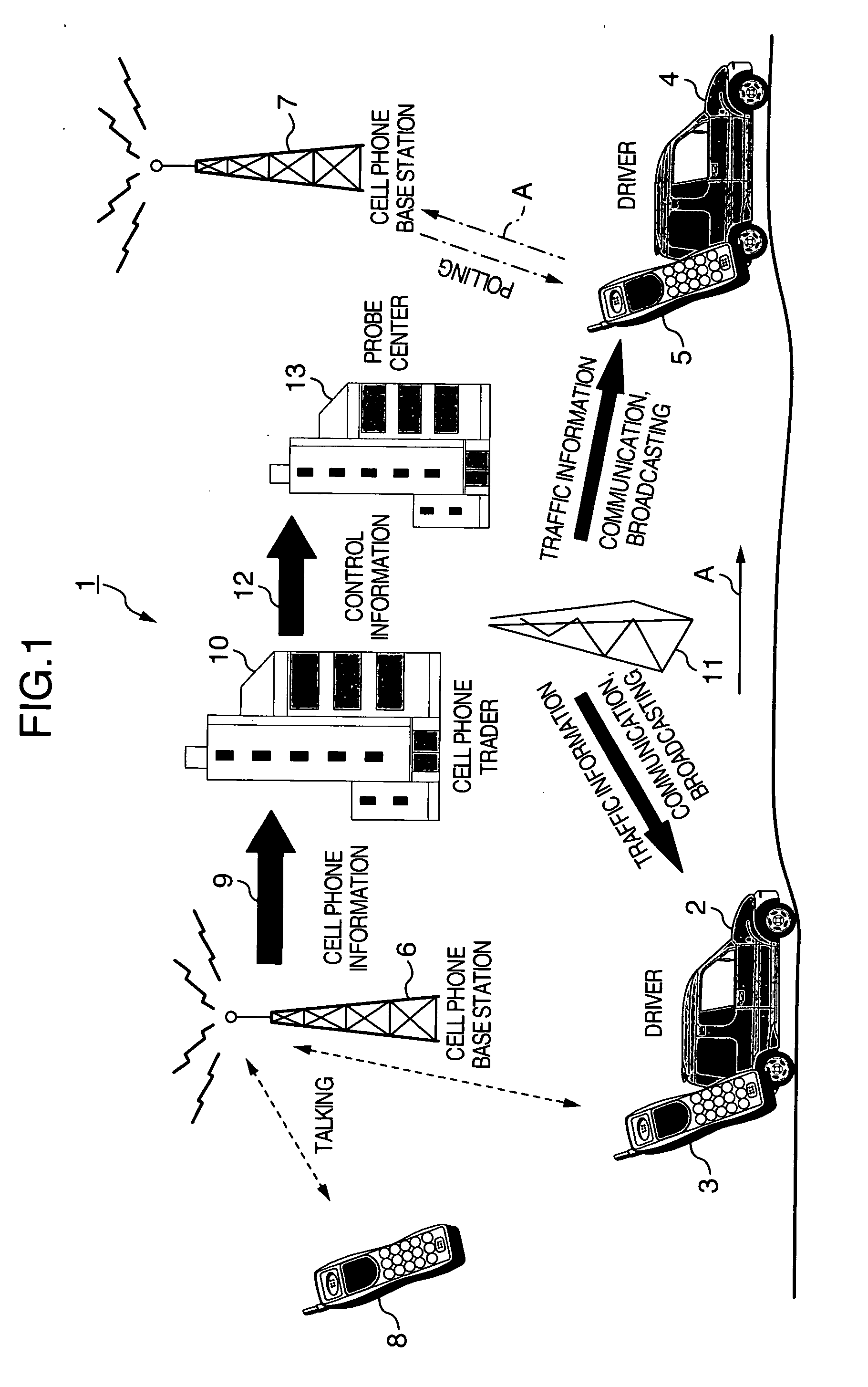

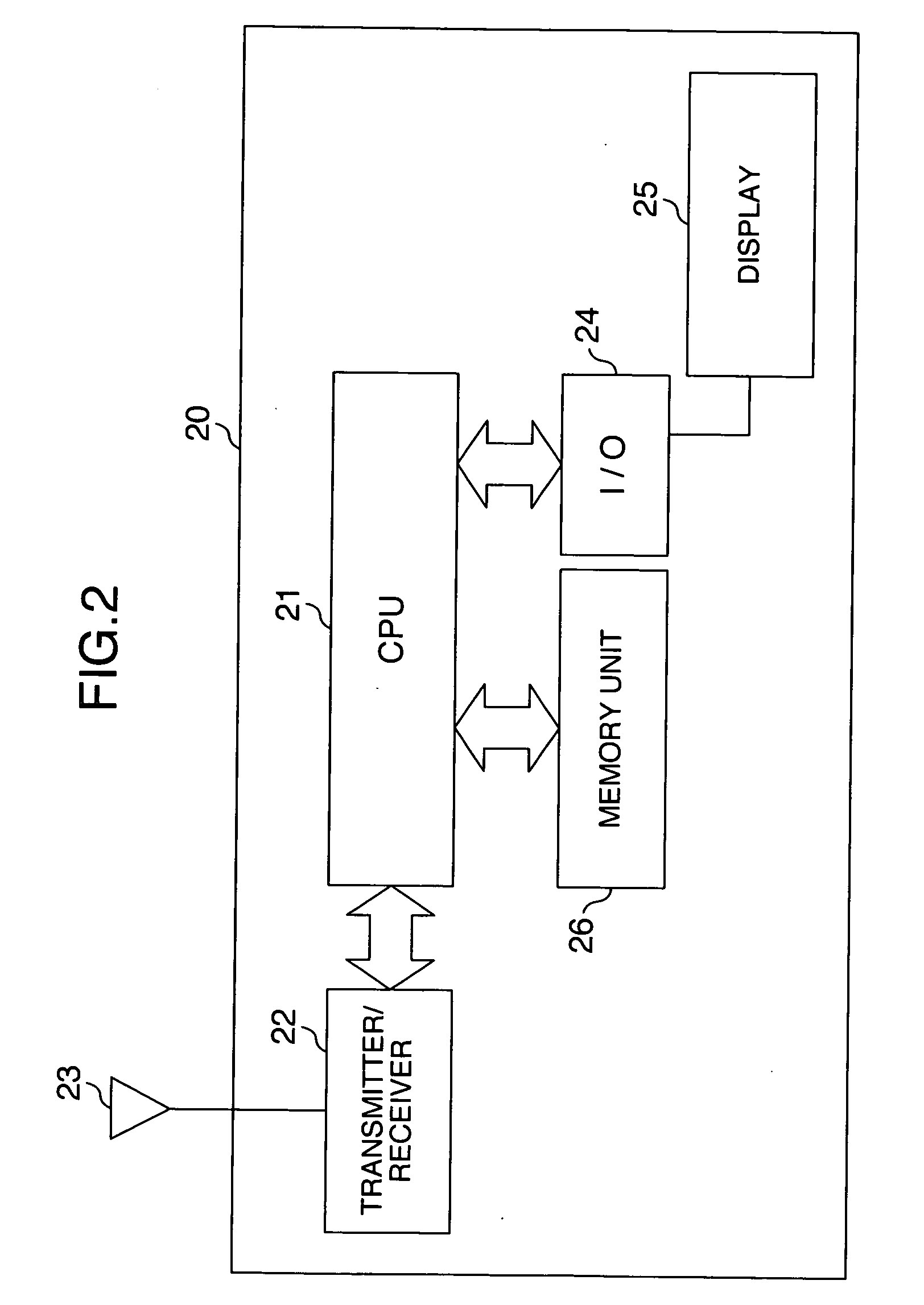

Data processing apparatus for probe traffic information and data processing system and method for probe traffic information

InactiveUS20060223529A1Capital investment can be minimizedMinimize investmentCommmunication supplementary servicesVehicle position indicationData processing systemDriver/operator

By utilizing a cell phone carried by a driver or a fellow passenger to exchange with a base station during talking (through polling during non-talking), position information of the cell phone is obtained. The position information is collected and gathered as probe data and by matching the data with road map data, traffic congestion information on roads is generated. Then, when a business car of a driver carrying a cell phone is not traveling in a range initially predicted, it is decided whether position data of the cell phone is suitable as probe information and accurate traffic congestion information is generated.

