Brushless multi-working-condition direct-current electrically-driven pump

A DC motor, electric pump technology, applied in pump control, non-variable capacity pump, engine components, etc., can solve the problem that the operating point is not adjustable or the adjustable range is small, the working state of the oil pump is single, and the power-to-weight ratio is low. problems, to achieve the effect of good manufacturing process and maintenance, suitable for industrial development, and high power-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] See the specific implementation Figure 1 to Figure 6 . The present invention will be further described in detail through specific embodiments below.

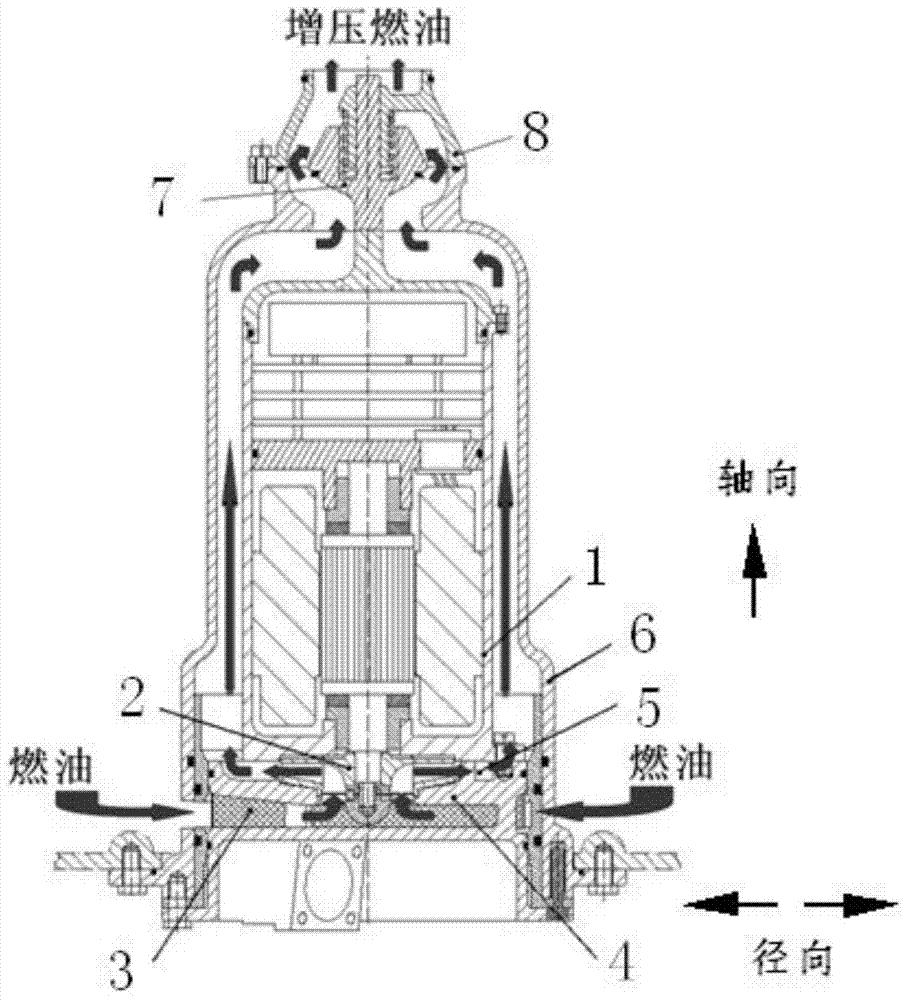

[0019] The multi-working condition brushless DC electric pump is composed of two parts: a pump core assembly and a disassembled self-sealing assembly, wherein the pump core assembly includes a brushless DC motor 1, a centrifugal impeller 2, a filter screen 3, a pump inlet section 4 and a diameter The guide vane 5 is equipped with a self-sealing assembly including a pump cover 6 , a one-way valve 7 and a valve housing 8 . Such as image 3 , Figure 4 shown. The centrifugal impeller (2) installed on the shaft of the brushless DC motor (1) is driven by a brushless DC motor (1) to rotate, and the fuel in the suction tank passes through the filter screen (3) and the radial channel of the fan-shaped section. Enter the pump inlet section (4), flow through the centrifugal impeller (2) for centrifugal boosting, and then ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com