Continuous casting and rolling device and method for producing long profiles

A technology of continuous casting and rolling and long products, applied in the direction of metal rolling, etc., can solve the problems of inability to apply continuous casting and rolling process, unable to make full use of hot casting billets, not set foot in the field of long products, etc., and achieve good application prospects. , Significant economic and social benefits, the effect of saving equipment investment and site area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

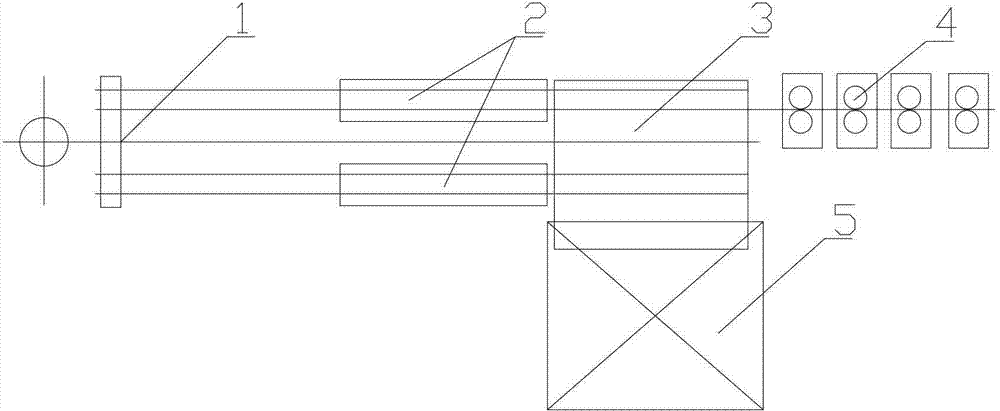

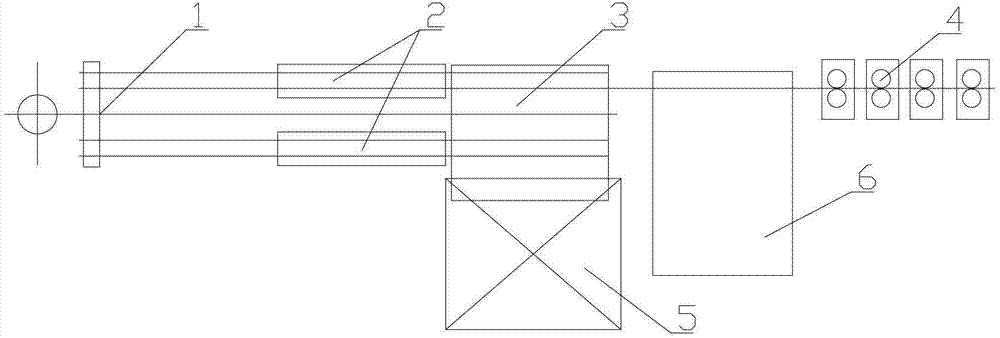

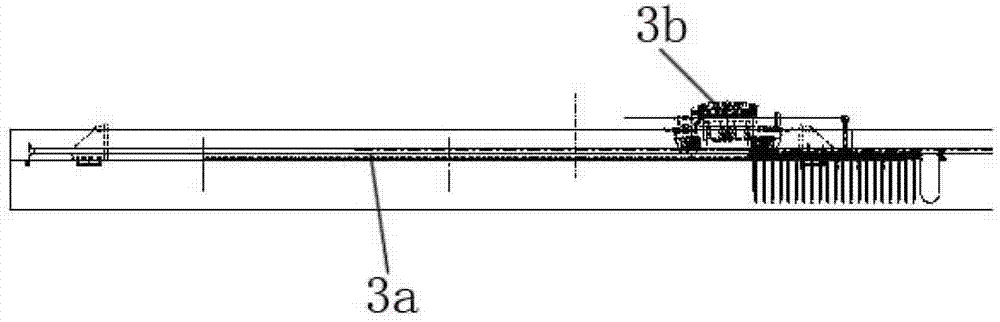

[0043] Such as figure 1 As shown, the embodiment of the present invention proposes a continuous casting and rolling device for producing long products, which includes a continuous casting machine 1, and the rear part of the cutting machine of the continuous casting machine 1 is closely connected with a roller hearth heating furnace 2 in sequence. , a traverse device 3 and a rolling mill 4 capable of low-temperature rolling.

[0044] The application process of this embodiment is as follows: the long material generally enters the continuous casting machine 1 in a multi-flow manner to produce multi-flow slabs. After the billet is cut by the cutting machine of the continuous casting machine, it directly enters the roller hearth heating furnace 2. Through the roller hearth heating furnace 2, the sensible heat of the billet can be realized and utilized, and the billet can be effectively heated and kept warm to make it cast The billet temperature reaches about 950-1050° C., so as to...

Embodiment approach 2

[0054] Embodiments of the present invention also propose a continuous casting and rolling method for producing long products, which includes the following steps:

[0055] A. Long products enter the continuous casting machine in a multi-strand manner to produce multi-strand slabs;

[0056] B. After the billet is cut by the cutting machine of the continuous casting machine, it directly enters the roller hearth heating furnace for heating and heat preservation;

[0057] C. The cast slabs coming out of the roller hearth heating furnace are sent to the rolling mill in sequence for each flow of slabs through the traverse device and directly rolled at low temperature.

[0058] Other structures, working principles and beneficial effects of this specific embodiment are the same as those of specific embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com