Low-temperature moving bed integrated adsorption desulfurization and denitrification system

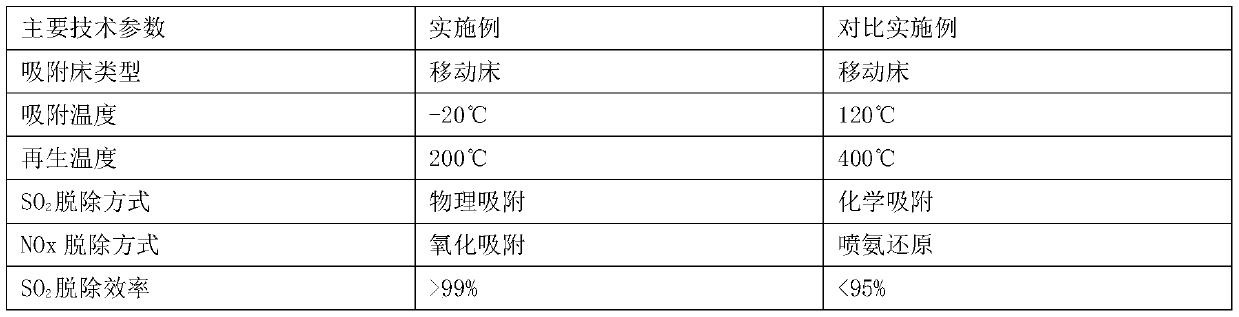

An adsorption desulfurization and moving bed technology, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of low denitrification rate of activated coke, inability to meet ultra-clean emissions, high regeneration temperature, etc., and reduce water consumption of power plants , less loading, and lower loss of adsorbent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

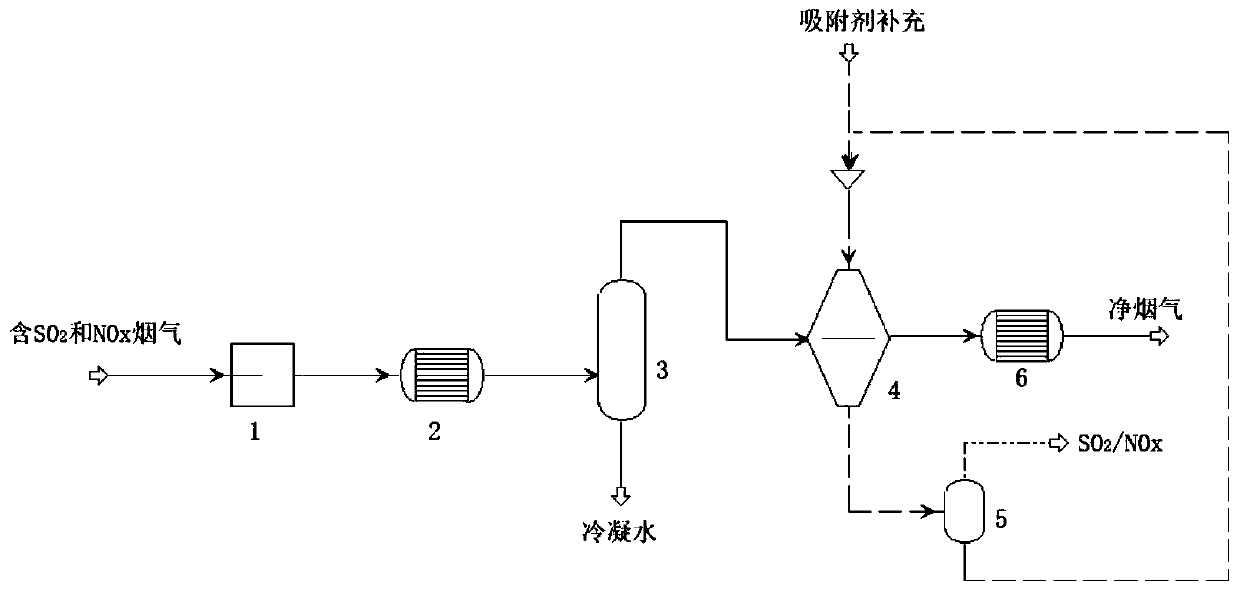

[0023] as attached figure 2 As shown, after the flue gas is pressurized by the flue gas induced draft fan 1, it enters the flue gas waste heat recovery device 2, and the flue gas temperature drops from 120°C to 70°C; the flue gas at 70°C enters the flue gas cooling system 3, and is cooled by spraying way down to -20°C. The flue gas cooling system 3 adopts a three-stage spray cooling method: the first stage is cooled to 35°C by spraying, the second stage is cooled to 5°C by chilled water spray, and the third stage is cooled by spraying low-temperature calcium chloride solution to -20°C, the first spray circulating fluid is cooled by cooling water, the second spray circulating fluid is cooled by a chiller; the third spray circulating fluid (calcium chloride solution) is cooled by a low-temperature refrigeration unit. The low-temperature flue gas cooled to -20°C by the flue gas cooling system 3 enters the low-temperature moving bed adsorption tower 4. In the embodiment, the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com