Owner:HITACHI LTD

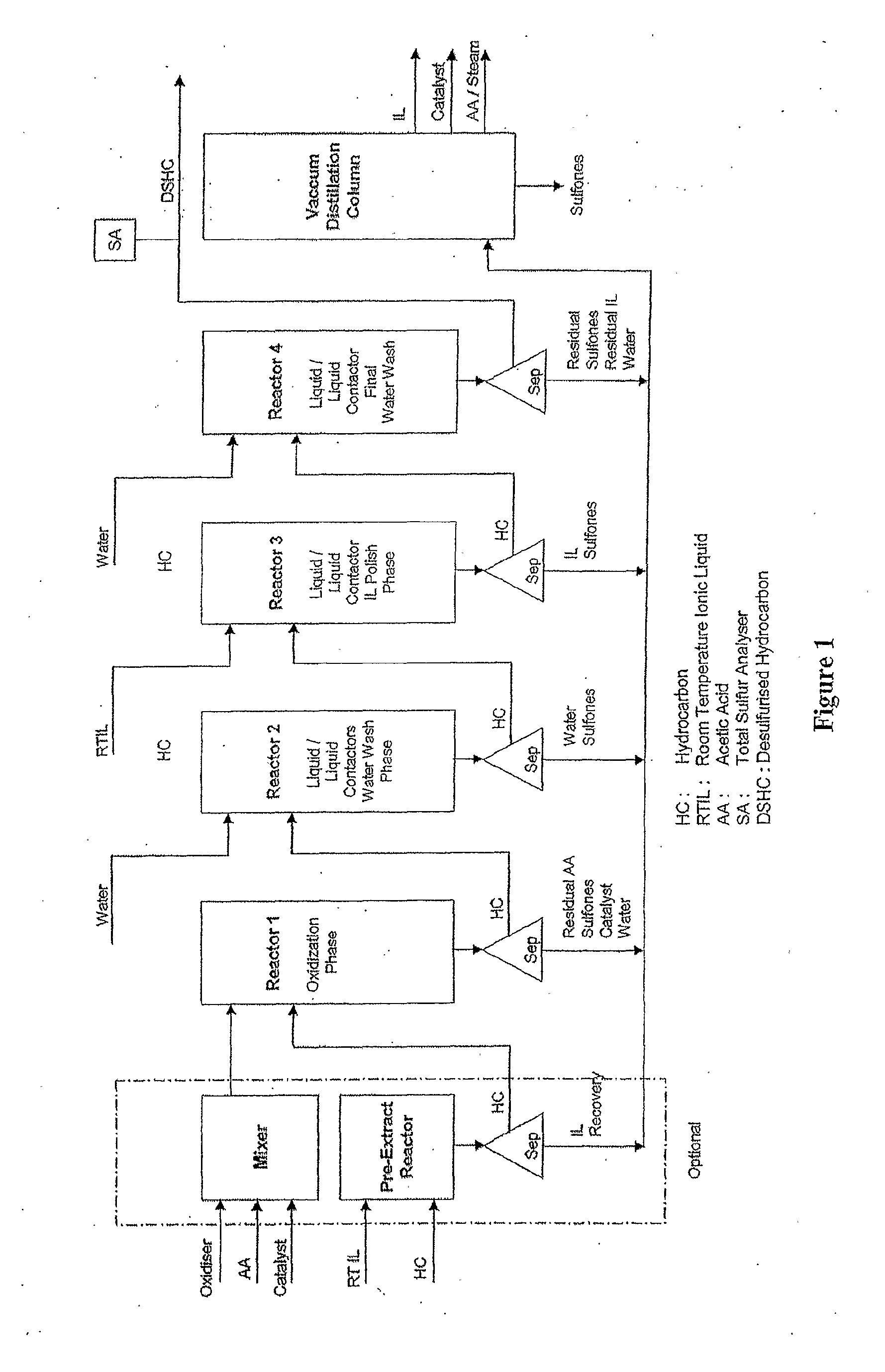

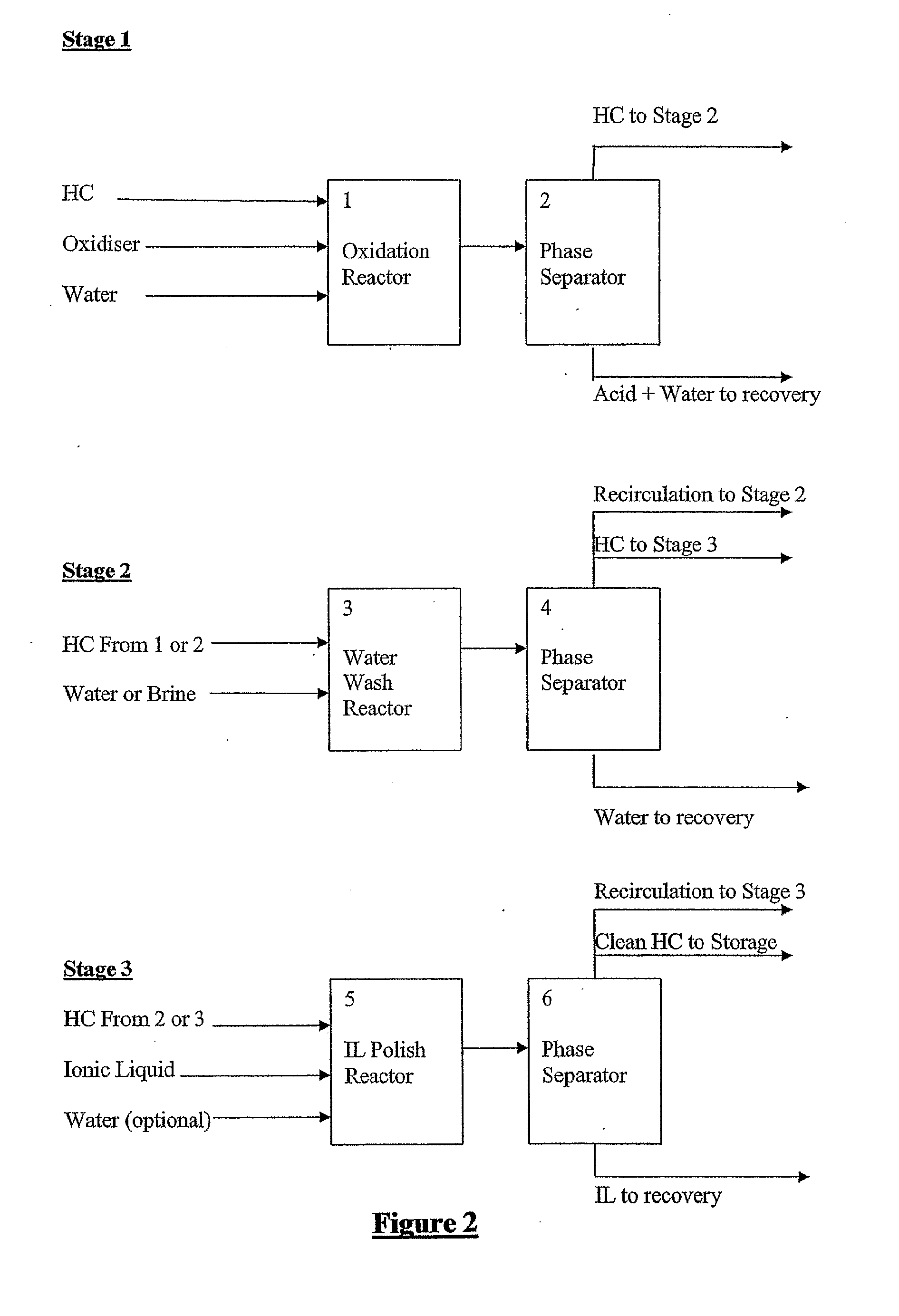

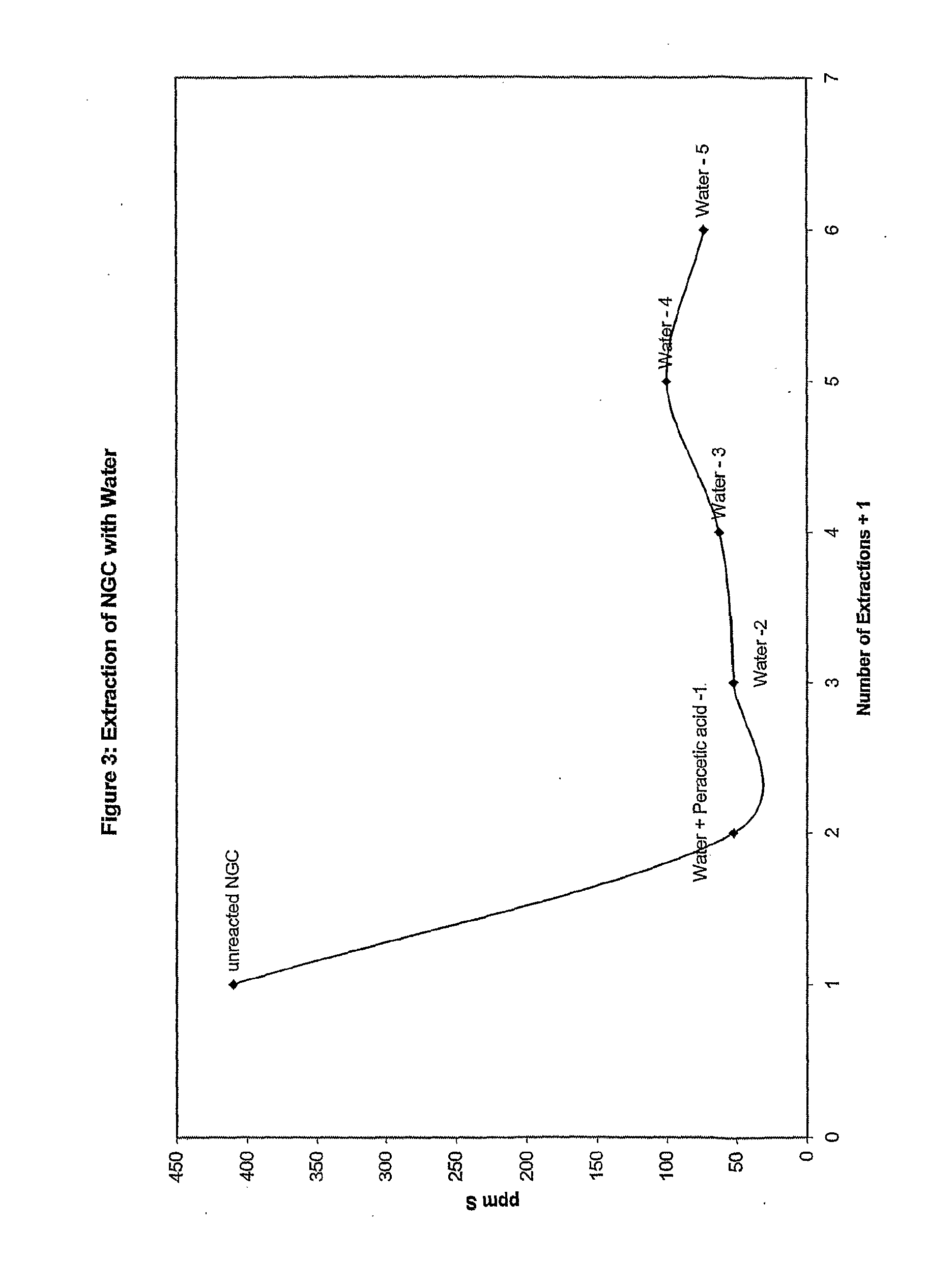

Process for Removing Sulphur From Liquid Hydrocarbons

ActiveUS20110203972A1Low and easy to handle waste streamSimple and economically viableRefining with oxygen compoundsTreatment with plural serial refining stagesPartial oxidationDistillation

