Catalytic cracking method and catalytic cracking device for producing propylene

A catalytic cracking device and catalytic cracking technology, applied in the direction of hydrocarbon cracking to hydrocarbon, bulk chemical production, only multi-stage series refining and cracking process treatment, etc., can solve the problem of difficult to meet the requirements of high-yield small molecule olefins, increase small molecule Solve problems such as small range of olefin yield and reduce the overall effect of the catalyst system, so as to achieve the effect of compact equipment, saving investment and space, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

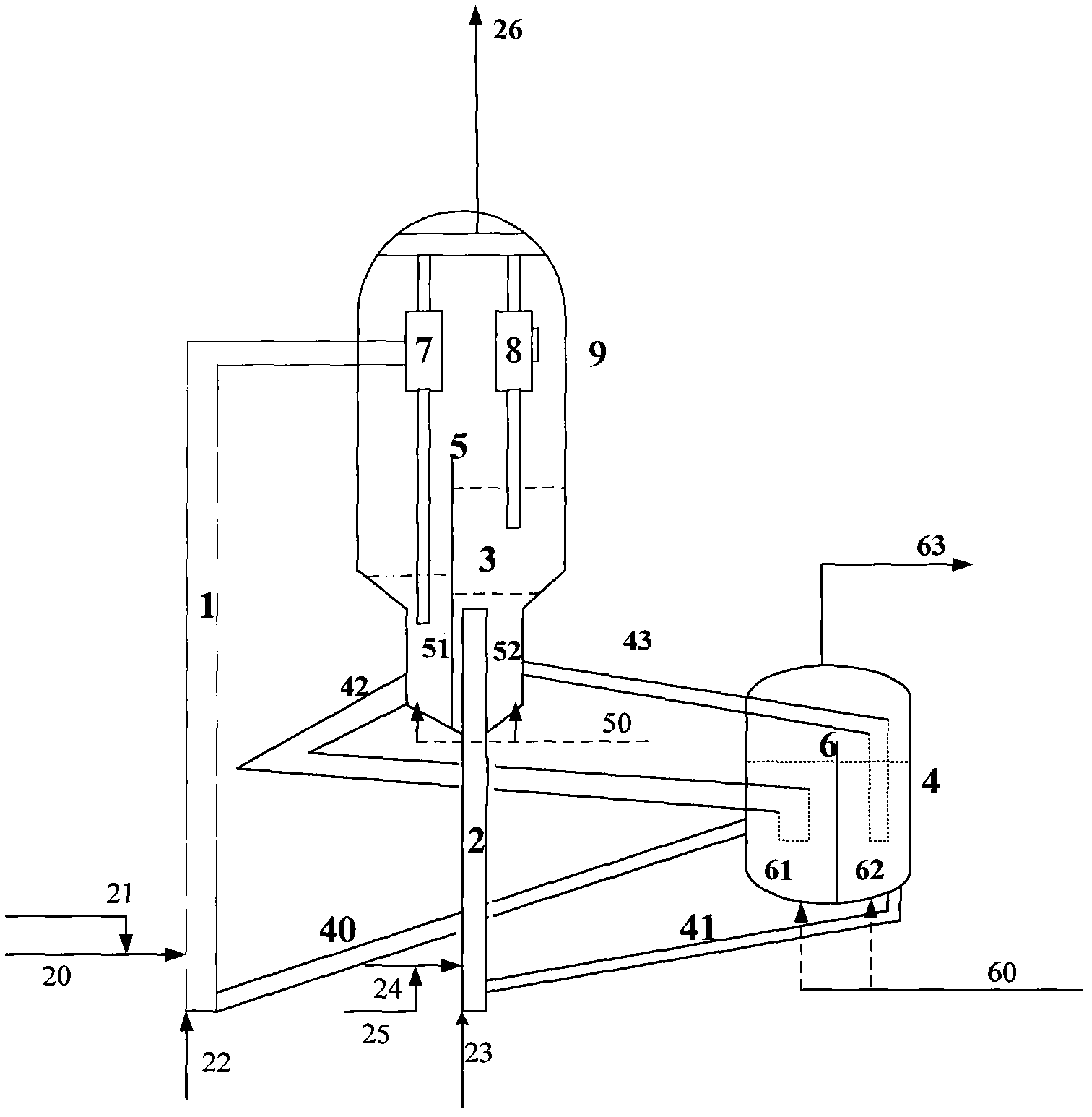

Method used

Image

Examples

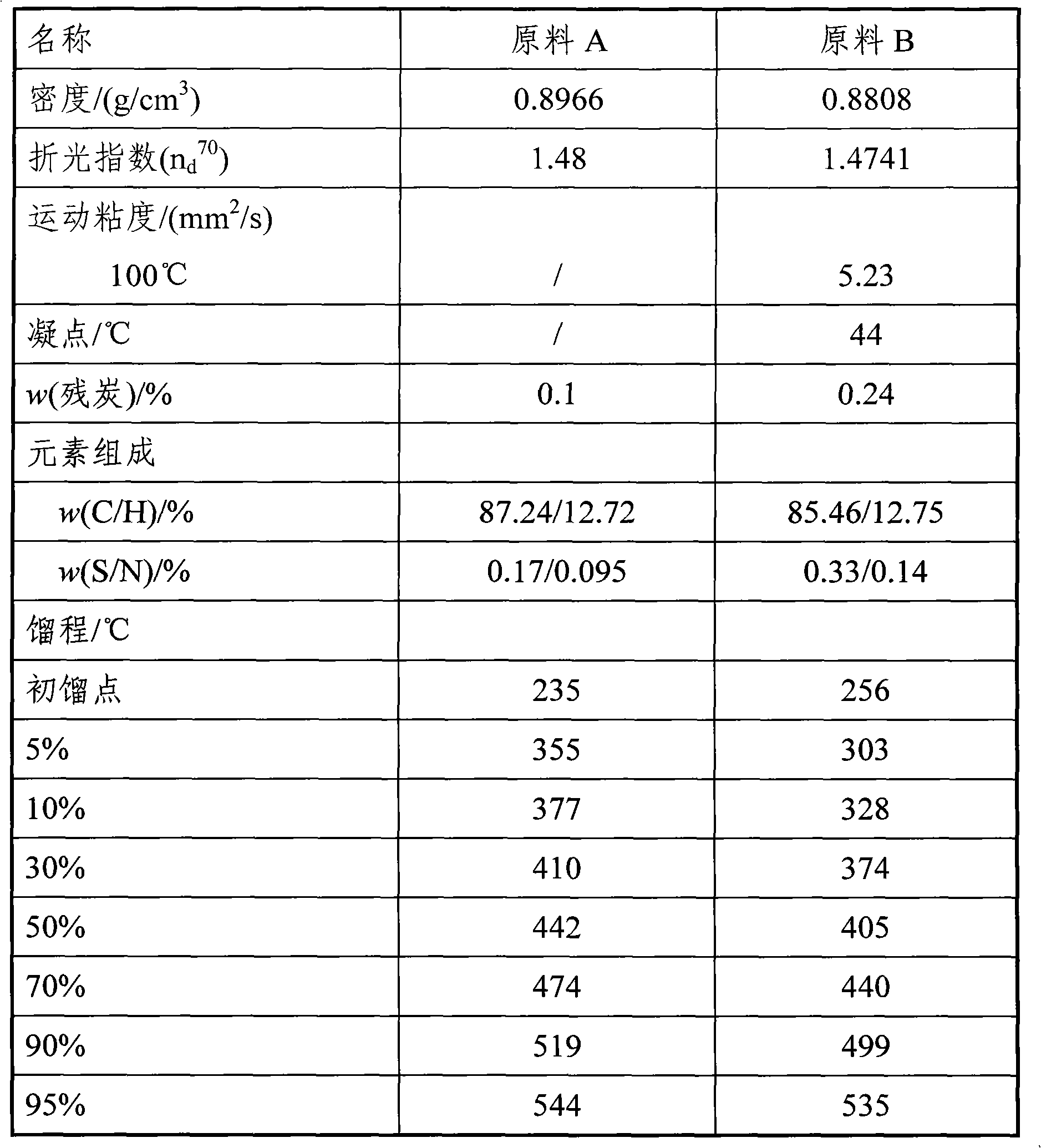

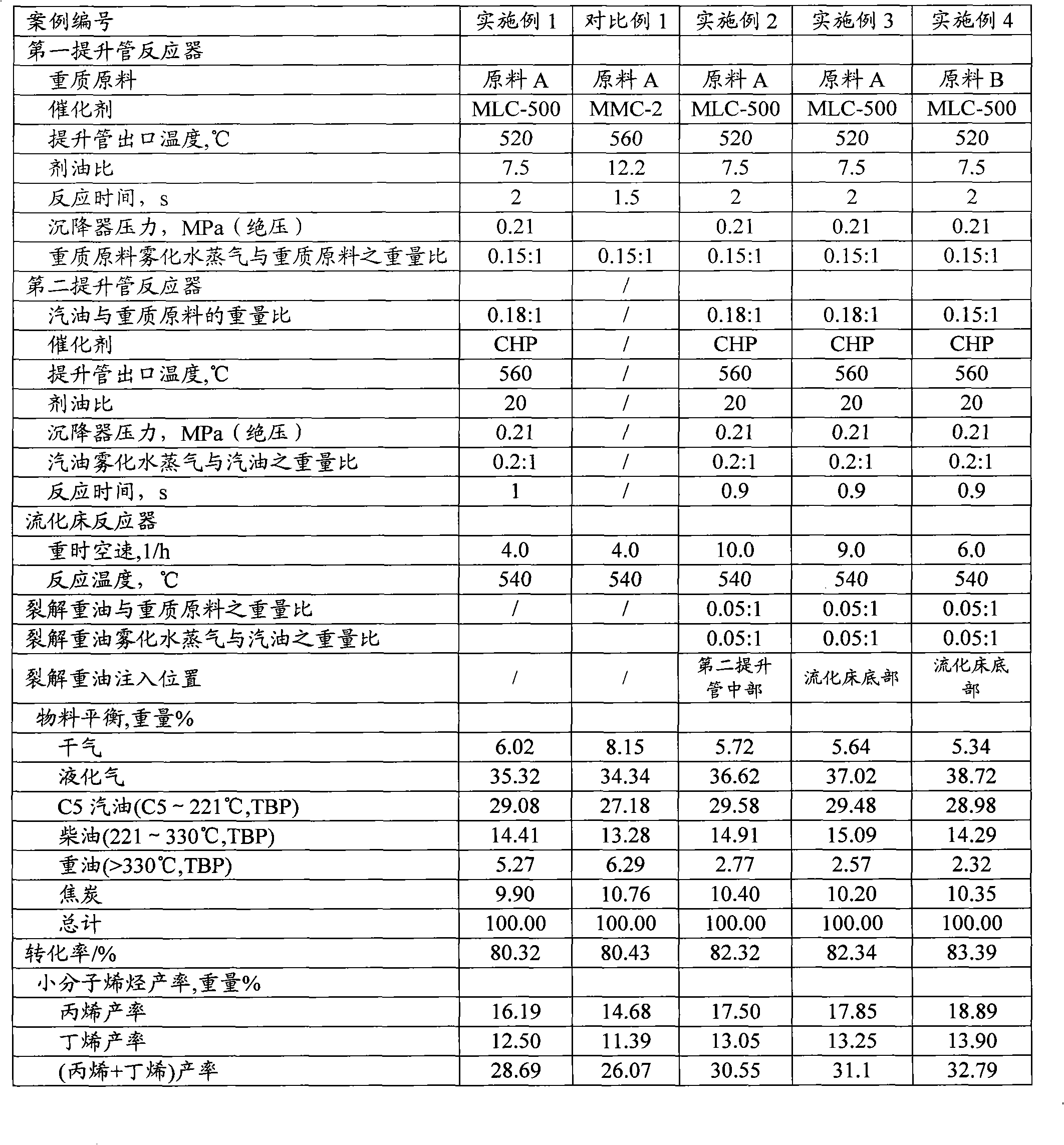

Embodiment 1

