Multistage spraying fluidization tail gas washing tower

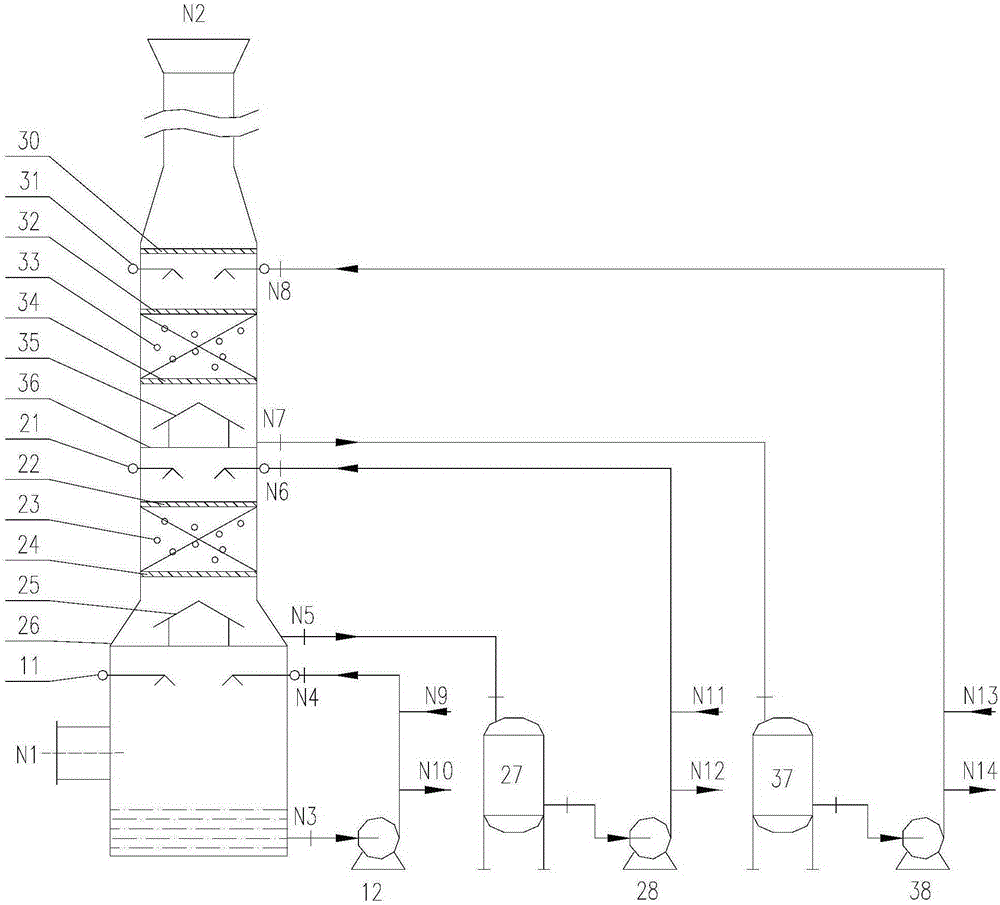

A tail gas scrubber, fluidized technology, applied in chemical instruments and methods, chemical/physical process, chemical/physical/physical chemical process, etc., can solve the problem of gas-liquid contact area and mass transfer efficiency reduction, packing and tray The problems of high construction cost and large consumption of washing liquid can achieve the effect of saving land occupation and investment, convenient system maintenance and high spray density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

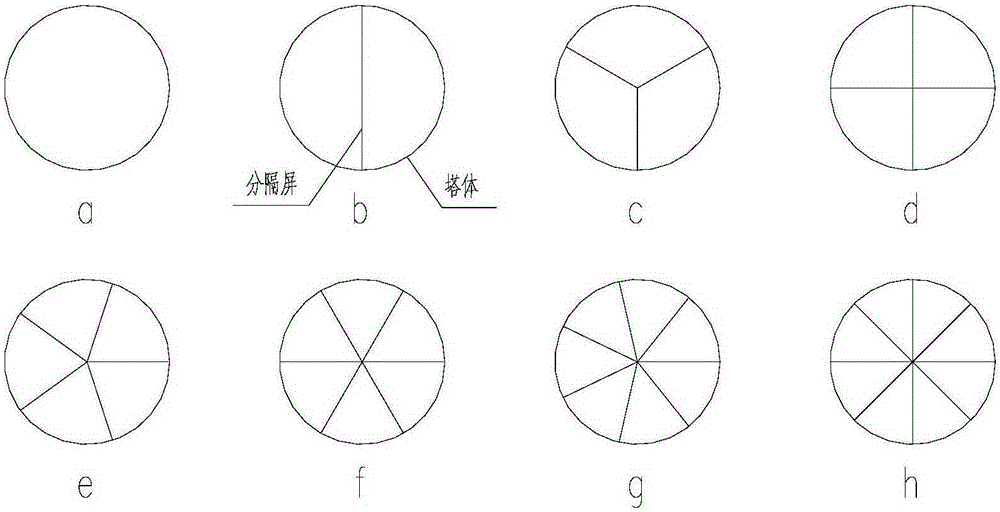

[0048] In order to ensure the effect of fluidized absorption and prevent bias flow, in this embodiment, the light spherical packing section is divided into multiple independent fluidized chambers with a partition screen. and other parameter selection, figure 2 A schematic cross-sectional view of a lightweight spherical packing segment containing 1 to 8 independent fluidization chambers with equal central angle sectors is shown. In the figure, a-h respectively correspond to 1-8 independent fluidization chambers.

[0049] After the lightweight ball packing section is divided into multiple independent fluidization chambers, the fluidization space of the light balls is restricted, making it difficult to gather in a certain part of the tower body as a whole, ensuring the fluidization of the entire fluidized packing section. The uniform contact with the gas to be washed reduces the phenomenon of bias flow and ensures the effect of fluidized washing.

Embodiment 3

[0051] When the three-stage spray fluidized washing tower in Example 1 is used to process the tail gas producing phthalic anhydride, the washing liquid in the first-level independent circulation spray section of the empty tower is water, which mainly absorbs the water-soluble organic matter in the tail gas, Such as phthalic anhydride, maleic anhydride, benzoic acid, naphthoquinone, maleic acid and phthalic acid, the collected washing liquid is sent to the organic enrichment liquid treatment section for treatment; the washing in the secondary fluidized independent circulation spray section The liquid is also water, which further promotes the full absorption of water-soluble organic matter, and the collected washing liquid is sent to the organic matter enrichment liquid treatment section for treatment; the washing liquid in the three-stage fluidized independent circulation spray section is alkaline liquid, which is mainly used for absorption SO 2 , the collected washing liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com