A process for the deep desulfurisation of hydrocarbons (HC), in particular Natural Gas Condensate (NGC), and HC comprising diesel, pre-extracted diesel and naphtha, is described which is capable of reducing the sulfur content of these HC from 500 to 30 ppm. The process comprises contacting the hydrocarbon material with an oxidant selected from organic peroxy acids, organic peroxides, inorganic peroxides and mixtures thereof, in at least a stochiometric amount sufficient to oxidise a sulfur compound to a sulfone compound; contacting the hydrocarbon material with an aqueous extractant to allow at least a portion of the oxidised sulfur compounds to be extracted into the aqueous extractant, and separating the hydrocarbon material from the aqueous extractant to give a hydrocarbon material of reduced sulfur content. Optionally, the process may include a second and subsequent extractions with the aqueous extractant to further reduce sulfur content. A final extraction with an IL may be conducted. The invention also provides for substitution of the aqueous extractant with an IL in one or more of the other extraction steps. The extractants and by products generated during f01 oxidation can be recovered by simple distillation techniques.

Owner:ULTRACLEAN FUEL LTD

System and method to measure hydrocarbons produced from a well

InactiveUS20160129371A1Accurate measurementReduce capital investmentLiquid separation auxillary apparatusConstructionsEngineeringControl valves

