Laminated board formed by fine disintegration and rearrangement of whole raw bamboos and production technical method thereof

A fine thinning and fine-grained technology, applied in the field of original whole bamboo fine thinning and recombined laminated wood and production technology, can solve the problems of loss of bamboo and failure to retain the largest physical stock of bamboo, so as to achieve the goal of not being easily deformed, maintaining resistance Tensile and compressive properties, the effect of uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

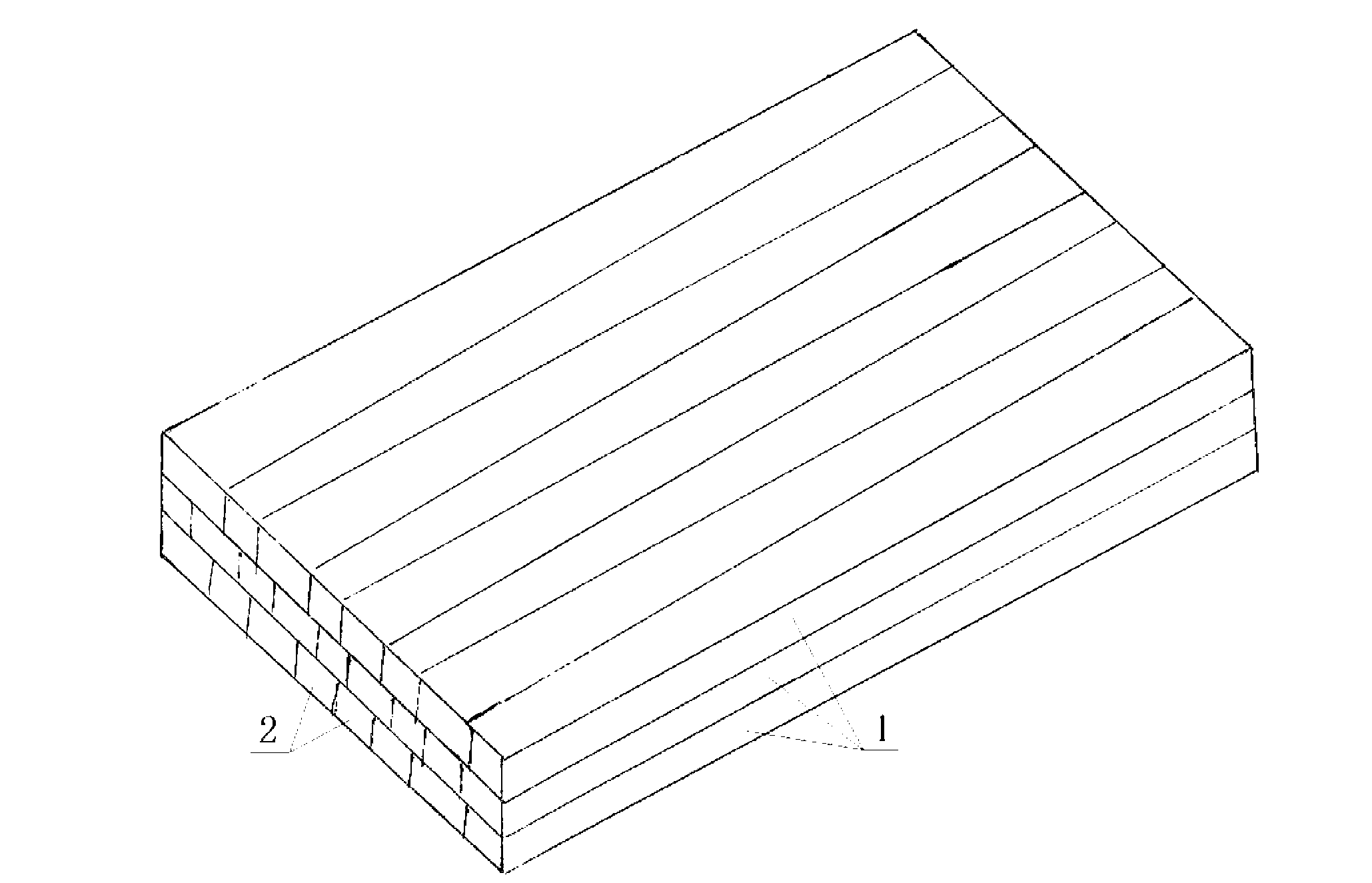

[0029] see figure 1 , the original state whole bamboo fine decompression and recombined laminated lumber of the present embodiment is formed by layering and superimposing three layers of fine decompression bamboo silk block single-layer boards 1, wherein the bamboo green between two adjacent layers of single-layer boards 1 Adhere to the green surface of the bamboo or the yellow of the bamboo and the green surface of the bamboo, bond and heat press with an adhesive to form an integrated body.

