Reheat steam temperature control system and method and thermal power generating unit device

A technology for reheating steam temperature and control system, which is applied in general control system, superheat temperature control, control/regulation system, etc., can solve problems such as adjustment and method to ensure the stability of reheated steam temperature and reduce economic benefits of thermal power units.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

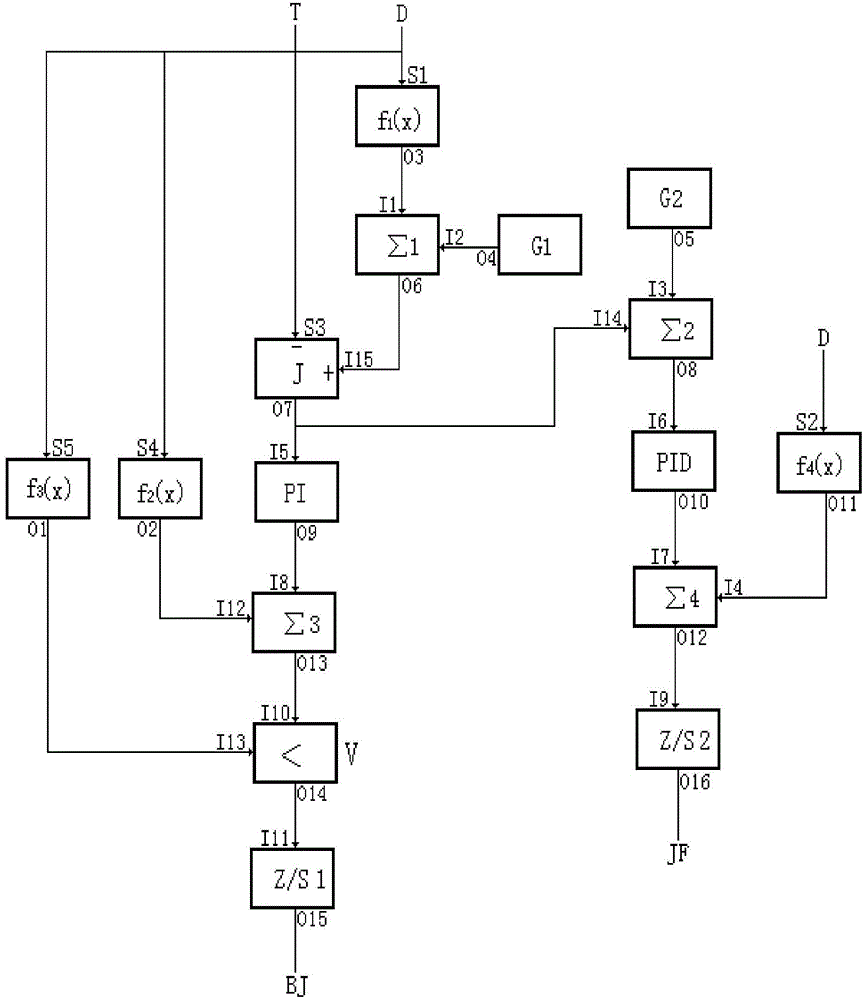

[0029] The present invention provides a reheat steam temperature control system, the schematic diagram of its circuit structure is as follows figure 1 As shown, it includes the first function module f1(x), the first addition module Σ1, the addition and subtraction module J, the first adjustment module PI, the third addition module Σ3, the small selection module V and the first operation module connected in sequence Z / S1, the input terminal of the first adding module Σ1 is also connected with the output terminal of the first constant value module G1, and the input terminal of the third adding module Σ3 is also connected with the output terminal of the second function module f2(x).

[0030] The output terminal of the addition and subtraction module J is also connected in turn to the second addition module Σ2, the second adjustment module PID, the fourth addition module Σ4 and the second operation module Z / S2, and the input terminal of the second addition module Σ2 is also connect...

Embodiment 2

[0045] In order to solve the above technical problems, the present invention also provides a thermal power unit equipment, including a boiler and a reheat steam temperature control system for controlling the temperature of the boiler, wherein the reheat steam temperature control system is the one described in the first embodiment above Reheat steam temperature control system.

Embodiment 3

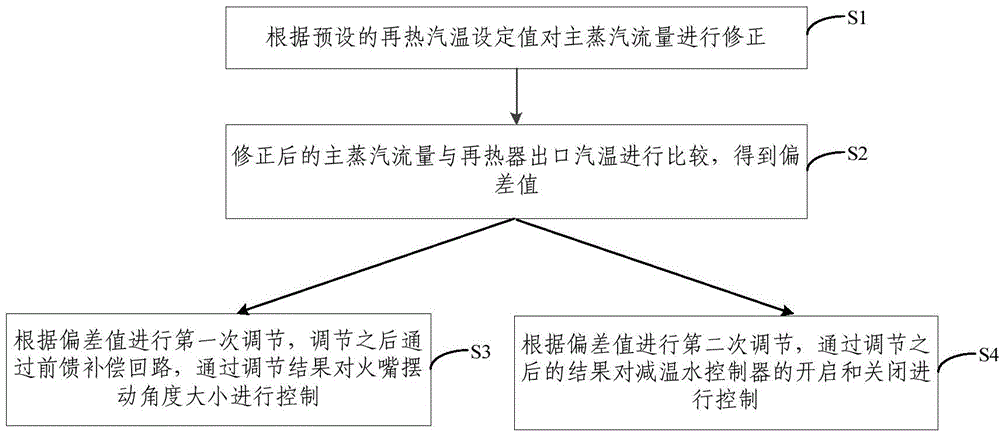

[0047] In order to solve the above-mentioned technical problems, the present invention also provides a reheat steam temperature control method for boiler temperature based on the reheat steam temperature control system described in the first embodiment above, including:

[0048] S1. Correct the main steam flow rate according to the preset reheat steam temperature setting value;

[0049] S2. Comparing the corrected main steam flow with the outlet steam temperature of the reheater to obtain the deviation value;

[0050] S3. The first adjustment is performed according to the deviation value, and after the adjustment, the swing angle of the burner is controlled through the adjustment result through the feed-forward compensation loop.

[0051] Further, after step S2 and before step S3, it also includes:

[0052] S4. Perform a second adjustment according to the deviation value, and control the opening and closing of the desuperheating water controller through the adjusted result. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com