Gas field sulfur-containing waste gas treatment method

A technology for waste gas treatment and gas fields, which is applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of difficult to treat waste water, difficult to meet the standard, and difficult to adapt to the exhaust gas, so as to improve the desulfurization efficiency and desulfurization performance, and accelerate the regeneration efficiency. , the effect of simplifying the process and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

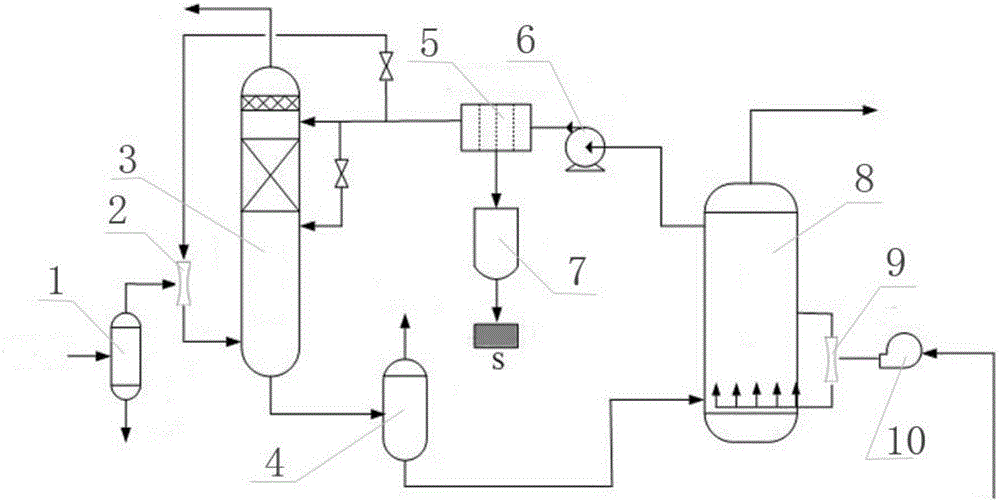

[0039] A method for treating sulfur-containing waste gas from a gas field, comprising the steps of:

[0040] (1) The raw material gas is separated into free water through the gas-liquid separator 1;

[0041] (2) The raw material gas separated from free water enters the absorption tower 3 through the Venturi tube-2 jet flow, and the temperature in the absorption tower is 20~180° C., and the pressure is normal pressure;

[0042] (3) The desulfurization solution enters the absorption tower 3 and mixes with the raw material gas of step (two), the divalent sulfur in the raw material gas in the absorption tower 3 is directly converted into sulfur, and the purified gas is discharged from the top of the absorption tower 3, and the desulfurization is poor The liquid enters the upper middle part and the bottom of the absorption tower 3 in two ways, the absorption tower 3 uses a bubble tower or a packed tower, the purified gas can be recycled, and the H2S in the purified gas is <10mg / m3;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com