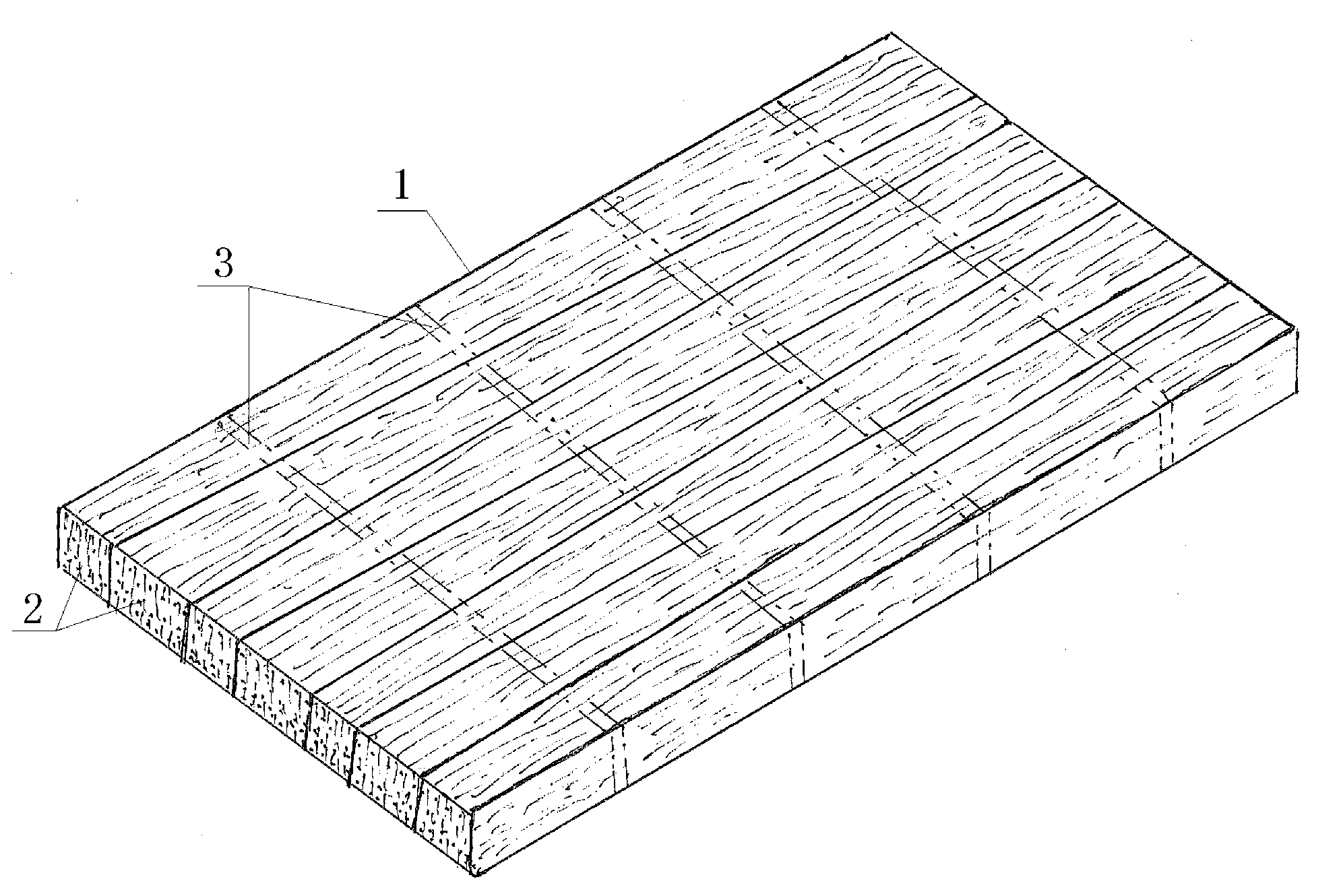

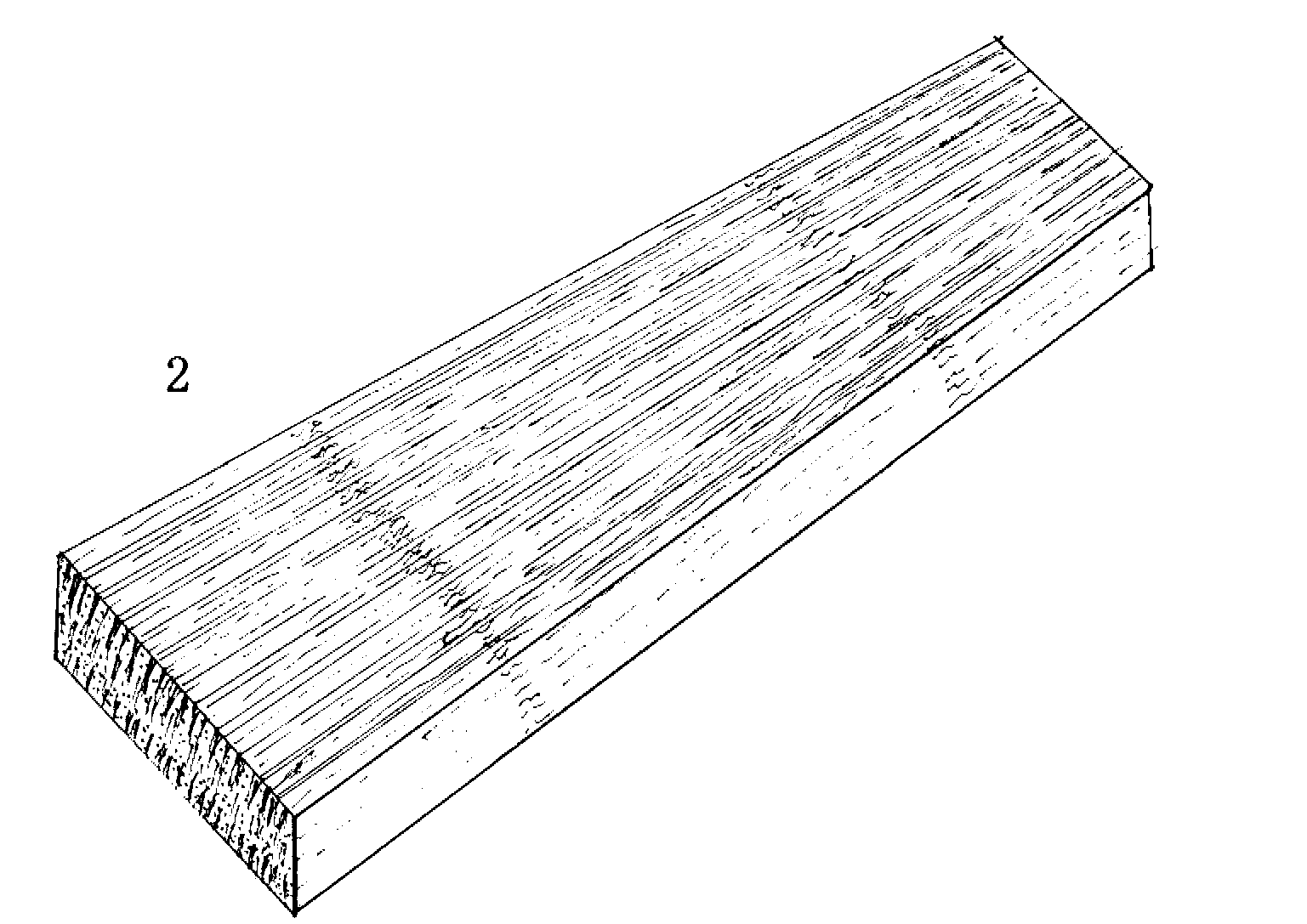

[0030] see figure 2 , is the schematic diagram of the formation of the single-layer board 1 of the refined and decomposed bamboo silk block of the present embodiment. It is composed of several trapezoidal refined and decomposed bamboo silk block units 2 with equal thickness and different width. The wide end and the narrow end of the block are alternat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com