[0043] The experiment was carried out in a medium-sized catalytic cracking unit. This device comprises two sets of independent reaction regeneration systems: the first riser reactor, internal diameter is 16 millimeters, and length is 3800 millimeters, and the catalyst used is MLC-500, raw material A shown in table 1 is cracked; The oil and gas are separated from the catalyst. The catalyst is stripped in the first stripper and then regenerated in the first regenerator. The regenerated catalyst is returned to the first riser reactor for recycling; the oil and gas are introduced into the product separation system for separation. The inner diameter of the second riser reactor is 16mm, and the length is 3200mm. After the second riser reactor, the fluidized bed reactor is connected in series. The diameter of the fluidized bed reactor is 64 millimeters (internal diameter), and the height is 600 millimeters; Tube reactors and fluidized bed reactors convert the gasoline fraction (disti...

Embodiment 2

[0048] With reference to Example 1, the difference is that the cracked heavy oil (the distillation range of the cracked heavy oil is 350~500° C.) that is introduced into the second riser reactor in the second riser reactor at a distance of 1.5 meters from the outlet of the product separation system, The weight ratio of the introduction amount of cracked heavy oil to raw material A is 0.05:1. The reaction conditions and reaction results are shown in Table 3.

Embodiment 3

[0050] According to the method of Example 2, the difference is that the cracked heavy oil is introduced into the bottom of the fluidized bed reactor, and the cracked heavy oil is not introduced into the riser reactor 2 . The reaction conditions and reaction results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com