Heat treatment spent liquor salt recovery processing method and apparatus

A treatment method and salt recovery technology, applied in heat treatment equipment, heating water/sewage treatment, metallurgical wastewater treatment, etc., can solve the problems of waste of resources, serious pollution, and high production costs, and achieve low consumption, high degree of automation, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

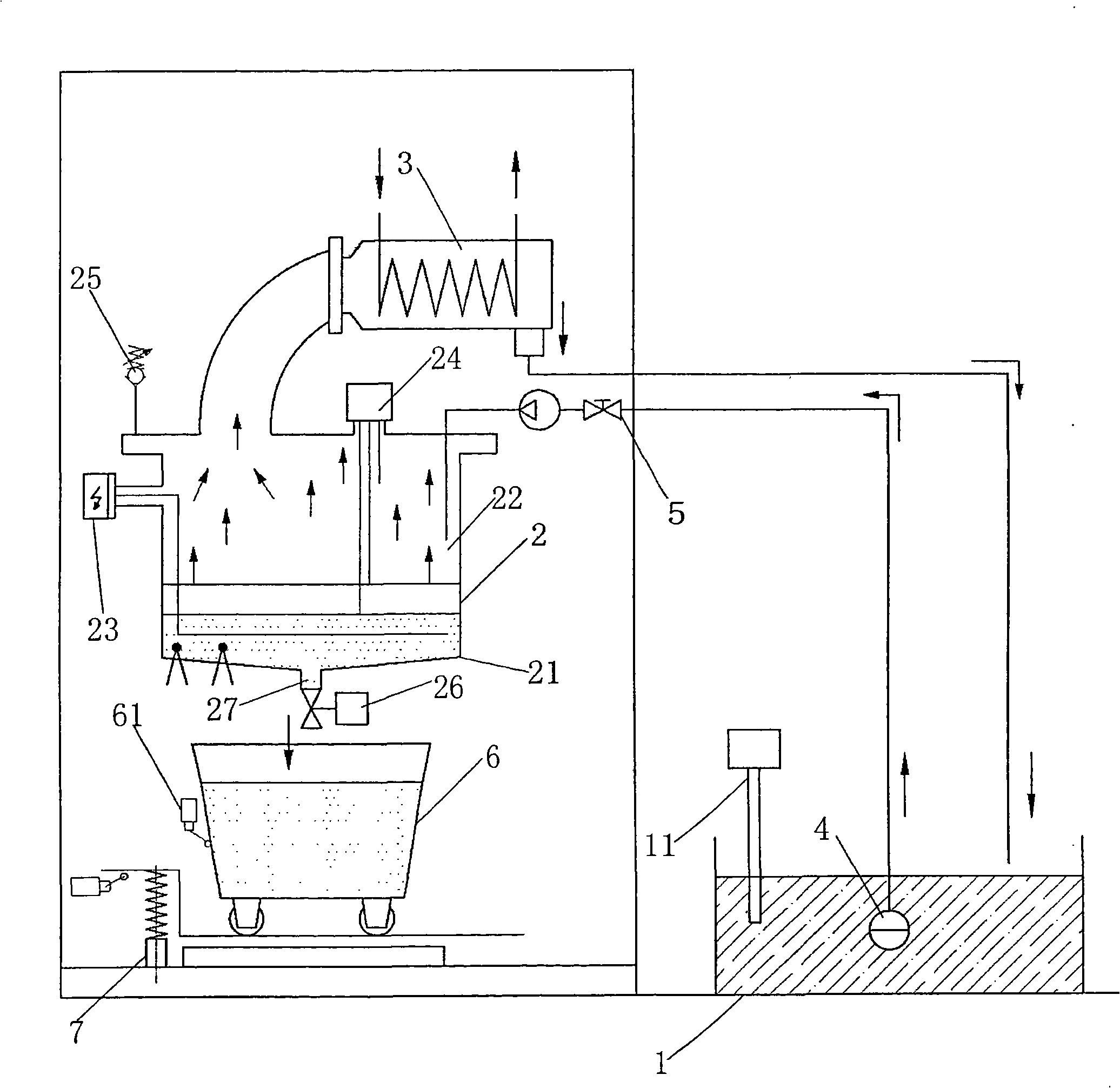

[0024] The heat treatment waste liquid recovery processing method comprises the following steps:

[0025] 1) Set the high liquid level and low liquid level of the salt recovery heating tank;

[0026] 2) Use the filter pump to pump the brine mixture in the quenching and cleaning tank into the salt recovery heating tank. When the brine mixture in the salt recovery heating tank reaches the set liquid level, the filter pump stops inputting liquid and sets it in the recovery heating tank The heater starts to heat up; when the temperature of the brine mixed liquid rises above 100°C, the water in the brine mixed liquid begins to evaporate into water vapor, and the water vapor is sent to the condenser to be cooled into water, and the cooled water becomes circulating water and then sent to Return to the washing machine for recycling;

[0027] 3) As the liquid in the recovery heating tank is heated at a high temperature, the water in the brine mixed liquid is gradually evaporated, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com