Air temperature adjusting system

A technology for regulating system and air temperature, which is used in joint combustion mitigation, cooling of turbine/propulsion units, engine components, etc. Cooling water consumption and other problems of the steam generator, to achieve the effect of improving thermal economic performance, low operation and maintenance costs, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

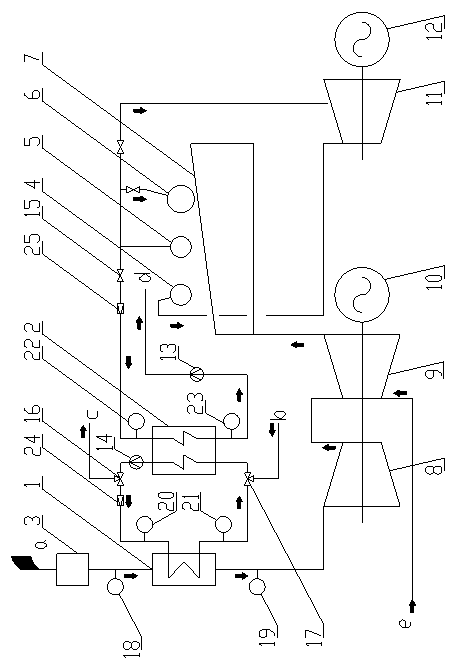

[0020] Example 1, such as figure 1 As shown: the circulation medium in the hot side of the air heat exchanger 1 is air, and the circulation medium in the cold side is water; the steam-type absorption refrigerator 2 uses water as a refrigerant and lithium bromide as an absorbent; the steam-type absorption refrigerator 2 The heat source inlet circulation medium is steam, and the outlet circulation medium is water.

[0021] An air filter 3 is provided on the hot side air intake pipe of the air heat exchanger 1, and the hot side air outlet pipe of the air heat exchanger 1 is connected with an air compressor 8, and the cold side air inlet pipe of the air heat exchanger 1 is The water outlet and the water outlet are respectively connected with the water outlet and the water inlet of the steam-type absorption refrigerator 2 through pipelines;

[0022] A water supply pump 14 is provided on the cooling water outlet pipeline of the steam-type absorption refrigerator 2 , and a condensat...

Embodiment 2

[0029] Other structures of Embodiment 2 are the same as those of Embodiment 1, except that there are two or more air heat exchangers 1 and steam-type absorption refrigerators 2 . The air heat exchangers 1 are connected in parallel, that is, the hot-side air outlets of each air heat exchanger 1 are connected to the gas turbine air compressor 8; they are all separately supplied to the gas turbine air compressor 8, The steam-type absorption refrigerators 2 are connected in parallel, that is to say, each steam-type refrigerator 2 is connected to one or more air heat exchangers 1 separately, supplies water independently, and works independently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com