Integrated gas/liquid separating device with automatically controlled liquid level

A technology of gas-liquid separator and liquid level control, which is applied in the direction of liquid degassing, separation methods, chemical instruments and methods, etc., which can solve the problems of high investment and use costs, complicated technology, etc., and achieve saving investment and use costs, saving The effect of investment, simplified process configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

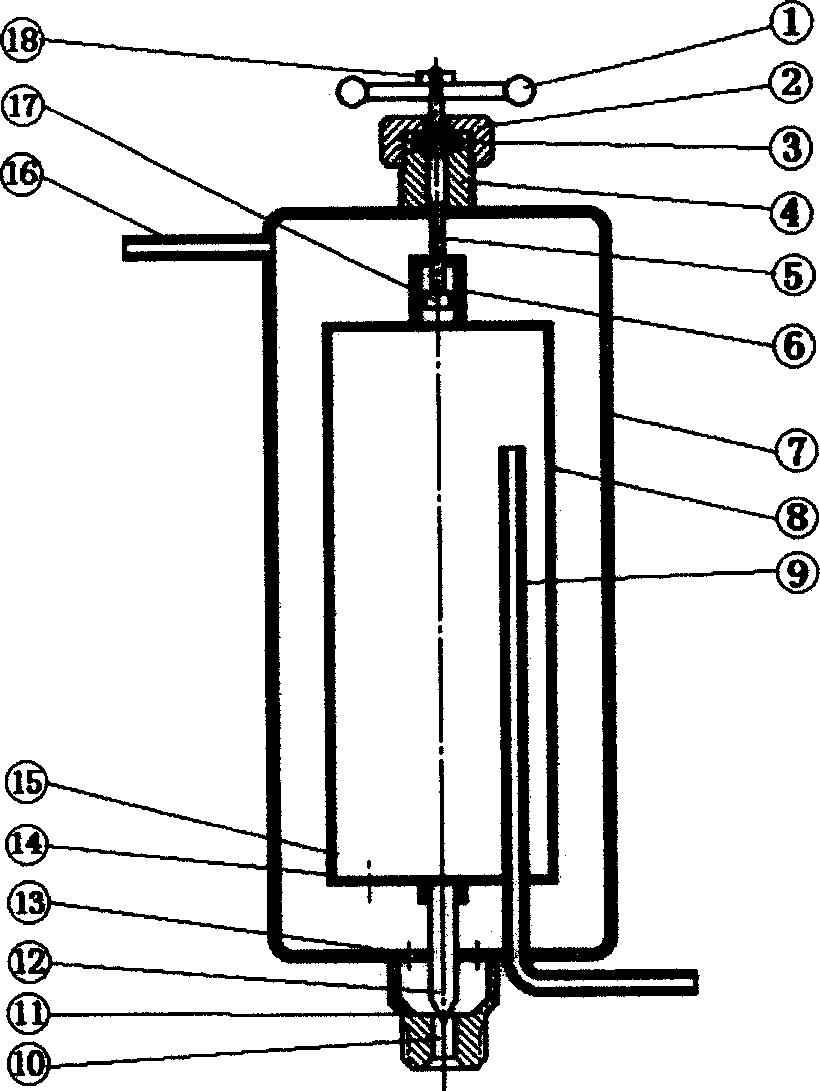

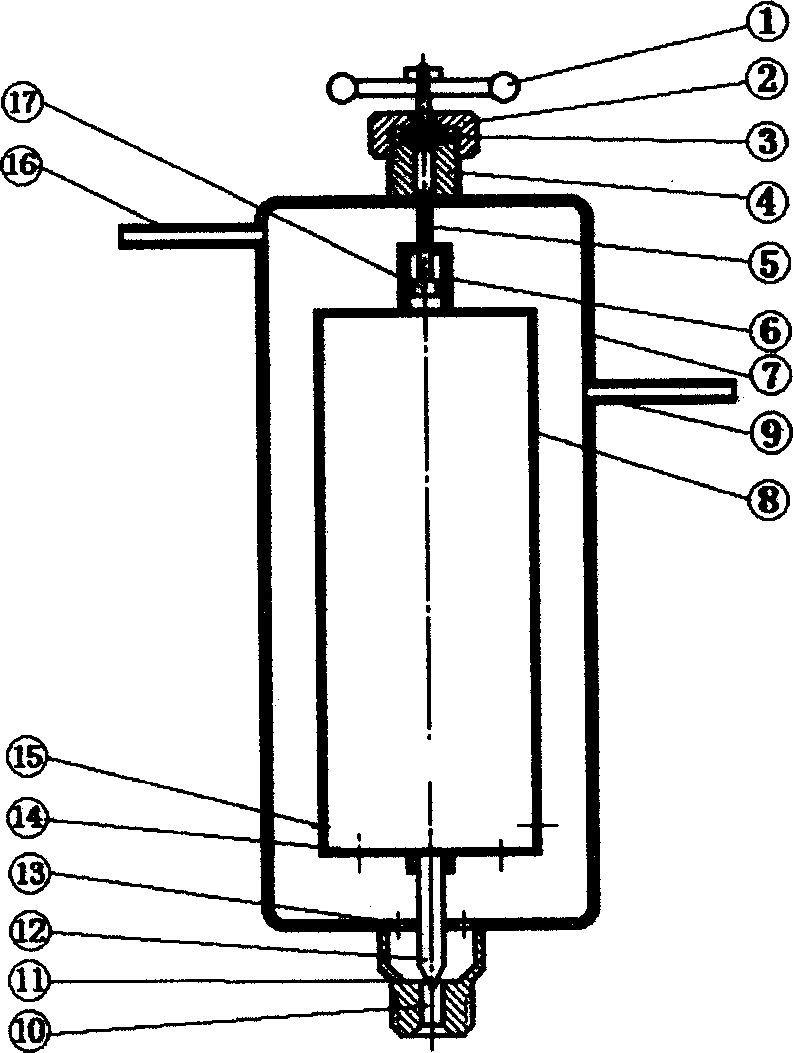

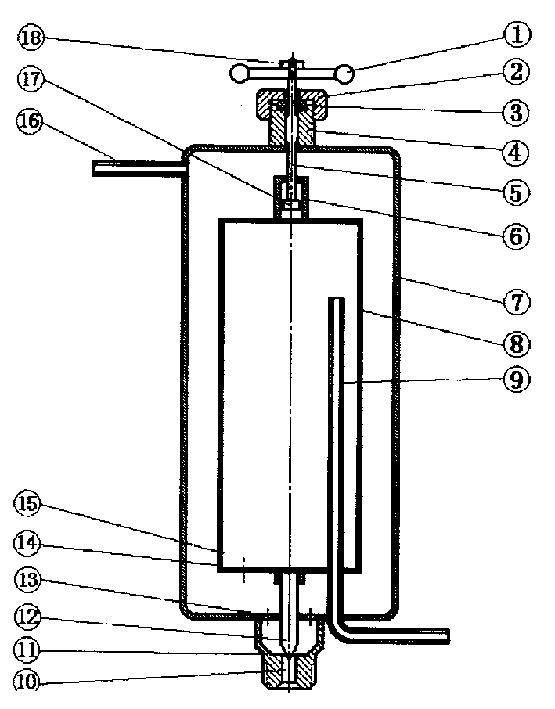

[0008] Attached below figure 1 Describe the detailed construction and use of the present invention. figure 1 In the liquid level control integrated gas-liquid separator shown, the gas-liquid two-phase fluid is separated in the buoy. The meaning of each serial number in the figure is: 1. Adjusting the handwheel, 2. Sealing nut, 3. Sealing ring, 4. Adjusting thread sleeve, 5 Adjusting thread slide rod, 6 Adjusting sliding sleeve, 7 Separator outer cylinder, 8 Float, 9 Feed pipe, 10 Drain valve outlet, 11 Drain valve body, 12 Drain valve needle rod, 13 Drain valve inlet, 14 Bottom holes of the buoy, 15 Bottom side holes of the buoy, 16 Exhaust pipe, 17 Adjustable thread slide rod chuck. Wherein the adjustment handwheel 1, the adjustment thread sleeve 4, the adjustment thread slide rod 5 and the adjustment slide sleeve 6 are composed, the adjustment handwheel 1 is rigidly connected with the adjustment thread slide rod 5, the adjustment thread sleeve 4 and the adjustment thread sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com