Preparation method of titanium dioxide nanorod array film

A nanorod array and titanium dioxide technology, which is applied in the field of hydrophobic surface preparation, can solve the problems of cumbersome preparation and achieve the effects of shortened preparation process, low shape and size requirements, and simple materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

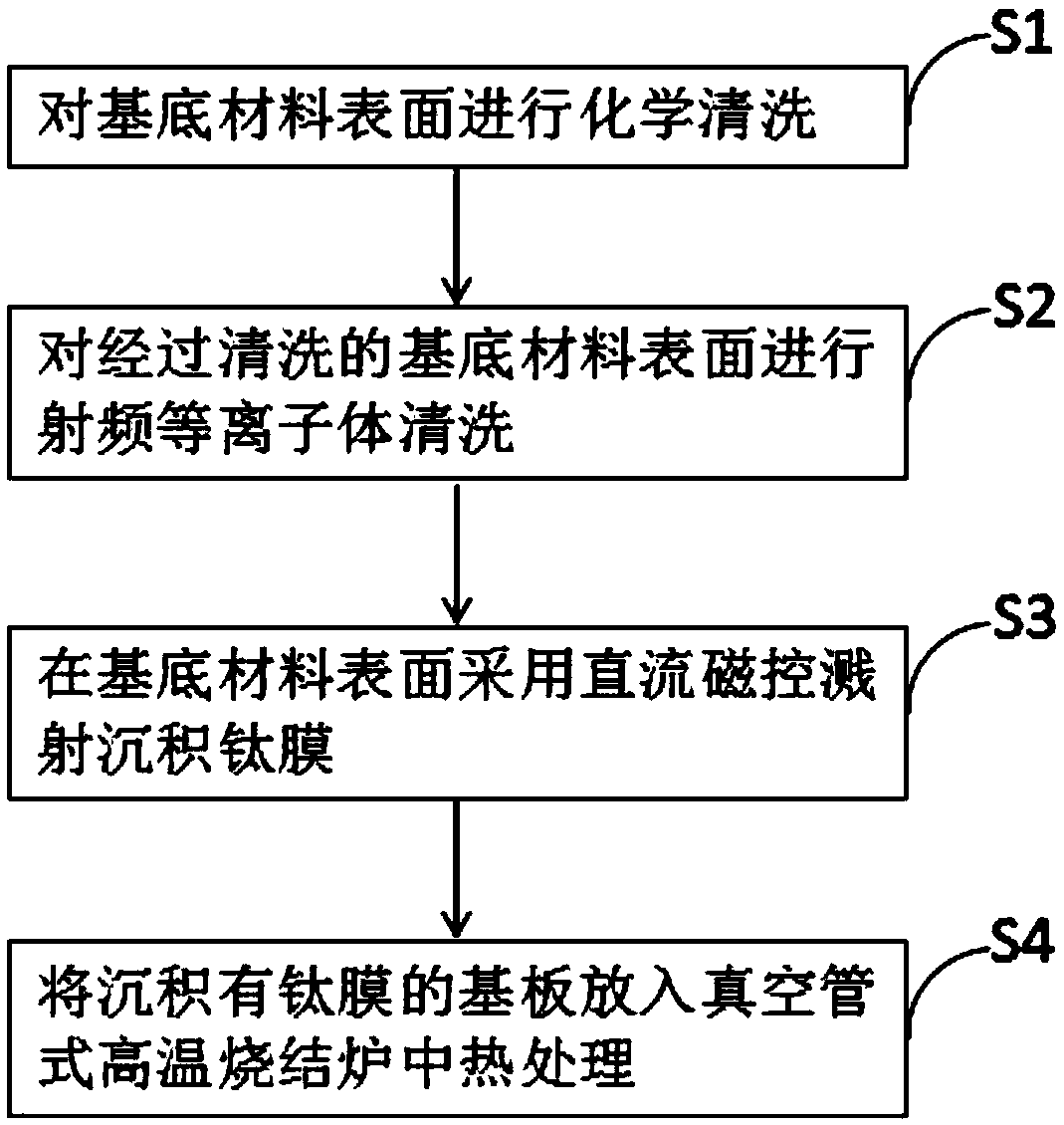

[0023] See figure 1 , A method for preparing titanium dioxide nanorod array film, including the following steps:

[0024] Step 1. Chemical cleaning is performed on the surface of the substrate material to be processed;

[0025] Step 2: Use radio frequency plasma to clean the surface of the substrate material;

[0026] Step 3: Deposit a layer of titanium film on the surface of the substrate using vacuum magnetron sputtering deposition technology;

[0027] Step 4: Heat the plated titanium film layer in a vacuum tube high-temperature sintering furnace to complete the preparation of the titanium dioxide nanorod array film with self-cleaning and hydrophobic properties.

[0028] When performing RF plasma cleaning on the surface of the substrate material in step 2, the background vacuum of the magnetron sputtering chamber is 5×10 -4 Pa~7×10 -4 Pa, access to H 2 And Ar 2 Mixed gas, H in the mixed gas 2 And Ar 2 The volume ratio is 4 to 96; the airflow is 20sccm~40sccm, the air pressure is 1Pa~...

Embodiment 1

[0033] Such as figure 1 As shown, a preparation of the surface of titanium dioxide nanorods with self-cleaning and hydrophobic properties includes the following steps: Step 1, cleaning the surface of the aluminum nitride ceramic plate, first soaking in absolute ethanol for 2 hours, and then placing it in an oven at 120°C for drying Bake for 5 minutes, then in an acetone solution at 50Hz ultrasonic cleaning for 10min, then in absolute ethanol at 50Hz ultrasonic cleaning for 10min, and finally put it in an oven at 120°C for 30min;

[0034] Step 2. Put the cleaned sample into the magnetron sputtering chamber, the vacuum of the chamber -4 At Pa; pass the mixed gas (4%H 2 ,96% Ar 2 ), the airflow is 30sccm, the pressure in the chamber is adjusted to 2Pa, the radio frequency power is 80W, and the radio frequency plasma sputtering is 30min;

[0035] Step 3. Use the chamber sample baffle to shield the aluminum nitride ceramic substrate, adjust the pressure in the chamber to 0.3Pa, and use ...

Embodiment 2

[0038] Such as figure 1 As shown, the preparation of a titanium dioxide nanorod array film with self-cleaning and hydrophobic properties includes the following steps: Step 1, cleaning the surface of the aluminum nitride ceramic plate, first soaking in absolute ethanol for 2 hours, and then placing it in an oven at 120°C Bake for 5 minutes, then in an acetone solution at 50Hz ultrasonic cleaning for 10min, then in anhydrous ethanol at 50Hz ultrasonic cleaning for 10min, and finally put it in an oven at 120°C for 30min;

[0039] Step 2. Put the cleaned sample into the magnetron sputtering chamber, the vacuum of the chamber -4 At Pa; pass the mixed gas (4%H 2 ,96% Ar 2 ), the airflow is 30sccm, the pressure in the chamber is adjusted to 2Pa, the radio frequency power is 80W, and the radio frequency plasma sputtering is 30min;

[0040] Step 3. Use the chamber sample baffle to shield the aluminum nitride ceramic substrate, adjust the pressure in the chamber to 0.3Pa, and use a DC power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com