Owner:CROSSSTREAM ENERGY

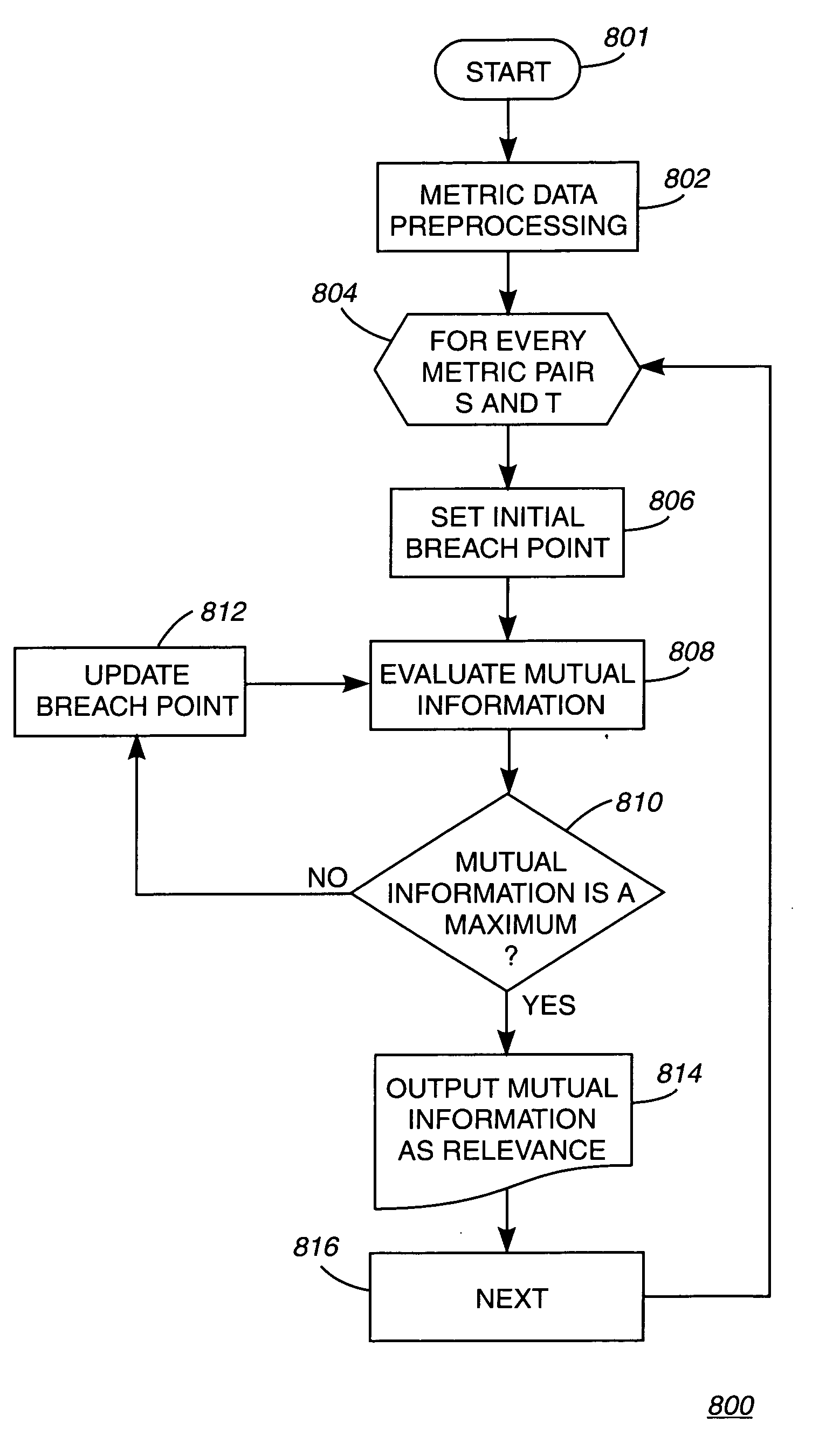

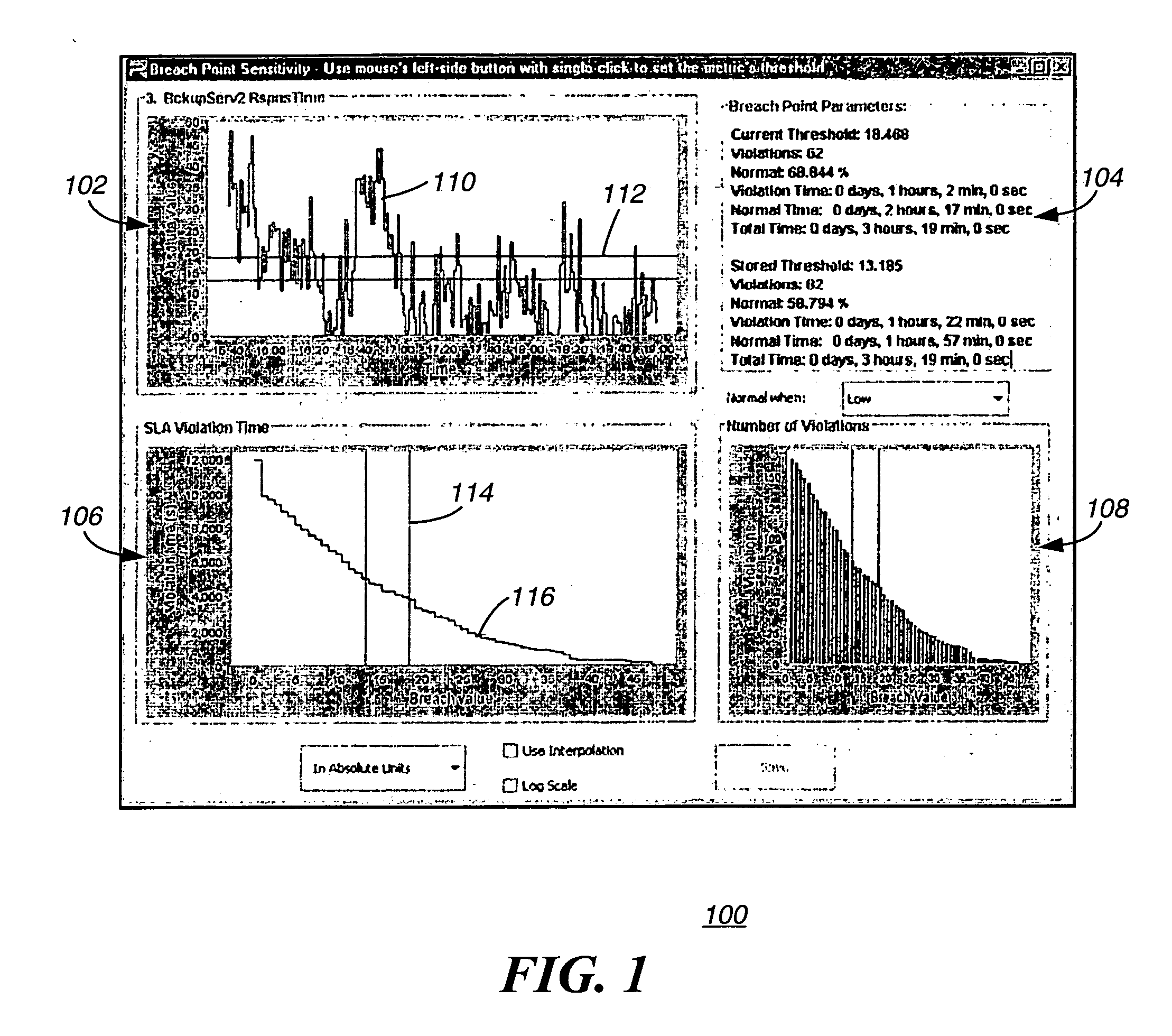

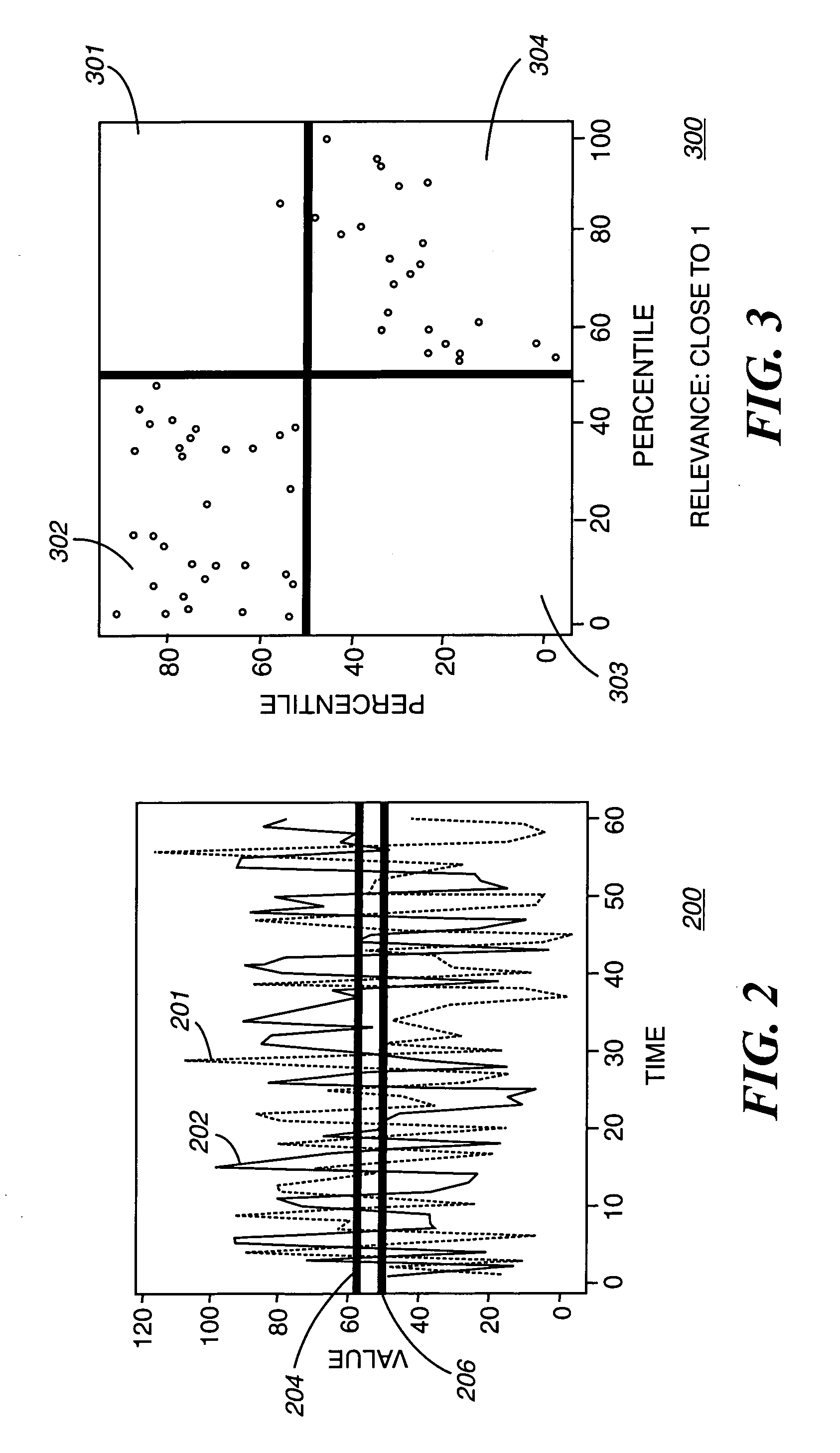

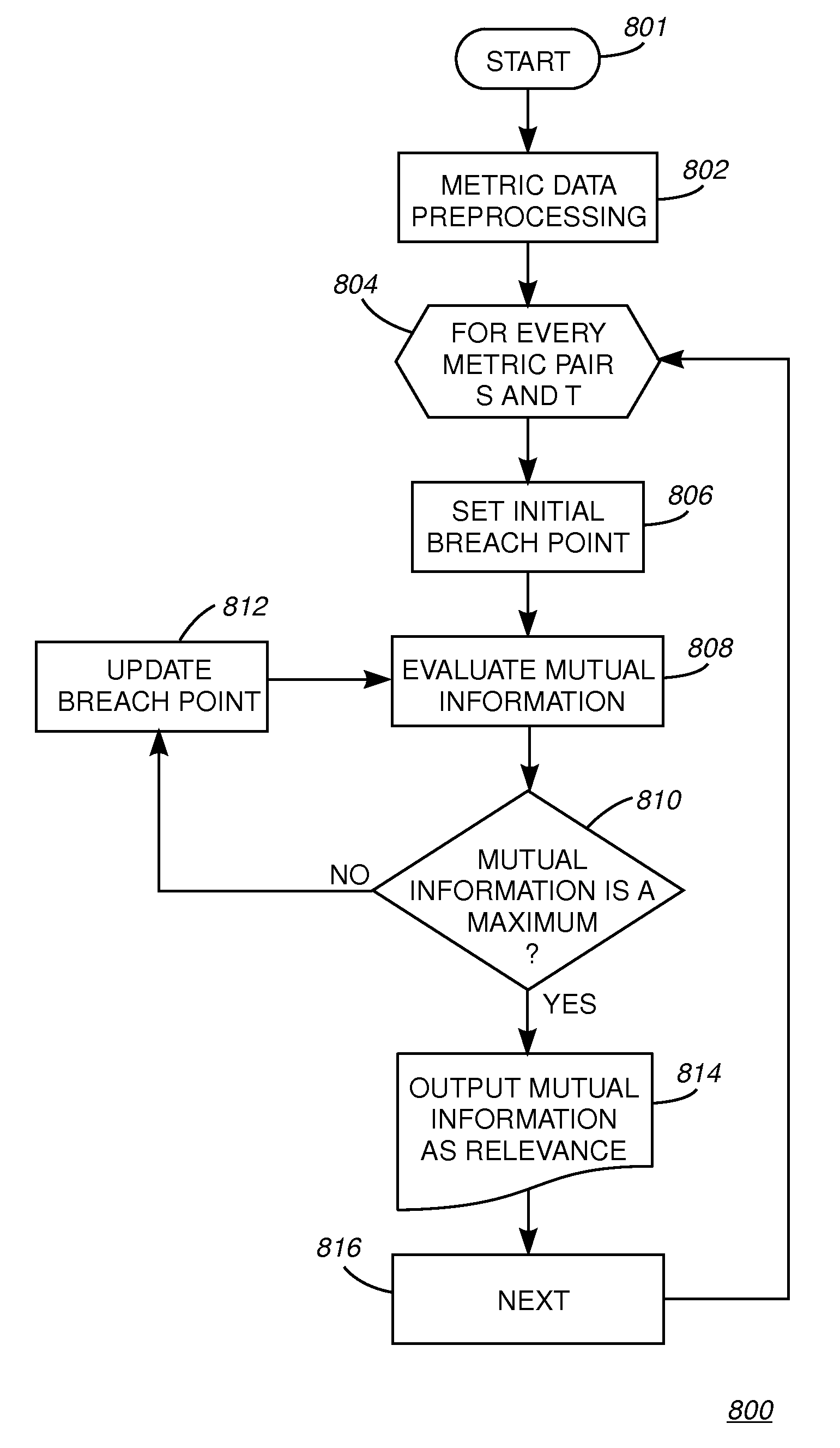

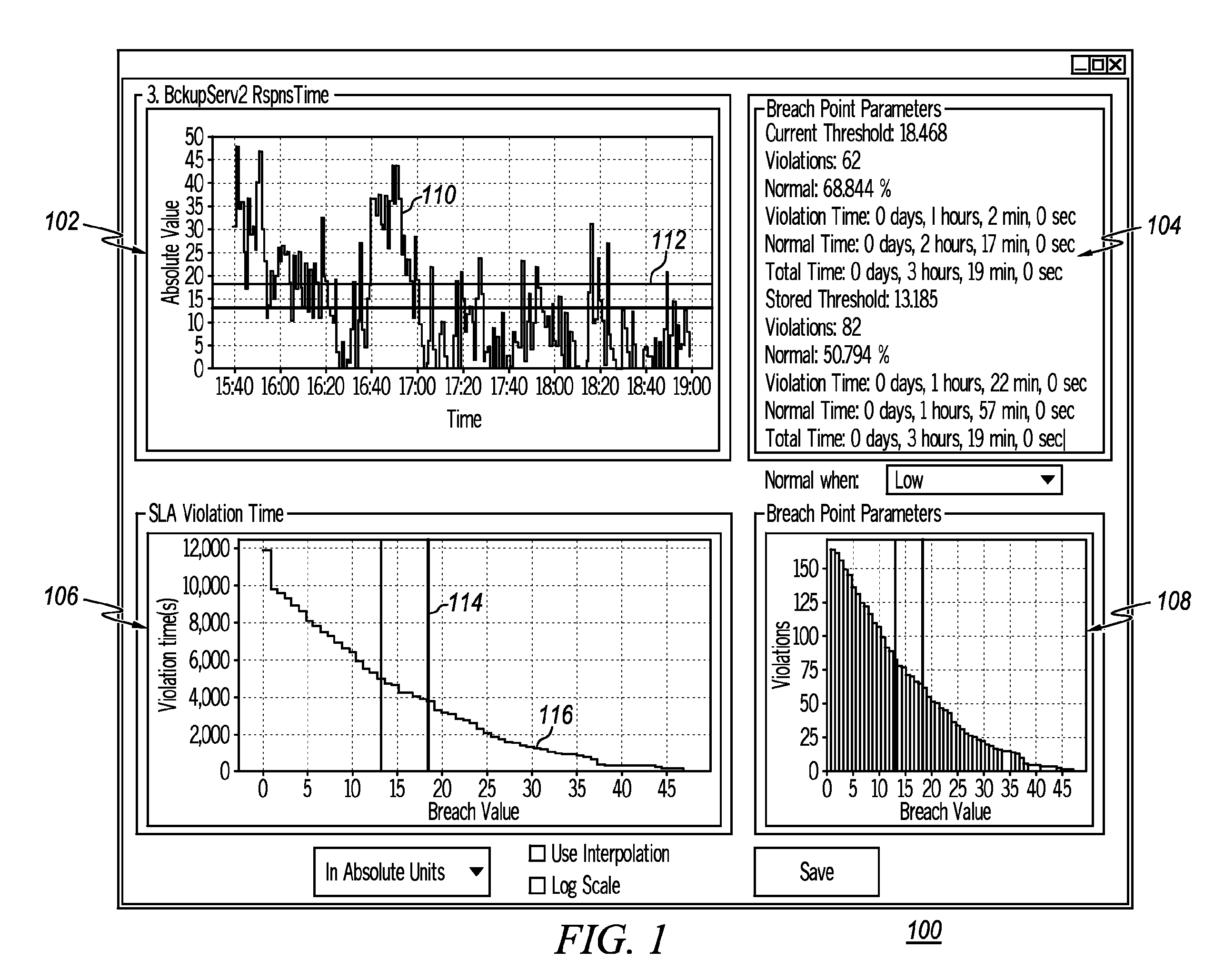

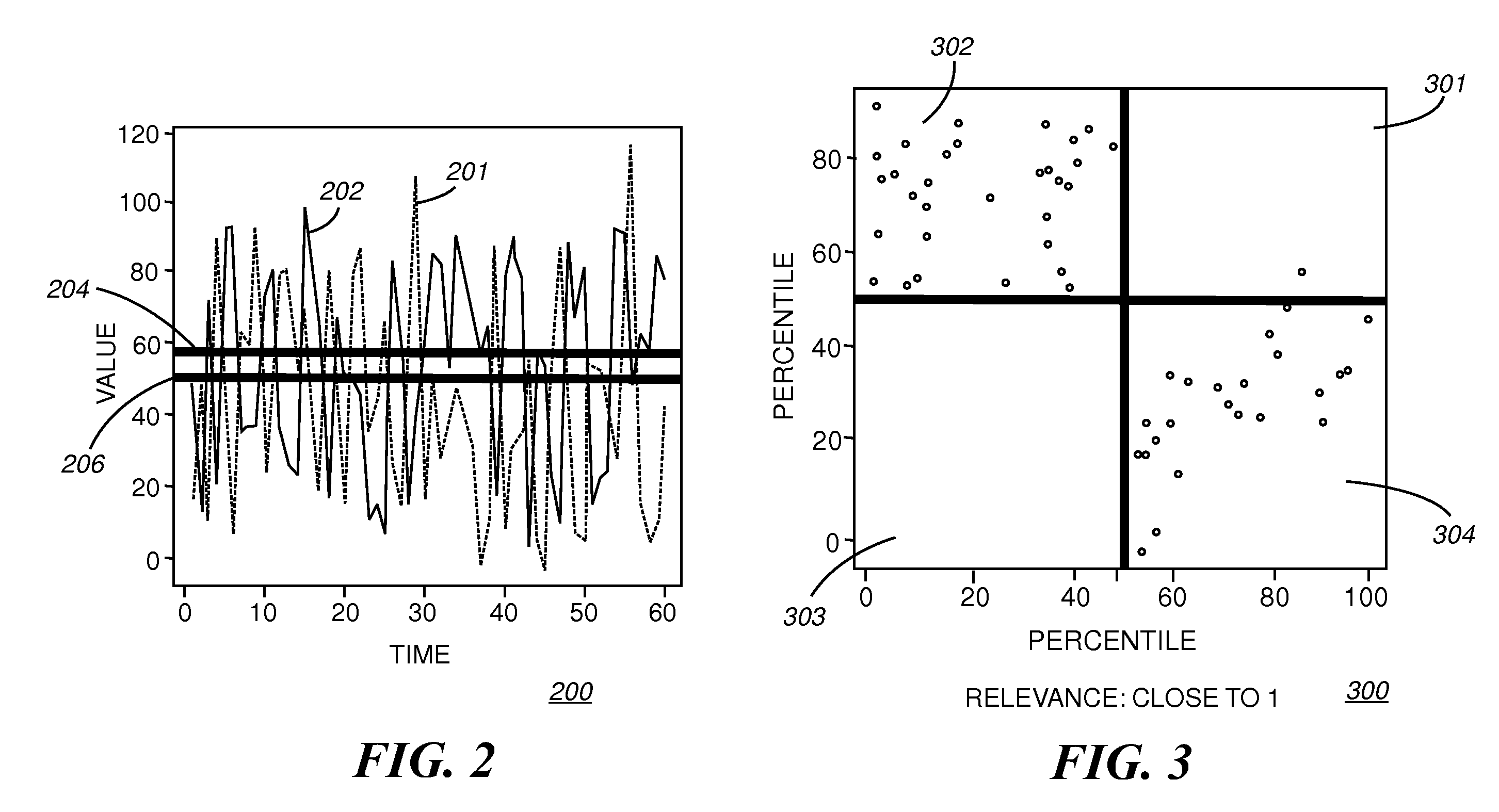

Identification of relevant metrics

InactiveUS20070263550A1Maximize distributionAvoid exceeding thresholdError preventionFrequency-division multiplex detailsFour quadrantsService-level agreement

A method and system for identifying relevant metrics among metrics that are measured to determine conformance with a service level agreement. The method includes selecting two sets of points, each set representing a given number of measurements for an individual metric and setting a separate threshold for each of the sets of points. The threshold values are selected to produce a set of quadrants so as to maximize distribution of points of intersection of each of the sets of points between a second quadrant and a fourth quadrant in a four-quadrant graph. The method can be performed on a computer system.

Owner:IBM CORP

Methods of integrating multiple management domains

ActiveUS9076111B2Easy to controlGood for healthMechanical apparatusSpace heating and ventilation safety systemsHealth safetyEngineering

An integrated solution strategy that integrates multiple domains together in a seamless and standardized way for increasing a users control over facilities and equipment. This integrated approach can lead to a reduction of energy usage, more efficient energy usage, increased safety, health, and security of a facility and its occupants, optimized production in industrial settings, and associated and other economic advantages. Accurate, reliable information about a facility or equipment is essential to making timely, informed decisions. Enhanced automation provides a reliable means of collecting and assembling a variety of operating data and archiving that data into a central database for evaluation, reporting, forecasting, and negotiation with resource marketers.

Owner:SCHNEIDER ELECTRIC USA INC

Apparatus, method, and computer program product for encoding enhanced issuer information in a card

ActiveUS20100325039A1Enhanced informationReduce complexityComplete banking machinesFinancePaymentPersonalization

Facilitating communications between an electronic payment device and an issuer host includes storing in the payment device a set of personalization parameters. A first set of status information indicative of available status information relating to the payment device is transformed into a second set of status information based on the set of personalization parameters, and / or a second set of actions is selected from a first set of actions indicative of available actions to be performed by the payment device based on the set of personalization parameters and an order received from the issuer for initiating at least one corresponding action in the payment device. The second set of status information includes a subset of the first set of status information; the second set of actions includes a subset of the first set of actions. The payment device transmits the second set of status information to the issuer and / or initiates the actions in the second set of actions corresponding to the order received from the issuer.

