Electric power plant cooling system for enhancing cooling efficiency by utilizing residual heat refrigeration manner

A technology of cooling efficiency and waste heat refrigeration, which is applied in the field of cooling systems, can solve the problems of waste heat cooling and waste, and achieve the effects of waste heat utilization, energy saving and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is a detailed introduction to the specific content of the power plant cooling system using waste heat refrigeration to improve cooling efficiency according to the accompanying drawings.

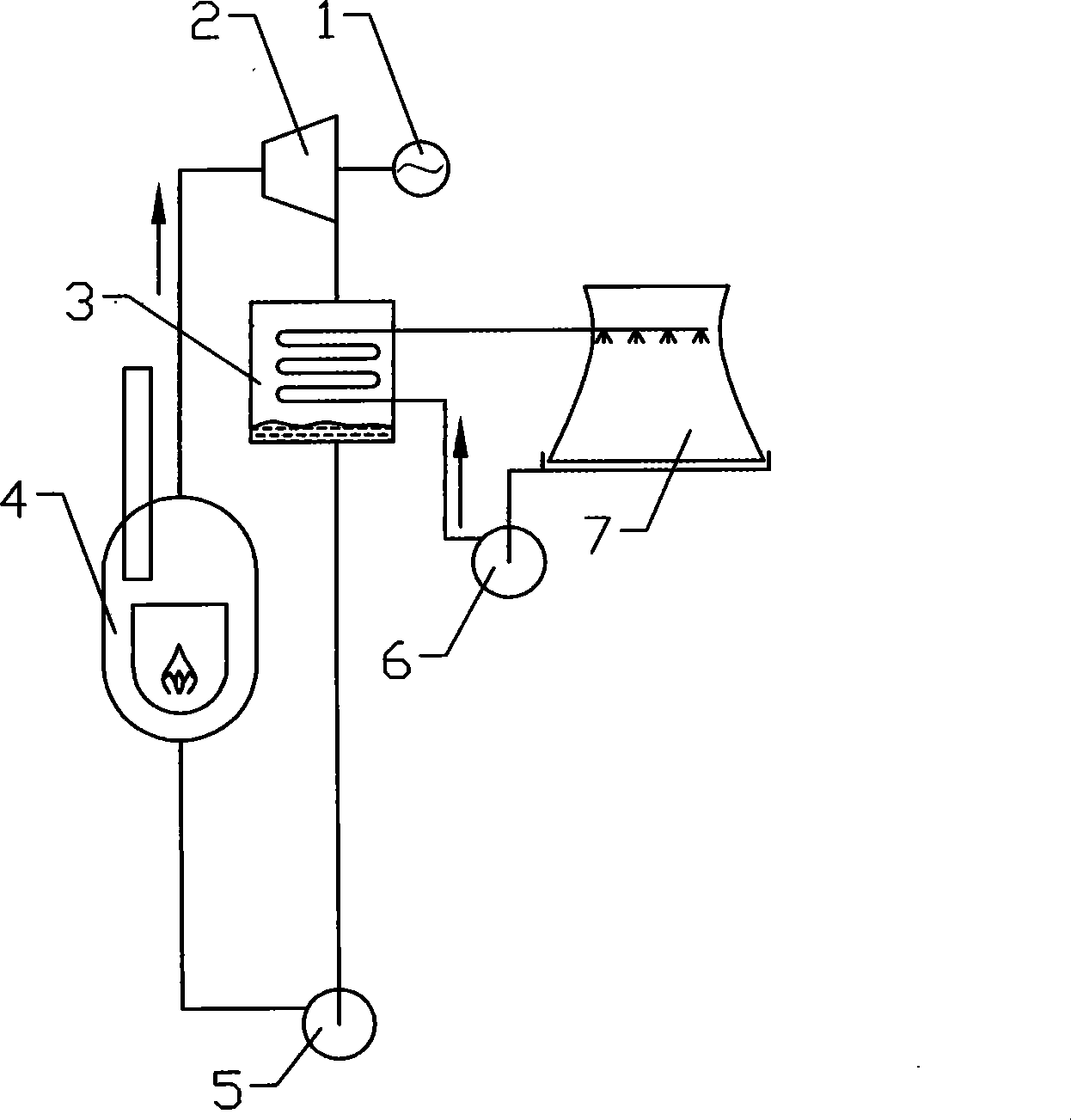

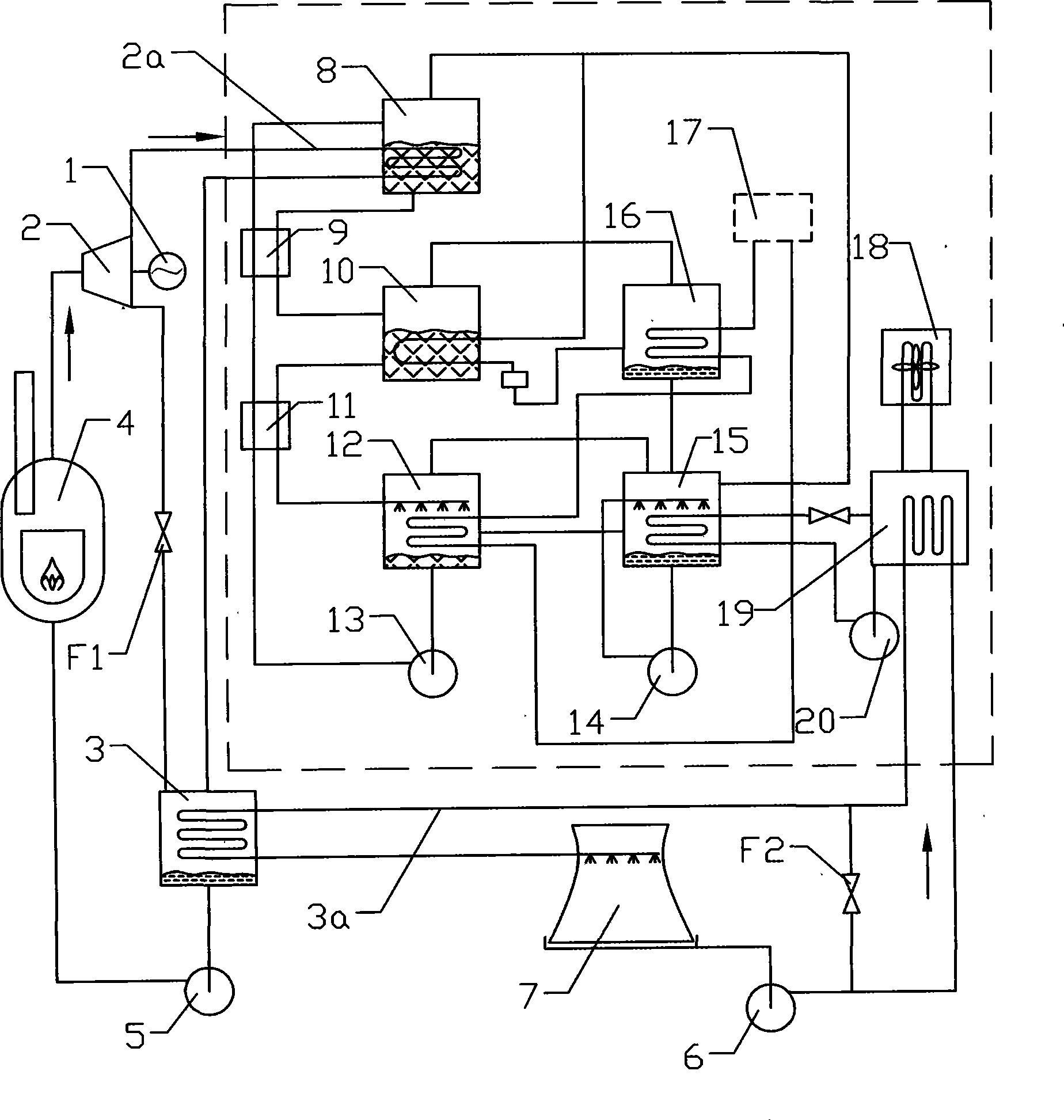

[0015] Such as figure 2 As shown, the generator 1 is driven by a steam turbine 2, and the power plant cooling system of the present invention includes a steam condensate circulation formed by connecting the steam turbine 2, the condenser 3, the condensate circulation pump 5 and the combustion boiler 4 sequentially through pipelines, and the condenser 3. The cooling water tower 7 and the cooling water circulation pump 6 are sequentially connected through pipelines to form a steam cooling water circulation, and the system mainly adds a lithium bromide refrigeration unit.

[0016] Such as figure 2 As shown in the middle dotted line box, the refrigeration unit includes an absorber 12, a solution pump 13, a low-temperature heat exchanger 9, a high-temperature heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com