Owner:MASTERCARD INT INC

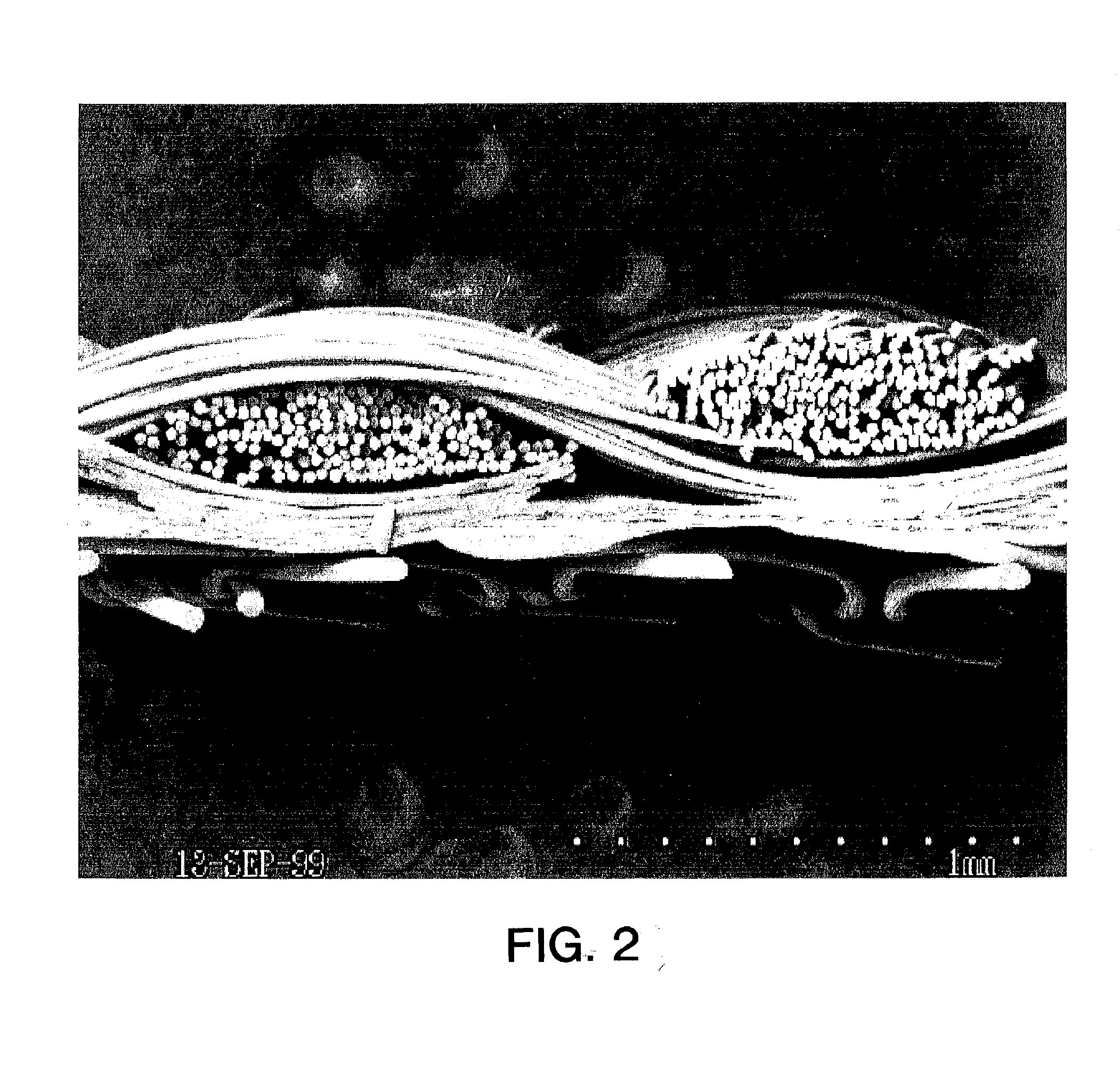

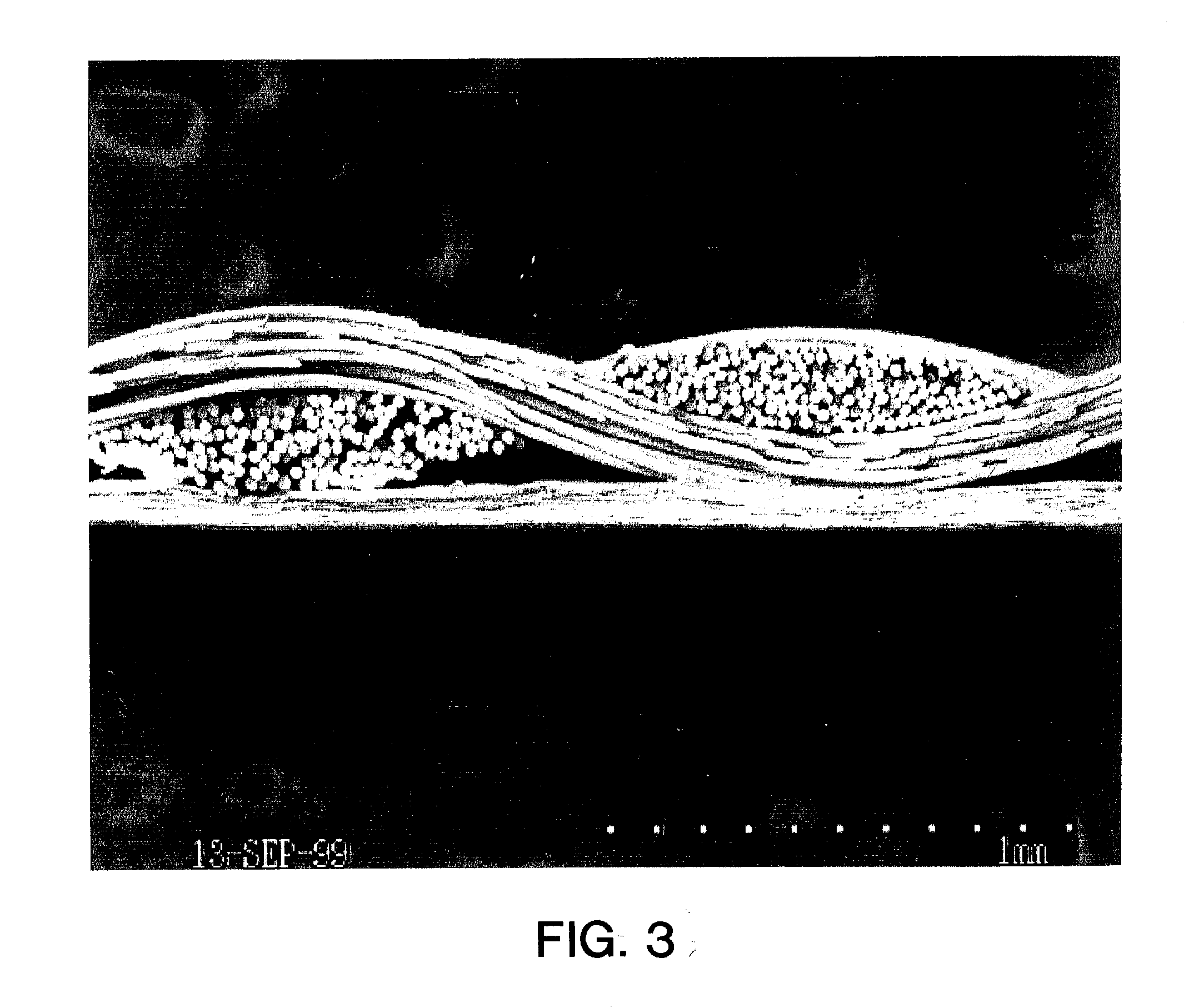

Cover For Contained Aerobic Treatment of Biodegradable Matter

InactiveUS20080011034A1Good and even supplyReduce operating costsBioreactor/fermenter combinationsBio-organic fraction processingWater vaporEnvironmental engineering

A system and method for the contained aerobic treatment of biodegradable matter, especially for box composting of organic wastes, is described. The system comprises a cover is a laminate of a porous polymeric layer adhered to a woven or knit or nonwoven fabric, in which the laminate has a specific air permeability and resistance to water vapor transmission (RET).

Owner:HOCHREIN KILIAN PETER +1

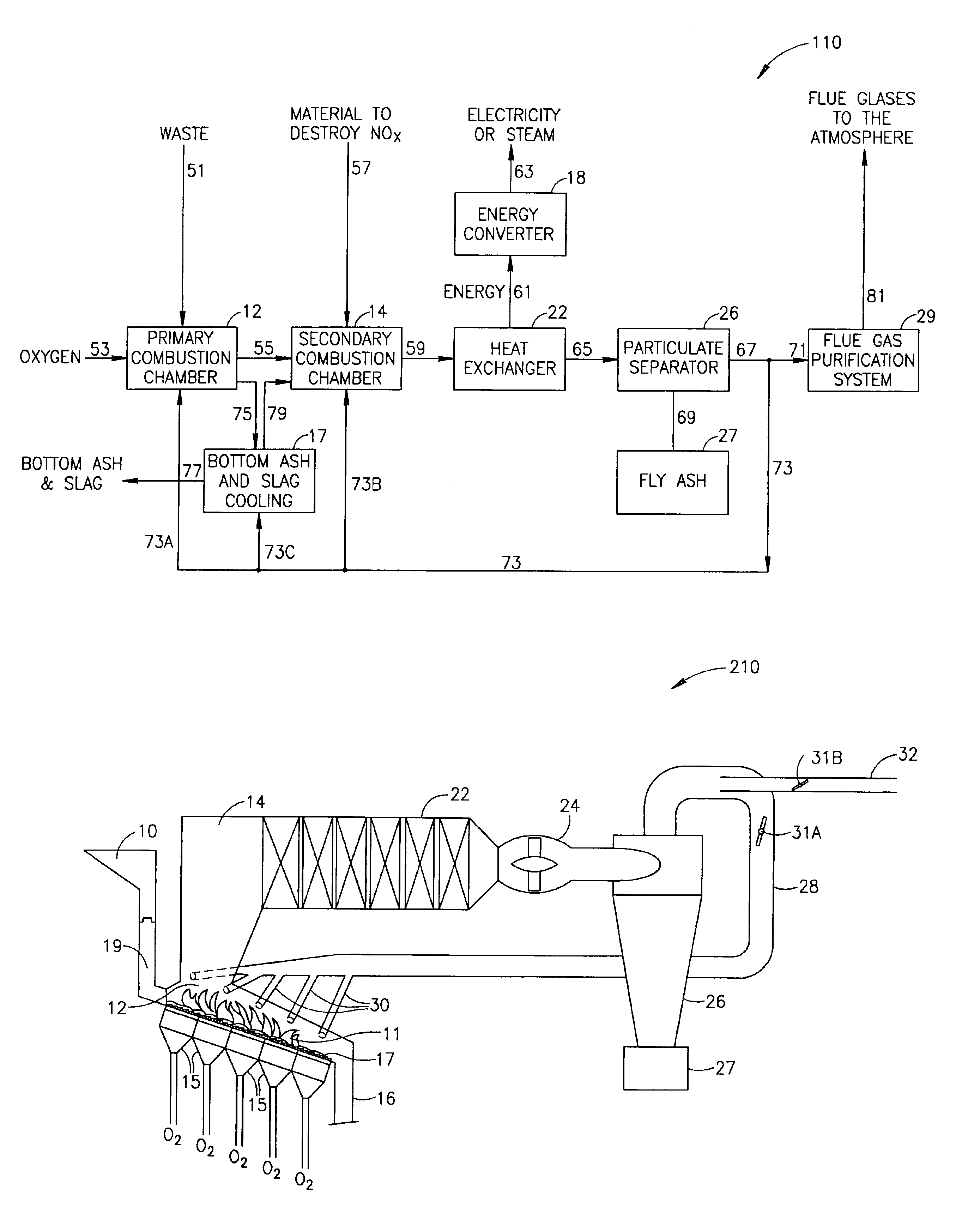

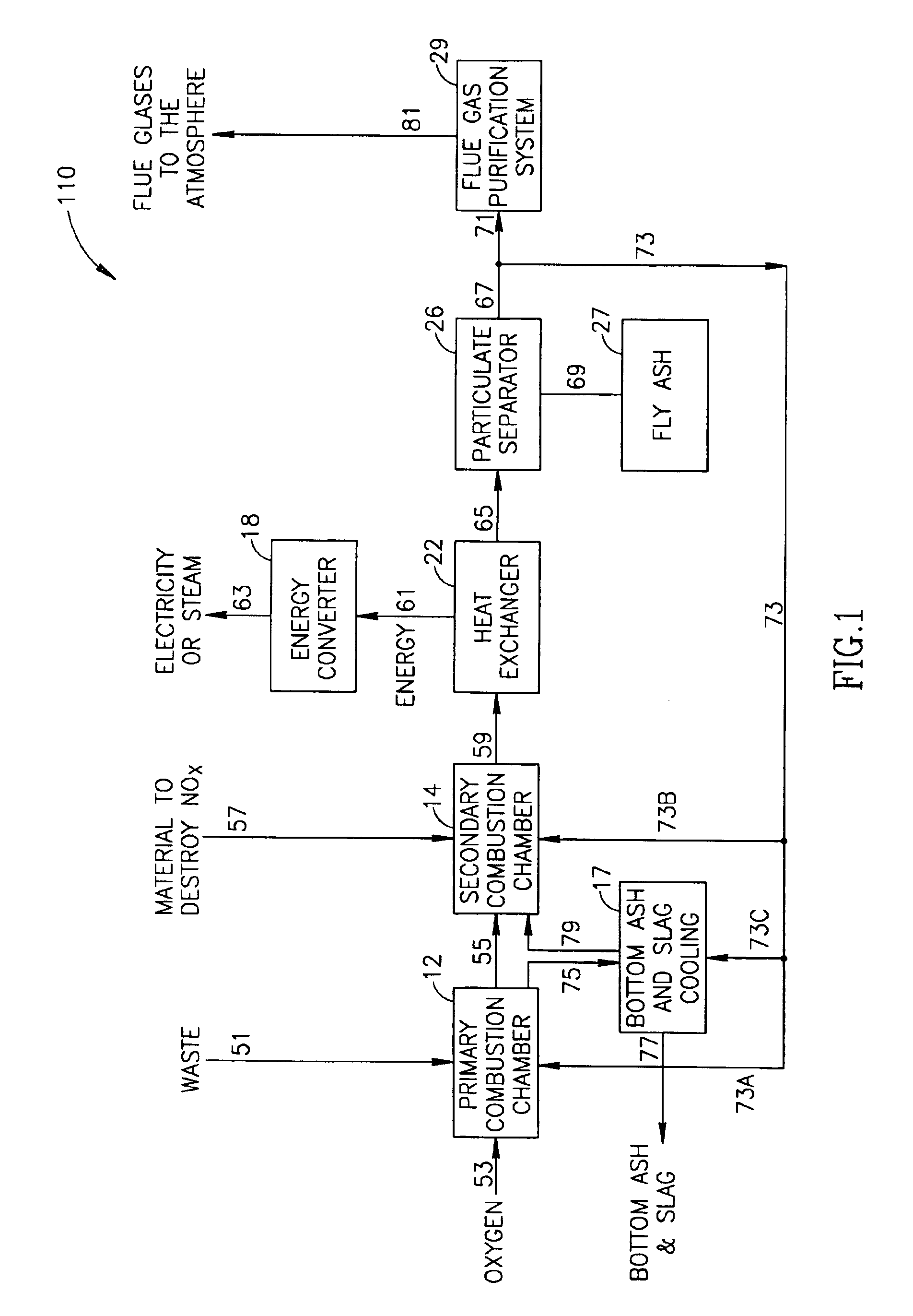

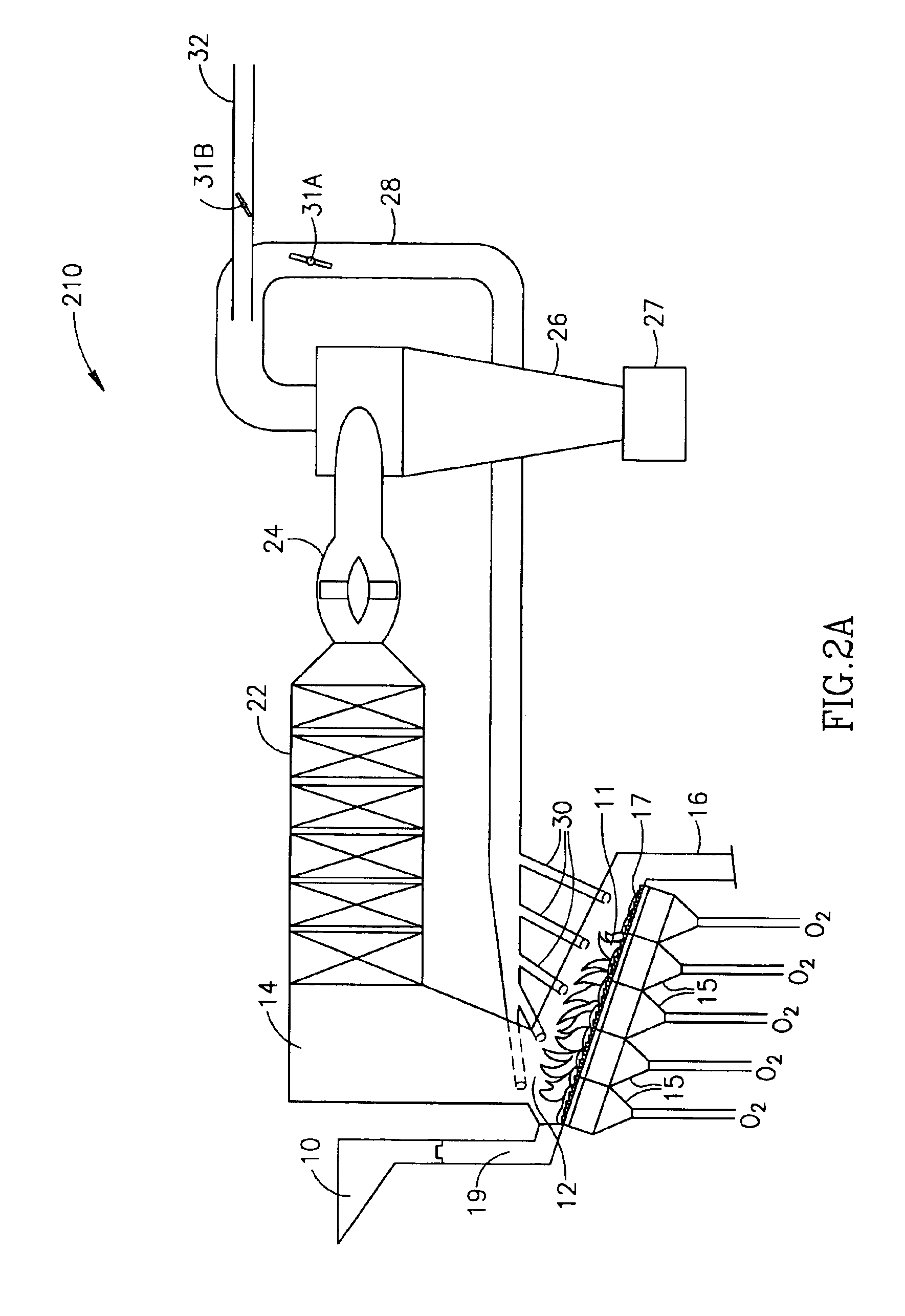

Incineration process using high oxygen concentrations

InactiveUS6952997B2Maximize throughputMinimizing gas emissionFurnace componentsEmission preventionParticulatesCombustion chamber

A process for incinerating combustible materials including the steps of: delivering combustible material and inlet gases to a primary combustion chamber, the inlet gases having an oxygen content of at least 50 vol %; burning the combustible material with the oxygen of the inlet gases in the primary combustion chamber producing flue gases and solid particulates as thermal decomposition products of the burnt combustible material; passing the flue gases and particulates to a secondary combustion chamber where further combustion occurs; cooling the flue gases exiting the secondary combustion chamber; returning a portion of the cooled flue gases to at least one of the combustion chambers where the cooled gases moderate the temperature in the at least one chamber; and passing the remaining portion of cooled flue gases on to a flue gas purification system where pollutants in the flue gases and particulates are substantially converted to benign compounds or removed entirely before the flue gases are emitted into the atmosphere.

Owner:PURE FIRE TECH

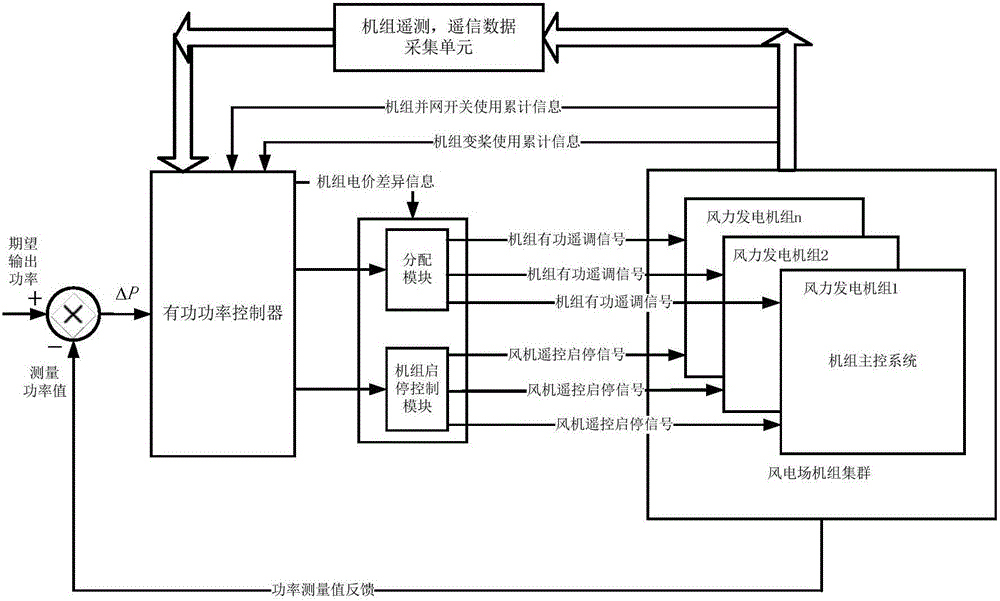

Wind farm economy-based active power adjusting method and system

ActiveCN105811472AProfit maximizationUniform service lifeSingle network parallel feeding arrangementsWind energy generationElectricity priceTurbine

The invention discloses a wind farm economy-based active power adjusting method and system. The method comprises the following steps: (A) dividing controllable priorities of all wind generator sets in a wind farm cluster according to the electricity price, and setting the wind generator set with low electricity price to be preferentially controlled high-priority set; (B) when an execution cycle T1 is reached, distributing stand-alone expected output power to all wind generator sets in the current controllable priority; (C) setting the minimum expected output power, and labeling the sets as controllable shutdown sets when the expected output power of the sets reaches the value; and (D) when an execution cycle T2 is reached, determining the shutdown order of the controllable shutdown sets according to the accumulated use frequencies of grid-connected switches of the sets and preferentially shutting down the set of which the grid-connected switch is low in accumulated use frequency. Active power adjusting control is carried out based on the wind farm economy; and the maximum profits of the wind farm and the minimum capital investment into wind turbine components can be achieved.

Owner:GUODIAN UNITED POWER TECH

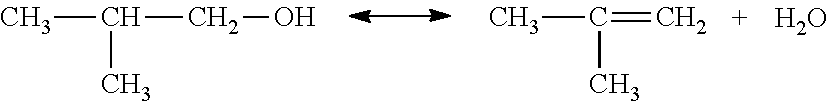

Simultaneous dehydration and skeletal isomerisation of isobutanol on acid catalysts

InactiveUS20130204057A1High yieldMinimize investmentHydrocarbon by isomerisationMolecular sieve catalystsButeneIsobutanol

Owner:TOTAL RES & TECH FELUY

Operationg of a switching node in a communications network comprising both a layered and a non-layered architectural environment

InactiveUS20050192004A1Good physical portabilityMinimize investmentMultiplex system selection arrangementsCircuit switching systemsCommunications systemService provision

The invention relates to a method for operating a switching node of a communications network, wherein the communications network comprises a layered architectural environment and a non-layered achitectural environment. The switching node provides processing capabilities for the processing of communications services both within the layered and the non-layered architectural environment The method comprises the steps of receiving a communication service request, determining according to at least one predetermined rule as an operation mode, whether the switching node is going to act for a processing of the requested communication service as a switching node of the layered architectural environment or as a switching node of the non-layered architectural environment, and processing the requested communications service in accordance with the determined operation mode of the switching node. The invention relates further to a corresponding network node, communications system and computer program

Owner:TELEFON AB LM ERICSSON (PUBL)

Simultaneous dehydration and skeletal isomerisation of isobutanol on acid catalysts

InactiveUS9233886B2High yieldMinimize investmentHydrocarbon by isomerisationMolecular sieve catalystsIsobutanolMolecular sieve

The present invention (in a first embodiment) relates to a process for the simultaneous dehydration and skeletal isomerization of isobutanol to make substantially corresponding olefins, having the same number of carbons and consisting essentially of a mixture of n-butenes and iso-butene, said process comprising:a) introducing in a reactor a stream (A) comprising isobutanol, optionally water, optionally an inert component,b) contacting said stream with a catalyst in said reactor at conditions effective to dehydrate and skeletal isomerize at least a portion of the isobutanol to make a mixture of n-butenes and iso-butene,c) recovering from said reactor a stream (B), removing water, the inert component if any and unconverted isobutanol if any to get a mixture of n-butenes and iso-butene,Wherein,the WHSV of the isobutanol is at least 1 h−1 or the temperature is from 200° C. to 600° C. and the catalyst is capable to make simultaneously the dehydration and skeletal isomerization of butene.The catalyst is a crystalline silicate of the group FER, MWW, EUO, MFS, ZSM-48, MTT, MFI, MEL or TON having Si / Al higher than 10,or a dealuminated crystalline silicate of the group FER, MWW, EUO, MFS, ZSM-48, MTT, MFI, MEL or TON having Si / Al higher than 10,or a phosphorus modified crystalline silicate of the group FER, MWW, EUO, MFS, ZSM-48, MTT, MFI, MEL or TON having Si / Al higher than 10,or a silicoaluminaphosphate molecular sieve of the group AEL,or a silicated, zirconated or titanated or fluorinated alumina.Advantageously the stream (B) is fractionated in a step d) to produce a n-butenes stream (N) and to remove the essential part of isobutene optionally recycled with stream (A) to the dehydration / isomerization reactor of step b).

Owner:TOTAL RES & TECH FELUY

Identification of relevant metrics

InactiveUS7783694B2Maximize distributionAvoid exceeding thresholdTransmissionComplex mathematical operationsFour quadrantsService-level agreement

A method and system for identifying relevant metrics among metrics that are measured to determine conformance with a service level agreement. The method includes selecting two sets of points, each set representing a given number of measurements for an individual metric and setting a separate threshold for each of the sets of points. The threshold values are selected to produce a set of quadrants so as to maximize distribution of points of intersection of each of the sets of points between a second quadrant and a fourth quadrant in a four-quadrant graph. The method can be performed on a computer system.

Owner:INT BUSINESS MASCH CORP

Ancillary cracking of heavy oils in conjunction with fcc unit operations

ActiveUS20110226668A1Minimize investmentShort stayCatalytic crackingTreatment with plural parallel cracking stages onlyUnit operationGasoline

The production of light hydrocarbons consisting of ethylene, propylene, butylenes, and of gasoline is enhanced by introducing a heavy oil feedstream derived from an external source into an ancillary downflow reactor that utilizes the same catalyst composition as an adjacent FCC unit for cracking the heavy oil and withdrawing the desired lighter hydrocarbon reaction product stream from the downflow reactor and regenerating the catalyst in the same regeneration vessel that is used to regenerate the spent catalyst from the FCC unit. The efficiency of the recovery of the desired lighter olefinic hydrocarbons is maximized by limiting the feedstream to the downflow reactor to heavy oils that can be processed under relatively harsher conditions, while minimizing production of undesired by-products.

Owner:SAUDI ARABIAN OIL CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com